4

Efficacy of Current Monitoring Technologies and Sampling Approaches

The committee’s statement of task (see Appendix A) calls for an assessment of the efficacy of current monitoring technologies and sampling approaches for informing underground coal mine operator’s decision making related to reducing respirable coal mine dust (RCMD) exposure to miners in underground coal mines.

Efficacy is often considered to be the capability of a monitoring technology and sampling approach to characterize RCMD exposure concentrations within the accuracy and precision desired, in the time and expense allotted, and with the functional ability to document the outcome. In addition to providing measurements for determining compliance with the regulatory mass-based concentration limit for RCMD (see Chapter 1), effective monitoring technologies and sampling approaches provide information on the hazardous aspects of RCMD that are of greatest relevance to disease risk in mine workers. That information allows for continual assessment of the effectiveness of regulatory requirements in reducing miners’ exposures and, ultimately, optimal health protection of miners. Important aspects of hazard assessment include determination of the deposited dose of RCMD particles in miners’ lungs, spatial variability of airborne RCMD concentrations within the mine, concentrations of various RCMD components, and the toxicity of those components at the measured concentrations.

As discussed in Chapter 1, the 2014 dust rule of the Mine Safety and Health Administration (MSHA) sets forth a respirable dust standard that limits miners’ exposures to airborne RCMD in underground coal mines to 1.5 mg/m3 during the full shift that the miner works (30 Code of Federal Regulations [CFR] 70.100). In addition, the rule requirements include the following:

- Increased sampling of airborne RCMD by mine operators, relative to previous sampling requirements;

- Use of new monitoring technology to obtain RCMD measurement results in near real time;

- Immediate corrective action when excessive RCMD concentrations are observed; and

- A method for determining regulatory noncompliance based on a single sample collected by MSHA.

Use of the continuous personal monitoring device (CPDM) by underground coal miners has been required since 2016 (see Chapter 1). It can continuously monitor RCMD concentrations and provide measurements of exposure concentrations in near real time to the miners wearing the device. CPDM readings provide wearers the opportunity to take steps deemed appropriate to reduce their exposures, where possible. The readings also indicate to mine operators when controls and work practices need to be assessed for corrective actions.

As regulatory requirements specify the RCMD monitoring technologies and sampling approaches to be used by operators in coal mines in the United States, this chapter considers efficacy with respect to several key potential outcomes of those requirements and several underlying assumptions, which are associated with potential information gaps (see Table 4-1). This chapter

focuses on the operator’s required use of the CPDM to monitor RCMD and MSHA’s use of gravimetric monitoring to obtain measurements of crystalline silica content in RCMD. The committee did not assess MSHA’s program for RCMD sampling inspections.1

TABLE 4-1 Potential Outcomes and Assumptions for Required Monitoring and Sampling Methods

| Method | Potential Outcomes | Assumptions |

|---|---|---|

| 1. Determine compliance with the RCMD standards for designated occupations (DOs) on sampled shifts.a | A1a. Data Are Representative: Required dust exposure data are representative of underground coal miners for all periods. When and where RCMD mass and silica content are monitored is sufficient to ensure health protection of miners. | |

| A1b. No Change in Particle Size Distribution: The proportionality between dust exposure and the mass of material deposited in the lung is unchanged. | ||

| For miners considered to be exposed to the highest RCMD concentrations, conduct CPDM sampling during 15 shifts per quarter, when production is at least 80% of a specified average. | 2. Inform workers in DOs of a need to change behavior in response to dust concentration readings while conducting tasks. | A2. Training And Behavior Modification: Current training and education programs are implemented in a consistent manner across the coal mine industry so that all mine workers are knowledgeable of RCMD exposures, resulting in behavior modification for dust exposure avoidance in response to information gathered from the CPDM. |

| 3. Provide information to mine operators for addressing airborne dust issues through process control. | A3. Process Control: Mining process control of dust is assured by determining compliance with dust regulations. | |

| 4. Determine sample variability for designated areas (DAs) and DOs. | A4. RCMD Mass And Silica Only: RCMD mass concentration (without specifying composition) and silica content are the characteristics of coal mine dust most strongly associated with health effects. | |

| Personal gravimetric monitoring of DOs for RCM mass and crystalline silica content. | 5. Provide information on D crystalline silica exposure for DOs. | A5. No Silica Monitor: Continuous, real-time measurement of crystalline silica content of RCMD is not achievable. |

aDesignated occupation (DO) is the occupation on a mechanized mining unit (MMU) that has been determined by results of RCMD samples to have the highest respirable dust concentration. In addition, other occupations on an MMU that are designated for sampling are referred to as other designated occupations. Designated areas (DAs) are specific locations in the mine where samples will be collected to measure sources of airborne RCMD in the active workings (that is, any place in a coal mine where miners are normally required to work or travel) (see 30 CFR 70.2).

___________________

1MSHA (2016) presents the agency’s procedures and guidelines for conducting RCMD sampling inspections, evaluating sampling results, establishing and removing sampling entities, establishing reduced dust standards because of silica concentrations, and monitoring operators’ RCMD control and sampling programs.

DETERMINE COMPLIANCE WITH RCMD STANDARDS FOR DESIGNATED OCCUPATIONS ON SAMPLED SHIFTS

Miners’ exposures vary widely because of differences in the mining environment and the kinds of activities the miners perform. Individual (personal) monitoring is important to ensure that the unique features of RCMD exposures are characterized, recorded, and controlled. Personal monitoring involves the use of a sampling device placed on an individual miner to obtain breathing-zone measurements of airborne dust concentrations to which that miner is exposed (Tebbens, 1973; Mark et al., 1986).

While progress was made in the monitoring of airborne RCMD concentrations after passage of the 1969 Coal Mine Health and Safety Act, there remained an issue with getting the measurement results of collected samples in a timely manner to inform exposure control decisions. In addition, it was recognized that real-time monitoring devices for measurements of airborne RCMD concentrations in the underground mine environment, were needed for more effective control. By 1980, there were several instruments that offered instantaneous measurement of mass concentrations of airborne dust that had been tested for use in mines (Thompson et al., 1981). The principles employed in those instruments included light scattering (for example, Tyndallometer, real-time aerosol monitor [RAM-1], and Safety in Mines Scattered Light Instrument [SIMSLIN II]); beta-ray attenuation (for example, Radioactive Decay Module [RDM 101, RDM 201, and RDM 301]) and the change in resonant frequency of a piezoelectric crystal. While those instruments were used in research studies, they were not used widely for routine mine monitoring because of problems of size, intrinsic safety considerations, calibration with mass collection devices and expense. Improvements in technology for continuously monitoring RCMD concentrations, however, has followed along several lines since the early 1990s. The research included an accelerated program to evaluate state-of-the-art technologies with the potential for developing a fixed-site RCMD monitor (Peluso, 1996). In addition, the Bureau of Mines and later NIOSH investigated technologies for personal monitoring and fixed-site area monitoring throughout that same time period.

Representativeness of Exposure Monitoring Data

The 2014 dust rule requires that a continuous personal dust monitor (CPDM) be worn by a miner in a designated occupation and other designated occupations to provide measurements for determining regulatory compliance.2 The mine operator and the miner who wears the monitor receive an indication of RCMD exposure concentrations in near-real-time and they can determine whether the airborne RCMD exposure limit of 1.5 mg/m3 is exceeded during the production shift that the miner works. That is a marked improvement over the previous monitoring method. It affords miners working in designated occupations with the potential opportunity during the course of the shift to reduce their exposures by moving to a less dusty location, while carrying out their job duties. It also indicates to the mine operator when an operating procedure might need to be modified to diminish the amount of dust being generated.

The point of the required monitoring is to determine regulatory compliance. As such, sampling is used presumably to identify worst-case exposures for addressing and eliminating those exposures. That approach is in contrast to traditional epidemiologic approaches where random samples may be collected to find an average exposure (Seixas et al., 1997; Rando et al., 2001). Using the results from sampling for regulatory compliance, the outcome of an epidemiologic

___________________

2 The designated occupation is the occupation on a mechanized mining unit (MMU) that has been determined by results of RCMD samples to have the highest RCMD concentration. Other designated occupations on an MMU that are designated for sampling are referred to as ODOs. The 2014 dust rule indicates that sampling the DOs and ODOs is the most effective method for protecting all miners from excess exposure to respirable coal mine dust (see 79 Fed. Reg. 24,903, May 1, 2014).

assessment informs a determination of the efficacy of the regulations, but that outcome may not necessarily be applicable to any other regulatory framework (Attfield and Morring 1992; Attfield and Seixas 1995).

However, there is a potential contradiction in Assumption A1a (Data Are Representative) listed in Table 4-1 that underlies the above-mentioned approach. From past experience, the miner in the designated occupation is believed to represent the highest exposure of all the occupations likely to be near where the work of that miner is undertaken. The designated occupation is at a location often considered to represent the highest dust output of the mining process. If the designated occupation is found not to be overexposed, it is assumed the mining process is unlikely to overexpose workers in other job categories in the vicinity. In addition, a determination of compliance with the regulatory requirements would represent a safe and healthy work environment for all miners in a designated area.3

According to that reasoning, it would be unnecessary, in theory, to require workers in other occupations to be monitored because the approach is considered to be a check on process control of airborne RCMD concentrations. Although the personal exposure of the designated occupation (and other designated occupation) are quantified, exposures of other miners are not. Therefore, in the event that the designated occupation was overexposed, there would be no way of knowing from the samples taken by the operator by how much any of the other occupations were overexposed. Although assuming the other occupations are overexposed in such a case would seem to be protective, there would be no indication of the extent to which the assumed overexposures were reduced. As a result, there is a lack of data indicating whether an unmonitored individual miner had experienced a high, cumulative exposure by the end of his or her career, regardless of how many days the airborne RCMD concentrations in the mine sections where the miner worked were determined to be greater or less than the regulatory exposure limit.

There also is difficulty in trying to adapt a historical approach to the more modern technology of direct-reading instruments by relying on the assumption that the designated occupation remains the highest exposed individual. When the miner in the designated occupation wears a CPDM unit and is able to determine when conditions are unfavorable in terms of RCMD exposure, that miner might be able to alter his or her location to mitigate the exposure while carrying out the designated occupation’s job duties. In that case, the miner may no longer have the highest exposure in the mine section. There is a need to evaluate the exposures of mine workers not wearing CPDMs to ensure that the approach of detecting and mitigating high-exposure concentrations for designated occupations reliably results in mitigating high exposures of all workers.

Respirable Dust Particle Size and Lung Deposition

The measurement of RCMD exposure from coal mining operations is usually accomplished using a size-selective sampling device for particles in a size range meeting a respirable sampling convention. There are several ways to describe the meaning of the term respirable dust. One definition is “that fraction penetrating through the conductive airways of the head and tracheobronchial tree and available for deposition in the nonciliated alveolar zone airspaces where the dusts can cause lung fibrosis” (Lippmann, 1970). That area is typically considered to be the region where the exchange of carbon dioxide and oxygen occurs between the lung and blood, and it includes the alveoli and respiratory bronchioles.

The regulatory definition of RCMD, however, is not based on human anatomy. The Code of Federal Regulations (30 CFR 70.2) defines respirable dust as “Dust collected with a sampling

___________________

3 Designated areas are specific locations (in outby areas) in the mine where samples will be collected to measure sources of airborne RCMD in the active workings (that is, any place in a coal mine where miners are normally required to work or travel). Designated areas are identified by the operator in the mine ventilation plan (30 CFR 75.371). On February 1, 2016, designated areas associated with an MMU were redesignated as other designated occupations.

device approved by the Secretary [of Labor] and the Secretary of HHS in accordance with [30 CFR] part 74 (Coal Mine Dust Sampling Devices) of this title.” That definition of respirable dust is more practical from a legal standpoint than the first definition. To implement a regulation based on the first definition, it would be necessary to determine the particle mass in the collected sample that is established as the respirable size fraction. In addition, it would be necessary to assess the characteristics of each miner’s lung that affect the actual particle penetration rate into the noncilliated alveolar region, or at least determine an average penetration rate for humans under relevant conditions. While from a toxicological standpoint that approach might be preferable, the interpersonal variability of human anatomy and physiology would present a formidable barrier to the application of that definition in a legal context.

However, particle measurements obtained according to the regulatory definition of respirable dust are used for health-related studies. However, in using data obtained according to the regulatory definition of RCMD, caution is needed in bridging the gap between practical applications and theoretical considerations. Consider, for example, an epidemiologic investigation to develop a dose-response relationship, which seeks to estimate the response of a biological receptor to an amount of material delivered to the target biological system, organ, or cell where it can produce an outcome. Airborne dust concentrations are often used as a prime source of information for epidemiologic studies, as the measurements represent the potential amount of material that the individuals of interest can be exposed to over a specified period. Because regulatory compliance programs require record keeping for airborne dust measurements, the records also incorporate how, when, and where the measurements were made. The airborne RCMD concentrations are used as a surrogate for dose.

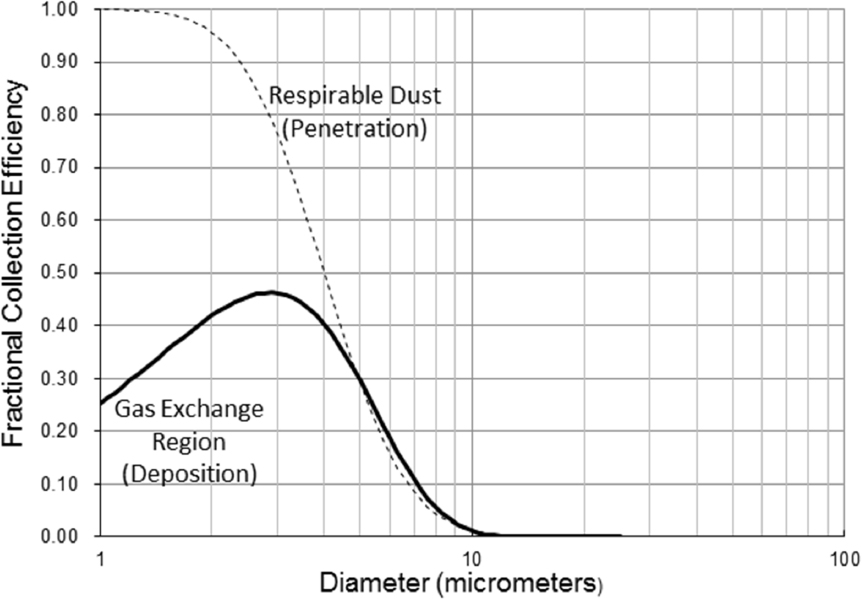

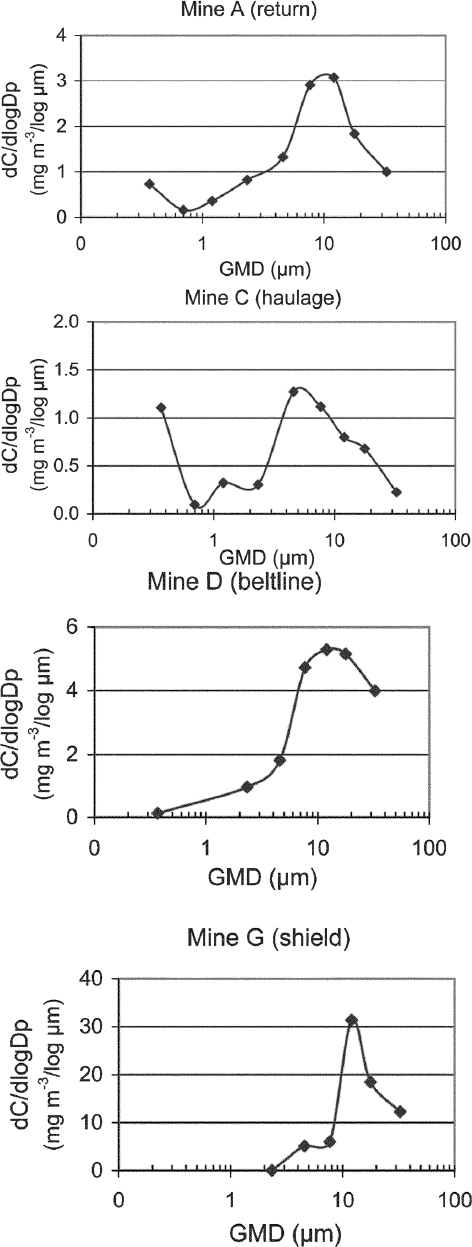

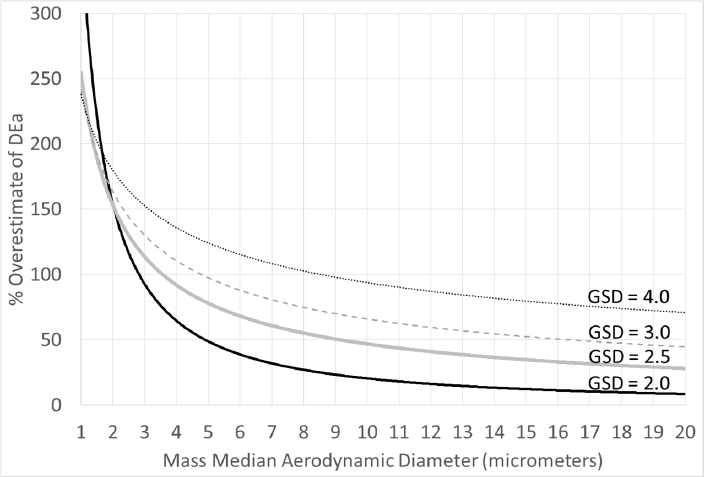

Measurements of airborne RCMD, as defined in 30 CFR 70.2, are not necessarily a dose measurement (that is, the mass of material deposited into the gas-exchange region of the lung). Also, the definition of respirable dust in Lippmann (1970) given above does not include the deposition of dust (that is, penetration of dust through the conductive airways of the head and tracheobronchial tree). The size range of particles that deposit in the noncilliated alveolar zone airspaces of the lung is only a fraction of the size range of dust that penetrates to that region. The difference is apparent in Figure 4-1. That figure uses an instrument-based expression for respirable dust (Souëf, 1999). The expression is actually a compromise of the previous definitions of particle sizes collected by two different instruments: the gravimetric dust sampler with a horizontal elutriator developed by the Mining Research Establishment (30 CFR 70.2) (sometimes called the MRE sampler) and the 10 µm Dorr-Oliver nylon cyclone. Those two instruments were the basis of measurements used in the epidemiologic derivation of the exposure limits in 30 CFR 70 (Tomb et al., 1973). The difference in size distribution between dust particles deposited in the lung and the respirable dust particles measured by an instrument is a function of the size distribution of the dust being inhaled (Figure 4-2). Dose, therefore, varies with the size distribution of the dust in the mine environment (Fisher and McCawley, 1997). Generally, the aerodynamic diameter of particles in coal mines are in the range 1 to 30 µm with a mean particle size (by mass) of approximately 10 µm (Figure 4-2). If RCMD particles were predominantly larger than 3 µm in aerometric diameter, exposure monitoring devices conforming to the respirable sampling criterion should reasonably represent the dose concentration given to the noncilliated alveolar region of the lung (Figure 4-2). However, if particles smaller than 3 µm make up a substantial portion of the mass collected by the respirable sampler, this mass might overestimate lung deposition. Therefore, it is important to understand whether new mining practices widely adopted since the early 1990s, when particle size distribution data were initially measured, have resulted in a change in the size distribution of mining-related air aerosols.

In 1959 at a conference in Johannesburg, South Africa, information on particle lung deposition as a function of particle size was first presented and shown to be similar to the size-selective sampling characteristics of the two proposed samplers noted above (Orenstein, 1960). Early attempts to define the size of coal mine dust particles that deposit in the lungs were based on miner

autopsy data (Davies, 1952). Microscopic examination of the dust found in pathological specimens of former coal miners’ lungs revealed that the diameter of the dust particles that penetrated into the air-exchange region of the lung was generally less than 5 µm.

A limitation is that the available data only covered a range of deposition values for particle sizes between approximately 10 and 3 µm. Responses to concerns expressed about the limitations of the size range that had been studied were based on the assumption that coal mines contained very little mass of dust in particle sizes less than 2 or 3 µm. It, therefore, would make little difference knowing the mass of particles in the smaller size range that was deposited in the lung or knowing how closely the size range of particles collected by the proposed samplers matched the lung deposition curve for particle sizes less than 3 µm. For coal mine dust, that assumption was correct. When aerodynamic size separation was made possible using impactors several decades later, it was found that the aerodynamic mass size distribution of coal mine dust was almost entirely greater than 3 µm (Burkhart et al., 1987; Potts et al., 1990). As indicated in Figure 4-1, the percent difference between the RCMD penetration curve and the lung deposition curve changes much less for the larger particle sizes, that is, the range of particle sizes likely to occur in underground coal mines. Thus, instruments conforming to the RCMD criterion used in underground coal mines should produce measurements of particles in a size range that are reasonably constant in proportion to the size range of deposited particles or dose of coal mine dust. This should allow, as would seem to be the case for data from epidemiologic studies of underground coal miners, a reasonable association between the measurement of RCMD and the prediction of coal workers’ pneumoconiosis.

Therefore, the RCMD criterion is potentially different, in theory, from the amount of dust that might be expected to be deposited in the human lung (that is, for values greater than 0 percent in Figure 4-3). When comparing toxicological exposure studies (where the dose can be directly measured) to epidemiologic data (where the dose is estimated from monitoring results using a sampler that may be sensitive to particle size distribution changes occurring due to process changes), this potential difference in respirable dust measurements needs to be taken into account. Also, should the mean particle size of the dust be less than 2 or 3 µm, potential differences in previous dose-response relationships need to be considered and perhaps quantified. A decrease in the mean particle size might happen, if, for example, new processes are introduced that create dust of a smaller median size particle. It may also occur if the operation being sampled is not used in an underground coal mine that is similar to those of the study cohorts from which the majority of the health effects data were derived. Therefore, it would be prudent with any measurement of RCMD to have some indication of the size distribution from which that sample is drawn.

In the range of dust sizes between 1 and 10 µm, the difference between estimates of exposure based on samples of airborne dust and the actual lung dose could vary between 0 and 250 percent. For example, a change in a process that originally generated a dust particle size distribution with a 100 percent overestimate of the dose could result in a new dust size distribution, which could have only a 50 percent overestimate of the dose. If the changed process still generated the same measured RCMD concentration, it would result in twice the dose because twice as much of the dust would be expected to deposit in the lung. Although a change in a size distribution will not necessarily change the total mass being generated, there could be a change in the

percent of the total mass being deposited which would presumably cause an increased risk of pneumoconiosis. Such a change in lung deposition could likely go unnoticed because current monitoring methods crudely approximate the amount of dust deposited in the gas-exchange region of the lungs for particles outside the range of the dust size distribution established previously for underground coal mines. Such a case points to potential uncertainties regarding Assumption A1b in Table 4-1 (No Change in Particle Size Distribution).

INFORM WORKERS IN DESIGNATED OCCUPATIONS OF A NEED TO CHANGE BEHAVIOR IN RESPONSE TO DUST CONCENTRATION READINGS WHILE CONDUCTING TASKS

The training requirements of the 2014 dust rule for miners who are to wear the CPDM are contained in 30 CFR 70.201(h) and 90.201(h). The mine operator must provide the training before miners will be wearing the device and every 12 months thereafter. The training must convey the importance of monitoring dust concentrations and properly wearing the CPDM. It also must provide an explanation of the basic features and capabilities of the CPDM, the various types of information displayed by the device, how to access that information, and how to start and stop a short-term sample run during compliance sampling. Paragraph (h) of the above-mentioned CFR section requires that the operator record the dates of the training, the names of the miners trained, and the subjects covered. The records must be kept for 24 months and made available on request to miners’ representatives and the U.S. Departments of Labor and Health and Human Services (that is, MSHA and the National Institute for Occupational Safety and Health [NIOSH]).

Sections 70.202 and 90.202 specify that only certified persons may conduct the RCMD sampling program (30 CFR 71.202). Those charged with maintaining and calibrating the equipment are certified separately (Sections 70.203 and 90.203). To become certified, an applicant must complete a training course and pass an MSHA examination initially and every 3 years thereafter. MSHA can revoke either certification for failure to carry out the required procedures. The regulations do not specify the length of the courses, but they are typically 8 hours and are mostly offered by the MSHA district offices.

There is no requirement that the training be carried out by a certified trainer, although 30 CFR 48 can be read to require that it be done by an MSHA-approved trainer, or an experienced supervisor or miner. It is typically done by the person certified to conduct the sampling.

Miners are not tested or required to demonstrate proficiency in the use of the CPDM. The device is relatively easy to use, putting aside the serious issues of its weight and bulk. Based on presentations to the committee at its April 2017 meeting (see Appendix C), the degree to which the first required element—the importance of the dust monitoring—is included in the training, appears to vary widely. Also, no amount of training can resolve this paradox inherent in the current use of the CPDM. As discussed previously, a miner wearing the monitor receives near-real-time exposure data and can sometimes move to a less dusty position. That is one of the main virtues of this cumbersome device. In fact, the mine operator may require the miner to move, as it could be viewed as unethical to require a miner to stay in a high-exposure location, as indicated by the CPDM, when a safer location is available. However, when the CPDM is used for compliance monitoring, a change in a miner’s location might cause that person to no longer be representative of the miners with the highest exposures.

Mine operators are demonstrating almost universal compliance with the allowable RCMD exposure limit of 1.5 mg/m3. It is unknown whether compliance is being achieved only for those miners wearing the CPDM, or for all miners in the work area. An analysis of the time-series data contained in the CPDM might help elucidate the issue by providing information about when the highest exposures are occurring, what might have been happening during that time in the mining process, and how long it took to address the issue.

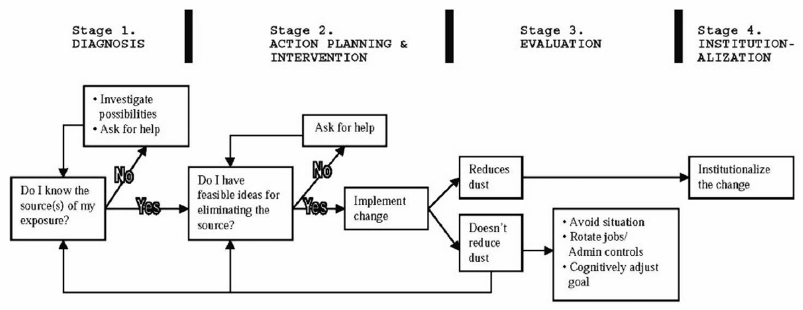

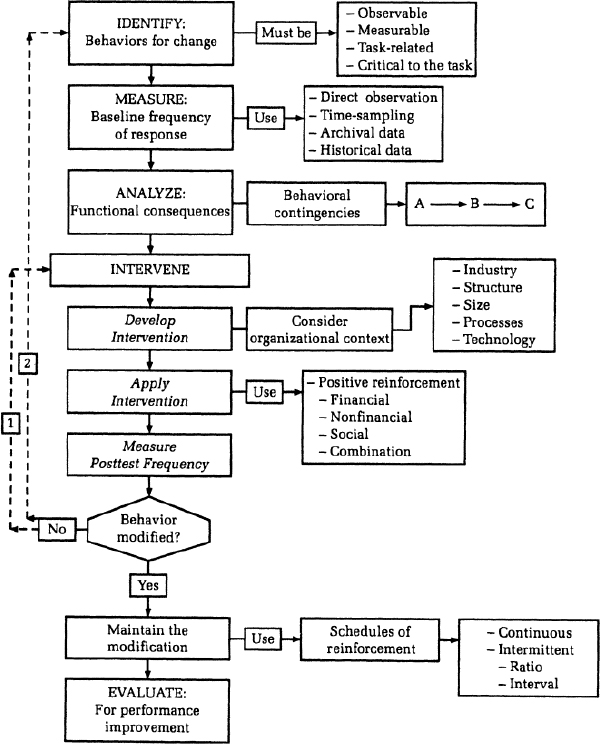

A current conceptual model for characterizing the process of learning from available CPDM measurements (Peters et al., 2008) is based on several lines of psychological research (Bandura, 1977, 2004; Janz and Becker, 1984; Kluger and DeNisi, 1996; Janz et al., 2002). The model proposed by Peters et al. (2008) is illustrated in Figure 4-4.

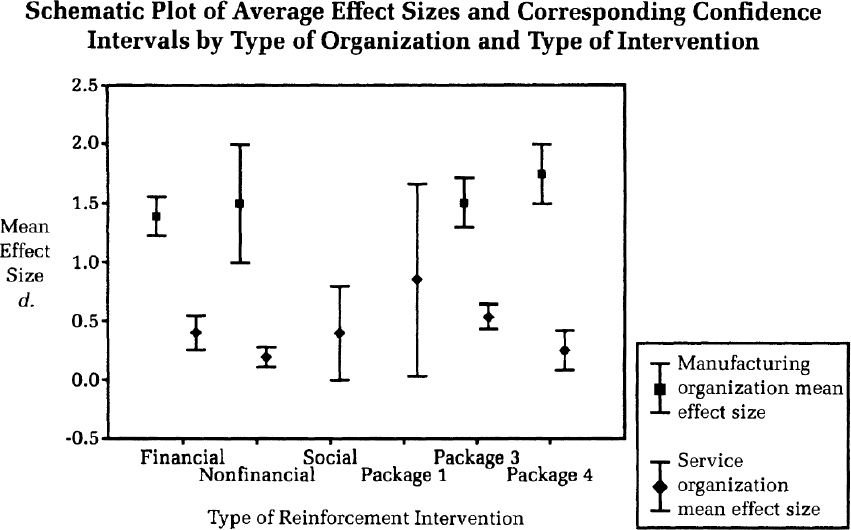

The conceptual model proposes attitudinal changes leading to action, which eventually is incorporated and solidified into institutional change. The rewards are primarily social rewards realized through the social contract between employer and employee. Although the eventual financial health benefits of the change cannot be ignored, the time frame in which those benefits take place is long and the gains are a matter of an absence of effect. Nonetheless, social rewards can be used for behavior modification in combination with nonfinancial interventions, such as performance feedback (Figure 4-5). Those effects on performance can significantly improve even beyond the effect produced by financial rewards, although significance is not demonstrated in a statistical sense. When a number of studies are considered by conducting a meta-analysis (Figure 4-6), the overall effect over time appears to be an average improvement in performance of 17 percent (Stajkovic and Luthans, 1997).

It is clear that current changes in regulatory compliance, presumably by modification of behavior based on feedback from the CPDM, are substantially greater than those reported in other types of literature on behavioral change. According to Ajzen (1985):

Beliefs represent the information people have about a behavior: its likely consequences, the normative expectations of others, and the likely impediments to its performance. Behavioral interventions provide information that change some of these beliefs, or that lead to the formation of new belief. As a result, intentions and behavior will often revert to what they were prior to the intervention. Only when the new beliefs accurately reflect reality can we expect that the effect of the intervention will persist over time.

Therefore, in addition to exploring the impetus for change of work habit in the coal mines it will also be necessary to determine if the change persists and for how long. Pointing to uncertainties regarding Assumption A2 in Table 4-1 (Training and Behavior Modification), those considerations introduce the question as to whether behavioral changes related to information from the CPDM are akin to changes associated with the use of personal protective equipment (PPE). In both cases, there is the ability to control exposure through personal action that can have a major influence on the resulting exposures. A study by Olson et al. (2009) concerning the use of PPE suggests that, again, social modeling is a potentially powerful determinant of prevention behaviors within workgroups. A review of 20 industrywide applications of behavior-based safety programs demonstrated that mandated behavior-based safety programs had greater involvement, trust in management, trust in coworkers, and satisfaction with the training than did programs where participation was entirely voluntary (DePasquale and Geller, 1999). Another evaluation of up to 5 years of injury data from 73 companies, drawn from a target population of 229 companies who implemented behavior-based safety programs, showed pre- to post-initiative incident levels across groups had a significant decrease in incidents following the behavior-based safety implementation (Krause et al., 1999). Employers need to be aware of the potential impacts of social modeling on prevention behaviors, such as PPE use, especially among newly hired workers. The Olson et al. study also confirms the general value of implementing and maintaining behavioral safety processes, which are designed to measure the prevalence of safe behaviors and conditions regularly and provide workers with feedback and reinforcement for meeting prevention goals. No such behavioral reinforcement program seems to be in effect in the coal mines for use with adoption of the CPDM. This draws into question whether the effectiveness seen to date will be permanent. On the other hand, behavior-based safety programs have been criticized as being a way of shifting the blame to the worker (Frederick and Lessin, 2000). The reported successes mentioned above and the lack of current programs to accompany the introduction and use of the CPDM suggests research and development that could be done longitudinally to determine if current successes are maintained as the program matures.

PROVIDE INFORMATION TO MINE OPERATORS FOR ADDRESSING DUST ISSUES THROUGH PROCESS CONTROL

As mentioned previously, personal monitoring involves the use of a device mounted on a miner that indicates the airborne dust concentrations to which a miner is exposed as he or she moves from place to place. In this case, personal exposure would therefore be that amount of RCMD measured in the breathing zone of the miner.

Because spatial and temporal variability of airborne RCMD particle characteristics are large, area monitoring has been widely employed to assess sources of dust and the effectiveness of dust control technology (Burkhart et al., 1987; Kissel and Sacks, 2002). Area monitoring involves the use of static (fixed-site) sampling devices to obtain measurements of the general concentration of dust in a workplace.

A review of the top ic suggests that the use of personal exposure monitoring, by itself, is an unreliable method for assessing process control actions to mitigate airborne RCMD concentrations (Kissel and Sacks, 2002). The ratios of measurements from personal exposure monitors to those made by area monitors were found to range up to more than 30-fold. While the authors note that this does not meet the NIOSH +/- 25 percent criterion, it pales in comparison to that of 3 to 10 for occupational settings (Rodes et al., 1991). Personal monitoring adds variability to the RCMD sampling results beyond the variability contributed by the intrinsic fluctuations in the process itself. Personal monitoring results reflect not only the RCMD concentrations contributed by the process, but also the variability of an individual miner’s actions, in general, and the particular actions, which generate dust apart from the process.

Those effects represent uncertainties in the basis for Assumption A3 (Process Control) listed in Table 4-1, as the performance of the coal mine operator’s dust control plan is assessed by the sampling results of the personal monitoring required in the 2014 dust rule. Process control is likely to be better informed through a plan that includes the regular use of area monitors that are fixed in an appropriate location. For example, Corn (1985) offers a scheme that includes options for determining personal exposure and area concentrations. Use of both types of monitoring would be appropriate to maintain a healthful working environment.

For underground coal mines, there is no established proportionality between the exposure measurements of the designated occupation and other miners who work in the same mine section and do not wear a CPDM. Exposure measurements of the designated occupation provide information to investigate whether process control measures should be adjusted, as discussed previously. However, that information is likely inadequate for that purpose because the approach does not quantify exposure for anyone but the miner in that occupation. That concern is consistent with cautions expressed by Esmen and Hall (2000) regarding reliance on limited exposure data that can result in seriously misleading conclusions.

A combination of sampling methods might be warranted for various sampling purposes, such as those listed in Table 4-2. Corn (1985) points out that a zoning method can be used to group employees based on similarities in either job or environment in which they work. Employees in each zone are selected randomly for personal sampling. The zoning approach is more efficient than a random sampling approach for determining high-exposure areas, since the zoning approach focuses on identified problem areas. Area sampling is effective for evaluating sources of contamination and identifying when the need for process changes should be investigated.

DETERMINE SAMPLE VARIABILITY FOR DESIGNATED AREAS AND DESIGNATED OCCUPATIONS

CPDM Considerations

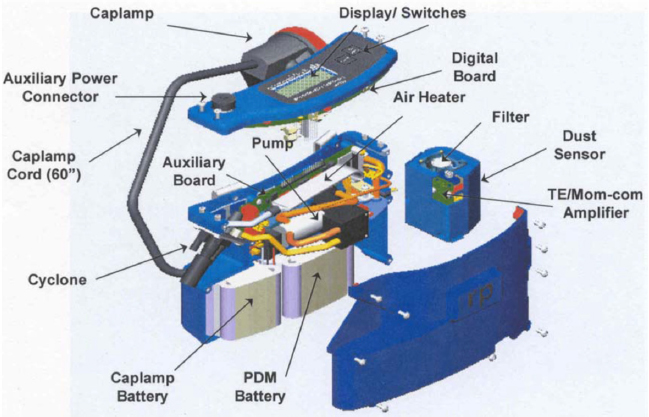

NIOSH has described the CPDM in detail (see Box 4-1). CPDM components are illustrated in Figure 4-7. Public comments on the CPDM have noted that cost, size, and weight are important drawbacks regarding the routine use of the instrument. Mine operators commented that the high unit cost limits the number of instruments likely to be purchased and used in the mine for purposes other than regulatory compliance, especially engineering studies of dust control. Miners have commented that the large size of the CPDM makes it difficult to wear the monitor in such a way that makes the readout display easily observable by the wearer for instantaneous feedback to inform behavior modification. Miners also commented that the weight of the CPDM makes the device burdensome to wear, considering the amount and weight of other equipment that must be worn by the miners.

TABLE 4-2 Selected Purposes of Air Sampling

| Evaluation of Individual Employee Exposure | Evaluation of Sources of Contaminant in a Work Area | Evaluation of Trends of Workplace Air Contamination |

|---|---|---|

| Conformance with a regulated standard (in the United States an 8-hour permissible exposure level or short-term ceiling limit) | Process change effects | In terms of employee exposure |

| Long-term average exposure (for epidemiologic studies) | Process efficiency monitoring | In terms of selected “air parcels” at fixed locations |

| Long-term average exposure of group members with similar exposures | Daily controls for process control or employee management (administrative controls) |

SOURCE: Corn, 1985.

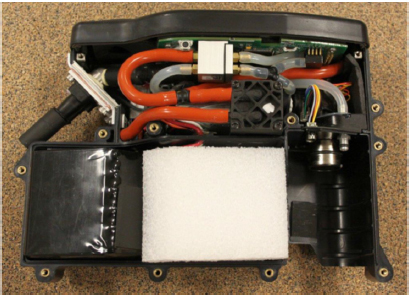

Figure 4-9 Continuous personal dust monitor (PDM3700) with cover panel removed. White foam spacer is in place of the battery required for the caplight on the earlier model shown in Figure 4-7 (Thermo Fisher Scientific, 2016).

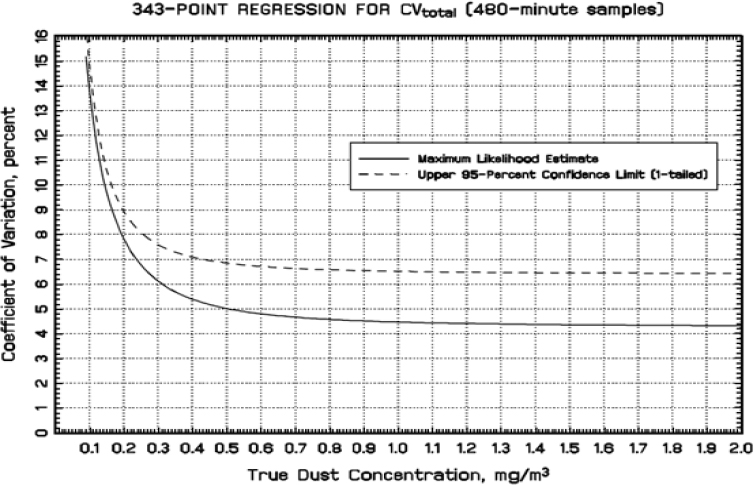

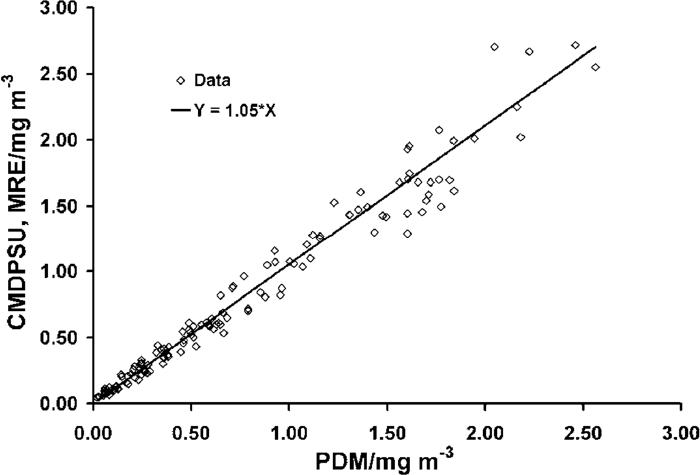

The precision of readings obtained in the past from approved regulatory compliance sampling equipment appears to have been sufficient to provide reliable mass-based measurements of airborne RCMD, as illustrated in Figure 4-10. The CPDM measurements, which are provided in near real time, were found to correlate closely with measurements obtained from using a coal mine dust personal sampler unit (CMDPSU) (Figure 4-11).

CPDM Sampling and Exposure Variability

In general, the following are considered to be the three main purposes for collecting RCMD samples:

- Demonstration of compliance. Sampling is conducted to determine whether an exposure limit is exceeded during a single shift (Leidel et al., 1977). It is not intended to assess associations between exposure and disease. Workplace exposures are affected by many sources of variability and they can vary spatially and temporally. The intent in using the CPDM is to identify high-exposure periods. If corrections made in response to those readings do not also reduce exposures of the other miners in the same area, the samples collected by the CPDM might underestimate their RCMD exposure.

- Assurance of process control effectiveness. Sampling is carried out in support of worker health surveillance for identification and mitigation of potentially hazardous exposures. Plotting and viewing the time-series sampling data on various control charts that show how a process changes over time can help identify causes of departure from normal conditions (usually seen as extreme individual values or series of values). Control effectiveness can be regained by correcting or removing the cause of the departure (Alwan and Roberts, 1988). Area monitoring is a useful means of evaluating dust control equipment and has been used extensively for the evaluation of techniques (Chugh et al., 2006; Goodman et al., 2006).

- Epidemiologic studies. Sampling data are used in future studies to reconstruct miners’ exposures to contaminants of interest and compare those exposures with disease risk. Epidemiologic studies can serve as a tool for assessing the adequacy and overall effectiveness of health and safety regulations. However, because of the regulatory nature of the samples being collected in coal mines, the results may not be comparable to studies done under other regulatory regimens. In addition, most available RCMD data were obtained from sampling efforts that targeted worst-case exposures and those data are not reflective of exposures to the general mining workforce. That has limited the extent of understanding relationships between RCMD exposures and risks for adverse health outcomes.

It is important to note that area sampling does not correlate with personal samples. In a study of area monitoring data and personal exposure data along longwall faces, Sun et al. (1997) found no direct relationship between the dust concentration of the shearer operator and the concentration at the tailgate of the face. Kissell and Sacks (2010) calculated the mean ratios of area sampling to personal sampling from five published studies of coal mines in the United States. The highest mean ratio was 30.7 and the lowest was 3.07. Therefore, the current personal sampling routines, by themselves, might not be sufficient to evaluate the processes that are the source of dust in the mines. Area monitoring is a well-established and acceptable method for that evaluation of the dust sources and the engineering controls used to diminish them.

Each of the three kinds of sampling mentioned above has particular needs regarding method, location, frequency, and statistical and chemical analyses of the collected samples. As the CPDM is used primarily for regulatory compliance sampling (and to some extent for engineering studies), a broader range of sampling approaches is needed to assess relationships between exposure and disease. Assumption A4 listed in Table 4-1 (Total RCMD and Silica Only) runs counter to that need.

PROVIDE INFORMATION ON CRYSTALLINE SILICA EXPOSURE FOR DESIGNATED OCCUPATIONS

As indicated in Chapter 1, increased silica exposure appears to explain at least some of the observed cases of rapidly progressive pneumoconiosis in coal miners. The 2014 dust rule requires

that the average airborne concentration of respirable quartz (the most common form of crystalline silica) not exceed 0.1 mg/m3 (100 µg/m3). When the airborne RCMD concentration in the active workings of a coal mine contains more than 5 percent quartz, a reduced allowable RCMD concentration is computed by dividing 10 by the quartz concentration, expressed as a percentage (30 CFR 70.101).

The CPDM is unable to measure quartz in RCMD samples. As discussed in Chapter 2, MSHA collects RCMD samples using a personal gravimetric sampler (CMDPSU) to monitor respirable quartz. Filters containing dust samples are sent to a laboratory for analysis, using infrared spectroscopy (MSHA, 2013). That entire process can take several days or more to provide the quartz results to the mine operator, starting from when the dust samples had been collected.

In addition to the time lag in getting results, the required analytical techniques might not account for the fraction of occluded (coated) quartz particles in a dust sample. Surface coating might alter the biological availability of the surface area of quartz particles and thus alter their potential for toxic effects. Occluded respirable quartz particles were found less frequently in samples of anthracite dusts compared to all bituminous dust samples (Harrison et al., 1997).

Currently, no device is capable of monitoring respirable quartz or crystalline silica in real time, as indicated by Assumption A5 in Table 4-1 (No Silica Monitor). Assuming that a continuous monitor to provide real-time measurements of crystalline silica is not feasible tends to be inconsistent with the importance of obtaining silica exposure information in a timely manner. Chapter 5 discusses ongoing efforts to develop methods for obtaining silica analytic results more rapidly, including work on a device to provide end-of-shift silica concentrations at the mine site (Cauda et al., 2016). Both x-ray fluorescence (XRF) and Fourier transform infrared spectroscopy (FTIR) have been suggested as post-shift methods of analysis. Apart from the technical challenges inherent in the methods themselves (Reig et al., 2002; Nayak and Singh, 2007) there is the issue of how to use the information in the most efficient manner. The CPDM’s intended use is to allow visualization of the potential threat of overexposure while there is time to take action. Not determining the crystalline silica content of the dust in real time would seem to invalidate that tactic. However, an argument could be made for tracking the silica content of the dust on a daily basis with the thought of predicting what that content might be for the next shift (Miller et al., 2012; Tuchman et al., 2008). The success of that approach, however, relies on the intrinsic variability of the silica content of the coal and rock materials (Colinet and Listak, 2012).

CONCLUSIONS

- Effective monitoring technologies and sampling approaches would provide information on not only on the total RCMD mass concentrations for meeting regulatory requirements, but also the hazardous characteristics of RCMD that are of greatest relevance to disease risk in miners.

- Continuous personal dust monitors (CPDMs) are being used to comply with the monitoring and sampling requirements of the 2014 dust rule. The ability to measure exposures in near real time by using CPDMs is an important technologic advancement compared to monitoring methods used previously. If a measurement collected during a full shift exceeds allowable limits, operators must take corrective actions immediately. In addition, miners wearing CPDMs receive information about their personal exposures and sometimes can modify their activities or locations within a mine in response to elevated readings.

- Changes in mining technologies during the past several decades might have led to changes in typical particle-size distributions of RCMD. If so, there might have been a change in the relationship between CPDM measurements of RCMD mass concentrations and the health effects associated with particle type, size, concentration, and deposition in the lung.

- Training in the use of CPDMs and education concerning important factors that affect exposure-response relationships can enhance workers’ ability to take precautions that reduce RCMD exposures. It is important to ensure that training and education programs are implemented in a consistent manner across the coal mining industry. Therefore, in addition to exploring the impetus for change of work habit in the coal mines it will also be necessary to determine if the change persists and for how long.

- CPDMs worn by individual miners in designated occupations are used to determine whether mine operators maintain RCMD concentrations at or less than the allowable exposure concentration. However, only a small number of miners wear a CPDM on any given shift, and it is possible that those coal miners using the CPDMs are not representative of the dust exposure to other miners who are not using the CPDMs. When miners wearing CPDMs react to high monitor readings to reduce their personal dust exposure (for example, by altering their locations while carrying out their job duties), the required RCMD measurements might no longer be representative of the miners with the highest exposures. Whether demonstrations of compliance with allowable RCMD exposure concentration is being achieved only for those miners wearing the CPDM, or for all personnel in the work area, is unknown.

- Area monitoring, which involves the use of measurement devices at fixed locations in underground mines, is critical for understanding environmental and operational factors that influence the concentration and particle characteristics of RCMD.

- The health hazards posed by crystalline silica exposure warrant greater focus on developing improved sampling and monitoring techniques.

REFERENCES

Ajzen, I. 1985. From intentions to actions: A theory of planned behavior. In Action Control: From Cognition to Behavior, J. Kuhl and J. Beckman, eds. Heidelberg: Springer, pp. 11-39.

Alwan, L. C., and H. V. Roberts. 1988. Time-series modeling for statistical process control. Journal of Business & Economic Statistics 6(1):87-95.

Attfield, M. D. and K. Morring. 1992. An investigation into the relationship between coal workers’ pneumoconiosis and dust exposure in US coal miners. American Industrial Hygiene Association Journal 53(8):486-492.

Attfield, M. D. and N. S. Seixas. 1995. Prevalence of pneumoconiosis and its relationship to dust exposure in a cohort of US Bituminous coal miners and ex‐miners. American journal of industrial medicine 27(1):137-151.

Bandura, A. 1977. Self-efficacy: Toward a unifying theory of behavioral change. Psychological Review 84(2): 191-215.

Bandura, A. 2004. Health promotion by social cognitive means. Health Education & Behavior 31(2):143-164.

Bartley, D. L., C. Chen, R. Song, and T. J. Fishbach. 1994. Respirable aerosol sampler performance testing. American Industrial Hygiene Association Journal 55(11):1036-1046.

Birch, E., and J. D. Noll. 2004. Submicrometer elemental carbon as a selective measure of diesel particulate matter in coal mines. Journal of Environmental Monitoring 6(10):799-806.

Burkhart, J. E., M. A. McCawley, and R. W. Wheeler. 1987. Particle size distributions in underground coal mines. American Industrial Hygiene Association Journal 48(2):122-126.

Cauda, E., A. Miller, and P. Drake. 2016. Promoting early exposure monitoring for respirable crystalline silica: Taking the laboratory to the mine site. Journal of Occupational and Environmental Hygiene 13(3):D39-D45.

Chugh, Y. P., A. Patwardhan, H. Gurley, A. Moharana, R. Carty. 2006. A field demonstration of an innovative spray system on continuous miners for dust control. In Proceedings of the 11th US/North American Mine Ventilation Symposium. Boca Raton, FL: CRC Press. pp. 233-240.

Colinet, J. F. and J. M. Listak. 2012. Silica and respirable content in rock dust samples. Coal age 117(12): 48-52.

Corn, M. 1985. Strategies of air sampling. Scandinavian Journal of Work, Environment and Health 11(3 Spec. No.):173-180.

Davies, C. N. 1952. Dust sampling and lung disease. Arhiv za higijenu rada i toksikologiju 3(1):54-58.

DePasquale, J. P., E. S. Geller. 1999. Critical success factors for behavior-based safety: A study of twenty industry-wide applications. Journal of Safety Research 30(4):237-249.

Esmen, N. A., and T. A. Hall. 2000. Theoretical investigation of the interrelationship between stationary and personal sampling in exposure estimation. Applied Occupational and Environmental Hygiene 15(1):114-119.

Esmen, N. A., D. L. Johnson, and G. M. Agron. 2002. The Variability of Delivered Dose of Aerosols with the Same RespirableConcentration by Different Size Distributions. Annals of Occupational Hygiene 46(4):401-407.

Fisher, D., and M. McCawley. 1997. Lack of correlation between PM10 measurements and upper respiratory tract dose. Annals of Occupational Hygiene 41(Suppl 1):14-18.

Frederick, J. and N. Lessin. 2000. Blame the worker: The rise of behavioral-based safety programs. Multinational Monitor 21(11):10-17.

Goodman, G. V. R., T. W. Beck, D. E. Pollock, J. F. Colinet, and J. A. Organiscak. 2006. Emerging technologies control respirable dust exposures for continuous mining and roof bolting personnel. In Proceedings of the 11th US/North American Mine Ventilation Symposium. Boca Raton, FL. pp. 211-216.

Harrison, J. C., P. S. Brower, M. D. Attfield, C. B. Doak, M. J. Keane, R. L. Grayson, and W. E. Wallace. 1997. Surface composition of respirable silica particles in a set of U.S. anthracite and bituminous coal mine dusts. Journal of Aerosol Science 28(4):689-696.

Hewett, P. 1991. Limitations in the Use of Particle Size-Selective Sampling Criteria in Occupational Epidemiology. Applied Occupational and Environmental Hygiene 6(4):290-300.

ICRP (International Commission on Radiological Protection). 1994. Human respiratory tract model for radiological protection. ICRP Publication No. 66. Annals of the ICRP 24(1-3):1-482.

ISO (International Standards Organization). 1995. Air Quality: Particle Size Fraction Definitions for Health-Related Sampling. Standard 7708. Geneva, Switzerland: ISO.

Janz, N. K., and M. H. Becker. 1984. The health belief model: A decade later. Health Education Quarterly 11(1):1-47.

Janz, N. K., V. L. Champion, and V. J. Strecher. 2002. The health belief model. In Health Behavior and Health Education: Theory, Research and Practice, 3rd ed., K. Glanz, B. R. Rimer, and F.M. Lewis, eds. San Francisco: Jossey-Bass, pp. 45-66.

Kissell, F. N. and H. K. Sacks. 2002. Inaccuracy of area sampling for measuring the dust exposure of mining machine operators in coal mines, Mining Engineering, Vol. 54, No. 2, pp. 17-23.

Kluger, A. N., and A. DeNisi. 1996. The effects of feedback interventions on performance: A historical review, a meta-analysis, and a preliminary feedback intervention theory. Psychological Bulletin 119(2):254-284.

Kogut, J., T. F. Tomb, P. S. Parobeck, A. J. Gero, and K. L. Suppers. 1997. Measurement precision with the coal mine dust personal sampler. Applied Occupational and Environmental Hygiene 12(12):999-1006.

Krause, T. R., K. J. Seymour, and K. C. M. Sloat. 1999. Long-term evaluation of a behavior-based method for improving safety performance: a meta-analysis of 73 interrupted time-series replications. Safety Science 32(1):1-18.

Leidel, N. A., K. A. Busch, and J. R. Lynch. 1977. Occupational Exposure Sampling Strategy Manual. NIOSH 77-173. National Institute for Occupational Safety and Health, Cincinnati, OH [online]. Available at https://www.cdc.gov/niosh/docs/77-173/pdfs/77-173.pdf (accessed March 16, 2018).

Lippmann, M. 1970. “Respirable” dust sampling. American Industrial Hygiene Association Journal 31(2):138-159.

Mark, D., J. H. Vincent, D. C. Stevens, and M. Marshall. 1986. Investigation of the entry characteristics of dust samplers of a type used in the British nuclear industry. Atmospheric Environment 20(12):2389-2396.

Miller, A. L., P. L. Drake, N. C. Murphy, J. D. Noll, and J. C. Volkwein. 2012. Evaluating portable infrared spectrometers for measuring the silica content of coal dust. Journal of Environmental Monitoring 14(1):48-55.

MSHA (Mine Safety and Health Administration). 2013. Infrared Determination of Quartz in Respirable Coal Mine Dust [online]. Available at https://arlweb.msha.gov/TECHSUPP/pshtcweb/MSHA%20P7.pdf (accessed March 23, 2018).

MSHA. 2016. Coal Mine Health Inspection Procedures. MSHA Handbook Series. Handbook Number: PH89-V-1 (27). June, 2016.

Nayak, P. S. and B. K. Singh. 2007. Instrumental characterization of clay by XRF, XRD and FTIR. Bulletin of Materials Science 30(3):235-238.

Olson, R., A. Grosshuesch, S. Schmidt, M. Gray, and B. Wipfli. 2009. Observational learning and workplace safety: The effects of viewing the collective behavior of multiple social models on the use of personal protective equipment. Journal of Safety Research 40(5):383-387.

Orenstein, A. J. 1960. Proceedings of the Pneumoconiosis Conference held at the University of Witwatersrand, Johannesburg, 9th-24th February, 1959. London: J&A Churchill Ltd.

Page, S. J., J. C. Volkwein, R. P. Vinson, G. J. Joy, S. E. Mischler, D. P. Tuchman, and L. J. McWilliams. 2008. Equivalency of a personal dust monitor to the current United States coal mine respirable dust sampler. Journal of Environmental Monitoring 10:96-101.

Patashnick, H., and E. G. Rupprecht. 1991. Continuous PM10 measurements using the tapered element oscillating microbalance. Journal of the Air & Waste Management Association 41(8):1079-1083.

Patashnick, H., M. Meyer, and B. Rogers. 2002. Tapered element oscillating microbalance technology. In Mine Ventilation: Proceedings of the North American/Ninth U.S. Mine Ventilation Symposium, June 8-12, 2002, Kingston, Canada, E. De Souza, ed. Lisse, Netherlands: Balkema, pp. 625-631.

Peluso, R. G. 1996. Continuous monitoring of environmental parameters in underground coal mines. Applied Occupational and Environmental Hygiene 11(7):615-617.

Peters, R. H., C. Vaught, E. E. Hall, and J. C. Volkwein. 2008. Miners’ Views About Personal Dust Monitors. Information Circular 9501. DHHS (NIOSH) Publication No. 2008-110. National Institute for Occupational Safety and Health, Pittsburgh, PA [online]. Available at https://www.cdc.gov/niosh/mining/UserFiles/works/pdfs/2008-110.pdf (accessed November 21, 2017).

Potts, J. D., M. A. McCawley, and R. A. Jankowski. 1990. Thoracic dust exposures on longwall and continuous mining sections. Applied Occupational and Environmental Hygiene 5(7):440-447.

Rando, R. J., R. Shi, J. M. Hughes, H. Weill, A. D. McDonald, and J. C. McDonald. 2001. Cohort mortality study of North American industrial sand workers. III. Estimation of past and present exposures to respirable crystalline silica. The Annals of occupational hygiene 45(3):209-216.

Reig, F. B., J. G. Adelantado, and M. M. Moreno. 2002. FTIR quantitative analysis of calcium carbonate (calcite) and silica (quartz) mixtures using the constant ratio method. Application to geological samples. Talanta 58(4):811-821.

Rodes, C., R. M. Kamens, and R. W. Wiener. 1991. The significance and characteristics of the personal activity cloud on exposure assessment measurements for indoor contaminants. Indoor Air 1(2):123-145.

Seixas, N. S., N. J. Heyer, E. A. E. Welp, and H. Checkoway. 1997. Quantification of historical dust exposures in the diatomaceous earth industry. The Annals of occupational hygiene 41(5):591-604.

Souëf, P. L. 1999. The meaning of lung dose. Allergy 54(s49):93-96.

Stajkovic, A. D., and F. Luthans. 1997. A meta-analysis of the effects of organizational behavior modification on task performance, 1975-95. Academy of Management Journal 40(5):1122-1149.

Sun, G., R. V. Ramani, E. W. Grygiel, and T. E. McNider. 1997. Relationship between Area Concentrations and Personal Exposures along Longwall Faces. Applied Occupational and Environmental Hygiene 12(12):991-998.

Tebbens, B. 1973. Personal dosimetry versus environmental monitoring. Journal of Occupational and Environmental Medicine 15(8):639-641.

Thermo Fisher Scientifc. 2016. Model PDM3700. Personal Dust Monitor Users Manual [online]. https://assets.thermofisher.com/TFS-Assets/LSG/manuals/EPM-manual-PDM3700.pdf (accessed June 16, 2018).

Thompson, E. M., H. N. Treaftis, T. F. Tomb, A. J. Beckert, and A. J. Gero. 1981. Laboratory evaluation of instantaneous reading dust monitors. American Industrial Hygiene Association Journal 42(3):191-197.

Tomb, T. F., H. N. Treaftis, R. L. Mundell, and P. S. Parobeck. 1973. Comparison of Respirable Dust Concentrations Measured with MRE and Modified Personal Gravimetric Sampling Equipment. Report of Investigations 7772. U.S. Department of Interior, Bureau of Mines, Washington, DC.

Tuchman, D. P., J. C. Volkwein, and R. P. Vinson. 2008. Implementing infrared determination of quartz particulates on novel filters for a prototype dust monitor. Journal of Environmental Monitoring 10(5):671-678.

Volkwein, J. C., R. P. Vinson, L. J. McWilliams, D. P. Tuchman, and S. E. Mischler. 2004. Performance of a New Personal Respirable Dust Monitor for Mine Use. Report of Investigations 9663. DHHS (NIOSH) Publication No. 2004-151 [online]. Available at https://www.cdc.gov/niosh/mining/UserFiles/works/pdfs/ri9663.pdf (accessed November 17, 2017).