9

Assessing Commercial Viability of Carbon Utilization Technologies

INTRODUCTION

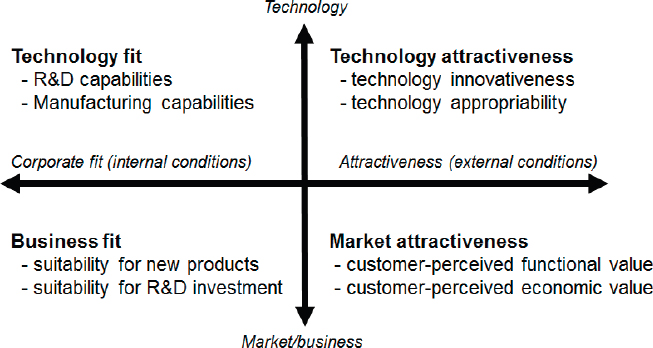

A number of technologies for transforming gaseous carbon wastes into useful products are being explored, and although some of the technologies have reached the commercial stage (Zimmerman and Kant, 2015), the majority are still in various stages of research and development. Assessing the commercial viability of carbon utilization technologies enables the comparison of technologies and the identification of areas where research and development might be most impactful. The evaluation of the commercialization of potential carbon utilization products or processes requires consideration of technology and economic viability, which are traditionally determined by conducting technoeconomic analysis (TEA), as well as other factors which may or may not be part of a TEA, as depicted in Figure 9-1, including strategic fit with a company’s long-term goals, global standards, and intellectual property (Lee et al., 2017).

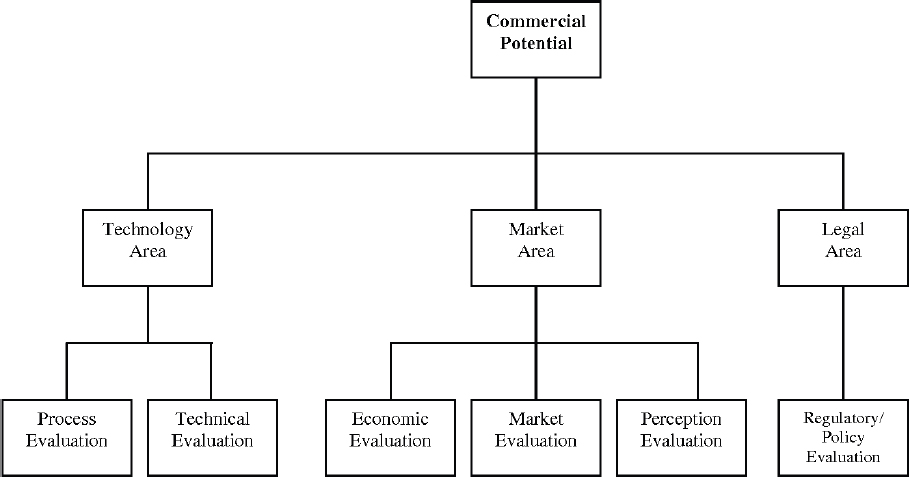

A variety of strategies have been developed to systematically assess all types of commercialization viability. Several years ago, researchers at the University of Cincinnati proposed a method for systematically evaluating commercialization potential, which they called the Strategic Technology Evaluation Program (see Figure 9-2), or STEP (Bandarian, 2007). While this is not the only framework for technology evaluation, the committee used the STEP framework in its evaluation of carbon utilization. The application of the STEP framework to assessing the commercial potential of carbon utilization begins with the technology area, shown on the far left of Figure 9-2.

ASSESSMENT OF THE TECHNOLOGY AREA

Technoeconomic Analysis

Technoeconomic analysis is a tool that is widely used to evaluate commercial viability of any new technology. TEAs are applied at multiple stages of the research and development process, with the information required, and the assessment methodology and rigor utilized become more detailed as the technology advances. The starting point for a TEA is to lay out a conceptual process design. Initial inputs may come from literature references, thermodynamic and process modeling, or scoping experiments. As technology development advances (see Box 9-1), engineering optimization will identify the major technical hurdles as well as the theoretical process yields based on thermodynamics. At this point, if the economics are still favorable, more detailed process flow diagrams will be developed so that engineering simulations can begin. The conceptual process description will outline all of the unit operations (e.g., pretreatment, reactor, separation, purification, recycle, etc.). Once the process flow is better defined, material and energy balance models are developed to assess the technology.

For the various technology readiness levels described in Box 9-1, TEAs can be performed and used to set technology improvement targets. At the fundamental research scale, relatively simple approaches involving values of reactants and products can be employed. These models can be the basis of cost estimations that can set targets for technology improvements. For example, a TEA for converting CO2 captured from a coal-based power plant to methanol concluded the process could only be economically attractive if the market price of methanol doubled, the cost of H2 was reduced by 250 percent, or the CO2 feedstock was highly valued (222 €/ton in 2015) (Pérez-Fortes et al., 2016). For pilot and higher levels of development, more detailed information regarding materials of construction, process control criteria, as well as expected equipment lifetimes will feed into further economic analysis and target setting.

Generally, for comparison of multiple technologies to solve a unique problem like CO2 management, a common costing framework is developed for use at various maturity levels. An example of a costing framework is described by Rubin et al. (2013) for CO2 capture technologies, which have been under development since 1995. Utilization of gaseous carbon waste streams is a relatively new technical area and most of the technologies are at a very early stage of development (Technology Readiness Levels (TRLs) 1-3) and thus not many engineering or process development insights have been developed. Therefore, development of a common costing framework for carbon utilization technologies will happen as technology maturity advances.

In general, the economics of renewable H2 make many of the CO2 utilization strategies uncompetitive with traditional technologies even though CO2 is a waste product. Currently only fossil-derived H2 can meet the Department of Energy’s target of supplying H2 at less than $2/kg expressed in 2007 dollars, with electrolysis-based methods being nearly threefold

higher in cost (HPTT Roadmap, 2017). Because the economics can be challenging, initiatives to subsidize demonstration plants such as the EU Innovation fund are being proposed to accelerate technology development.1 In the United States, the 45Q Tax Credits (as explained in detail later in this chapter) to fossil energy users to sequester or reuse their CO2 emissions is also intended to encourage industrial investments in these technologies (Silverstein, 2018).

Technoeconomic Factors Relevant to Carbon Utilization

The TEA methodology described above is generally applicable; however, in assessing technologies for utilization of gaseous carbon waste streams, particular attention has to be paid to the following technical and economic factors:

- Cost, quantity, and purity of the gaseous carbon waste stream available;

- Cost and carbon footprint of other reactants (as described in detail in Chapter 8 on LCA), in particular if H2 for reacting the waste gas to make products is needed;

- Cost of utilities, in particular electricity and steam (and their carbon footprint per LCA guidelines);

- Quality of the product made and its marketability at desired price;

- Boundary conditions or battery limits for process technology: inside battery limits versus outside battery limits;

- Availability of capital with appropriate risk tolerance; and

- Policy drivers (e.g., tax credits, subsidies, green premium, and preferred markets).

Insights provided by TEAs for early stage carbon utilization technologies are illustrated by the following examples.

Example 1: CO2 Capture from Power Plants

A first example of a TEA considers capture of CO2 from coal- and natural gas–fired power plants to develop a research and development roadmap for CO2 capture technologies. A comprehensive study done by the National Energy Technology Laboratory (NETL) in 2015 has been used as a benchmark to track the progress of Department of Energy Fossil Energy Research and Development (R&D) in the CO2 capture domain (NETL, 2015). This study was performed using consistent and transparent methodology (all the assumptions were carefully documented), and it established performance and cost data for fossil energy power systems, including pulverized coal (PC) plants fueled with bituminous coal and natural gas combined cycle (NGCC) plants, all with and without carbon capture and storage. The cost

___________________

1 See https://ec.europa.eu/clima/news/public-consultation-establishment-eu-innovation-fund_en (accessed October 10, 2018).

and performance data used in this study were compiled from published reports, information obtained from vendor quotes and users of the technology, and data from designing and building electric utility projects. The study found that adding CO2 capture was the largest component of the cost of electricity for PC (75 percent) and NGCC (52 percent) and adds between $56/ton of CO2 captured for PC and $71/ton of CO2 captured for NGCC. Sale of the captured CO2 for utilization applications could provide a revenue stream to improve the economics of carbon capture; however, if the full cost of carbon dioxide capture is applied as a CO2 feedstock price to utilization technologies, the feedstock price will be of order $60 per ton of carbon dioxide with current technologies. However, as the carbon capture technologies mature, the carbon capture cost from combustion facilities is expected to come down.

Example 2: Production of Methanol and Fuels from CO2

As discussed in Chapter 4, Carbon Recycling International in Iceland produces approximately 4,000 tons of methanol from CO2 each year using the renewable hydro and geothermal energy to produce H2 via electrolysis and uses CO2 captured from a geothermal power plant located next to the CO2-to-methanol facility. Simple calculations based on the reaction stoichiometry of CO2 + 3 H2 = CH3OH + H2O indicate that if the H2 price from renewable energy is $4/kg, and CO2 (of desired purity and concentration needed for this reaction) is free similar to the Iceland case, the contribution of H2 itself to the methanol cost will be about $750/ton (compared to a conventional methanol cost of approximately $423/ton),2 assuming no capital and operating costs. If the H2 price comes down to about $2/kg from renewable electricity, this cost will reduce to $375/ton of methanol. Under this scenario, methanol produced from waste CO2 may become cost competitive. This high-level TEA provides useful insights on where to focus research and development efforts.

Example 3: Biogas Conversion

As discussed in Chapter 7, effective conversion of biogas into value-added products requires biogas upgrading to remove CO2 and other contaminants (H2S, siloxanes, HCl, H2O, etc.). Some biogas can contain as much as 50 percent CO2 as discussed in Chapter 7. Biogas upgrading processes are quite capital intensive and, as a result, methane produced from biogas cannot generally compete with fossil methane. However, biogas plants are being built worldwide with government incentives to produce a number of products. Besides electric power and heat, other products include bio-CNG (compressed natural gas), bio-LNG (liquefied natural gas), bio-H2, and bio-CH4 to produce chemicals and fuels. The Environmental Protection Agency classifies biomethane as renewable natural gas (RNG). The RNG qualifies for the credits promulgated for Renewable Fuel Standards through Renewable Index Numbers

___________________

2 See https://www.methanol.org/news/methanol-price-trend-overview-forecast-2018/.

(RINs). For example, $1/gallon RIN credit (based on ethanol price) will add about $7 per million British thermal units (MMBtu) premium to biomethane. This premium is encouraging private-sector investment in biogas plants.

Sensitivity Analysis

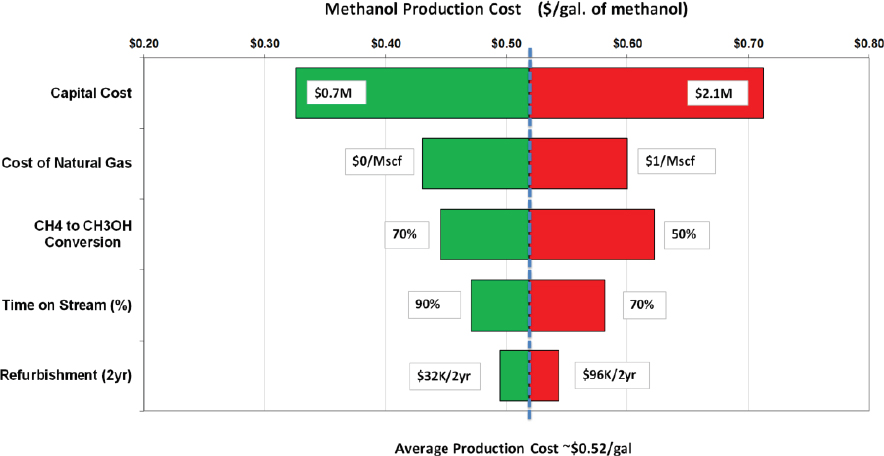

Sensitivity analyses of TEAs for the evaluation of early stage carbon utilization technologies can often reveal key research needs. The results of such sensitivity analyses are often shown in “tornado charts.” The committee was not able to identify any public domain comprehensive TEA sensitivity analysis for commercial technologies; however, a recent technology development example with flared natural gas conversion to methanol can be used as an illustration for future CO2 utilization processes. An example of a tornado chart for the flared gas conversion is shown in Figure 9-3, which shows a sensitivity analysis of a novel technology being developed by RTI International and Massachusetts Institute of Technology to convert flared gas into methanol using an engine reformer (Browne, 2016). In this process, methane is partially oxidized with air into syngas in a commercial internal combustion engine operating in a fuel-rich mode. The resulting syngas is cleaned and conditioned using traditional methods to produce a syngas with a H2-to-CO ratio of 2 to feed into a catalytic reactor to produce methanol. From Figure 9-3, the capital cost of the system emerges as the most

important factor. In the figure, a baseline capital cost estimate of $1.43 million was used, while a 50 percent change to the capital cost was used as upper and lower bound. The figure shows that a 50 percent reduction in capital cost reduces the methanol production cost by approximately $0.20/gallon. This suggests that research aimed at reducing capital costs, especially of the compressor or the need for compression, is a high-priority target. This is an example of using sensitivity analyses of TEA to identify priority research areas when developing new technologies for utilization of gaseous carbon wastes. Sensitivity analyses are employed not only to identify research targets, but also to understand the impact that key assumptions have on TEAs. The sensitivity analysis also provides a good window on cost and performance to account for variability and uncertainty associated with early stage development of the carbon reuse technologies. For example, project and process contingencies can be incorporated in the sensitivity analysis. The value of these contingencies will depend on the maturity of the technology (AACE, 1991).

The sensitivity analysis can be extended to estimate costs of a first-of-a-kind (FOAK) plant and extrapolate it to the Nth-of-a-kind (NOAK) plant. FOAK cost estimations are generally made for a first commercial plant based on a new technology built with the maximum amount of standard equipment and materials, and labor and productivity assumptions based on recent design and operational experience and lessons learned with similar plants. FOAK plants are typically designed conservatively with redundancies to minimize unanticipated operational risks. In most cases, FOAK plant cost represents the highest capital cost per unit of product volume. With building of multiple plants, a technology learning curve is used to develop the cost estimates of a NOAK plant (NETL, 2013). Depending upon the maturity and market penetration of the technology, the cost of a NOAK plant can be 10-50 percent lower than a FOAK plant cost. Other contributing factors are scale, modularity, materials cost, inflation, geographic location, and regulatory compliance. For the CO2 utilization technologies, it is expected that NOAK plant costs could be 10-25 percent lower than a FOAK plant based on a NETL study (NETL, 2013).

ASSESSMENT OF THE MARKET AREA

Moving past the technology assessment, the next step in commercialization assessments is to assess the market area. A key feature of the market area leg of STEP is the definition of the market a particular product or technology will be able to address (Jain et al., 2003).

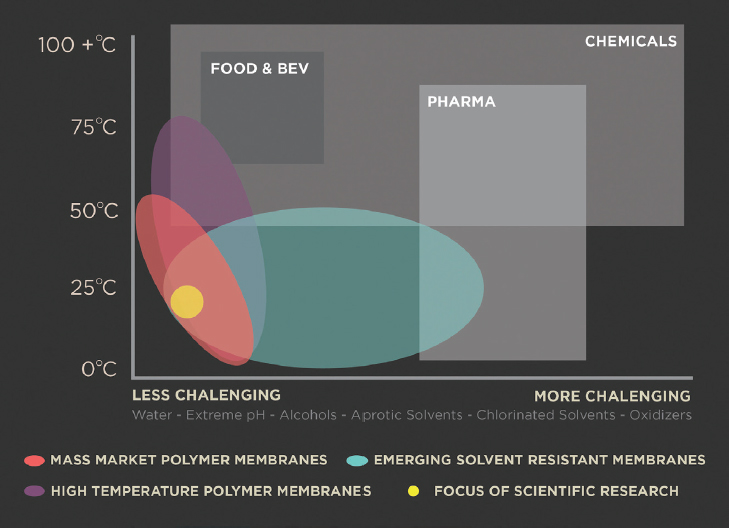

With a new technology, there needs to be a full understanding of the market opportunities. Interviews with potential customers are often utilized to better understand the market needs and to determine whether the new technology offering will be unique. These interviews can be part of an iterative process as the technology continues to be better defined as it develops. A successful application of TEA combined with interviews was documented in a recent report on graphene oxide membrane development (Dave, 2017). After using TEA to

determine their graphene oxide membranes were not economical for reverse osmosis applications, researchers used industrial interviews to identify opportunities where there were unmet needs. As shown in Figure 9-4, three areas of unmet needs included mass-market polymer membranes, emerging solvent-resistant membranes, and high-temperature polymer membranes. The yellow dot in Figure 9-4 illustrates the current focus of the science community among the other unmet needs. The results of the TEA opened up entirely new scientific areas to explore (Dave, 2017).

Because carbon utilization technologies are largely early in their development, detailed customer interviews are not possible. However, initial feedback from customers has been favorable for CO2-based products, especially if the incorporation was longer lived and if the fossil resource savings were viewed as being meaningful. Interestingly, the amount of CO2 incorporation in the product was not a significant factor for consumer preference (van Heek et al., 2017).

___________________

1 Reprinted from Six Degrees of Separation: Connecting Research with Users and Cost Analysis, Joule 1, 410-415, Dave, S. H., B. D. Keller, K. Golmer, & J. C. Grossman, Nov. 15, 2017, with permission from Elsevier.

Factors to Consider for Market Evaluation

Differentiating Aspects to New Technologies

An assessment of the differentiation advantages of a new product can be difficult and often requires having detailed market understanding. For example, when products based on compostable biobased polylactic acid were first introduced into the market, they were not well received, either by consumers because of changes in the performance or by manufacturers because they required changes in downstream manufacturing. In addition, while the polymer had environmental advantages, it was also more expensive to manufacture, making market adoption difficult (Iles and Martin, 2013). In general, consumers are not willing to pay a premium for a “green” product. However, Braskem’s bioethanol-based polyethylene (PE) is an example where through new business models, they were able to define a 15-30 percent “green” premium over traditional PE via development of the “I am Green” product label based on the ASTM D6866-11 international standard for determining the biobased content via radiocarbon analysis. In this case, the offering is identical to more traditional feedstock-based PE, so there are no needed changes in downstream manufacturing, removing this hurdle from introducing the technology (Iles and Martin, 2013).3 Because preliminary consumer interviews do not suggest a preference for higher CO2 incorporation, it is unclear whether establishing a similar market preference will be possible in gaseous waste carbon–derived products (van Heek et al., 2017).

Potential Market Barriers for New Technologies

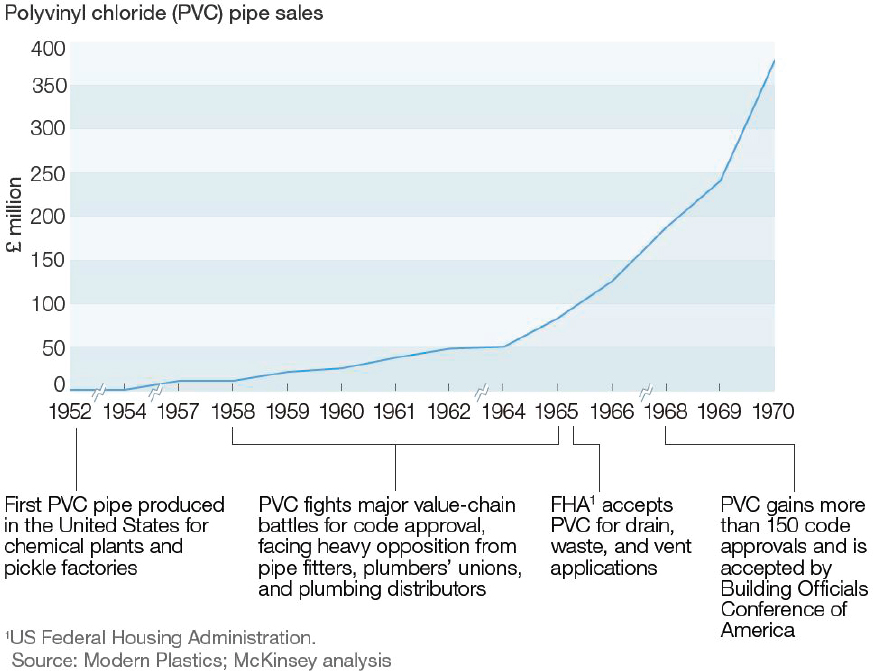

While the majority of market evaluation focuses on the end market for the technology, an equally important factor is to identify any potential barriers leading to the end market to understand if there will be changeover costs for introducing a new technology. An example illustrating some of these issues is in the introduction of polyvinyl chloride (PVC) into the North American marketplace. While it was first introduced in limited applications in 1952, it could not penetrate into the housing market until the mid to late 1960s, despite its advantages and demonstrated durability. The delay was in part due to necessary changes to building codes. As highlighted in Figure 9-5, market penetration of PVC increased rapidly after it was accepted into various building codes. However, a switch to PVC pipe would also result in lost revenue for plumbers and pipe distributors, and their concerns helped to slow the market expansion of PVC as is also depicted in Figure 9-5 (Boren et al., 2012; Musso, 2009). Assessment and management of displacement concerns will be a key step toward introducing new feedstock-based products into the market place.

___________________

Perception Evaluation

Perception evaluation is tied with the market evaluation, yet it can impact more than the addressable market. Perception evaluation is subjective and can be geographically and/or demographically centered. For example, the willingness of a consumer to purchase products made from waste materials or prepared using genetically modified organisms could differ dramatically depending upon the location of the market (Jain et al., 2003). Perception issues provide barriers to commercialization (Kant, 2017). Providing consumers with access to accurate information can be a barrier (Jones et al., 2017). For example, a recent study with “mystery shoppers” demonstrated car dealerships themselves were negatively affecting electric vehicle sales due in part to a lack of knowledge of the technology as well as a lack of willingness to promote the technology due to their perceptions about viability and profitability of

electric vehicles to their dealership (de Rubens et al., 2018). As many of the gaseous waste carbon–based products like chemicals are intermediates which will not be immediately marketed to the public, many of the current educational efforts are aimed at the business level and not at the final consumer. It is unclear how the resulting products made from these intermediates will ultimately be marketed (Jones et al., 2017). Overall, the adoption of products derived from gaseous carbon waste streams could similarly be challenging without an understanding of consumer perceptions. Engaging behavioral economists could be helpful in conducting perception evaluations to ensure the assessment is robust to minimize risk.

ASSESSMENT OF THE LEGAL AREA

The last branch of STEP (see Figure 9-2) is the legal branch. Like perception evaluation, policy and regulatory evaluation could be highly regionalized. In dealing with the gaseous carbon waste streams, this evaluation leg will be particularly important to fully assess the serviceable addressable market4 as well as the economics of the technology.

Policy Evaluation

The geographical concentration of CO2 utilization efforts has been found to mirror the availability of public funding, which was the main driver for the development of these technologies rather than a market pull (Kant, 2017; Zimmermann and Kant, 2017). If subsidies or other policies are in place that can improve the new technology’s competitiveness, it is also important to understand their longevity to determine the impact on investment returns. If these subsidies or policies are well defined, they can be incorporated in the TEA. An example is the recent legislation passed by Congress in March 2018 (Futures Act): beneficial reuse of CO2 to produce products such as fuels, chemicals, plastics, and construction materials such as cement, or to produce algae to make biofuels will qualify for a tax credit starting from $12.83 per ton of CO2 and linearly increasing to $35 per ton by 2026 and thereafter adjusted every year for inflation. The legislation requires a minimum of 25,000 tons of CO2 use and tax credits are valid up to 500,000 tons of CO2 per plant. Besides capturing and utilizing CO2 from coal- and natural gas–fired power plants, the tax credits under 45Q are valid for utilizing CO2 produced from ethanol, ammonia, hydrogen, natural gas sweetening, and other industrial sources.5

___________________

4 The total addressable market is the revenue opportunity for a product or service if 100 percent of the market share was achieved, whereas the serviceable addressable market is the portion to the total addressable market which can be serviced by a given product or service.

5 See https://www.forbes.com/sites/kensilverstein/2018/02/15/tax-credit-may-rev-up-carbon-capture-and-sequestration-technology/#4e0a53774a06.

Regulatory Evaluation

Regulatory issues could either improve the chances that a technology is adopted or prove problematic for developing carbon utilization technologies. For example, regulations that impact the price of gaseous carbon emissions would change the economics of carbon utilization technologies. Building codes or other regulations could influence the adoption of technologies such as CO2-enhanced concrete, requiring extensive testing and verification. Interviews with CO2 utilization ventures found that many of them were concerned about the regulatory context, citing that regulations are based on current technologies and may exclude new technologies (Kant, 2017). For areas like construction materials or consumer goods, these could be significant hurdles for new gaseous carbon waste–containing products. The complexity of this issue was discussed in Chapter 3, where construction standards and codes may vary across small geographical areas, for example, city-specific codes. In these cases, a significant amount of resources will be spent in application testing and verification rather than in development of the technology itself. Further complications for introducing new products arise when the products need to be tailored for individual market segments. Therefore, linking early stage technologies with companies familiar with the end consumers is very important (Maine and Seegopaul, 2016). Regulations are not harmonized so global introduction of new technologies could be problematic (Kant, 2017).

Intellectual Property

An evaluation of intellectual property (IP) associated with the technology is also an important part of the legal evaluation. There are two perspectives that can be used for IP evaluation: (1) freedom to operate and (2) strength of the IP. Freedom-to-operate analysis identifies blocking patents which need to be licensed to practice the technology and/or for any potential infringement issues. Lack of clarity on the IP is a barrier to investment in the development and commercialization of the technology. Having an IP strategy in place is also necessary for facilitating customer interactions (Kant, 2017). Good decisions around what to disclose and what to maintain as expertise and trade secrets can also be key to deterring competition as well as securing licensing for a new technology (Arora, 1997).

OVERALL COMMERCIALIZATION CONCLUSIONS

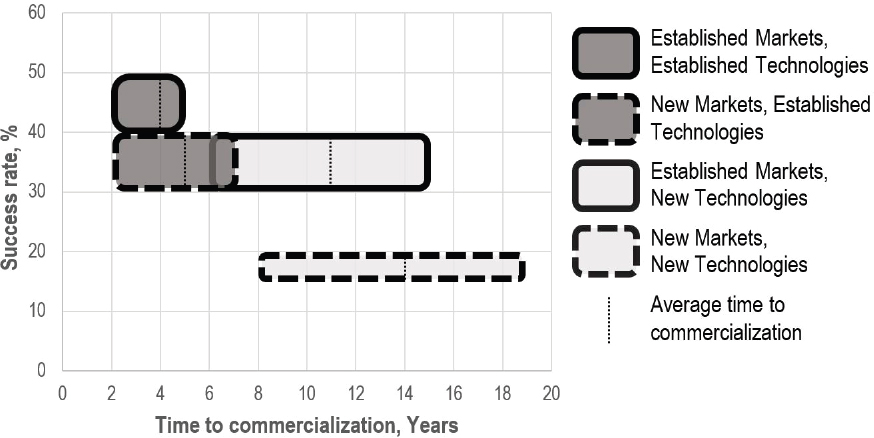

In the preceding sections, factors in three areas—technology, market, and legal—were described for evaluating commercial viability. However, even if all of these criteria are met, the resulting technology may still not be a commercial success. Through a series of interviews and analysis of successful innovations in the chemical industry, McKinsey outlined the challenges in the market introduction of technology (Miremadi et al., 2013). A high-level summary of their findings is presented graphically in Figure 9-6.

In this summary, commercialization time is defined as the length of time from the project launch to the point where the annual sales are equivalent to the R&D investment, and the success rate is defined as the percentage of projects with positive return on a net present value basis, using the cost of capital with no risk adjustment. The study identified the interaction between two factors, the “degree of market familiarity” and the “degree of technology familiarity,” to bin the time to commercialization and success rates. In the best-case scenario (high degree of market familiarity and high degree of technology familiarity), the commercialization time for established markets ranged from 2 to 5 years with a success rate ranging from 40 to 50 percent. For these products, the development costs were typically lower than for other types of products, and as a result, the margin, the gain associated with the new product as compared with the product it replaced, above any market cannibalization,6 is only 0-5 percent. In contrast (low degree of familiarity and low degree of technology familiarity), product introductions of a new technology into a new market are far more complex, with commercialization times ranging from 8 to 19 years and success rates of 15-20 percent. Because these are new technologies, the majority of the commercialization time is spent on technology devel-

___________________

6 A reduction in sales volume or sales revenue of a product as a result of the introduction of a new product by the same producer.

opment, yet the reason many of these technologies fail is because of poor definition of new markets (Miremadi et al., 2013).

Many of the strategies for gaseous carbon waste utilization are based on developing “drop-in” technologies for established markets. For the chemical industry, the McKinsey assessment would predict a 30-40 percent success rate for this approach with timelines on the order of 6 to 15 years to allow for full evaluation and vetting of a new technology as companies will be very hesitant to harm their reputation by launching a new technology into one of their well-established markets (Miremadi et al., 2013). Because waste gas streams may contain variable trace components, additional evaluation may be necessary in order to validate full qualification for a particular application.

RESEARCH AGENDA ITEMS

As discussed throughout this chapter, evaluation of the commercial potential for new technologies is complex as more than just the technology needs to be factored into the assessment. These problems are multifaceted and, as such, a multidisciplined approach will be needed for successful technology product launches based on these new feedstocks. Understanding of market and societal implications of introducing new technologies will help in identifying market opportunities for new technologies and in identifying communication strategies to educate consumers and the marketplace on the societal value of developing and using these products. The development of databases of technical performance, financials, and cost of various CO2 utilization technologies at different stages of maturity will support the development of knowledge-sharing networks. Additionally, development of predictive and analytic tools for detecting consumer trends and tools for identifying suitable production locations based on inputs such as raw material availability and/or suitability, favorable permitting requirements, and so on would improve technology development and commercial deployment. Ideally, collecting feedback from potential industrial users and consumers throughout the research process could both accelerate progress and increase the likelihood of commercial success. The committee identified priority research needs to consider when conducing TEAs for carbon utilization:

Technoeconomic assessment benchmarking

Research is needed to develop standardized, transparent inputs and assumptions for technoeconomic analysis implemented for carbon utilization. This could lead to more consistent assessments of technologies.

Entrepreneurial research hubs

Research is needed to elucidate issues such as social and behavioral acceptance and understanding of commercialization needs. Entrepreneurial research hubs could support links between fundamental research and market needs.

Pilot plant facilities

Research is needed at pilot plant facilities to reduce the risks involved in the commercialization of new technologies. This could facilitate the development of technologies beyond the laboratory scale.

Increased exposure to issues experienced during scale-up could also highlight entirely new areas of research. Typically scale-up research is done in industrial research settings; however, industry may be unlikely to invest in development of these nascent technologies beyond the laboratory scale due to the lack of market, regulatory, and policy drivers. Therefore, government investment will be critical to enable these technologies to reach pilot and demonstration scale. Design and development of flexible pilot plant facilities to de-risk the commercialization of new technologies will be needed.

Advanced testing

Research is needed to develop predictive accelerated aging evaluation methodologies for mineral carbonation. Such models would help de-risk technologies and streamline their introduction into conservative market applications where extensive performance data are needed to establish codes for use.

REFERENCES

AACE (American Association of Cost Engineers) International. 1991. Conducting Technical and Economic Evaluations as Applied for the Process and Utilities Industries. Available at http://web.aacei.org/docs/default-source/toc/toc_16r-90.pdf (accessed October 10, 2018).

Arora, A. 1997. Patents, licensing, and market structure in the chemical industry. Research Policy 26:391-403.

Bandarian, R. 2007. Evaluation of commercial potential of a new technology at the early stage of development with fuzzy logic. Journal of Technology Management and Innovation 2(4):73-85.

Boren, M., C. Musso, and V. Chen. 2012. The path to improved returns in materials commercialization. McKinsey & Company. Available at https://www.mckinsey.com/business-functions/operations/our-insights/the-path-to-improved-returns-in-materials-commercialization.

Browne, J. B. 2016. A Techno-Economic and Environmental Analysis of a Novel Technology Utilizing an Internal Combustion Engine as a Compact, Inexpensive Micro-Reformer for a Distributed Gas-to-Liquids System. Columbia University.

Dave, S. H., B. D. Keller, K. Golmer, and J. C. Grossman. 2017. Six degrees of separation: Connecting research with users and cost analysis. Joule 1:410-415.

de Rubens, G. Z., L. Noel, and B. K. Sovacool. 2018. Dismissive and deceptive car dealerships create barriers to electric vehicle adoption at the point of sale. Nature Energy 3:501-507. doi: 10.1038/s41560-018-0152-x.

HPTT (Hydrogen Production Tech Team) Roadmap. November 2017. Available at https://www.energy.gov/sites/prod/files/2017/11/f46/HPTT%20Roadmap%20FY17%20Final_Nov%202017.pdf (accessed October 10, 2018).

lles, A., and A. N. Martin. 2013. Expanding bioplastics production: Sustainable business innovation in the chemical industry. Journal of Cleaner Production 45:38-49.

Jain, R. K., A. O. Martyniuk, M. Harris, R. Niemann, and K. Woldmann. 2003. Evaluating the commercial potential of emerging technologies. International Journal of Technology Transfer and Commercialization 2:32-50.

Jones, C. R., B. Olfe-Kräutlein, H. Naims, and K. Armstrong. 2017. The social acceptance of carbon dioxide utilisation: A review and research agenda. Frontiers in Energy Research 5:1-13.

Kant, M. 2017. Overcoming barriers to successfully commercializing carbon dioxide utilization. Frontiers in Energy Research 5(22):1-19.

Lee, S., C. Cho. J. Choi, and B. Yoon. 2017. R&D project selection incorporating customer-perceived value and technology potential: The case of the automobile industry. Sustainability 9:1918-1936.

Maine, E., and P. Seegopaul. 2016. Accelerating advanced materials commercialization. Nature Materials 15:487-491.

Miremadi, M., C. Musso, and J. Oxgaard. 2013. Chemical innovation: An investment for the ages. McKinsey & Company. Available at https://www.mckinsey.com/industries/chemicals/our-insights/chemical-innovation-an-investment-for-the-ages.

Musso, C. 2009. New learning from old plastics: The effects of value-chain-complexity on adoption time. Technovation 29:299-312.

NETL (National Energy Technology Laboratory). 2013. Technology Learning Curve (FOAK too NOAK) Quality Guidelines for Energy System Studies. U.S. Department of Energy. DOE/NETL-341/081213. Available at https://www.netl.doe.gov/File%20Library/research/energy%20analysis/publications/QGESS_FOAKtoNOAK_Final.pdf (accessed October 10, 2018).

NETL. 2015. Cost and Performance Baseline for Fossil Energy Plants Volume 1a: Bituminous Coal (PC) and Natural Gas to Electricity Revision 3. U.S. Department of Energy. DOE/NETL-2015/1723. Available at https://www.netl.doe.gov/energy-analyses/temp/CostandPerformanceBaselineforFossilEnergyPlantsVolume1aBitCoalPCandNaturalGastoElectRev3_070615.pdf (accessed October 10, 2018).

Pérez-Fortes, M., J. C. Schöneberger, A. Boulamanti, and E. Tzimas. 2016. Methanol synthesis using captured CO2 as raw material: Techno-economic and environmental assessment. Applied Energy 161:718-732.

Rubin, E. S., C. Short, G. Booras, J. Davison, C. Ekstrom, M. Matuszewski, and S. McCoy. 2013. A proposed methodology for CO2 capture and storage cost estimates. International Journal of Greenhouse Gas Control 17:488-503.

Silverstein, K. 2018. Tax credit may rev up carbon capture and sequestration technology. Available at https://www.forbes.com/sites/kensilverstein/2018/02/15/tax-credit-may-rev-up-carbon-capture-and-sequestration-technology/#4e0a53774a06 (accessed September 6, 2018).

van Heek, J., K. Arning, and M. Ziefle. 2017. Reduce, reuse, recycle: Acceptance of CO2-utilization for plastic products. Energy Policy 105:53-66.

Zimmermann, A., and M. Kant. 2015. The Business Side of Innovative CO2 Utilisation. Available at http://enco2re.climate-kic.org/wp-content/uploads/2016/01/The-business-side-of-innovative-CO2-utilisation.pdf (accessed October 10, 2018).

This page intentionally left blank.