3

Highway Infrastructure

PAVEMENTS AND MODELING SERVICE LIFE

David H. Timm, Auburn University

Timm’s presentation focused on the evolution of structural pavement design. Since 1992, he explained, there has been a 144 percent increase in vehicle-distance traveled in miles. This places a tremendous demand on the highway infrastructure, while the funding for highway improvement has remained mostly flat. In light of this high demand, lack of funding, and aging infrastructure, the American Society of Civil Engineers (ASCE) awarded the nation’s roadway infrastructure a “D” in 2013.1 The ASCE noted that approximately $101 billion is wasted in time and fuel each year, and the Federal Highway Administration suggested that it would take an investment of approximately $170 billion per year to elevate this grade to an “A.” Given the gap between this amount and the 2015 Fixing America’s Surface Transportation Act2 funding, which designated only approximately $40 billion per year over 5 years to the improvement of national highways, it is imperative that better performance pavement structures are created at lower cost, Timm explained. He commented that problems in highway infrastructure are often a result of structural

___________________

1 To view the report card, see ASCE, “2013 Report Card for America’s Infrastructure,” http://2013.infrastructurereportcard.org/road-infrastructure/, accessed January 22, 2018.

2 For more information, see U.S. Department of Transportation, “Fixing America’s Surface Transportation Act or ‘Fast Act,’” https://www.fhwa.dot.gov/fastact/legislation.cfm, accessed January 2, 2018.

issues in pavement that is not designed for the heavy loads that travel on it and that has far outlived its original design life—pavement distresses include asphalt fatigue cracking, ruts, surface shearing, corner breaks, punch-outs, slab cracks, and blowups. These distresses can also damage vehicles, he continued.

Timm provided an overview of the evolution of pavement design, beginning with the emergence of pavement engineering as a subdiscipline of civil engineering in the 1950s. Numerous highways were built across the United States in the 1950s; the American Association of State Highway and Transportation Officials (AASHTO)3 was responsible for developing a unified design system for these roads by 1960. Two significant empirical equations emerged from this work to develop and design asphalt and rigid pavements. Empirical models, which included factors such as vehicle weight, traffic, soil composition, and reliability and variability terms, helped to determine the appropriate thickness of the pavement. Timm noted a number of limitations with empirical methods, primarily that the conditions and technologies today are far different than they were in the 1960s, and the equations create designs too conservative for today’s economy and infrastructure.

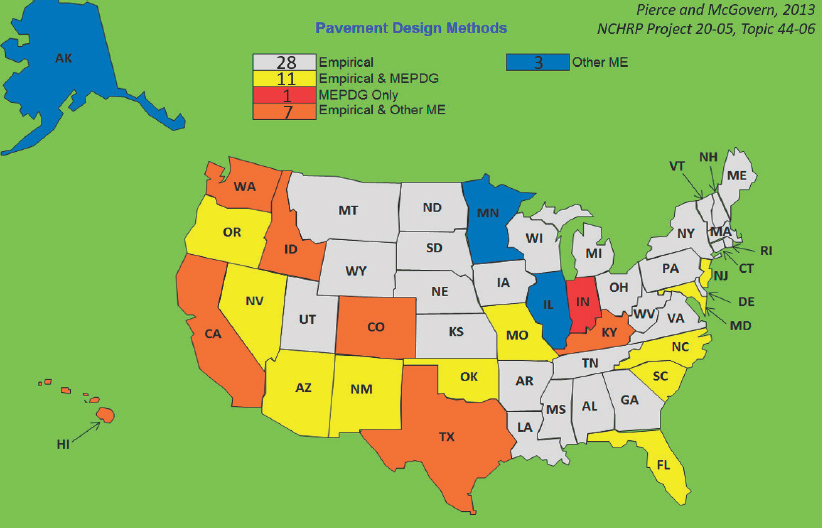

By the 1990s, mechanistic-empirical pavement design models began to be used to characterize material properties and simulate different kinds of loads to determine states of stress and strain in the structures. The National Cooperative Highway Research Program worked to develop new pavement design methodologies within AASHTO guidelines, and these projects resulted in mechanical-empirical design tools for engineers that are in use today (e.g., AASHTOWare became commercially available in 2013). These codes are far more complicated than those of past decades in that they allow hundreds to thousands of inputs, demand more testing requirements, and involve climate factors in prediction. These predictions about the number of years before a particular type of crack will occur greatly improve infrastructure planning. The drawbacks of this system, according to Timm, include the notion that (1) pavement performance predictions still have to be evaluated, calibrated, and verified; (2) pavements are still being designed to fail; and (3) there is no limit to the pavement thickness allowed by the equation. He also noted that there is not much uniformity across the United States in terms of approaches to pavement design (see Figure 3.1); some states use older empirical methods, some use more modern mechanistic-empirical approaches, and still others have created their own design procedures.

Timm then turned to a discussion of perpetual asphalt pavements: these pavements have at least 35 years of service, minimal structural improvement, and no deep structural distresses. The goal is to stop designing for failure and to design for success instead, and states throughout the country have been awarded for their perpetual pavements. Perpetual pavement design means that design happens below

___________________

3 The website for AASHTO is https://www.transportation.org.

the endurance limit of the material so that cracks will be confined to the surface. He added that Auburn University has developed perpetual pavement design software called PerRoad.

Timm explained that asphalt and concrete industries have also embraced green technologies and are becoming more sustainable by using recyclable products in the mix designs of their materials. Although sometimes challenging, using recycled materials can be cost effective. The most pressing challenge for pavement structural engineers, according to Timm, is to figure out how to incorporate all of these new materials (e.g., stone matrix asphalt, reclaimed asphalt pavement, warm-mix asphalt, ground tire rubber) into the various design codes.

Timm concluded by emphasizing that (1) pavement thickness design is still in transition from empirical to mechanistic-empirical; (2) mechanistic-empirical design is more robust, with better characterizations and adaption to new conditions; and (3) perpetual pavements are key to a sustainable future.

Discussion

Haydn Wadley, University of Virginia, asked how countries beyond the United States are designing better roadways. Timm responded that both South Africa’s roadways and Germany’s Autobahn rely on advanced mechanistic design—they use deep foundations, strong pavement from the bottom up, and a sacrificial layer at the surface. Mehdi Ahmadian, Virginia Polytechnic Institute and State University (Virginia Tech), asked whether new models for pavement design include dynamic forces from vehicles. Timm noted that although the state of practice ignores vertical dynamics, research grade models do incorporate that factor. In response to a question from Mike Rigdon, Institute for Defense Analyses (retired), Timm explained that specifications are in place to ensure that the asphalt mix meets minimum requirements. Rosario Gerhardt, Georgia Institute of Technology, asked whether there have been systematic studies to evaluate the base material of a road surface—material designs for asphalt or concrete will likely behave differently when placed on different base materials. Timm agreed that this is an important point and noted that much of the current research is devoted to improving materials on hand.

MODELING THE CHLORIDE-INDUCED CORROSION SERVICE LIFE OF STEEL-REINFORCED CONCRETE STRUCTURES: APPLIED TO BRIDGE DECKS

Richard Weyers, Virginia Polytechnic Institute and State University

Weyers discussed the process of modeling the chloride-induced corrosion service life of the reinforced concrete structures that have been applied to bridge decks in Virginia, New Jersey, Minnesota, New York, and Florida. He emphasized that these decks are only one of the critical components of a bridge. He also noted that while it is impossible to avoid corrosion on the steel reinforcements inside concrete, it is possible to try to predict and then delay this negative outcome. As the interstate system was constructed, the United States adopted a bare pavement policy—state highways would be cleared of snow and ice during the winter. As a result, the distribution of chlorine-based deicing salts on highway surfaces increased fourfold, causing bridge decks to deteriorate as the chloride diffused through the concrete toward the steel reinforcements. Weyers noted that both the exposure environment and the population of a particular place influence how much deicing salt is applied to highways.

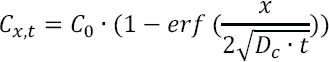

The equation used for service life modeling has only four parameters (surface chloride concentration C0, diffusion coefficient Dc, reinforcement cover depth x, and chloride corrosion initiation concentration). To determine the chloride concentration in time where the steel reinforcements are located (Cx,t) only three of the

parameters can be used, but because the parameters are not uniform, a probabilistic model is ultimately needed. For a more complete introduction to chloride-induced corrosion, see Corrosion of Steel in Concrete: Prevention, Diagnosis, Repair4 and Resistance of Concrete to Chloride Ingress: Testing and Modelling.5

Weyers shared an example of a bridge that was built with epoxy-coated reinforcing steel in 1979 in Virginia and inspected in 2009. The bridge carries U.S. Route 15 over I-66. The survey of the damage to the bridge revealed delaminations, spalling, and cracking as well as different types and locations of damages based upon different conditions (e.g., when water runs to the side of an elevated bridge, the shoulders have more damage owing to greater quantities of chloride absorbed over a long period of time). After only 30 years, approximately 14 percent of the bridge was damaged (and looked like it would deteriorate at a rate of 1.6 percent per year from there on). Weyers then showed the cover depth distributions and the surface chloride concentrations from his analysis, both of which were fairly normally distributed. Looking at the diffusion coefficients revealed that they are a significant parameter that is quite variable, as is the chloride initiation value. Ultimately, he observed that reinforcing concrete with epoxy-coated steel was not a reliable way to protect the system from corrosion.

Weyers next described his analysis of a bridge that was built with bare steel in 1969 in New Jersey (and overlaid in 1997 with latex-modified concrete) and inspected in 2010. The bridge carries I-95 over Sharon Station Road. He added that, usually, the upper deck of a bridge will need some rehabilitation approximately every 35 years. The cover depth distributions and the surface chloride concentrations from his analysis were both fairly normally distributed. However, there was a small difference in the surface chloride concentrations between the bridge in Virginia and this bridge in New Jersey, in part owing to the latex overlay on the latter. The bridge in New Jersey is estimated to deteriorate at a rate of only 5 percent over 30 years, according to Weyers.

He highlighted a bridge in Minnesota that is subject to more severe winter weather than the bridges in Virginia and New Jersey. The bridge carries Highway 123 over Kettle River—built in 1948, rebuilt in 1984, and inspected in 2010, this bridge had epoxy-coated reinforcement without any overlay. The survey of

___________________

4 L. Bertolini, B. Elsener, P. Pedeferri, E. Redaelli, and R.B. Polder, 2013, Chapter 6, Chloride-induced corrosion, pp. 93-112, in Corrosion of Steel in Concrete: Prevention, Diagnosis, Repair, second edition, Wiley, https://doi.org/10.1002/9783527651696.ch6.

5 L. Tang, L.-O. Nilsson, and P.A. Muhammed Basheer, 2011, Resistance of Concrete to Chloride Ingress: Testing and Modelling, CRC Press, London and New York.

the bridge revealed substantial cracking. The surface chloride concentration was drastically more on this Minnesota bridge than on those in either Virginia or New Jersey, which is expected given the climate and the increased need for salt on the roadways during the winter months. Using Weyers’s model, it takes approximately 20 years for 4 percent of the bridge to deteriorate, after which it deteriorates at a rate of 1.1 percent per year.

Weyers briefly discussed a bridge built in New York in 1990—reinforced with epoxy-coated reinforcement bars and bare steel mesh—and inspected in 2010. The bridge carries State Route 21 over Karr Valley Creek. The greatest damage was surveyed to be at the piers and the abutments of the bridge, with substantial longitudinal cracking in the deck as well. Surface chloride concentration on this bridge was just a bit higher than that of the bridge in Minnesota. The final bridge that Weyers discussed was built in 1997 in Florida and inspected in 2011. Carrying State Route 430 over Halifax River, the bridge was reinforced with bare steel, and it utilized microsilica pozzolans. As expected, surface chloride concentration on this bridge is miniscule. Although Florida does not usually receive snow, the wind can bring chloride from the inland water canals to contaminate the bridge structure. According to Weyers, the pozzolans densify the concrete and close up the void system, which lowers the diffusion coefficient and thus the rate of the chloride penetration into the concrete. He found that this level of exposure to chloride is too low for the bridge to experience corrosion damage within at least 100 years.

By evaluating the combined diffusion coefficients from the bridges in Virginia, New Jersey, Minnesota, and New York, Weyers confirmed that material characteristics of concrete can be controlled, unlike environmental conditions. Weyers concluded by reiterating the following suggestions for evaluating bridge decks based on modeling performance via chloride-induced corrosion:

- Look at the damage;

- Use the surface chloride as a parameter by measuring the environment and conditions relative to the population and the maintenance philosophy (need 30 surface chloride concentrations);

- Use the cover depths as an additional parameter (need 30 cover depths);

- Determine diffusion coefficients to indicate the range of values;

- Model the diffusion coefficient; and

- Determine the presence or absence of pozzolans.

Discussion

General Paul Kern, The Cohen Group, asked whether sand is a better option than chloride to treat roadways in the winter. Weyers noted that individual states must evaluate both what is better for the structures and what moves traffic most safely

in order to answer this complex question. Jesus de la Garza, Virginia Tech, asked whether there are any advancements (in addition to Florida’s use of microsilica) in concrete that will help minimize the diffusion coefficient. Weyers responded that some states, like Virginia, use low-permeable concretes to minimize the diffusion coefficient. These concretes are made from materials that are waste products (e.g., fly ash comes from the production of electricity and coal; slag cement comes from the production of steel; and microsilica comes from the production of a silica iron material). Virginia has also moved away from the use of epoxy-coated reinforcing steel, owing to its unreliability, and moved toward the use of a corrosion-resistant reinforcing steel, in which the metallurgy can be controlled. He suggested that, owing to these new materials, the bridges being built now could last 100 years. In response to a final question from Rigdon, Weyers noted that although galvanizing can help to increase corrosion initiation values, the process can lose its effectiveness over time.

BREAKTHROUGH IN SELF-HEALING DAMAGE-TOLERANT CONCRETE TECHNOLOGY FOR RESILIENT INFRASTRUCTURE

Victor Li, University of Michigan

Li provided an overview of the challenges associated with the current generation of infrastructure: resiliency, durability, and sustainability. He defined resiliency as the ability to recover quickly from a major event such as extreme loading, and he described durability as the ability to lengthen the service life and decrease the number of repairs needed on infrastructure while maintaining load-carrying capacity at all times. As a result, if the quality of the materials used to build infrastructure is improved and the extent of repairs is lessened, less energy will be wasted and less greenhouse gas will be emitted, so that infrastructure will become more sustainable. He believes that enhancing the tensile strain capacity of concrete is the best way to achieve resiliency, durability, and sustainability. A truly high-performance concrete would have damage tolerance, rapid damage recovery through self-healing properties, deterioration resistance in varied environments, fracture resistance, and crack width control. In other words, a truly high-performance concrete must also have high ductility, he explained.

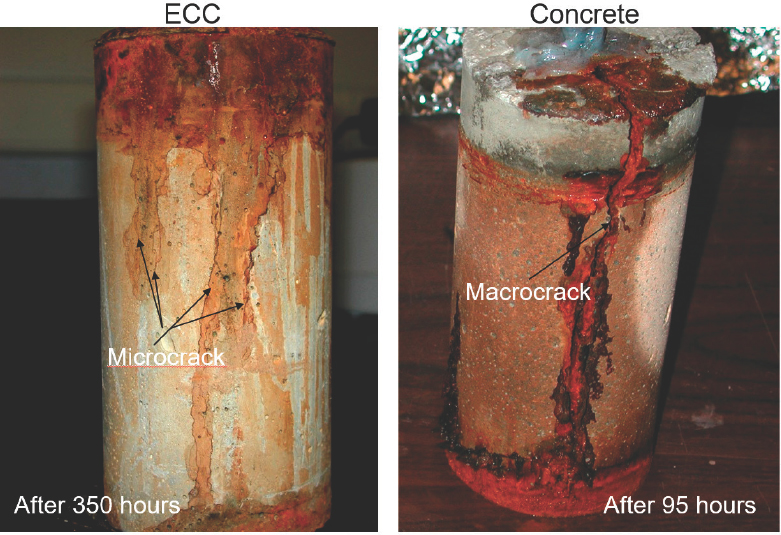

Li described the different reactions that result under extreme loading of a ductile bendable concrete, also known as engineered cementitious composite (ECC). While a high-strength concrete fractures, the ECC only deforms (and may exhibit controlled microcracks half the width of a human hair), similar to a metallic material. In testing, he determined that the ECC acts much like a ductile steel and has a deformation capacity over 300 times that of normal concrete. This indicates that the ECC would enable high resiliency in infrastructure, even under extreme

loading. ECC also has self-controlled tight crack width, which can control the transport properties and reduce the diffusion coefficient, thus reducing deterioration. According to Li, ECC remains durable even in a corrosive environment because the corrosion is distributed in small amounts among its many microcracks.6 ECC’s tight crack widths also allow for suppression of cover spalling even in the face of expanding corroded steel (see Figure 3.2).

Li added that ECC can heal itself; with exposure to air and water, the crack is filled and the mechanical properties are recovered—a process that has been occurring in natural seashells (nacre) for millions of years.

Li noted that, so far, there are limited instances of translating ECC from the laboratory to the field. However, ECC coupling beams have been used to enhance the resiliency of tall buildings, and thus to resist earthquakes, because of their ability to absorb energy. The tallest building to use these beams as of 2016 was 60 stories high, although several other buildings have been constructed using the same material. Durable ECC link-slab has been used in the replacement of conventional expansion joints on bridge decks as well, Li continued. This material

___________________

6 Note that many codes assume that cracks up to a certain width do not result in corrosion.

has the capacity to stretch and compress under varied temperature cycles while maintaining durability. Outside the United States, durable ECC has been used in the construction of dampers for viaduct retrofits in Japan. This can help prevent damage or movement from earthquakes, while absorbing energy in the process. He added that it also remains durable in the face of the corrosive salt water beneath it. Li’s final example of the use of ECC pertained to durable reservoir dam repair: dams that have been damaged by concrete spalling and cracking can be repaired with ECC to reduce the potential for future leakage.

Li reiterated that he hopes to see more resilient, durable, and environmentally sustainable material and infrastructure in the near future. Although he acknowledged that there are obstacles in using this new material widely, he emphasized that this material makes it feasible to attain resiliency, durability, and sustainability simultaneously. He added that, because of its ductility, damage tolerance, and self-healing properties, ECC is suitable both for defense readiness and for civilian needs. He noted that while the material is expensive as compared to traditional concrete, it can be used selectively in parts of infrastructures. It also offers the potential for overall higher infrastructure performance at an overall lower cost. For example, referring to the example of the 60-story building that contained ECC coupling beams, Li explained that even though the material itself cost more than previously used materials, the install cost was actually lower than previous versions because the use of ECC changed the design by simplifying (i.e., eliminating conventional anti-seismic devices) and speeding up the construction. And such a building with reduced column size has greater real estate value—an additional economic incentive for using ECC. Li also noted that the use of higher durability materials can lead to reduced maintenance requirements, which are another source of high infrastructure costs.

Discussion

In response to a question from de la Garza, Li explained that self-healing is a chemical process. In addition to the low water/cement ratio and the large amount of unhydrated cement grains that allow continued hydration with water exposure, there are calcites (that likely form as a result of the dissolution of the carbon dioxide from the air in the water) that chemically react with the calcium hydroxide. Li noted that while this chemical process happens in all concrete, the self-healing mechanism is unreliable in normal concrete because it has cracks that are simply too large to self-heal. Additionally, calcites will fall away with normal concrete but not with bendable concrete.

Timm asked how other properties of ECC compare with those of normal concrete. Li clarified that ECC is not a single material but rather a family of materials. In terms of compressive strength, there are both low-strength and high-strength

(up to 200 MPa) options available, depending on the needs of the infrastructure. He added that there are also versions of the material that differ based on the application. Rigdon asked whether the ballistic properties of the material have been investigated, and Li confirmed that this research is under way. Dianne Chong, Boeing (retired), asked Li if he had created an economic model including both life cycle cost and maintenance cost. Li acknowledged that while some assessment in this area has demonstrated an overall savings in the lifetime of a structure that uses ECC, more analysis would be useful.