8

Life-Cycle Assessment of Carbon Utilization

Life-cycle assessment (LCA) is a technique used to evaluate energy, water, and materials (e.g., chemicals and metals) inputs, outputs, and emissions over the life cycle of a process or product. The International Standards Organization (ISO, 2006) describes the principles and framework of LCA, which take into account the acquisition of raw materials, raw material conversion to product, transportation and distribution of product to point of sale and/or distribution, product use, and product disposal stages of a product’s life cycle.

LCA is particularly relevant for evaluating carbon utilization. While carbon utilization technologies take up CO2 and methane that would otherwise be emitted, the conversion of these greenhouse gases into products consumes energy and materials. Energy and materials consumption results in emissions of greenhouse gases which may or may not, on net, reduce overall emissions as a result of using the carbon utilization technology (Bruhn et al., 2016; von der Assen et al., 2013, 2014). The net greenhouse gas emissions of the carbon utilization process are not the only emissions to consider, however. A key consideration is whether the CO2- or methane-derived product will displace another product. For example, the fabrication of a polymer, using carbon dioxide as one of several building blocks, may on net emit greenhouse gases, since energy and other materials used in making the polymer may result in greater emissions of greenhouse gases than are taken up in the polymer by using carbon dioxide. If, however, that polymer fabricated with carbon dioxide displaces a polymer with greater life-cycle greenhouse gas emissions, the net effect is a reduction in emissions. This product displacement can be a significant component of the overall greenhouse gas benefit of carbon utilization technologies. For example, as described in Box 10-2 (see Chapter 10) for polyols produced by Covestro, the greenhouse gas emissions from the waste gas utilization process are 2.6-2.9 kg CO2e/kg (not net negative); however, they result in emissions that are 0.4-0.6 kg CO2e/kg less than the production of conventional polyols, making the overall waste gas utilization and product displacement net negative. The factors used by the committee in this report to define “net-negative life-cycle greenhouse gas emissions” for waste gas utilization are described in Box 8-1.

In addition to greenhouse gas mitigation, carbon utilization technologies can have other benefits (Bruhn et al., 2016), including increased energy and chemical feedstock security, reduced risk of environmental damage from feedstock extraction, and other factors including enhancing a circular carbon economy. Furthermore, discovery of new reactions and processes associated with carbon utilization may lead to development of new processes that are less hazardous than those they replace.

LCA can be used to address a variety of important questions regarding carbon utilization technologies:

- Does converting waste gases to a product (e.g., fuels, polymers, chemicals, or building materials) emit more greenhouse gases than are sequestered in the product?

- If there is a conventional way to make the product, is the greenhouse gas utilization route to the product less energy, emissions, water, and pollutant intensive?

- Are there trade-offs among different energy and environmental impacts of carbon utilization technologies? For example, perhaps a carbon utilization route is less energy intensive than a conventional route to a product but more water intensive.

- What are the energy and environmental impact drivers of carbon utilization technologies and where are the most significant research and development efforts needed to curtail them? How do these drivers shift if a different source of waste gas is used or a different conversion technology applied?

- What are the energy consumption and environmental burdens associated with preparing waste gas for use (e.g., purified, pressurized, heated, or cooled) from different sources?

- What are environmental impacts of materials widely used in CO2 utilization routes, including catalysts, energy-carrying materials such as hydrogen, and solvents?

- How would the displacement of conventional routes to products with carbon utilization routes ripple through the supply chain and what are the corresponding energy and environmental impacts?

- Which uses of waste gases (e.g., to chemicals or building materials) offer the greatest net greenhouse gas emissions abatement?

Several recent carbon capture and utilization LCA overviews and reviews (Artz et al., 2017; Cuellar-Franca and Azapagic, 2009; Rahman et al., 2017; von der Assen et al., 2013, 2014) provide a summary of the application of LCA to carbon utilization with some discussion of ongoing issues and research needs. The reviews suggest that the application of LCA in evaluating carbon utilization is expanding rapidly. Notably, whereas in 2013, von der Assen et al. reported only a handful of LCAs of utilization studies regarding chemical production, in 2017, Artz et al. reported a larger number of technologies, including production of dimethyl carbonate, polyols, syngas, formic acid, methanol (solar based, co-electrolysis,

and hydrogenation), methane from CO2, and Fischer-Tropsch fuels. Of liquid fuels produced from waste CO2, algae-derived diesel has received a great deal of attention (NRC, 2012; Tu et al., 2017; Zhou et al., 2017). LCAs on mineral carbonation have been more limited, with Giannoulakis et al. (2014) providing a summary of key issues associated with this topic relevant to European Union power generation systems. They describe the importance of process configuration, consideration of transportation of CO2 versus minerals, and the difference in activation step energy intensity by type of mineral.

While LCA has an important role to play in the evaluation of carbon utilization technologies, there are multiple methodological considerations and details in the application of LCA to carbon utilization technologies that must be carefully addressed if LCA is to provide a consistent and transparent framework for evaluating carbon utilization technologies. Each of these aspects, as described below, should be considered and described transparently when reporting LCA results along with material and energy flow data and sources and assumptions.

FACTORS TO CONSIDER IN LCA OF CARBON UTILIZATION SYSTEMS

System Boundary

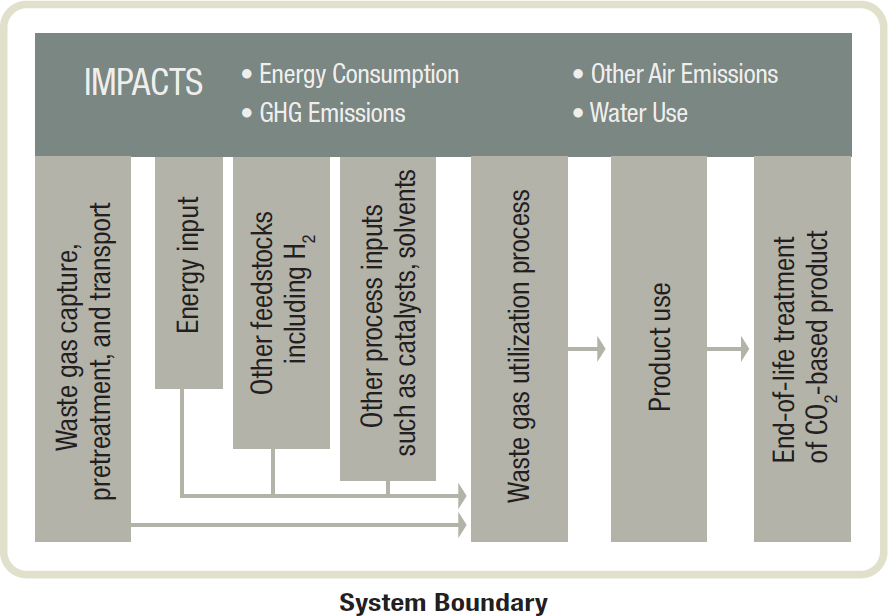

The system boundary of an LCA defines which elements of a product’s life cycle are under consideration in a given analysis. Figure 8-1 depicts a system boundary appropriate for considering a single carbon utilization technology. In carbon utilization LCA, the system boundary must include the waste gas capture and any pretreatment steps prior to purification in addition to CO2 compression and transport to the point of conversion, if conversion is not co-located with capture (CO2 Sciences, Inc., 2016; Cuella-Franca et al., 2014; von der Assen et al., 2013, 2016).

The LCA should also include the sourcing of additional conversion process inputs such as hydrogen and energy. The origins of both of these inputs are often key determinants of LCA results (Artz et al., 2017; von der Assen et al., 2014). Electricity, for example, can be produced from coal or natural gas power plants (which may in turn be the source of CO2) or renewable sources. Hydrogen and natural gas can be produced from renewable or nonrenewable resources with differing associated energy and emissions intensities. Other conversion process inputs such as catalysts, adsorbents, and solvents and their production should also be included in the system boundary. The use phase is also an important consideration. In the case of building materials, for example, the performance or amount of material required to achieve a given lifetime of a piece of infrastructure may differ between conventional materials and those made via a carbon utilization technology. The fate of a product at end of life is also a critical aspect of a waste gas utilization product’s life cycle within the system boundary, as described later in this chapter. If carbon utilization–based and conventional routes to a common product are to be compared, it is also important to establish an analogous system boundary for the conventional product that takes into account the same factors.

In considering the system boundary, it is also important to consider which energy and environmental impacts will be assessed in the analysis. While energy consumption and greenhouse gas emissions are logical impacts to include in carbon utilization LCA, other impacts including water consumption and air pollutant emissions should not be ignored. However, with the exception of water consumption in the case of algal biofuel (Tu et al., 2017), LCA generally remain unexamined for fuels, chemicals (Artz et al., 2017), and materials produced from waste gaseous carbon.

Functional Units

In a LCA, the functional unit is the basis on which the energy and environmental impacts of a product are compared. With the system boundary described above, if a chemical were the product under consideration, an appropriate functional unit could be a kilogram (kg) of that chemical, especially if an analyst were comparing, for example, methanol produced via a carbon utilization technology as compared to conventional technology. A kilogram of methanol will function equivalently whether produced from CO2 or via conventional routes. How-

ever, materials may be produced from carbon utilization technologies that differ in material structure but offer similar functions as conventional materials and would therefore be considered functional rather than direct replacements. For example, in the case of a carbon utilization–derived building material, a functional unit could be a tensile strength or the ability to bear a given amount of weight over a certain amount of time, and some products derived from carbon utilization processes may be able to achieve those functional properties with less product mass than a conventional material.

A comparison between conventional and carbon utilization pathways is not necessarily confined to a single functional unit. For example, a carbon utilization system consisting of carbon dioxide captured from a power plant and a carbon utilization process can be viewed as having two products: the electricity generated by the power plant and the carbon utilization product. The system would include coal or natural gas production and conversion to electricity with associated carbon capture and conversion technology. The system boundary would encompass the entire power plant and carbon utilization through the end of the product’s life cycle to consider how, on net, CO2 emissions and other factors vary based on which carbon utilization technology is associated with a power plant. For example, there may be synergies between the electricity generation process and the carbon utilization process if some of the heat normally wasted by a power plant is used to operate the utilization technology.

A key methodological issue in LCA of carbon waste gas utilization systems is the treatment of the energy and emissions intensity of the waste gaseous carbon stream itself. In a case in which CO2 emitted by a power plant is not used to produce a fuel, chemical, or material, the (unpurified for conversion) CO2 emissions are assigned to the power plant. When the CO2 stream is an input into a waste gas conversion process, the CO2 stream’s energy and emissions intensity varies depending upon the analysis approach. For example, the CO2 stream could still, as above, be assigned to the power plant. Alternatively, it could be burdened only with emissions associated with CO2 capture and pretreatment, or finally be burdened with emissions associated with sourcing the power plant fuel (e.g., coal mining). Von der Assen et al. (2017) provide an overview of the relative burden of preparing CO2 from European chemical plants, natural gas processing plants, paper mills, power plants, and iron and steel plants. Similarly, Supekar and Skerlos (2014) provide estimates of the energy and environmental impacts of recovering CO2 from ammonia and ethanol plants, hydrogen plants, and natural gas wells with a market-based allocation approach. Strategies taken for handling the energy and emissions intensity of waste gas and other process inputs that would otherwise be wastes are under development. For example, the Renewable Fuel Standard (RFS) treats biogas used to produce compressed natural gas (CNG), liquefied natural gas (LNG), or electricity as carbon neutral (burden free). The burdens assigned to the biogas are those for upgrading it and processing or converting it to CNG, LNG, or electricity. The RFS adopts the same approach for organic carbon in municipal solid waste that could be converted to a fuel. As Lee et al. (2017) point out, though, this treatment may be oversimplistic because, in part, the

TABLE 8-1 Emission factors for electricity and hydrogen.

| Process Input | Emission Factor (GREET1_2017) |

|---|---|

| Gaseous hydrogen from different sources | |

| North American natural gas (NG) | 0.11 kg CO2e/MJ |

| Solar energy, nuclear energy | 0.02 kg CO2e/MJ |

| Electricity from different sources | |

| U.S. national average grid (34% coal, 32% natural gas, 20% nuclear, 4% residual oil, 10% other) | 0.15 kg CO2e/MJ |

| NG-fired power plant | 0.14 kg CO2e/MJ |

| Nuclear power plant | 0.0025 kg CO2e/MJ |

counterfactual scenario, or what would have happened to the waste if it were not converted toward further use as a fuel, chemical, or material, is not considered. Clearly, treatment of the waste gaseous carbon stream remains an area for examination. In any case, while the approach taken is subjective, consistency and transparency are essential if LCA results for carbon utilization processes are to be compared.

In addition to transparency in analysis assumptions, it is critical to use common—or at a minimum transparently documented—emission factors for key carbon utilization process inputs and inputs to the conventional fuels and products that the carbon utilization process is compared to (Artz et al., 2017). Otherwise, comparisons of LCA results are not meaningful. Table 8-1 contains emissions factors (GREET1_20171) for the United States for the production of electricity (national average grid) and hydrogen from several sources, which can enable consistent inputs into LCA of carbon utilization technologies.

Co-Products in LCA

In some cases, facilities converting waste gas emissions into products may have more than one output. As a simple example, a power plant with carbon utilization technology would produce both power and, potentially, a chemical or fuel. If the system boundary included the production of both power and carbon utilization–derived product(s), a technique to divide energy and emissions burdens among these products would be necessary.

Several different approaches to co-product handling are possible. Allocation approaches divide energy and emissions burdens among co-products based on their mass, energy, or market value shares. Von der Assen et al. (2013) considered a waste gaseous carbon utilization system that requires co-product allocation (Box 8-2, Figure 8-2-1). In this case, a power

___________________

plant generates electricity co-producing a carbon utilization product, methanol. Here, the burdens of the system might be assigned between the electricity and methanol based on their market values. This approach is often considered relevant in systems in which one product drives the economic viability of the system producing the co-products. This can be the case for mining of platinum (Benavides et al., 2015), for example. Platinum is a high-value metal and recovering it is one of the main reasons why platinum mines operate, although the mass share of platinum is very small (~3×10-4 wt%) among all metals produced at a platinum mine. A disadvantage associated with market allocation is that the market value of chemicals, fuels, and other products can fluctuate widely over time, which would cause LCA results to shift accordingly. Another option is to allocate system burdens based on the mass shares of the coproducts. Mass allocation may be relevant when a utilization technology produces more than one chemical product and the functional unit is on a mass basis. In the system considered in Figure 8-2-1, however, mass-based allocation cannot be used because electricity is massless. Finally, energy allocation is most applicable when all co-products are used for their energy content. For example, an analysis of the recovery of methane in biogas to displace natural gas use would likely use energy content to allocate burdens. Potentially, products emerging from a biorefinery using algae as a feedstock could be handled with energy allocation if they were mainly energy carriers, including a hydrocarbon fuel and potentially methane from anaerobic digestion of spent algae. However, not all energy content is functionally equivalent. Energy in the form of electricity is not functionally equivalent to energy produced by the combustion of a methanol fuel.

In contrast to allocation techniques, which do not expand the system boundary, displacement or system expansion approaches do just that and take into account the displacement of conventional products. One common example of this approach is when corn-derived ethanol life-cycle assessments consider the displacement of conventional animal feed by biorefinery-produced distillers grains solubles (Canter et al., 2016). In this example, the corn ethanol is credited with avoided production of animal feed. It is important to note, however, that displacement credits are generally viable when applied to co-products that have a low share of total product output to avoid distorting LCA results (Wang et al., 2011). For example, in soybean-based production of biodiesel, glycerol is a co-product produced in the soybean crushing process: 82 percent of the mass output of that step is soy meal, and 18 percent is soy oil that is fed to the process stages that produce biodiesel. If the soy meal is treated as displacing animal feed and co-produced glycerol is treated as displacing petroleum-derived glycerol, life-cycle GHG emissions for soy biodiesel are approximately a third of the GHG emissions calculated with the market allocation method. Recently, Cai et al. (2018) examined co-product allocation methods for biorefineries co-producing fuels and chemicals. This is relevant to waste gaseous carbon systems that co-produce a fuel (electricity or liquid fuel) and a chemical. They concluded that treating the co-produced chemicals as displacing conventional products is viable even if the mass share of the co-products is large. They note that if the market is not

saturated with the co-produced chemical, displacement could be considered a viable approach. The authors also considered the process purpose co-product method, which examines the conversion process at an individual unit operation level and assigns burdens to products that “use” any given steps according to their mass, energy, or market value shares. This method requires unit operation-level material and energy flows from a facility or a process model and permits an in-depth analysis of which process burdens are attributable to which product. It is also possible to adopt a hybrid allocation approach, combining co-product treatments such as energy allocation and displacement, for example. Most critically, analysts should transparently report the co-product handling method they used and the rationale for doing so. If viable, investigating the sensitivity of results to co-product handling method should be reported.

Attributional and Consequential LCA

The techniques discussed in previous sections of this chapter would be adopted in attributional LCA, in which the supply chain of a product or process is followed linearly as a series of steps over which inputs and outputs are accumulated and assigned to the product of interest. As carbon utilization technologies achieve widespread market penetration, they will impact the structure of product markets. LCA modeling of the consequences of structural disruption through the economy, widely impacting material and energy consumption, is referred to as consequential LCA. This approach, most applicable when a disruptive as compared to an evolutionary change is expected, is adopted to capture indirect effects that would not be observed in a purely attributional approach. For example, CO2 is used today as an input to carbonated beverage production, and the advancement of CO2 capture and purification technology could influence the existing CO2 market and shift how CO2 is used. A detailed description of consequential LCA can be found elsewhere (Earles and Halog, 2011; Zamagni et al., 2012). To date, consequential LCA has been sparingly applied to waste carbon utilization and several outstanding research needs are apparent. First, many of the partial and general equilibrium models used in consequential LCA lack the detail necessary to track the influence of waste carbon–derived products, fuels, and materials on existing supply chains and markets. Development of more detailed models to represent these sectors is therefore a research need. Additionally, data sets used in consequential LCA may use outdated data which should be updated with recent chemical market information including production volumes and market prices. Furthermore, the treatment of uncertainty in consequential LCA needs to be further developed such that it is possible to better interpret consequential LCA results and discern the most significant drivers of environmental effects of disruptive use of waste carbon–derived fuels, chemicals, and products. Finally, there is a need to apply consequential LCA to waste carbon–derived fuels, materials, and chemicals that could be produced at volumes that are disruptive to current markets. It should be noted that, regardless of whether an attributional or consequential LCA approach is adopted, uncertainty and variability are important to

quantify to the extent possible (Igos, 2018; Lloyd and Ries, 2007). Uncertainty characterization may be difficult, however, in LCAs of waste carbon utilization given the emerging nature of the technology and limited data regarding conversion processes.

Temporal Issues

Carbon utilization product life cycles can extend over periods of months to decades and understanding the temporal distribution of emissions is important in comparing carbon utilization technologies. Some utilization technologies may delay CO2 and/or CH4 emissions for only a short period of time, while others may sequester carbon in products for decades or longer. In analyses that consider temporal factors, one key decision is the time horizon, or duration of study, that should be adopted.

As an example, if power plant CO2 emissions are captured, treated, and converted to a polymer that is used in a durable plastic product, the pulse of CO2 emissions from the power plant that would have occurred in year zero are reduced to some extent (taking into account emissions associated with the carbon utilization process itself) and the avoided emissions may be embedded in that durable product for decades, resulting in some degree of sequestration. If the durable plastic, however, were incinerated (rather than landfilled) after a useful life of just a few years, effective sequestration would be shorter.2 Moreover, if the waste gas were converted to a chemical that would be used for several years in a process with some percent lost to process inefficiencies and/or combustion of process waste streams, effective sequestration would again be much shorter. Finally, if the waste gas were converted to a liquid fuel, any sequestration would be very short lived because the fuel would likely be combusted in a vehicle or at a power plant shortly after production. In other analyses with temporal aspects, for example, LCA of biofuels, time horizons including 30 years (for example, in the U.S. Environmental Protection Agency’s Renewable Fuel Standard) and 100 years (Daystar et al., 2016; Peters et al., 2011) have been adopted. Both Daystar et al. (2016) and Peters et al. (2011) offer insights into frameworks for incorporating temporal effects into LCA.

In all cases, it is important to consider what conventional fuels, chemicals, and products would be displaced as a result of the carbon utilization process. In the liquid fuels example, if the same energy content of fuel production from crude oil were avoided, less carbon from fuel combustion would be emitted on net with the utilization process serving essentially to accelerate the carbon cycle, taking CO2 from a waste stream that was atmosphere bound, converting it to a fuel, and avoiding emissions of “fresh” CO2 contained in fossil resources recently extracted.

___________________

2 Another possible end-of-life scenario for a plastic product or, potentially building materials, is recycling. If this is the approach the analysis adopts, concepts such as open- versus closed-loop recycling may need to be introduced. See https://link.springer.com/content/pdf/10.1007%2FBF02978810.pdf (accessed October 10, 2018).

Counterfactual Scenarios

In LCA, it is possible to consider counterfactual scenarios that account for what would happen if a new technology comes into use or if a shift occurs in how technology is used. Then, emissions from the new technology case can be compared to the counterfactual, or business-as-usual, case to assess which scenario has lower emissions or impacts overall. Introducing a counterfactual scenario can be difficult because the evolution of technology and technology usage over time in both the new technology and the business-as-usual case must be projected, often with a significant uncertainty. For example, in an analysis of wood chip–derived power in the United Kingdom (Stephensen, 2014), counterfactual analyses considered what might happen to the land used to produce this biopower feedstock if the wood were not converted to chips for biopower. A number of counterfactual scenarios were included, ranging from allowing the land to become an old-growth forest to converting it to agricultural use. The choice of counterfactual scenario, which relied on essentially unknown future land management practices, greatly influenced results comparing biopower with conventional coal- or natural gas–derived power.

In the case of carbon utilization, a business-as-usual case would account for the fate of the waste gas and how a carbon utilization–derived product would conventionally be produced over time in the absence of carbon utilization technology. Furthermore, if it is assumed that renewable electricity or hydrogen is used in a carbon utilization process, it may be an element of a counterfactual scenario to evaluate other uses for these low–greenhouse gas process inputs (e.g., to fuel electric or fuel cell vehicles, or use in other processes).

The choice to incorporate a counterfactual scenario depends upon the intent of the analysis. If a carbon utilization LCA is intended to compare two different carbon utilization technologies to produce the same product, a counterfactual scenario may not be useful. If, however, the intent of the analysis is to consider using waste landfill gas to produce energy (Lee et al., 2017) or chemicals, it may be useful to consider over time how a business-as-usual scenario with ongoing landfill emissions compares to a new technology scenario with methane conversion to energy, or a product that may eventually be landfilled or incinerated.

RESEARCH AGENDA ITEMS

Compared to LCA of conventional fuels and chemicals, the field of carbon utilization LCA is developing and has specific challenges and considerations as described in the previous sections and Table 8-2. As the field evolves and LCAs of various waste gaseous carbon utilization technologies grow in number and complexity, it will be critical for analysts to consider and document their approach to transparently reporting their data, data sources, and assumptions.

TABLE 8-2 Summary of key LCA considerations for different types of CO2 utilization products.

| Building Materials | Polymers | Chemicals | Liquid Fuels | |

|---|---|---|---|---|

| System Boundary |

|

|||

| Functional Units |

|

|

|

|

| Co-products |

|

|

|

|

| Building Materials | Polymers | Chemicals | Liquid Fuels | |

|---|---|---|---|---|

| Temporal |

|

|

|

|

| Attributional & Consequential LCA |

|

|||

| Potential Counterfactual Scenarios | Building materials such as wood, steel, or aggregate that do not incorporate waste CO2 | Ongoing widespread use of fossil fuel–derived polymers or some level of penetration of biomass-derived polymers | Alternative emerging technologies (e.g., new feedstock from biomass, new catalysts, new separation technologies) | Electricity or fossil- or biomass-derived liquid fuels or a combination thereof |

In addition to the issues identified earlier in this chapter, there remain outstanding needs and issues associated with carbon utilization LCA for analysts to investigate and resolve:

- What is the best way to evaluate carbon utilization pathways that are emerging in the absence of large-scale production data and how frequently should the analysis be updated as the technology develops?

- What is a defensible technique to capture uncertainty in carbon utilization LCA results given the emerging nature of the technology?

- What are standard baselines that can be employed as business-as-usual cases for counterfactual analyses?

- Which system boundary assumptions and decisions are defensible for analyses that target different questions?

- When is it appropriate to introduce consequential LCA and what methods represent best practice?

Overall, the committee identified priority research needs to address the issues raised in this chapter. Priority areas include the following:

Life-cycle assessment benchmarking

Research is needed to develop benchmark life-cycle assessments of waste gas generation, waste gas cleanup, waste gas transport, electricity inputs, hydrogen inputs, and other enabling technologies to facilitate consistent and transparent assessments of the net greenhouse gas emissions of carbon utilization technologies. These benchmark assessments would include multiple environmental attributes of carbon utilization life cycles, such as greenhouse gas emissions, water use, air emissions, and materials use. This could lead to more consistent assessments of technologies.

Life-cycle assessment of emerging waste carbon utilization technologies

Research is needed to learn from transparent life-cycle assessments (LCA) of emerging technologies, taking into account a system boundary that includes waste gas capture and cleanup, the conversion process, use phase, and end-of-life considerations. Although LCA results for emerging technologies will undoubtedly evolve, LCA at this early stage will help guide research toward activities that will heighten energy and environmental benefits.

Assessment of disruptive change

Research is needed to develop life-cycle assessment tools that move beyond assessing marginal changes in existing, static systems and address disruptive changes resulting from large-scale carbon utilization. This will provide tools for assessing disruptive changes necessary for performing consequential LCAs of carbon capture and utilization systems.

REFERENCES

Artz, J., T. Müller, K. Thenert, J. Kleinekorte, R. Meys, A. Sternberg, A. Bardow, and W. Leitner. 2017. Sustainable conversion of carbon dioxide: An integrated review of catalysis and life cycle assessment. Chemical Reviews 118(2):434-504. doi: 10.1021/acs.chemrev.7b00435.

Benavides, P. T., Q. Dai, J. Sullivan, J. C. Kelly, and J. B. Dunn. 2015. Material and Energy Flows Associated with Select Metals in GREET 2: Molybdenum, Platinum, Zinc, Nickel, Silicon. Argonne National Laboratory ANL/ESD-15/11. Available at https://greet.es.anl.gov/publication-mo-pt-zn-ni-si (accessed October 10, 2018).

Bruhn, T., H. Naims, and B. Olfe-Kräutlein. 2016. Separating the debate on CO2 utilisation from carbon capture and storage. Environmental Science & Policy 60:38-43. doi: 10.1016/j.envsci.2016.03.001.

Cai, H., J. Markham, S. Jones, P. T. Benavides, J. B. Dunn, M. Biddy, L. Tao, P. Lamers, and S. Phillips. 2018. Techno-economic analysis and life-cycle analysis of two light-duty bioblendstocks: Isobutanol and aromatic-rich hydrocarbons. ACS Sustainable Chemistry & Engineering 6:8790-8800.

Canter, C. E., J. B. Dunn, J. Han, Z. Wang, and M. Wang. 2016. Policy implications of allocation methods in the life cycle analysis of integrated corn and corn stover ethanol production. BioEnergy Research 9:77. doi: 10.1007/s12155-015-9664-4.

CO2 Sciences, Inc. 2016. Global Roadmap for Implementing CO2 Utilization. Available at https://assets.ctfassets.net/xg0gv1arhdr3/27vQZEvrxaQiQEAsGyoSQu/44ee0b72ceb9231ec53ed180cb759614/CO2U_ICEF_Roadmap_FINAL_2016_12_07.pdf (accessed October 10, 2018).

Cuellar-Franca, R. M., and A. Azapagic. 2014. Carbon capture, storage and utilisation technologies: A critical analysis and comparison of their life cycle environmental impacts. Journal of CO2 Utilization 9:82-102. doi: 10.1016/j.jcou.2014.12.001.

Daystar, J., R. Venditti, and S. Kelley. 2016. Dynamic greenhouse gas accounting for cellulosic biofuels: Implications of time based methodology decisions. International Journal of Life Cycle Assessment 22(5):812-826. doi: 10.1007/s11367-016-1184-8.

Earles, J. M., and A. Halog. 2011. Consequential life cycle assessment: A review. International Journal of Life Cycle Assessment 16:445. doi: 10.1007/s11367-011-0275-9.

Giannoulakis, S., K. Volkart, and C. Bauer. 2014. Life cycle and cost assessment of mineral carbonation for carbon capture and storage in European power generation. International Journal of Greenhouse Gas Control 21:140-157.

Igos, E., E. Benetto, R. Meyer, P. Baustert, and B. Othoniel. 2018. How to treat uncertainties in life cycle assessment studies? International Journal of Life Cycle Assessment. doi: 10.1007/s11367-018-1477-1.

ISO (International Standards Organization). 2006. Environmental Management: Life Cycle Assessment: Principles and Framework. Vol. 14040. London: British Standards Institution. Available at https://www.iso.org/standard/37456.html (accessed October 10, 2018).

Lee, U., J. Han, and M. Wang. 2017. Evaluation of landfill gas emissions from municipal solid waste landfills for the life-cycle analysis of waste-to-energy pathways. Journal of Cleaner Production 166:335-342. doi: 10.1016/j.jclepro.2017.08.016.

Lloyd, S. M., and R. Ries. 2007. Characterizing, propagating, and analyzing uncertainty in life‐cycle assessment: A survey of quantitative approaches. Journal of Industrial Ecology 11:161-179. doi: 10.1162/jiec.2007.1136.

NRC (National Research Council). 2012. Sustainable Development of Algal Biofuels in the United States. Washington, DC: The National Academies Press. https://doi.org/10.17226.13437.

Peters, G. P., B. Aamaas, M. Lund, C. Solli, and J. S. Fuglestvedt. 2011. Alternative “global warming” metrics in life cycle assessment: A case study with existing transportation data. Environmental Science & Technology 45:8633-8641. doi: 10.1021/es200627s.

Rahman, F. A., Md. M. A. Aziz, R. Saidur, W. Bakar, M. R. Hainin, R. Putrajaya, and N. Hassan. 2017. Pollution to solution: Capture and sequestration of carbon dioxide (CO2) and its utilization as a renewable energy source for a sustainable future. Renewable and Sustainable Energy Reviews 71:112-126. doi: 10.1016/j. rser.2017.01.011.

Stephenson, A. L. 2014. Scenarios for Assessing the Greenhouse Gas Impacts and Energy Input Requirements of Using North American Woody Biomass for Electricity Generation in the UK. U.K. Department of Energy and Climate Change. Available at https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/349024/BEAC_Report_290814.pdf (accessed October 10, 2018).

Supekar, S. D., and S. J. Skerlos. 2014. Market-driven emissions from recovery of carbon dioxide gas. Environmental Science & Technology 48(24):14615-14623.

Tu, Q., M. Eckelman, and J. Zimmerman. 2017. Meta-analysis and harmonization of life cycle assessment studies for algae biofuels. Environmental Science & Technology 51(17):9419-9432.

von der Assen, N., J. Jung, and A. Bardow. 2013. Life-cycle assessment of carbon dioxide capture and utilization: Avoiding the pitfalls. Energy & Environmental Science 6:2721-2734. doi: 10.1039/C3EE41151F.

von der Assen, N., J. Jung, and A. Bardow. 2014. Life cycle assessment of CO2 capture and utilization: A tutorial review. Chemical Society Reviews 43(23):7982-7994. doi: 10.1039/c3cs60373c.

von der Assen, N., L. J. Müller, A. Steingrube, P. Voll, and A. Bardow. 2016. Selecting CO2 sources for CO2 utilization by environmental-merit-order curves. Environmental Science & Technology 50(3):1093-1101.

Wang, M., H. Huo, and S. Arora. 2011. Methods of dealing with coproducts of biofuels in life-cycle analysis and consequent results in the U.S. context. Energy Policy 39. doi: 10.1016/j.enpol.2010.03.052.

Zamagni, A., J. Guinée, R. Heijungs, et al. 2012. Lights and shadows in consequential LCA. International Journal of Life Cycle Assessment 17:904. doi: 10.1007/s11367-012-0423-x.

Zhou, W., J. Wang, P. Chen, C. Ji, Q. Kang, B. Lu, K. Li, J. Liu, and R. Ruan. 2017. Bio-mitigation of carbon dioxide using microalgal systems: Advances and perspectives. Renewable and Sustainable Energy Reviews 76:1163-1175. doi: 10.1016/j.rser.2017.03.065.