2

Effects of Rock Dust Applications on Coal Mine Dust Measurements

The practice of rock dusting involves the use of an inert rock dust material applied to the surfaces of an underground coal mine. The statement of task for this study (see Appendix A) asks the committee to assess the effects of rock dust mixtures and their application, as required by current U.S. regulations, on respirable coal mine dust measurements. The definition of rock dust and requirements for its content and application are provided in the U.S. Code of Federal Regulations (see Table 2-1). Those requirements are applicable to all underground coal mines in the United States.

Rock dusting is a proven practice that has been utilized in some way since the early 1900s (Harris et al., 2010). A review of rock-dusting practices by Harteis et al. (2016) and the references cited therein provide ample evidence that

- Coal dust represents an explosion hazard in underground coal mines, which has been demonstrated collectively by experimental work and documentation of coal mine explosion disasters, and

- Coal dust explosion hazards often can be mitigated effectively through a proper rock-dusting program.

TABLE 2-1 U.S. Rock Dusting Regulations

| Definition 30 CFR 75.2 |

Rock dust. Pulverized limestone, dolomite, gypsum, anhydrite, shale, adobe, or other inert material, preferably light colored, 100 percent of which will pass through a sieve having 20 meshes per linear inch and 70 percent or more of which will pass through a sieve having 200 meshes per linear inch; the particles of which when wetted and dried will not cohere to form a cake which will not be dispersed into separate particles by a light blast of air; and which does not contain more than 5 percent combustible matter or more than a total of 4 percent free and combined silica (SiO2), or, where the Secretary finds that such silica concentrations are not available, which does not contain more than 5 percent of free and combined silica. |

| Application 30 CFR 75.402-403 |

All underground areas of a coal mine, except those areas in which the dust is too wet or too high in incombustible content to propagate an explosion, shall be rock dusted to within 40 feet of all working faces, unless such areas are inaccessible or unsafe to enter or unless the Secretary or his authorized representative permits an exception upon his finding that such exception will not pose a hazard to the miners. All crosscuts that are less than 40 feet from a working face shall also be rock dusted. |

| Where rock dust is required to be applied, it shall be distributed upon the top, floor, and sides of all underground areas of a coal mine and maintained in such quantities that the incombustible content of the combined coal dust, rock dust, and other dust shall be not less than 80 percent. Where methane is present in any ventilating current, the percent of incombustible content of such combined dust shall be increased 0.4 percent for each 0.1 percent of methane. |

It is important to understand that coal dust explosion hazards are real and documented, and rock dusting is currently the leading practice available to mitigate that hazard. The practice is of interest in this study because of the size fraction of particles that are respirable (less than 10 µm in aerodynamic diameter) and available for entrainment in working environments in typical rock dusts currently used in the United States. This chapter discusses the current technology and its application for rock dusting, composition and particle size distribution of available rock dusts, and effect of rock-dusting practices on measurements of respirable coal mine dust (RCMD) and compliance with the 2014 dust rule, and potential health effects of rock dust exposure.

ROCK DUST TECHNOLOGY AND PRACTICES

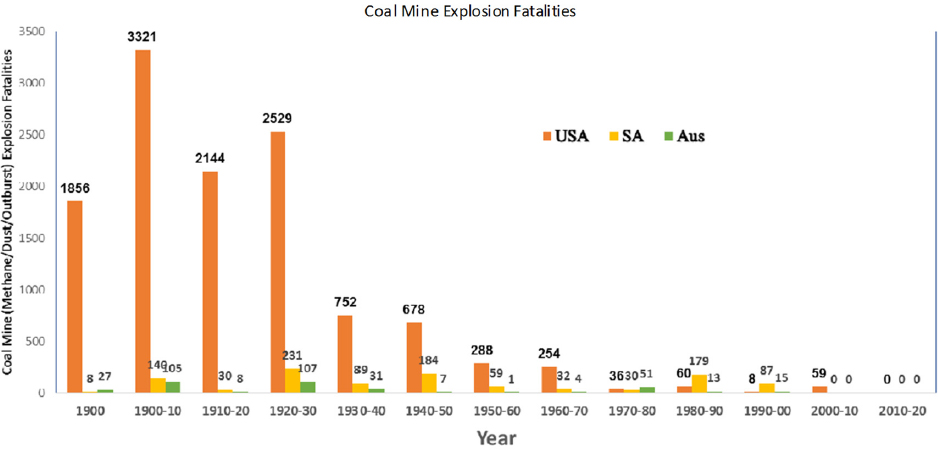

Recent history has shown that coal mine explosions present a risk for fatal incidents in the United States and underscore the importance of rock-dusting practice for the safety of underground coal mining. Volumes of research have been published on the effectiveness of rock-dusting practices for mitigating coal dust explosions. A presentation by Belle to the committee on October 5, 2017, showed evidence that coal mine explosion fatalities have decreased since the early 1900s. Much of that decrease is likely attributable to the practice of rock dusting, particularly in U.S. coal mines (see Figure 2-1). The fatalities significantly dropped following the decade from 1920 to 1930—a significant period considering the use of rock dust to mitigate coal dust explosions.

Much of the definitive work for rock-dusting requirements began with the work of the U.S. Bureau of Mines in the 1920s and 1930s. Bulletin 369 presents the foundation for the particle size distribution and specification required by federal regulations (Bureau of Mines, 1933).

In September 2011, the National Institute for Occupational Safety and Health (NIOSH) Office of Mine Safety and Health Research tested 393 rock dust samples gathered from underground coal mines and found that 47 percent did not permit the requisite amount of particles to pass through a 200 mesh sieve.1 Overall, 51 percent of the 278 underground mines, where samples were taken, used rock dust that did not permit 70 percent or more to pass through a 200 mesh sieve. In addition, NIOSH studied very fine rock dust particles, which enhance caking potential when wet. NIOSH concluded that all 10 samples it analyzed tended to form a cake when wet and could not be dispersed easily with a light blast of air (NIOSH, 2011). Those findings were inconsistent with the definition of rock dust in 30 CFR 75.2.

After much work related to determining coal dust particle sizing and a large suite of information generated through years of explosibility testing at the Lake Lynn Experimental mine and the Bruceton Mine under the Bureau of Mines and NIOSH, Harris et al. (2010) recommended: “In view of these results, there is a need to re-examine the particle size specifications for rock dusts and determine the material specific requirements relevant to the incombustible content needed to prevent explosion propagation.” The authors also recommended that, “In view of current results from the NIOSH coal dust particle size survey in US mines and preliminary size analyses of rock dusts, the effect of rock dust particle size in preventing coal flame propagation should be re-examined through large-scale explosion tests.” Since the nature of coal dust explosions has been researched extensively, much of the current research focuses on rock dust composition. Prior research had used rock dust specifications detailed in Bulletin 369 and subsequently detailed in federal regulations. An evaluation under current mining conditions and coal mine dust parameters was needed in order to create recommendations to improve the performance of rock dusting practices.

Prior research has shown that mean particle size is important for rock dust performance. In small-scale laboratory tests, the larger the rock dust particle size, the more rock dust is required to inert2 the coal dust and prevent an explosion from propagating. It has been shown in various small chamber tests that by reducing the size of the rock dust particles, the surface area of the rock dust increases and promotes greater radiant heat absorption (Dastidar et al., 1997).

Several types of rock-dusting methods can be employed. Regulations allow for dry dust application and wet dust applications, in some cases.

Dry dusting can be performed by a machine, which slings dry dust onto surfaces of the mine. Dry dusting can also be performed by workers, who manually carry bags of rock dust and scoop out the material and throw it onto the exposed surfaces. Dry dusting typically performs better than wet dusting with respect to lift and dispersion in the event of an explosion. However, stringent respirable dust regulations can hamper productivity with respect to dry rock dusting. If dry dusting is taking place on the intake ventilation course, dust which does not adhere to the exposed surfaces floats along the air course up to the active section where mining personnel are operating equipment. Because the volume of rock dust which can be dispersed over a given time frame is limited by the 2014 dust rule, that rock dust application method tends to limit productivity of the mine and does not allow for a timely dusting of the mine’s virgin, exposed coal seam, thereby increasing the amount of coal mine dust that has the potential to be fuel in the event of an explosion because it is not inerted enough by rock dust. To counteract the RCMD generated by dry dusting, some mines have moved to wet dusting. Some operations have managed compliance with the 2014 dust rule by not dusting while personnel are inby (toward the mine interior) at the active working sections during production, thus reducing the exposure to workers on the section. For example, a letter from a coal mine operator to the committee states that changes in rock dusting on belt entries during designated area sampling have occurred to ensure compliance with the 2014 dust rule during these shifts.3 That issue is of particular concern because the conveyor belt in the belt entry is a major source of coal dust. Continual rock dusting is often required to maintain the 80 percent incombustible material limit in these entries.

___________________

1 Mesh refers to the number of openings across one linear inch of screen. As the mesh number increases, the size of the openings decreases. The openings of a 200 mesh sieve are approximately 74 µm.

2 The action of mitigating coal dust explosion hazards by rock dust is often referred to as inerting the coal dust.

3 Letter from E. Patrick Brady (Murray Energy Corp.), dated April 27, 2017.

It needs to be emphasized that immediate safety is compromised for miners when insufficient incombustible material is present in coal entries. In addition, operators may choose not to rock dust during shifts where a continuous personal dust monitor (CPDM) is in use (see Chapter 1). Although some operators have expressed that no changes to rock-dusting practices have occurred since the adoption of the CPDM requirement and reduced RCMD exposure limit, it is evident from the operator sampling data reported by the Mine Safety and Health Administration (MSHA)4 that the use of the CPDM has driven some changes in rock-dusting behavior. However, it is critical that efforts to comply with the rock-dusting requirements and RCMD requirements not compromise the effectiveness of either explosion mitigation or RCMD exposure reduction.

Wet dusting involves mixing dry dust with water and then spraying the mixture onto the exposed mine surfaces. While this method initially alleviates the respirable dust problems associated with dry dusting, a new set of problems arises.5 Wet rock dust that is applied to surfaces of underground coal mines must dry before it is able to prevent an explosion from propagating. Wet dusting also commonly produces clumps of rock dust, which is termed caking. Caked rock dust retains some weight of the water and, in the event of an explosion, the caked dust will not disperse into the entry where it could extinguish the flame front. In essence, a completely new set of problems arises with wet dusting.

With the problems associated with each respective dusting application, mine operators are forced to employ nonideal application practices concerning explosion hazard mitigation. If they choose dry dusting, miners at the mining face are exposed to increased RCMD concentrations and production slows. If they choose wet dusting to alleviate the dry dust problems, the desired properties and purpose of the rock dust might not be attained.

In addition, several companies are developing technologies for including additives in wet dust mixes to allow for a more friable and thus dispersible dried rock dust product following application. Companies are also working on treating rock dusts with chemicals, such as stearic acid, oleic acid, and sodium oleate, to prevent caking and thus maintain particle size distributions and dispersibility in varying mine atmospheric environments (IMERYS, 2014; Huang et al., 2015; Perry et al., 2015).

Technologies are being developed by Dywidag Systems International (DSI) (now controlled by Jennmnar Inc.) and Strata Worldwide (Strata) in an effort to alleviate the problems and hindrances seen from dry and wet dust applications. With the use of proprietary technology, each system utilizes a wet dust mixture with respective additives (such as polymers and foams) to create a substance which can be sprayed onto exposed mine surfaces. Each system has the potential to reduce the amount of respirable dust generated largely, in a way that is similar to wet dusting applications but dries in a timely manner and has little to no caking. Such methods are intended to allow for greater, more consistent surface coverage when compared to dry dust slinging operations, yet still provide lift characteristics similar to that of dry dust when exposed to explosions. Those technologies and others are being evaluated by multiple research organizations and companies.

During the process of developing new rock dust technologies, the particle size distribution of feed rock dust has come under much scrutiny. Determination of the optimum rock dust particle size distribution is necessary to develop optimized solutions that mitigate the possibility of massive coal dust explosions and protect miners from respiratory hazards associated with RCMD exposure.

Other concepts have been investigated for mitigating coal dust explosions. Many of these concepts involve passive and active trigger barriers that employ concentrated sources of dispersible rock dust at specific areas of underground mines. Passive barriers include systems of concentrated rock dust (or water) that are expected to be dispersed by a coal dust explosion in progress. The dispersed rock dust is designed to arrest the progression of the explosion. Many types of barriers have been designed that include tray systems, bags, and tanks that are easily ruptured or overturned by the dis-

___________________

4 In a presentation to the committee on June 29, 2017, Gregory Meikle (MSHA) indicated that 99.7 percent of the samples collected from Aug 1, 2016, to May 31, 2017, were in compliance with the sampling requirements of the 2014 dust rule.

5 Dry dust must be applied over wet rock dusted areas once the wet rock dust has dried (75.403 Maintenance of Incombustible Content of Rock Dust Section updated July 2015\Release V-51; MSHA Program Policy Manual).

turbance of the explosion approaching and passing. Actively triggered systems utilize sensing technology to detect the arrival of a coal dust explosion front precisely and trigger a response that disperses the concentrated rock dust (or water) with the use of energetic materials (such as chemical propellants) or compressed gas (Zou and Panawalage, 2001). Research on those methods for mitigating coal dust explosions is less extensive than the volume of research available on more typical rock dust applications.

PARTICLE SIZE DISTRIBUTIONS OF ROCK DUST

Most of the commercially available rock dust is composed of limestone or marble, although regulations allow for other materials (see Table 2-1). As the particle size distribution of rock dust is important for its ability to mitigate coal dust explosions, explosibility of coal dust is dependent on the particle size distribution of the coal dust. Prompted by the disaster at Upper Big Branch in 2010 (MSHA, 2011), research has intensified to classify and understand the effects of both.

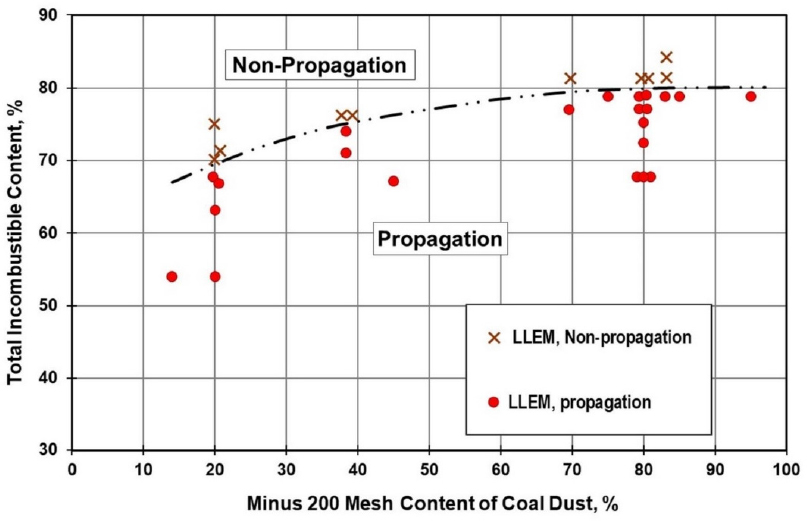

Figure 2-2 shows the results of work performed by Cashdollar et al. (2010) with typical specification rock dust, as defined in Bulletin 369. The figure outlines the basis for a regulatory target of 80 percent incombustible material in mine intake entries, because propagation did not occur above 80 percent incombustible content. The figure does not include the variable of rock dust size distribution. Evaluation of coal dust size distribution by Cashdollar et al. found that smaller particle size distributions required a higher percent content of incombustible material. The lack of investigation into the effects of rock dust particle size has left considerable doubt concerning the effectiveness of larger rock dust particles, such as those found in the NIOSH 2011 investigation, where most rock dust samples did not meet the 200 mesh requirement (NIOSH, 2011). That is evidenced by the fact that a higher quantity of incombustible content with a majority of materials smaller than 200 mesh is needed for smaller coal dust particle sizes (Figure 2-2). The relationship between particle sizes of rock dust and coal dust and the fundamental function of rock dust as a coal dust explosion inhibitor is not fully characterized in the literature. Data presented in Figure 2-2 suggest that coal mines are susceptible to explosion propagation even at 80 percent incombustible content of coal mine dust, given high content of minus 200 mesh coal dust material. It also suggests that smaller particle size distributions in the rock dust applied may provide a better heat sink and allow for the lower incombustible contents required to prevent propagation.

It is important to consider the effectiveness of different particle size distributions of rock dust to mitigate coal dust explosions generated by different size distributions of coal dust. With newer technology and advances in mining techniques, the traditional definition of the size distribution of coal dust that has been used in much research to date may not represent current conditions. More-recent work shows that fine particles are more effective at mitigating coal dust explosions definitively. Harris states:

The PSDs [particle size distributions] of the rock dusts vary greatly with some having multiple peaks in the distribution and although sieving can be used to characterize the PSD of rock dusts, the most effective particles for inerting lie in the respirable size range and cannot be sieved. To better characterize such wide variations, multiple and varying sized sieves would be required and the finest size to be assessed would typically be 38 μm or possibly 20 μm (635 mesh sieve not widely available commercially). However, the respirable portion of rock dust is the most effective and cannot be assessed using sieves. (Harris et al., 2015)

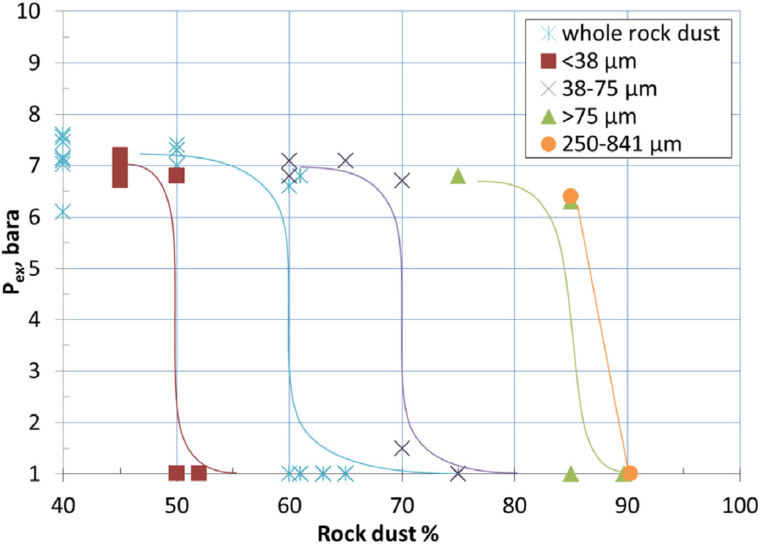

This statement is supported by work presented by Man and Harris in 2014. Figure 2-3 shows that smaller size distributions of rock dust particles require a smaller percentage of incombustible content of coal mine dust (shown as percent rock dust) to mitigate explosions than do larger particle size distributions. Each curve represents different percentages of rock dust that were added to the experimental chamber (x-axis) and the resulting explosion pressure in the chamber (y-axis). Explosion pressures at 1 bar represent an event where no explosion occurred. For each particle-size curve, there is a distinct percentage above which the rock dust is able to mitigate the explosion. Data show

that the smaller particle sizes begin inerting the coal dust explosions at lower percent rock dust. For example, the curve for particle size less than 38 μm had explosion pressures greater than 6 bar until the percentage of rock dust reached 50 percent, where explosion pressures are listed at 1 bar.

The culmination of recent work is summarized well by Harris et al. (2015). The authors conclude that rock dust particles smaller than 38 μm are more effective than larger ones at inerting coal dust. The authors recommend a particle size distribution with 95 percent of material finer than 200 mesh for mitigating the propagation of coal mine dust explosions. In addition, the authors describe a way of correlating specific surface area of rock dust particles to performance. It is expected that specific surface area will be investigated further in future work.

It is evident that more comprehensive research is needed to identify optimum rock dust particle size distributions with different particle sizes of coal dust. Investigation of a maximum particle size of rock dust capable of inerting coal dust explosions is necessary to determine if eliminating the respirable size (less than 10 µm) particles from rock dust would be an effective means of reducing the contribution of rock dust to RCMD exposures. That work also would be pertinent to finding effective rock-dusting practices based on work performed by Sapko et al. (2007) regarding the particle size distribution for coal mine dust in U.S. coal mines.

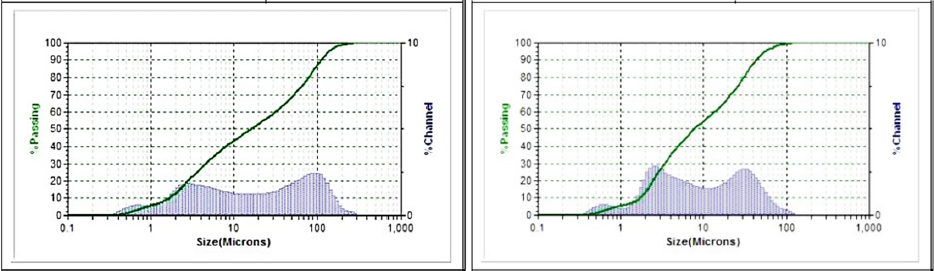

Because of ongoing debates concerning the effectiveness of rock dust requirements in mitigating coal mine dust explosions, it is appropriate to discuss the implications of making such a change to the requirements. Take, for example, the case of implementing the recommendation for 95 percent of material minus 200 mesh. Figure 2-4 (left-hand side) shows particle size analysis for a typical sample of rock dust that would be supplied to a mine for rock-dusting applications. The sample is 78 percent minus 200 mesh and the respirable-size portion of the dust is 43.5 percent passing 10 µm. The right-hand side of Figure 2-4 illustrates a sample that would be created to meet a requirement for 95 percent minus 200 mesh. The sample is 98 percent minus 200 mesh and the respirable portion of this dust is 55 percent passing 10 µm (Phagan, 2017). The figure indicates that employing rock dust to mitigate explosions and reducing RCMD concentrations attributable to rock dusting are competing goals.

It is apparent that respirable particles are present in rock dust products that are available for use in underground coal mines. A presentation provided by NIOSH, dated June 2, 2016, describes some of the ways that rock-dusting practices affect CPDM measurements and provides recommendations on how to mitigate RCMD exposure from rock dusting (NIOSH, 2016). The presentation describes the concern that rock dust can be entrained in the mine atmosphere by the flow of ventilation air, moving equipment, and the process of rock dusting itself. A few recommendations, such as wetting the floor following dusting and using surfactants, are presented, but little research has been done to describe how those actions would affect rock dust effectiveness in mitigating explosions.

The 2016 NIOSH presentation shows preliminary results from a study of CPDM measurements taken upwind and downwind from the application of treated and untreated rock dust (NIOSH, 2016). The study revealed that concentrations of RCMD downwind from rock dusting operations

ranged from 489 to 1,100 mg/m3. Those values are much greater than the 1.5 mg/m3 exposure limit in the 2014 dust rule. More concerning is that the rock dust that was treated to prevent caking and allow for greater dispersibility in the event of an explosion was more likely to elevate RCMD concentrations even after rock-dusting operations were completed. Resultant concentrations downwind were in concentrations of up to 4.38 mg/m3 even when wetting the floor to prevent entrainment. One concern regarding those results is that rock dusting during mine operations is not advisable because it can elevate RCMD concentrations. The other concern is that treated rock dust is more susceptible to entrainment for the very same reasons that it is probably more effective at long-term protection from coal mine dust explosions.

SILICA CONTENT OF ROCK DUST

As indicated in Table 2-1, current regulations require that rock dust not contain more than 5 percent combustible matter and not more than a total of 4 percent free and combined silica (SiO2) or, where the Secretary finds that such silica concentrations are not available, that it not contain more than 5 percent of free and combined silica. Silica is considered to be the mineral of primary concern for silicosis and other related diseases. The term free silica refers to pure SiO2 phases, which are generally in the form of the mineral quartz. Combined silica refers to the silicate minerals containing other elements in stoichiometric proportions, such as feldspar (NaAlSi3O8 KAlSi3O8) or kaolinite (Al2Si2O5(OH)4), or in rare cases silicate glass; such phases have 40 to 70 percent SiO2 by weight.

The silica requirement is a general definition for rock dust that is applicable in underground coal mines. Most commercially available rock dust products are generated from pulverized limestone or marble. Quartz is the predominant form of respirable silica observed in the air of underground coal mines. The concentration of respirable quartz in the mine atmosphere must be less than 100 μg/m3. The sampling for quartz concentration must be performed using the coal mine dust personal sample unit (CMDPSU, also referred to as a gravimetric sampler) rather than the CPDM that is now required for RCMD sampling in underground coal mines. The CPDM is not capable of measuring quartz concentration. MSHA collects CMDPSU samples and monitors quartz concentration to determine regulatory compliance. Filters containing dust samples from a CMDPSU are sent to a laboratory for analysis, which can take several days to complete.

Analysis of bulk samples of treated and untreated limestone dust and treated and untreated marble rock dusts showed that quartz content in the respirable size component was less than 1.5 percent (Soo et. al., 2016). That analysis also showed the quartz content in marble rock dust samples was negligible.

The contribution of rock dust to the quartz concentration relative to the contribution from dust created by mining operations has not been documented. Furthermore, the contribution of rock dust to the concentration of RCMD has not been evaluated fully. Elevated amounts of silica, including quartz, in rock materials immediately surrounding coal deposits in Appalachian coal mines have been reported (Schatzel, 2009). The requirement for a low-silica content in rock dust products suggests that the silica contribution from rock dusting to airborne RCMD in coal mines would be limited in the presence of higher concentrations of silica in rock materials surrounding coal seams. However, the silica exposure contribution from rock dusting would vary, in part, according to the amount of silica in the surrounding rock and the coal being mined, as well as the proportion that rock dust contributes to the total mass of airborne RCMD.

POTENTIAL HEALTH EFFECTS OF ROCK DUST EXPOSURE

Even with the undisputed importance of rock dust in explosion mitigation, questions arise about potential health hazards associated with rock dust exposure. As described previously, major sources of rock dust are marble (calcite or dolomite) and limestone (mainly calcium carbonate), with respirable silica constituting no more than 4 to 5 percent for regulatory compliance in U.S. coal mines (30 CFR 75.2). Generally speaking, marble and limestone are among the least harmful of the

inorganic dusts and no constituent-specific exposure limits have been specified for them. Those dusts are often referred to as low-toxicity dust not otherwise specified, nuisance dust, or particles not otherwise classified or regulated (Hearl, 1998).

A number of early studies and case reports describe lung health effects in workers in marble and limestone industries including mining, quarrying, and stone cutting. Doig (1955) described silicosis and emphysema in eight limestone grinders and miners after sustained high exposure beginning in the 1920s to limestone dust containing silicates. Bridge and Nagelschmidt (1956) report that a clinical and chest x-ray survey of 14 limestone workers exposed to dust containing less than 1 percent quartz found no evidence of pneumoconiosis. Based on the occupational processes and exposures described in those early studies, their relevance to current rock-dusting-related risk is questionable.

A more recent case report of a limestone quarry worker describes lung function abnormalities, radiographic nodular opacities, and surgical lung biopsy findings of foreign body granulomas composed of birefringent particles containing calcium, aluminum, and silicon, suggestive for limestone pneumoconiosis (Crummy et al., 2017). A case of autoimmune systemic sclerosis occurring in a marble worker with lung biopsy findings of nodular pneumoconiosis, suggestive for silicosis, has also been described (Bello et al., 2015).

Contamination of rock dust with free silica, even in small concentrations, can add to a miner’s cumulative exposure to respirable silica and thus contribute to risk for a number of adverse silica-related health outcomes. Inhaled silica particles of respirable size can trigger a cascade of lung inflammation and injury that over time increases the risk for silicosis, emphysema, and chronic bronchitis. Crystalline silica is considered a Class I carcinogen by the International Agency for Research on Cancer and, in high concentrations, can increase the risk for kidney and some autoimmune diseases. In general, the committee found few case reports or studies implicating rock dust exposure in risk for clinically significant coal mine dust lung disease.

Rock dust adds to the total RCMD exposure experienced by miners. Cumulative dust exposure increases the risk of both respiratory diseases and cardiovascular diseases (CVDs). A number of studies have found causal relationships between CVD and long-term exposure to particulate matter with an aerodynamic diameter less than 2.5 µm (EPA, 2009). Recent studies have used brachial-ankle pulse wave velocity (baPWV), which reflects the stiffness of both central and peripheral muscular arteries as a predictor of cardiovascular events and mortality. In a case-control study of more than 1,000 Chinese coal miners with CWP, increased baPWV was associated with increased risk for CVD risk factors and CDE (Zheng et al., 2017).

In addition to reducing visibility (with potential safety implications), rock dust that deposits in the upper airways can trigger eye, nose, and throat irritation symptoms (runny nose, watery eyes, cough, and phlegm). Long-term exposure to low-toxicity dust may lead over time to rhinitis or bronchitis, and may contribute to risk for chronic obstructive pulmonary disease even at concentrations that are less than currently acceptable concentrations (Cherrie et al., 2013). A survey of chronic respiratory symptoms among 70 high-exposed limestone production workers in Zambia found that, after controlling for age, smoking, previous jobs, and respiratory illnesses, the more highly exposed workers had a significantly increased relative risk of persistent daily cough and sputum production compared to lower exposed workers (Bwalya et al., 2011).

CONCLUSIONS

- Rock dusting is a proven and necessary technique for mitigating coal mine dust explosion hazards. Previous assessments, such as those done by the Rock Dust Partnership (NIOSH, 2016), have highlighted the need for developing and evaluating rock-dusting systems that can provide adequate coverage of coal mine surfaces, be applied wet (or with low amounts of entrained dust), and dry to an easily dispersible state.

- Measurements of RCMD concentrations include respirable rock dust particles, by definition. However, it appears that complying with the rock-dusting requirements (30 CFR 75.2 and 75.402-403) has not been a large obstacle to demonstrating compliance with the sam

-

pling requirements of the 2014 dust rule. It is critical that efforts to comply with the rock-dusting requirements and RCMD requirements not compromise the effectiveness of either explosion mitigation or RCMD exposure reduction.

- Smaller rock dust particles (approaching the respirable size of less than 10 µm aerodynamic particle diameter) are more effective than larger ones at mitigating explosion risks. Smaller particle sizes mean greater surface area per unit mass than larger particles and thus greater heat sink ability.

- Continued research is needed on rock-dusting application practice and mine worker training to ensure explosion mitigation effectiveness is not compromised in an effort to meet mine air quality standards. Full-scale underground mine testing, such as was conducted at the Lake Lynn Experimental Mine, is needed to determine the effectiveness of such systems.

- It is evident that more comprehensive research is needed to identify optimum rock dust particle size distributions for applications in underground mines with different particle sizes of coal mine dust. Investigation of a maximum particle size of rock dust capable of inerting coal mine dust explosions is necessary to determine if eliminating the respirable-size particles from rock dust is a viable solution. That work also would be pertinent for finding effective practices based on work performed by Sapko et al. (2007) regarding the particle size distribution for coal mine dust in U.S. coal mines.

- Although rock dust contributes substantially to the total mass of RCMD, it is not possible to determine the percent contribution of rock dust using the currently required monitoring technology. As a result, two mines using different rock-dusting approaches (such as wet instead of dry application methods or dusting at different times and rates during mining operations) might have very different RCMD compositions and yet exhibit similar measured mass concentrations. Therefore, heavy contributions of rock dust could distort health assessments of relationships between RCMD exposure and diseases caused by dust components insignificantly contributed by rock dust.

- The requirement for a low-silica content in rock dust products suggests that the silica contribution from rock dusting to airborne RCMD in coal mines would be limited in the presence of higher concentrations of silica in rock materials surrounding coal seams. However, the silica exposure contribution from rock dusting would vary according to the amount of silica in the surrounding rock and the coal being mined, as well as the proportion that rock dust contributes to the total mass of airborne RCMD. Sustained high exposures to rock dust and other so-called nuisance dusts, for which constituent-specific exposure limits are not specified, may trigger respiratory symptoms of irritation and cough and could contribute to a higher risk of COPD. However, in general, the committee found few case reports or studies implicating rock dust exposure in risk for clinically significant coal mine dust lung disease.

- Although the quartz content of rock dust particles in the respirable size range is generally less than 1.5 percent, the potential for rock dust to contribute to silica exposure is an important concern. Exposures to the highest rock dust concentrations are likely to occur at air-intake areas of mines when rock dust is applied or from dust reentrainment by man-trip vehicles used for transporting miners to and from their work areas in the mine.

REFERENCES

Belle, B. 2017. Coal Mine Dust Exposure Monitoring and Sampling in Underground Mines in Selected Industrialized Countries. Presentation from Principal Ventilation and Gas Manager for Anglo American group’s Coal Business unit at the Sixth Meeting on Occupational Exposure to Respirable Coal-Mine Dust, October 5, 2017, Washington, DC.

Bello, S., A. Rinaldi, S. Trabucco, L. Serafino, C. Bonali, and G. Lapadula. 2015. Erasmus syndrome in a marble worker. Reumastismo 67(3):116-122.

Bridge, D. S., and G. Nagelschmidt. 1956. Report on the absence of pneumoconiosis among workers in pure limestone. British Journal of Industrial Medicine 13:6-8.

Bureau of Mines. 1933. Explosion Tests of Pittsburgh Coal Dust in the Experimental Mine, 1925 to 1932. Bureau of Mines, Bulletin 369, 44 pp.

Bwalya, D., M. Bråtveit, and B. E. Moenet al. 2011. Chronic respiratory symptoms among workers at a limestone factory in Zambia. Archives of Environmental & Occupational Health 66(1):47-50.

Cashdollar, K. L., M. J. Sapko, E. S. Weiss, M. L. Harris, C. Man, S. P. Harteis, G. M. Green. 2010. Recommendations for a New Rock Dusting Standard to Prevent Coal Dust Explosions in Intake Airways. Pittsburgh, PA: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2010-151, (RI 9679), 2010 May; 49 pp.

Cherrie, J. W., L. M. Brosseau, A. Hay, and K. Donaldson.et al. 2013. Low-toxicity dusts: Current exposure guidelines are not sufficiently protective. Commentary. Occupational Hygiene 57(6):685-691.

Crummy, F., I. Carl, C. H. S. Cameron, and L. G. Heaney. 2017. A possible case of pneumoconiosis in a limestone quarry worker. Occupational Medicine 54(7):497-499.

Dastidar, A. G., P. R. Amyotte, and M. J. Pegg. 1997. Factors influencing the suppression of coal dust explosions. Fuel 76(7): 663-670.

Doig, A. T. 1955. Disabling pneumoconiosis from limestone dust. British Journal of Industrial Medicine 12:206-216.

EPA (U.S. Environmental Protection Agency). 2009. Integrated Science Assessment (ISA) for Particulate Matter. Final Report. Washington, DC: U.S. Environmental Protection Agency.

Harris, M. L., E. S. Weiss, S. P. Harteis, G. V. R. Goodman, and M. J. Sapko. 2010. Rock dusting considerations in underground coal mines. In S. Hardcastle and D. L. McKinnon, eds. Proceedings of the 13th Mine Vent Symposium (Laurentian University, Sudbury, Ontario, Canada, June 13–16, 2010). Sudbury, Canada: MIRARCO, pp. 267-271.

Harris, M. L., M. J. Sapko, I. A. Zlochower, I. E. Perera, and E. S. Weiss. 2015. Particle size and surface area effects on explosibility using a 20-L chamber. Journal of Loss Prevention in the Process Industries pp. 37:33-38. doi:10.1016/j.jlp.2015.06.009.

Harteis, S. P., D. W. Alexander, M. L. Harris, M. J. Sapko, and E. S. Weiss. 2016. Review of rock dusting practices in underground coal mines. Pittsburgh, PA: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2017-101 (IC 9530), 89 pp.

Hearl, F. J. 1998. Current exposure guidelines for particulates not otherwise classified or regulated: History and rationale. Applied Occupational and Environmental Hygiene 13(8), Workshops on Airways Disease and Occupational Exposure to Particulates Not Otherwise Classified/Regulated.

Huang, Q., R. Honaker, K. Perry, and B. Lusk. 2015. Oleate-modified rock dust for wet applications in underground coal mines. Transactions of the Society for Mining, Metallurgy, and Exploration 338(1).

IMERYS. 2014. Development of an anti-caking rock dust. NIOSH Broad Agency Announcement (BAA):2012N-14257, Contract No. 200-2012-52496, April.

Man, C. K., and M. L. Harris. 2014. Participation of large particles in coal dust explosions. Journal of Loss Prevention in the Process Industries 27:49-54.

MSHA (Mine Safety and Health Administration). 2011. Fatal underground mine explosion, April 5, 2010. Performance Coal Company Upper Big Branch Mine–South, Massey Energy Company, Mine ID:46-08436. Arlington, VA: U.S. Department of Labor, MSHA, December 6, 2011.

NIOSH (National Institute for Occupational Safety and Health). 2011. Non-conforming rock dust. U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. HID 16, p. 4.

NIOSH. 2016. Rock Dust Partnership Meeting: Attributes of Rock Dust to Prevent Coal Dust Explosions. June 2, 2016. Pittsburgh Mining Research Division.

Perry, K. A., B. T. Lusk, R. Q. Honaker, R. Q. Eades, and Q. Huang. 2015. Modern Rock Dust Development and Evaluation. Final Report submitted to Commonwealth of Kentucky per Contract Doc ID No. PON2 127 1300001705 1. Kentucky Energy and Environment Cabinet Department for Energy Development and Independence, May.

Phagan S. 2017. Production and Characteristics of Rock Dust Applied in Underground Mines, Presentation to Committee on April 13, 2017, Morgantown, WV.

Sapko, M. J., K. L. Cashdollar, and G. M. Green. 2007. Coal dust particle size survey of U.S. mines. Journal of Loss Prevention in the Process Industries 20(1):616-620.

Schatzel, S. J. 2009. Identifying sources of respirable quartz and silica dust in underground coal mines in southern West Virginia, western Virginia, and eastern Kentucky. International Journal of Coal Geology 78:110-118.

Soo, J. C., T. Lee, W. P. Chisholm, D. Farcas, D. Schwegler-Berry, and M. Harper. 2016. Treated and untreated rock dust: Quartz content and physical characterization._Journal of Occupational & Environmental Hygiene 13(11):D201-D207. doi: 10.1080/15459624.2016.1200195.

Zheng, Y., L. Liang, T. Qin, G. Yang, S. An, Y. Wang, Z. Li, Z. Shao, X. Zhu, T. Yao, S. Wu, and J. Cai. 2017. Cross-section analysis of coal workers’ pneumoconiosis and higher brachial-ankle pulse wave velocity with Kailuan study. BMC Public Health 17:148.

Zou, D. H., and S. Panawalage. 2001. Passive and Triggered Explosion Barriers in Underground Coal Mines – A Literature Review of Recent Research. Report to CANMET Natural Resources Canada.