CHAPTER FIVE

Direct Air Capture

INTRODUCTION

The results of recent integrated assessment modeling (Fuss et al., 2013) have made clear the need to include negative emissions technologies (NETs) as one component in a portfolio of solutions (e.g., mitigation, energy efficiency, renewables, fuel-switching) to prevent greater than 2°C global warming by 2100. Among these NETs is the direct removal of carbon dioxide (CO2) from the atmosphere, commonly referred to as direct air capture. To be considered a NET, direct air capture systems must sequester the captured CO2 on a timescale that positively impacts climate change. Currently, the only reasonable approach to store captured CO2 is geologic sequestration, which is covered in Chapter 7.

Direct air capture has received significant attention in the public media because it provides a means to reverse CO2 emissions, appears to be a relatively “easy fix” to climate change, and is a relatively new and high-tech NET. In addition to negative emissions potential, direct air capture systems benefit from their inherent flexibility of placement, which can reduce the need for pipelines1 from the capture site to the sequestration reservoir. Furthermore, direct air capture systems have the flexibility to produce CO2 for the commodity market at a desired purity. However, thermodynamics sets a lower bound on the energy required to separate a mixture of gases. Dilute streams are more difficult to separate and require more energy than more concentrated mixtures. A discussion of the thermodynamic limitations appears in Appendix D. The direct air capture approaches described in this chapter are technically feasible, but because CO2 in air is ~300 times more dilute than in flue gas from a coal-fired power plant, the separation process for the same end CO2 purity will likely be more expensive than capture from fossil fuel power plants.

CO2 removal from gas streams is an important component of many industrial processes. The choice of removal technology is governed by the concentration and pressure of the gas stream. Physical solvents are used at high concentrations in natural gas processing and chemical production. Lower concentrations require use of chemical

___________________

1 Approximate cost of CO2 transportation via pipeline is $2.24/tonne CO2 per 100 km of dedicated pipeline (DOE, 2015a).

bases that react with CO2, a Lewis acid. Among the simplest of these are hydroxides and amines. These can be introduced either as components of a liquid (usually aqueous) solution, or as functional groups on the surface of a high surface area solid material. Thus, CO2 can be captured from dilute gas streams, including air at ~400 ppm CO2, by contact with basic liquids and solids. However, capture is only the first step. For manufactured direct air capture systems2, the capture agent, either liquid or solid, must be able to release CO2 at conditions of temperature and pressure that are accessible with low energy input, so that the capture agent can be used repetitively, and to prepare CO2 for some form of secure sequestration. Capture generally happens spontaneously using these chemical agents, and the most significant energy costs are incurred in the step that recovers and concentrates the captured CO2. Capture is generally an exothermic process, and desorption for concentration is an endothermic process.

This chapter evaluates two types of direct air capture CO2 separation processes: one employing liquid solvents and one utilizing solid sorbents. Material and energy balances are carried out and compared to quantify the net reduction of CO2 from the atmosphere depending on the energy sources assumed (e.g., renewables, nuclear, natural gas, or coal). This analysis helps to identify the technical challenges of each capture process to inform development of a future research and development (R&D) agenda. A discussion and analysis of CO2 compression, transport, and subsequent geologic sequestration are covered separately in Chapter 7 on Geologic Sequestration and Appendix F. This chapter also provides estimates of the annual CO2 reduction potential, cost, and capacity associated with each capture process.

___________________

2 The focus of this chapter is on manufactured direct air capture systems, which utilize chemical or physical processes that are designed to capture CO2 from the ambient air. These systems differ from those that rely on natural phenomena such as CO2 uptake by plants or minerals in the natural environment.

often used different system boundaries; for example, not all studies accounted for all the steps needed for a complete cycle. Some utilized generic correlations for process operations, while others performed out detailed optimizations of specific systems. As progress continues on pilot and demonstration plants, more accurate costs can be expected to become available.

BACKGROUND

Economics (Literature Review)

The cost of carbon capture for direct air capture systems has been a contentious issue. The estimates found in the literature span an order of magnitude, from $100 to $1,000/tCO2 (Ishimoto et al., 2017). These estimates represent the costs of CO2 captured and not the costs of net CO2 removed from the atmosphere, with these costs tending to render direct air capture among the most expensive atmospheric CO2 removal approaches. One challenge to comparing estimates is that earlier reports

Estimates at the high end of the cost spectrum ($1,000/tCO2, House et al., 2011) were not based on a specific technology. Rather, they were based on direct air capture energy requirements and application of second-law efficiencies to the calculation of minimum separation energy based on 75 percent air capture and 95 percent CO2 product. A range of energy resource costs from wind to natural gas were considered, leading to an approximate upper estimate of $1,000/tCO2.

Estimates of $641-819/tCO2 based on a benchmark liquid system were provided in the first report to assess direct air capture, produced by the American Physical Society (APS) (Socolow et al., 2011). Although comprehensive in its analysis, that report’s benchmarking system introduced key limitations. This system conceptually adapted the technology for CO2 capture from flue gas streams—countercurrent flow of gas and liquid caustic solutions in a packed column—to CO2 capture from air. Because air has much lower concentrations of CO2, the volume of gas flow per ton of CO2 captured is much larger and the power requirements to overcome the pressure drop in the vertical packed tower configuration contribute to significant capital and operating costs. Although optimization of the operating conditions for this design could reduce costs somewhat (estimated as $528-579/tCO2 [Mazzotti et al., 2013] and $309-580/tCO2 [Zeman, 2014]) the basic geometry and gas-liquid contact scheme would remain the same. Such designs are now recognized as not broadly applicable to direct air capture systems.

As highlighted by several studies, altering the flow configuration to reduce pressure drop can dramatically reduce capture costs compared to the APS benchmark system, which is based on a more conventional approach that mimics post-combustion capture absorber technology. Holmes and Keith introduced a combination of a cross-flow scheme for the gas relative to the falling liquid and a novel scheme involving the co-capture of CO2 from air combined with an oxy-fired natural gas regeneration in a carbonate-based capture system. This configuration led to estimates between $336-389/t CO2 (Holmes and Keith, 2012) and $93-220/tCO2 (Keith et al., 2018). For solid adsorbents, low pressure–drop configurations analogous to the “honeycomb” structure of monoliths for automobile catalytic converters and other ultra-low-pressure–drop configurations are preferred motifs (Realff and Eisenberger, 2012). These novel configurations will require further testing and demonstration to realize the lower price points.

Laboratory studies of processes based on both solid and liquid sorbents have tended to estimate lower operating costs. Examples include amine-functionalized sorbent processes estimated at $82-155/t CO2 (Kulkarni and Sholl, 2012), though this study only considered operating costs. Earlier cost estimates based on aqueous chemical capture designs were similar at $60-145/t CO2 (Stolaroff et al., 2008) and $165/t CO2 for a complete system excluding sequestration (Keith et al., 2006). However, caution should be taken when making comparisons across studies because the completeness of the system considered, and the purity of the CO2 stream produced, vary among them.

Commercial Status

Several companies are currently working to commercialize direct air capture systems (Table 5.1). These companies are primarily focused on units that operate on the scale of 1 Mt/y CO2 capture from the air and are primarily privately funded.

Many direct air capture systems have been proposed. These can be distinguished by characteristics including the choice of liquid solvent or solid sorbent, method for CO2 release/capture (regeneration), and purity of the output CO2 stream.

Although pure (> 99 percent) CO2 is desired for geological storage or sequestration, more dilute streams containing 3-5 percent CO2 can still be useful for supply to enclosed greenhouses and algae farms (Wilcox et al., 2017). Although commercial entities need to monetize CO2 to offset R&D costs and grow their business, if CO2 is separated from air for utilization, then it must be sequestered on a timescale that positively impacts climate to be considered a NET. Of the companies listed in Table 5.1, all but Carbon Engineering utilize capture by amine (or ammonium)-based solid sorbents, although some are considering other kinds of structured solid sorbents in their continued development. Carbon Engineering’s process involves aqueous hydroxide solutions that react with CO2 to precipitate a carbonate salt. Most approaches rely on heating or a combination of heat and vacuum to release captured CO2 from its bound state on the solid sorbent or, in the case of the precipitate in the Carbon Engineering process, to thermally decompose the carbonate. The resulting alkaline oxide, or hydroxide in the latter case, is then re-dissolved in the aqueous solution, thereby restoring its CO2 uptake capacity. Alternative methods of regenerating solid sorbents have been advanced by Wang et al. (2013), as well as companies such as Infinitree (humidity swing). In the latter case, after capture under relatively dry conditions, exposure of the CO2-saturated sorbent to humid air under mild vacuum causes release of CO2.

TABLE 5.1 Companies Working to Commercialize Direct Air Capture Systems

| Company | System Type | Technology | Regeneration | Purity/Application | Scale |

|---|---|---|---|---|---|

| Carbon Engineering | Liquid solvent | Potassium hydroxide solution/calcium carbonation | Temperature | 99% | Pilot 1 t/d |

| Climeworks | Solid sorbent | Amine-functional-ized filter | Temperature or vacuum | 99% w/dilution depending on application | Demonstration 900 t/y |

| Global Thermostat | Solid sorbent | Amine-modified monolith | Temperature and/or vacuum | 99% | 1,000 t/y |

| Infinitree | Solid sorbent | Ion-exchange sorbent | Humidity | 3-5% algae | Laboratory |

| Skytree | Solid sorbent | Porous plastic beads functional-ized with benzylamines (Alesi and Kitchin, 2012) | Temperature | Air purification, greenhouses | Appliance |

At the time of writing, all the companies have technologies that are either in the laboratory stage or have advanced to one-off pilot or demonstration plants. Climeworks has advanced the farthest, operating a 900 t/y demonstration plant in Switzerland where CO2 is used for various applications, rather than stored in geologic reservoirs.

ANALYSIS: ENERGETICS, CARBON FOOTPRINTS, AND COSTS

This section presents the Committee’s analyses of the energetics, carbon footprints, and economics of direct air capture systems based on liquid solvents and solid adsorbents. Both analyses were based on the following baseline assumptions:

- Plant capture rate from air = 1 Mt/y CO2

- Concentration in air = 400 ppmv CO2

- Volumetric flow rate ≥ 58,000 m3/s air

- Capture fraction from air ≥ 60+ CO2

- Concentration of product ≥ 98 percent CO2

- Emission factors

- Heat from natural gas = 227 g CO2/kWh

- Heat from coal = 334 g CO2/kWh

- Heat from nuclear = 4 gCO2/kWh

-

- Heat from solar = 8.3 gCO2/kWh

- Electricity from grid (U.S. average) = 743 gCO2/kWh

- Electricity from natural gas = 450 gCO2/kWh

- Electricity from coal = 950 gCO2/kWh

- Electricity from nuclear = 12 gCO2/kWh

- Electricity from solar = 25 gCO2/kWh

- Electricity from wind = 11 gCO2/kWh

- Plant life = 10 years3

When designing a plant capable of capturing 1 Mt/y CO2 from the air, one has to carefully consider the energy resources that will power the plant to determine the net removal of CO2 from the air. For instance, if fossil fuels supply the energy in the absence of conventional carbon capture and sequestration (CCS), the net removal of CO2 from the air may be significantly reduced. When comparing the costs of direct air capture across varying boundary conditions, the estimates for direct comparison can be aligned through the use of a cost factor, represented by:

Cost Factor = 1/1-x

such that x is the CO2 emitted per CO2 captured. As x approaches 1, or for every ton of CO2 captured, 1 ton is released, the factor approaches infinity, as does the cost. In contrast, as x approaches zero, the cost of net CO2 removed becomes closer to the cost of capture. Examples of technologies that may lead to an x near zero are those that use low-carbon energy resources to supply the required heat and power to operate the system, which may be unique for a given direct air capture approach. For example, the liquid solvent approach requires temperatures of up to 900°C for regeneration. Technologies that may achieve this temperature include concentrated solar power towers (DOE, 2013), combustion of low-carbon hydrogen, PV or wind-sourced electric heating, and alternative designs of nuclear including high-temperature gas-cooled reactors (Harvey, 2017). In comparison, the solid sorbent–based approach requires significantly lower temperatures for regeneration (i.e., < 150 °C). Hence, the options for providing low-carbon energy differ but may include geothermal and light water nuclear reactors. It is also important to consider the embodied emissions of the materials required to build a plant capable of operating at 1 Mt CO2 per year. Although the embodied emissions are not included in the current analyses, the amount of steel and cement for these plants may be nonnegligible. The current analysis makes clear that direct air capture, if fueled by low-carbon energy pathways, will have the greatest impact. However, fueling direct air capture plants with low-carbon energy resources in

___________________

3 Same as used by the U.S. Department of Energy for baseline power plant studies, such as in Draucker et al., 2010.

place of using those resources to directly replace fossil fuel–based point-source emitters requires careful consideration.

The design of both direct air capture approaches included an air contactor and regeneration facility. In general, a practical process requires five key attributes: (1) low-cost air contactor to allow for a contactor area that is large enough to minimize pressure drop, because the low concentration of CO2 in air requires passage of large gas volumes through the contactor; (2) optimal CO2-sorption thermodynamics, which relates to having a sorption isotherm with suitably high CO2 uptake at CO2 partial pressures below 500 ppmv to minimize sorbent inventory and overall size of the process. The need for high CO2 uptake at low partial pressures suggests that sorbents need strong, chemical interactions with CO2, in contrast to separation processes that operate at higher CO2 partial pressures, where sorbents employing weaker, physical interactions may be used; (3) rapid sorption/desorption kinetics, which results in fast sorption and desorption, faster cycling, and therefore less sorbent needed for the same output; (4) low sorbent regeneration energy so that the CO2 binding energy is high enough to achieve a good uptake capacity, but not so high that endothermic sorbent regeneration energy requires unacceptably high regenerator costs. Furthermore, effective process designs will minimize the thermal mass of equipment that is repeatedly thermally cycled between sorption and desorption—that is, the sensible heat of the process should be minimized; and (5) low capital costs, which applies to virtually any process but is particularly relevant for direct air capture systems, with the lifetime of sorbent media posing a potentially important capital cost for some designs.

The committee followed different approaches to analyze the liquid solvent and solid sorbent direct air capture systems described below. The liquid solvent systems analysis is derived from a conceptual process design published by Carbon Engineering (Holmes and Keith, 2012; Keith et al., 2018). The committee conducted its analysis before Keith et al. published in 2018, but after careful examination of that work, determined that its analysis aligns closest with the design “C” configuration, which omits the onsite power island and instead uses grid electricity to supply all electrical work, suitable in regions with available low-carbon electricity. However, the C configuration assumes compression of CO2 to 15 MPa, and compression is not included in the committee’s analysis. Compression results in an energy of 0.48 GJ/tCO2 and cost of $8/tCO2, assuming an electricity cost of $60/MWh—leading to additional emissions of 0.1 Mt CO2 for every Mt CO2 captured, assuming an average grid emissions factor of 744 kgCO2/MWh.

In particular, for the regeneration of Carbon Engineering’s capture material, the heat is sourced by burning natural gas in an oxygen-fired kiln in which CO2 is produced by

both the combustion of natural gas and the calcination of CaCO3, the material that is partially responsible for removing CO2 from the air. The committee’s analysis of this process considers the overall energetics and economics of the combined process, as well as that obtained by direct air capture only, excluding the CO2 produced from fossil fuel combustion. Several companies are pursuing solid sorbents systems (e.g., Climeworks, Global Thermostat, and Skytree), each developing their own unique proprietary process with different design features. Therefore, rather than analyzing a specific process, a generic sorbent-based process is considered, and key process parameters varied to provide a range of energetic and process costs.

Liquid Solvent Systems

Process Description

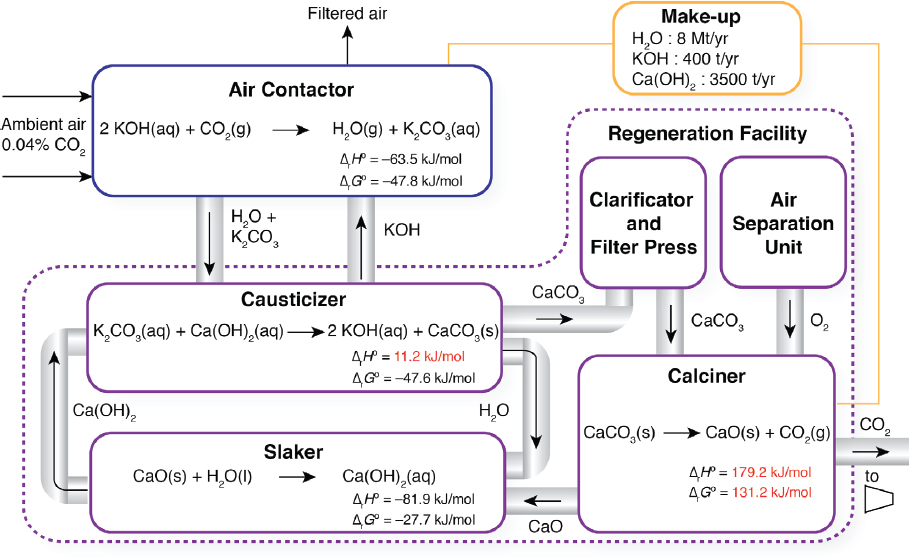

The two major components of a liquid solvent direct air capture process are the air contactor and regeneration facility (Figure 5.1). In this process, an aqueous potassium hydroxide solution (KOH) reacts with the CO2 from the air to form water and potassium carbonate (K2CO3) in an air contactor. The potassium carbonate aqueous solution is then fed to a causticizer, where it is reacted with calcium hydroxide (Ca(OH)2) to form calcium carbonate (CaCO3) precipitate. The CaCO3 slurry is then fed to clarificatory and filter press to remove water, before it is fed to a calciner where the CaCO3 precipitate is heated with natural gas in an oxy-fired kiln to about 900°C thereby producing solid calcium oxide (CaO) and high-purity CO2 gas that can be compressed and transported for long-term sequestration.

Unit Operations

Air Contactor

The air contactor is used to contact the air with a KOH aqueous solution such that CO2 reacts to produce K2CO3:

2KOH + CO2 → H2O + K2CO3

The ambient air enters the contactor at 400 ppm and exits with 75 percent CO2 captured in the solvent as K2CO3. Because of the high stability of this product species, a caustization step is required to react K2CO3 with Ca(OH)2 to form calcium carbonate CaCO3, regenerating the KOH solution for reuse in the contactor.

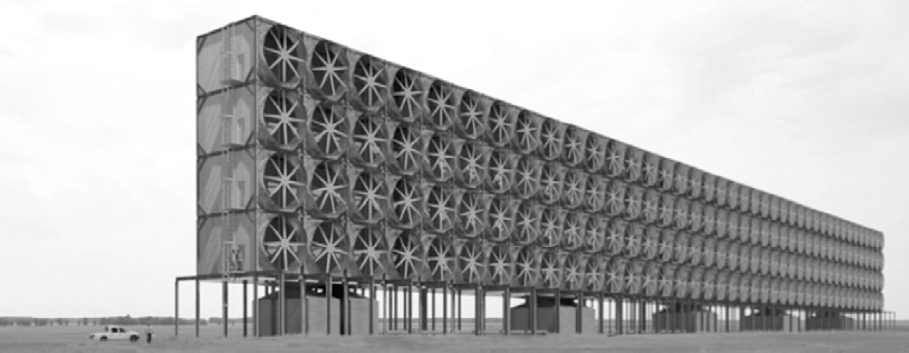

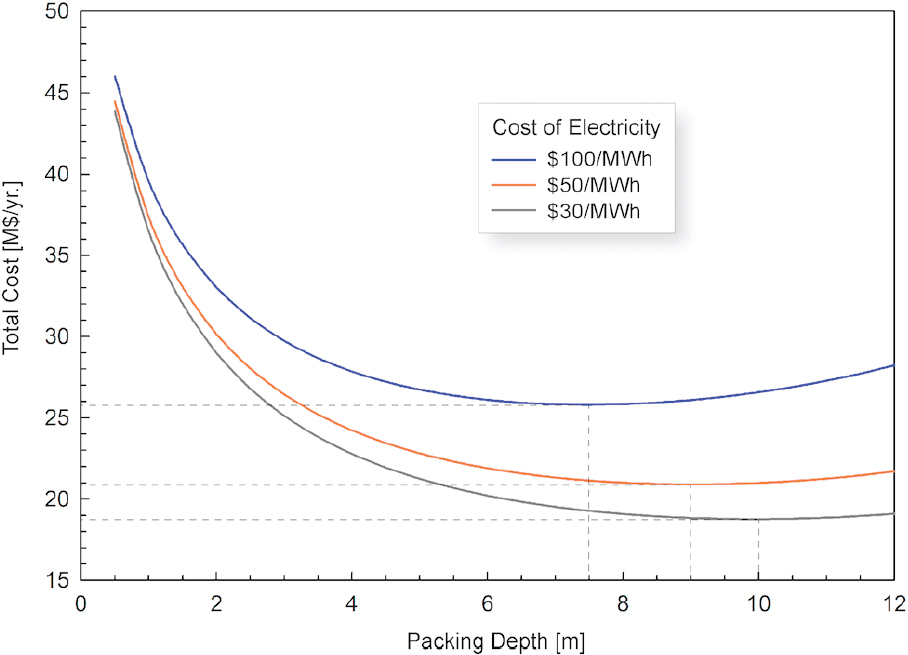

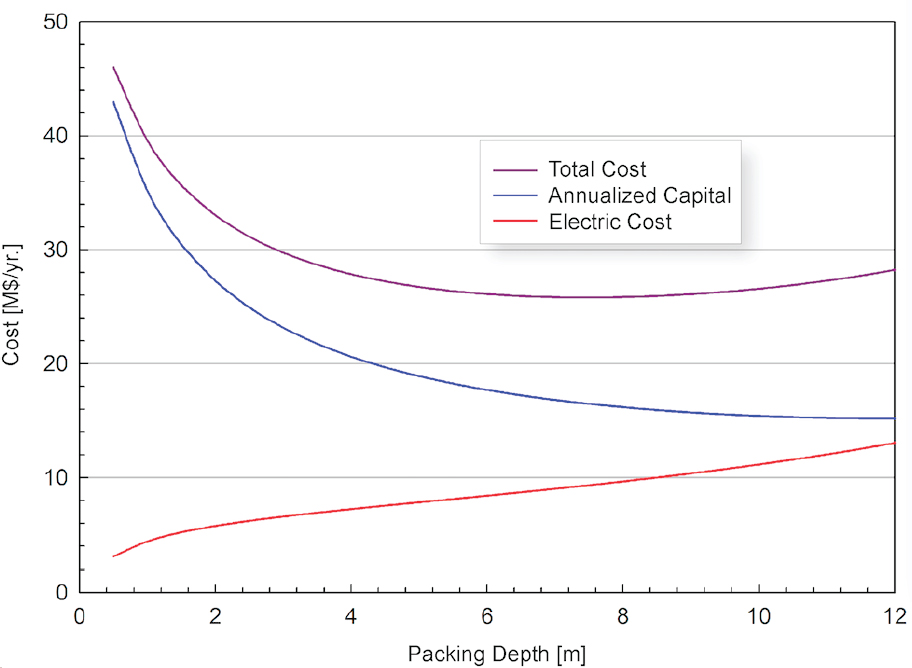

Contactor Sizing: In the air contactor, air is blown using fans over PVC-based packing material like that used in industrial cooling towers, as depicted in Figure 5.2. The solvent is a 1 M KOH aqueous solution that is sprayed uniformly over the packing material. The packing material assumed is Brentwood XF12560. Holmes and Keith (2012) determined that a capture fraction of 0.75 CO2 in air was optimal based on their solvent-based separation process. With an air velocity of 1.5 m/s and 75 percent CO2 capture from air, the contactor area needed to separate 1 Mt/y CO2 is 38,000 m2. The largest commercial packed towers have areas of about 100 m2, which would indicate the need to construct hundreds of towers to achieve 1 Mt/y CO2. Because of this challenge, Holmes and Keith have proposed adopting technology used in large-scale cooling towers and waste treatment plants. Their optimal air contactor design is approximately 20 m × 8 m × 200 m, and 10 contactors would be needed to capture 1 Mt/y CO2, a considerable improvement over a conventional packed tower. Moreover, the packing volume for their system is estimated at 20,000 m3, compared to a large cooling tower volume of 10,000 m3 and a conventional packed tower of about 285 m3. These considerations highlight that an optimized direct air capture contactor design

will significantly differ from that of a conventional coal or natural gas post-combustion carbon capture plant.

Pressure Drop: When calculating the pressure drop, one has to consider the packing material composition (e.g., metal, plastic, ceramic) in addition to the nature of the air flow through the wetted packing material. For post-combustion applications, the flow is often modeled as counter-current (Mazzotti et al., 2013; Socolow et al., 2011), while in the work of Keith et al. (2012, 2018) it is modeled in a cross-flow configuration. The literature provides several pressure-drop correlations for conventional metal packing material with counter-flow configurations, but does not appear to do so for pressure-drop correlations for the PVC packing material with the cross-flow configuration as described in Keith et al. (2012, 2018). For this reason, in the Committee’s analysis, a range in fan power energy consumption is established by considering separately the pressure drop associated with stainless steel and PVC packing materials. In the work of Keith et al. (2012, 2018), the pressure-drop across the packed tower is based on the following correlation developed specifically for the PVC packing material, Brentwood XF12560:

ΔP = 7.4Dv2.14

where ΔP is the pressure drop in (Pa), D is the column depth in (m), and v is the air velocity in (m/s). Based on Holmes and Keith’s design (v = 1.5 m/s, D = 6–8 m), the resulting pressure-drop ΔP = 106–141 Pa (1.0-1.4 mbar).

SOURCE: Holmes and Keith, 2012.

Mazzotti et al. (2013) showed that a novel, stainless steel packing material designed specifically for post-combustion capture may achieve a ΔP = 380 bar (v = 2.57 m/s, D= 3.6 m). This pressure drop was derived for a counter-current flow contactor where air velocity and capture fraction were treated as optimizable variables. Implications behind the choice of packing material will be discussed in greater detail in the process economics section.

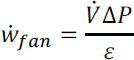

Fan Work: From the pressure drop, the fan power (MW) required to drive 58,000 m3/s flowing air through the contactor can be calculated from:

where ![]() is the volumetric flow rate (m3/s) and ɛ is the fan electrical efficiency (60 percent assumed). This yields an air contactor fan work = 10-37 MW. Thus, for a carbon capture rate of 1 Mt/y CO2, the fan energy required is 0.32-1.18 GJ/t CO2 (14.2-52.5 kJ/mol CO2) captured. This equates to 0.073-0.269 Mt/y CO2 emissions from coal-fired power and 0.044–0.160 Mt/y CO2 from natural gas-fired power, resulting in an average annual net CO2 capture of 0.83 Mt/y and 0.90 Mt/y for coal and natural gas power to the fan, respectively.

is the volumetric flow rate (m3/s) and ɛ is the fan electrical efficiency (60 percent assumed). This yields an air contactor fan work = 10-37 MW. Thus, for a carbon capture rate of 1 Mt/y CO2, the fan energy required is 0.32-1.18 GJ/t CO2 (14.2-52.5 kJ/mol CO2) captured. This equates to 0.073-0.269 Mt/y CO2 emissions from coal-fired power and 0.044–0.160 Mt/y CO2 from natural gas-fired power, resulting in an average annual net CO2 capture of 0.83 Mt/y and 0.90 Mt/y for coal and natural gas power to the fan, respectively.

Water Loss: Depending on the molarity of the hydroxide solvent and the relative humidity, the water loss in the air contactor could be 1-30 mol/mol H2O per CO2 captured. Stolaroff et al., 2008 showed that increasing the concentration of hydroxide resulted in less water loss. Specifically, water loss was nearly eliminated for a ~ 7.2 M NaOH at 15°C and 65 percent relative humidity. However, Holmes and Keith (2012) estimated the minimum hydroxide concentration to mitigate water loss was 2 M KOH. Stolaroff et al., 2008 showed that a water loss of 20 mol/mol H2O per CO2 captured is typical for low concentration hydroxide solutions (e.g., 1.3 M) at 65 percent relative humidity. Thus, a liquid solvent direct air capture system with a 1 Mt/y CO2 capture rate will require the addition of about 8.2 Mt/y water to make up for water loss.

Solvent Pump

To calculate the work required to pump KOH for even distribution across the packing material, the pressure drop, volumetric flow rate, and liquid density are required. This information was not available for the system of Holmes and Keith (2012), but they presented a rule of thumb in that the energy required for fluid pumping is approximately 15 percent of that required of the fan energy. This equates to 0.048-0.065 GJ/t CO2

(2.13–2.84 kJ/mol CO2) captured. The additional CO2 generated by using coal or natural gas to generate electricity for solvent pumping results in 0.013 and 0.0077 Mt/y CO2, respectively.

Slaker

In the slaker, CaO reacts with H2O exothermically to regenerate Ca(OH)2, which is reused in the causticizer:

CaO + H2O → Ca(OH)2

Inert grit may be produced in the slaker, which impacts the efficiency of this step. Grit production depends on particle size, temperature, and the type of equipment used (Hassibi, 1999). Work for the slaking process has been estimated at 0.005 GJ/t CO2 (0.2 kJ/mol CO2) (Baciocchi et al., 2006), while efficiencies in the literature range from 0.95 to 0.99 (Emmett, 1986). Using an average efficiency, slaking work contributes additional emissions of 0.001 and 0.0007 Mt/y CO2 when the electricity is sourced from coal and natural gas, respectively. Despite the exothermic nature of the slaking reaction and heat exchange that occurs between the slaking and causticization steps, this low-grade heat may not be easily integrated and becomes difficult to consider in the cumulative energy for regeneration.

Causticizer

In the causticizer, an K2CO3 aqueous solution is pumped from an exit stream in the air contactor and reacted with Ca(OH)2 to make CaCO3 and regenerate KOH for reuse in the air contactor:

H2O + K2CO3 + Ca(OH)2 → 2 KOH + CaCO3

Typical causticization efficiencies for sodium hydroxide (KOH efficiencies are lacking in the literature) range from 0.8 to 0.9, which means that energy requirements will increase to account for the additional processing needed to compensate for nonideal conversions (Mahmoudkhani and Keith, 2009). However, the causticization step has negligible work requirements compared to other steps in the regeneration cycle (Baciocchi et al., 2006); thus, incremental changes in work due to causticization efficiency are manifested in downstream processes (e.g., clarification and filter press).

Following the causticization reaction, the supernatant KOH (aq) solution is clarified, mixed with additional reclaimed solvent and pumped back to the absorber. The

required work in the clarification step is estimated to be 0.109 GJ/tCO2 (4.8 kJ/mol CO2) assuming ideal conversion efficiencies in upstream processes (Baciocchi et al., 2006). Adjusting this work value for realized slaking and causticization efficiencies results in emissions of 0.025 and 0.015 Mt/y CO2 for coal and natural gas, respectively. Precipitated CaCO3 is filtered, thickened, and pressed in preparation for transport to the kiln for calcination. Heating and drying of the CaCO3 is necessary to remove as much water content as possible before passage to the energy-intensive calcination step. This preparation is also energy intensive, requiring an estimated 3.18 GJ/tCO2 (140 kJ/mol CO2), or the equivalent of 0.30 and 0.20 Mt/y additional CO2 emissions using heat derived from coal and natural gas, respectively.

Calciner

Following filtration, clarification, and drying, CaCO3 must be heated to high temperatures (~ 900°C) in a calciner to form calcium oxide (quicklime) and highly concentrated CO2:

CaCO3 → CaO + CO2

After calcination, the quicklime is returned to the slaker, where it reacts with water exothermically to regenerate Ca(OH)2 and heat the slaking solution to about 95°C (Baciocchi et al., 2006). Although low-grade heat such as this is often difficult to integrate, a separate CaCO3 steam drying process using heat recovered from lime hydration could offset thermal requirements for drying by 2.39 GJ/t CO2 (105 kJ/mol CO2) (Zeman, 2007). In addition, calcination efficiencies of over 0.9 have been reported in the literature (Martinez et al., 2013; Stamnore and Gilot, 2005). Heat requirements reported in the literature (Baciocchi et al., 2006; Zeman, 2007) for the calcining process range from 6 to 9 GJ/tCO2 (264-396 kJ/mol CO2). This includes an efficiency factor of 0.75 for the direct use of thermal energy.

Because of this large thermal requirement, CO2 emissions associated with traditional calcination processes are significant, ranging from 0.38 to 0.57 and 0.56 to 0.84 Mt/y CO2 for natural gas and coal firing, respectively. To minimize CO2 generated in the direct air capture process, any thermally generated CO2 could, in theory, become co-captured with that from ambient air. However, the balance of post-kiln exhaust is largely nitrogen, and if the end goal is to produce a near-pure (≥ 99 percent) CO2 stream, then additional CO2 separation equipment is required. Oxygen-fired (oxy-fired) kilns can obviate the need for additional CO2 separation equipment, because they produce an exhaust that is composed of only CO2 and H2O, allowing the production of a near-pure CO2 stream after the water is condensed out. For heat recovery

from the calciner, a heat-exchanger is used to cool the 900°C flue gas exiting to 200°C with the incoming gas. Then, the 200°C flue gas is passed through a condenser and further cooled to 30°C. Pure oxygen for the oxy-fired kiln is separated from air using an air separation unit (ASU), where its electric requirements are 0.30 GJ/t CO2 (13.2 kJ/mol CO2), leading to a footprint of 0.068 and 0.041 Mt/y CO2 using electricity-derived from coal and natural gas firing, respectively.4

Chemical Make-up

Reagent loss may occur at several points in a liquid solvent direct air capture process. Because of the nature of direct air capture, foreign contaminants may enter the absorber (e.g., insects, birds, particulate matter, sulphur oxides [SOx] and nitrogen oxides [NOx]) and then accumulate and combine with Ca-ions to form undesirable products. Further Ca-ion loss can occur during filtration and kiln firing. It is preferred to make up Ca-ion loss with CaCO3 because of its relatively low cost ($200/t delivered) and smaller carbon footprint than other lime products, such as quicklime (CaO) and slaked lime (Ca(OH)2).5 In addition, KOH may be lost in the absorber through aerosol formation and spray drift (Keith and Holmes, 2012. Operational expenditures for chemical makeup have been estimated to be $0.90/tCO2 captured (Socolow et al., 2011). Assuming this cost is split into $0.20/tCO2 for KOH (aq) and $0.70/tCO2 for CaCO3(s), results in make-up requirements of 400 t KOH/y6 and 3,500 t CaCO3/y, respectively. Given that KOH is produced in the energy intensive chloralkali process (7 GJ/t KOH), make-up from KOH production yields a footprint of 590 t/y CO2. Emissions from CaCO3(s) makeup may be attributed to vehicle emissions from delivery (0.11 kg/t-mile CO2), accounting for the round-trip, and any additional disposal required from waste buildup in the loop.7

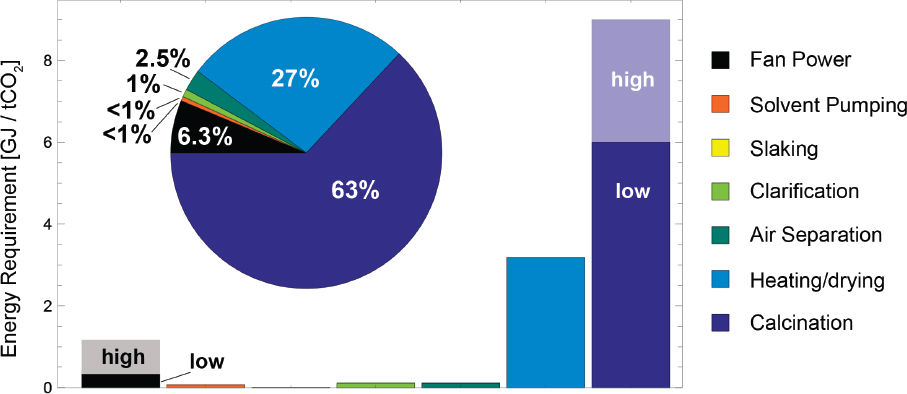

Mass and Energy Balance

Estimated energy requirements for liquid solvent direct air capture systems are provided in Table 5.2 and depicted in Figure 5.3, and totals of 0.74-1.66 GJ/t CO2 and

___________________

4 Based on 200 kWh per tonne O2 produced in the ASU, and 0.56 mol O2 per mol CaCO3 supplied to the calciner.

5 Emissions from CaCO3 mining range from 1.5 to 80 kWh/t, resulting in negligible CO2 emissions when compared to other steps outlined in this section.

6 Based on a bulk purchase price of $506.5/t NaOH (Integrated Environmental Control Model [IECM]).

7 This disposal may be considered analogous to reclaimer waste disposal in MEA regeneration ($260/t) (IECM).

9.18-12.18 GJ/t CO2, for electricity and thermal energy requirements, respectively. The fans, pumps, slaker, causticizer/clarifier, and air separation units are all assumed to run off of grid-sourced electricity, while the heater/dryer and calciner represent the thermal requirements of the overall system. As shown in Figure 5.3, collectively, the energy required from running the electric components of the system totals from 6 to 18 percent of the entire energy demand for the process. In particular, the dominant energy-intensive component of this process is the thermal regeneration of CaO and subsequent production of high-purity CO2, followed by the step of heating and drying of CaCO3. These steps collectively reduce the net CO2 captured to between 0.11-0.42 Mt/y CO2 if natural gas is used as the thermal energy source and 0-0.11 Mt/y CO2 for coal. In other words, using coal as the thermal source results in nearly equivalent emissions of CO2 as that captured. These estimates include a thermal credit of 1.5 GJ/tCO2 from the cooling of the calciner exhaust unit. Because of the uncertainty associated with a well-defined system that could recover the heat generated from the hydration reaction of the steam drying process, this credit was not included in these estimates. This is also a primary difference between the analysis of the current work and that of Keith et al. (2018), because they assume significant heat integration resulting in an average thermal work requirement of 5.25 GJ/tCO2 compared to the lower bound of 8.4 GJ/tCO2 in the current work. Incorporating heat recovery methods as described in Zeman (2007), this requirement may be reduced to 6 GJ/tCO2. However, given the lack of clarity about heat integration approaches in the open literature, they were excluded from the current study. Further, because the calciner is oxy-fired, this approach in particular co-captures the CO2 from air in addition to that generated from burning natural gas for the heat source. Consideration of this particular approach reveals that an additional 0.38-0.57 Mt/y CO2 can be produced at high purity along with that captured directly from the air.

Assuming an initial atmospheric concentration of CO2 at 400 ppm at 25°C, the minimum work of capturing 75 percent of the CO2 at 98 percent purity is 0.45 GJ/tCO2 (20 kJ/mol CO2). Based on the energy requirements outlined for liquid solvent direct air capture systems, the “real” work is 8.2-11 GJ/t, leading to an exergy efficiency8 of 4.1-6.2 percent.

Process Economics

In assessments of the costs and benefits of direct air capture, an area of contention has been the broad range of costs reported in the literature. Comparing costs without

___________________

8 Exergy efficiency is defined as the ratio of minimum work to real work: Wmin/Wreal.

TABLE 5.2 Liquid Solvent Direct Air Capture System Unit Operation Energy Requirements and CO2 Generation

| Unit Operation | Energy Required (GJ/t CO2) | CO2 Generated (Mt/y) | |

|---|---|---|---|

| Natural Gas | Coal | ||

| Contactor fans | 0.32-1.18 | 0.044-0.160 | 0.071-0.095 |

| Solvent pump | 0.048-0.065 | 0.007-0.009 | 0.011-0.014 |

| Slaker | 0.005 | 0.0007 | 0.001 |

| Causticizer/clarifier | 0.109 | 0.015 | 0.028 |

| Air separation unit | 0.30 | 0.041 | 0.028 |

| Heater/dryer | 3.18 | 0.20 | 0.30 |

| Oxy-fired calciner | 6.0-9.0 | 0.38-0.57a | 0.57-0.85a |

| Exhaust gas cooling | -1.5 | -0.11 | -0.15 |

| Additional heat recoveryb | -2.4c | — | — |

| Total (w/o gas cooling credit) | 9.9-14 | 0.69-1.00 | 1.00-1.31 |

| Total (w/gas cooling credit) | 8.4-12.5 | 0.58-0.89 | — |

a Emissions co-captured with those from ambient air.

bHeat recovered from hydration of CaO for use in CaCO3 drying (Zeman, 2007).

c Neglected in process total.

first normalizing conditions and boundaries is misleading; thus, it is important to emphasize that the cost estimates presented here are for the separation and capture of CO2 from ambient air from modestly optimized, generic direct air capture systems operating at 75 percent capture with highly concentrated CO2 product (~ 98 percent purity), which is needed to minimize compression costs and volume requirements for geological sequestration. These cost estimates reflect the total annual economic penalty incurred for removing 1 Mt CO2 from air on a per ton CO2 captured basis. However, additional CO2 emissions can be generated in several of the steps required in direct air capture systems. It is important to account for these emissions directly in the avoided cost expression by assuming a penalty for any emissions generated. This cost of CO2 avoided is always higher than the cost of CO2 captured and approaches infinity as the amount of CO2 generated during capture approaches the amount captured. It is important to account for these emissions directly in the net cost expression by assuming a penalty for any emissions generated. This net cost of CO2 removed is always higher than the cost of CO2 captured and approaches infinity as the amount of CO2 generated during capture approaches the amount captured. The cost estimates presented here also vary by energy source and do not include costs for compression, transportation, injection, and sequestration.9

The estimated capital and operating costs for a 1 Mt/y CO2 liquid solvent direct air capture system are provided in Table 5.3. This cost analysis presents an optimistic scenario based on optimal parameters (for instance, Holmes and Keith [2012] and Keith et al. [2018]), where co-dependent parameters are jointly optimized to minimize system cost. Here, any literature values on installed equipment costs are taken directly, whereas direct equipment costs are multiplied by a 4.5 factor to convey total installed cost (Rudd and Watson, 1968). A realistic case is presented whereby parameters are set at their respective upper bounds as indicated in Table 5.3. A realistic worst-case scenario still aims to minimize cost through single- and joint-parameter optimization, but additional factors (e.g., higher cost of electricity, extent of heat integration, new technology multiplying factors, equipment quotes) elevate additional cost components, leading to a higher total cost. These estimates yield capture costs of $147-264/tCO2 for natural gas–fueled systems and $140-254/tCO2 for coal-fueled systems (Table 5.4). The estimated net costs per CO2 removed are $199-357/tCO2 for natural gas–fueled systems and approach infinity in the case of coal-fueled systems, because more CO2 is generated than captured.

___________________

9 Because costs for compression, transportation, injection, and storage for CO2 captured both through bioenergy with carbon capture and sequestration (BECCS) and direct air capture are assumed to be approximately the same, the report discusses them once in Chapter 7 and again Appendix F.

TABLE 5.3 Estimated Capital (CAPEX) and Operating (OPEX) Costs for a Generic Liquid Solvent Direct Air Capture System with a Capacity of 1 Mt/y CO2 Removal

| CAPEX | Cost ($M) | Comment |

|---|---|---|

| Contactor array | 210–420 | Lower bound: reported cost of air contactor array from Holmes and Keith (2012), based on optimal percent capture of 75% and bed depth of 6-8 m and PVC packing material at ca. $250/m3. Upper bound: projected cost of re-optimized Keith and Holmes configuration using stainless steel packing ($1,500/m3), shallow packing bed (3 m), and 1.5 × new technology cost factor. |

| Slaker, causticizer, clarificator | 130–195 | Lower bound: capital costs taken from Socolow et al. (2011) and adjusted to 2016 USD. Upper bound: 1.5× factor to account for new technology. Though the Ca-recovery cycle is mature and well studied in the pulp and paper industry, learning costs may be associated with integration into a direct air capture system. |

| Air separation unit and condenser | 65-100 | Lower bound: calculated from scaled CAPEX reported for air separation unit (ASU) in the integrated environment control model (IECM; Rubin et al., 2007) integrated gasification combined cycle (IGCC) process. Upper bound: 1.5 × factor applied for integration with calcination in direct air capture system. Condenser cost scaled from IECM estimate and assumed negligible ($300K) relative to ASU and other components |

| Oxy-fired calciner | 270–540 | Lower bound: price quote from industry source with 4.5 × factor used for scaling inside battery limits (ISBL) equipment costs to full costs (Socolow et al, 2011). Upper bound: calciner price quoted in Socolow et al. (2011), with 4.5 × factor applied. Note: one would need oxy-fired natural gas and coal kilns for each case, and commercial viability of these are unknown. |

| CAPEX Subtotal ($M) | 675-1255 | |

| CAPEX Annualized ($M/y) | 81-151 | Assumes a plant life of 30 years and fixed charge factor of 12%. |

| OPEX | Cost ($M/y) | Comment |

|---|---|---|

| Maintenance | 18-33 | Range calculated as 0.03 of total capital requirement. |

| Labor | 6-10 | Range calculated as 0.30 of maintenance cost. |

| Makeup and waste removal | 5-7 | Lower bound: assumes $500/t KOH, $250/t Ca(OH)2, $0.30/t H2O, $260/t waste disposal (Rubin et al., 2007). Upper bound: applies 1.5 factor to make up OPEX. |

| Natural gas | 25-35 | Range calculated from low and high thermal requirements reported in Table 5.2, assuming natural gas cost of $3.25/GJ. |

| Coal | 18-25 | Range calculated from low and high thermal requirements reported in Table 5.2, assuming 2016 U.S. average bituminous coal, $48.40/short ton, or $2.33/GJ. |

| Electricity | 12-28 | Range calculated from electrical requirements reported in Table 5.2, with electricity price of $60/MWh. |

| OPEX Subtotal (NG) | 66-113 | |

| OPEX Subtotal (coal) | 59-103 |

Although not accounted for in the current work, the compression of CO2 would add on the order of $8/tCO2 to the cost of net removal, which enables comparison to costs reported in the literature that do account for compression (Keith et al., 2018; Mazzotti et al., 2013; Socolow et al., 2011). The cost of net CO2 removed reported in the current work ($490-880/tCO2 removed) may be compared to the avoided costs reported in the APS study ($641-819/tCO2 avoided) and the related follow-up study of Mazzotti et al. ($510-568/tCO2 avoided). Mazzotti et al. considered three Sulzer packing materials: Mellapak-250 Y (also used in Socolow et al., 2011), Mellapak-500 Y, and Mellapak-CC, a novel stainless-steel packing material designed specifically for carbon capture. Optimization of the system around a specific packing material (Mellapak-250 Y) resulted in a 7 percent reduction in the avoided cost: $610/tCO2 (Socolow et al., 2011) vs $568/tCO2 (Mazzotti et al., 2013). Use of the advanced packing material (Mellapak-CC) resulted in an even lower avoided cost of $510/tCO2. Both Mazzotti et al. and APS assume a counter-flow configuration in the development of the pressure-drop relationship, which directly relates to the fan power required. This differs from that reported in Keith et al. (2018), which is based on a novel PVC-based packing material with a pressure-drop correlation assuming a cross-flow configuration. This

TABLE 5.4 Summary of Carbon Capture Costs for a Liquid Solvent Direct Air Capture System Powered by Natural Gas or Coal

| Cost ($/tCO2) | Natural Gas | Coal |

|---|---|---|

| Capture costa | 147-264 | 140-254 |

| Net-removed costb | 199-357 | ∞ |

| Produced cost, oxy-fired calcinerc | 113-203 | ∞ |

aBasis = 1Mt net CO2 removed from air.

bBasis = per net unit of CO2 removed with an average of 0.3 Mt CO2 for natural gas and zero for coal.

cBasis = per net unit of CO2produced including co-capture of CO2 from natural gas oxy-fired kiln with an average of 1.3 Mt CO2.

plastic packing is approximately one-sixth the cost of the metal packing assumed in APS and is expected to have a significantly lower pressure drop (ca. 10 pa/m) when compared to more commonly examined metallic packing materials (ca. 100 pa/m). If the plastic packing proves to be durable enough to withstand the caustic solvent over the life of the plant, the APS capital expenditure (CAPEX) estimate would decrease by nearly $15/tCO2 before considering system optimization. Additionally, a two-thirds reduction in operational energy expenditures on fan power may be achieved via the reduced pressure drop, resulting in an additional cost savings of $7/tCO2 assuming electricity from natural gas at $60/MWh. This emphasizes the need for demonstration-scale projects in this field so that novel materials for packing, such as plastics coupled to unique configurations such as cross-flow, can be tested and verified.

An additional difference in the APS system design is the vertical absorber approach with an array of 330 squat scrubber towers with a total cross-sectional area of 37,000 m2. Though quoted at 50 percent capture, the higher air velocity (2.0 m/s vs 1.5 m/s considered here) yields a cross-sectional area comparable to the system described in this report (38,000 m2). However, the design of 330 squat towers is shown to be capital intensive with a total installed cost of $1.3 billion—roughly 60 percent of the total system cost. Conversely, Holmes and Keith (2012) demonstrated a total installed cost of about $150 million for an array of 10 air contactors with the design shown in Figure 5.2. Finally, the APS reported a calciner with an installed cost of $540 million. However, industrial calciners with output compatible with 1Mt/y CO2 capture systems may be purchased for about $60 million, leading to a total installed cost of $270 million—50 percent less than the cost reached by the APS study.

As previously discussed, Keith et al. (2018) suggest that these differences may be partially due to the design configurations, such as PVC packing coupled to a cross-flow

configuration compared to metal packing coupled to a counter-flow configuration, with the former resulting in a lower pressure drop in addition to reduced capital expense in addition to the horizontal absorber design and extensive heat integration. Although new materials and configurations may result in reduced costs, without the opportunity to test them under realistic conditions (e.g., real environment and extended time), it will be difficult to realize the lower bounds of these cost estimates. The current work accounts for these previous studies (Keith et al., 2018; Mazzotti et al., 2013; Socolow et al., 2011) and provides a broad range of energies and costs that encompasses all of the steps in the solvent-based separation process. The broad range of energies and costs confirms the need for R&D in this space so that a true baseline cost for direct air capture may be established.

In addition to natural gas and coal resources for fueling the direct air capture plant, the committee also considered a low-carbon route based on solar photovoltaics (PV) and electrolytic H2 to meet the power and heat requirements, respectively, in an attempt to minimize “x” in the cost factor of the equation on page 194. The committee also investigated an additional route based purely on solar PV with the assumption that an electric-fired kiln is used for the calcination process; the cost details are presented in Appendix D. Table 5.5 details the capital, operating, and maintenance costs based on this low-carbon scenario, which results in an average net removed CO2 cost range of $317-501/tCO2.

In terms of the capital expense, the primary differences for this pathway is the replacement of an oxy-fired kiln with the H2-fired kiln, the absence of an air separation unit, use of an electrolyzer for H2 production, use of a compressor and pressurized storage tank for on-site H2 storage, and the installation of PV modules, inverters, and battery storage for on-site electrical generation. The energy requirements for operating fans, solvent pumps, slaker, causticizer/clarifier, and gas cooling unit (see Table 5.2) are used as input parameters to determine the energy costs of PV solar, including battery storage so that the system operates continuously. Further, a water flow rate of 5.7 ×105 t/y H2O is needed to produce an average of 4.15 kmol/hr H2 to then produce the heat required for a direct air capture plant designed to remove 1 Mt/y CO2. The energy required for electrolysis dominates the energy operating costs as shown in Table 5.5, followed by the H2 compression energy required.

TABLE 5.5 Economic Costs Associated PV, Storage, and H2-Fired Calciner for Solvent-Based Direct Air Capture

| CAPEX | Cost ($M) | Comment |

|---|---|---|

| Contactor array | 210-420 | Lower bound: reported cost of air contactor array from Holmes and Keith (2012), based on optimal percent capture of 75%, bed depth of 6-8 m, and polyvinyl chloride (PVC) packing material at ca. $250/m3. Upper bound: projected cost of re-optimized Keith and Holmes configuration using stainless steel packing ($1,500/m3), shallow packing bed (3 m), and 1.5 × new technology cost factor. |

| Slaker, causticizer, clarificator | 130-195 | Lower bound: capital costs taken from Socolow et al. (2011) and adjusted to 2016 USD. Upper bound: 1.5 × factor to account for new technology. Though the Ca-recovery cycle is mature and well studied in the pulp and paper industry, learning costs may be associated with integration into a direct air capture system. |

| H2-fired calciner | 360-720 | Lower bound: price quote from industry source for oxy-fired kiln with 6 × factor used for scaling ISBL equipment costs to full costs and to account for new technology. This may be too low due to the uncertainty of the commercial availability of a H2fired kiln. Efficiency of 95% assumed. Upper bound: calciner price quoted in Socolow et al. (2011), with 6 × factor applied to account for new technology. |

| Condenser | 0.3 | Condenser cost scaled from IECM estimate and assumed negligible ($300K) relative to other components. |

| Water | 1.1 | Water investment at $2/t at 3.6×103 - 4.7×103 kmolH2/hr, 5.7×105 tonnes water required per year, assuming negligible losses. |

| Electrolyzer | 260-420 | Alkaline (mature) $850-1,500/kW; assuming HHV of 283.74 MJ/kmol H2 (IEA, 2015b) giving electrolyzer power requirement of 310-525 MW. |

| CAPEX | Cost ($M) | Comment |

|---|---|---|

| PV+battery | 865-1465 | Direct electricity needs, i.e., 33-73 kJ/mol CO2 for direct air capture processing, 430-730 kJ/mol CO2 for electrolyzer, and 51-68 kJ/mol CO2 for H2 compression. Assumes total installed cost of $2.2/WAC including PV modules and inverter, with battery storage adding an additional $15/MWh (Fu et al., 2017). |

| Compressor | 22-37 | 88% efficiency compression to 18MPa, $70/kWH2 (IEA, 2015b; Ogden, 2004). |

| Pressurized tank | 73-207 | $236-394/kWH2 |

| CAPEX Subtotal | 1,921-3,045 | |

| Annualized Capital Payment ($M/y) | 230-365 | Assumes a plant life of 30 years and fixed charge factor of 12%. |

| OPEX | Cost ($M/y) | |

| Maintenance | 58-91 | Range calculated as 0.03 of total capital requirement. |

| Labor | 17-27 | Range calculated as 0.30 of maintenance cost. |

| Makeup (H2O, KOH, Ca(OH)2) and waste removal | 5-7 | Lower bound: assumes $500/t KOH, $250/t Ca(OH)2, $0.30/t H2O, $260/t waste disposal (Rubin et al., 2007). Upper bound: applies 1.5 factor to make up OPEX. |

| PV+battery | 6.7-11.3 | Assumed as $18/kWac (Fu et al., 2017). |

| OPEX Subtotal | 87-136 | |

| Cost = Avoided Cost ($/tCO2 yr-1)a | ||

| PV+Storage+H2-Fired | 317–501 | |

a Basis = 1Mt CO2

Solid Sorbent Systems

Process Description

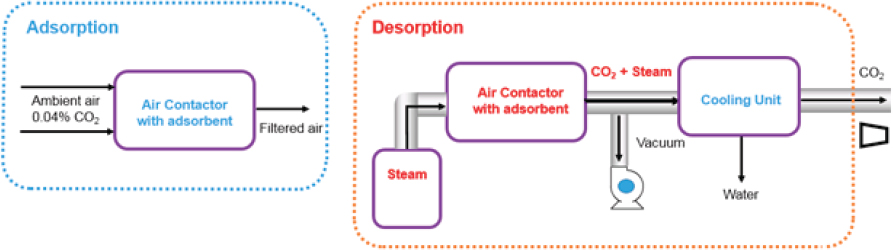

Like liquid solvent systems, solid sorbent direct air capture systems have two main processes: adsorption and desorption that operate cyclically (Figure 5.4). In these systems, air is blown through a solid adsorbent contained within an air contactor, where the CO2 in the air is adsorbed onto the solid adsorbent. Next, the solid adsorbent with CO2 is exposed to heat and/or vacuum to liberate the CO2 from the solid adsorbent. Finally, the solid sorbent is cooled before it is restarted.

Owing to the suitability of temperature swing adsorption (TSA) for capturing ultra-dilute species (Lively and Realff, 2016), the committee assessed a generic adsorption process employing either just TSA or TSA in combination with vacuum swing adsorption (VSA) to place probable bounds on energy consumption, CO2 emissions, and associated costs for solid sorbent systems.10 This section describes a generic, hypothetical process, as well as its estimated energy use and consequent CO2 emissions.

___________________

10 Such a process does not map to the humidity swing approach employed by Infinitree, as outlined in Table 5.1.

Unit Operations

Adsorption

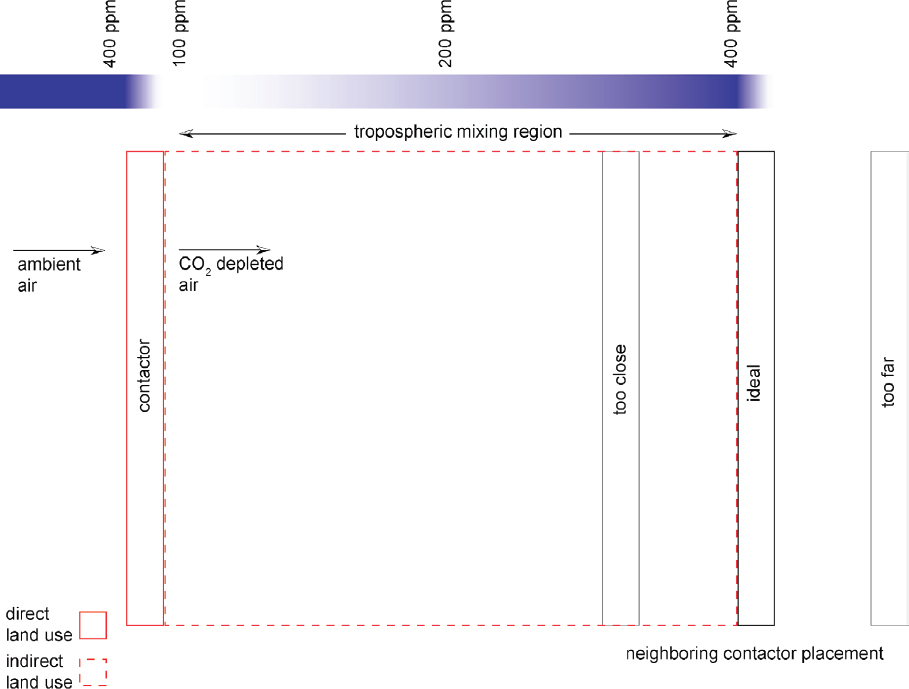

Air is blown through a solid structure (contactor) that contains a suitable CO2-adsorbing material and CO2-depleted air is emitted from the process. In the adsorber, the main contributor to energy use is the electrical energy required for fans to drive air through the contactor containing the solid sorbent. The primary driver for the energy consumption associated with this step is the pressure drop through contactor. This part of the process deviates substantially from the more often studied flue gas separations.

Desorption

After the solid sorbent has been saturated with CO2, it is moved to the desorber11 where heat (TSA) or heat and vacuum (TSA/VSA) systems are used to desorb CO2 (regeneration) and produce a concentrated CO2 stream. Regeneration is the most energy-intensive step for a solid sorbent direct air capture system and includes the thermal energy needed to induce CO2 desorption (ΔHads) and heat up the sorbent, contactor and other equipment (ΔHsens), as well as electrical energy needed for vacuum pumps (if employed). Energy consumption in the condenser is deemed negligible, although some heat could be recovered if integrated into steam generation, and is therefore not considered in this analysis. Overall, the energetics for this energy-intensive step of the process are the same as for a similar regeneration step in a process targeting a more concentrated feed (e.g., capture from flue gas). Because of the energy intensity, process design innovations for this desorption step can have a large impact on the overall process efficiency. Designs that give rapid heat transfer, as well as minimize the CO2 partial pressure over the adsorption media, are advantageous, providing both concentration and thermal driving forces for CO2 desorption.

Mass and Energy Balance

In general, solid sorbent system designs aim to (1) minimize pressure drop for flow through the air-sorbent contactor; (2) minimize contactor mass while maximizing sorbent mass (thus minimizing the sensible heat energy losses); (3) maximize the CO2

___________________

11 Or the adsorber is switched into desorption mode, if a single unit is deployed.

uptake; and (4) advantageously manage the water uptake.12 For the generic process considered here, key process parameters were varied within a physically realistic range (Table 5.5). Adapting Realff and Kawajiri’s methodology (Sinha et al., 2017), the committee estimated individual contributors to the energy consumed in the process and the cost of CO2 capture.

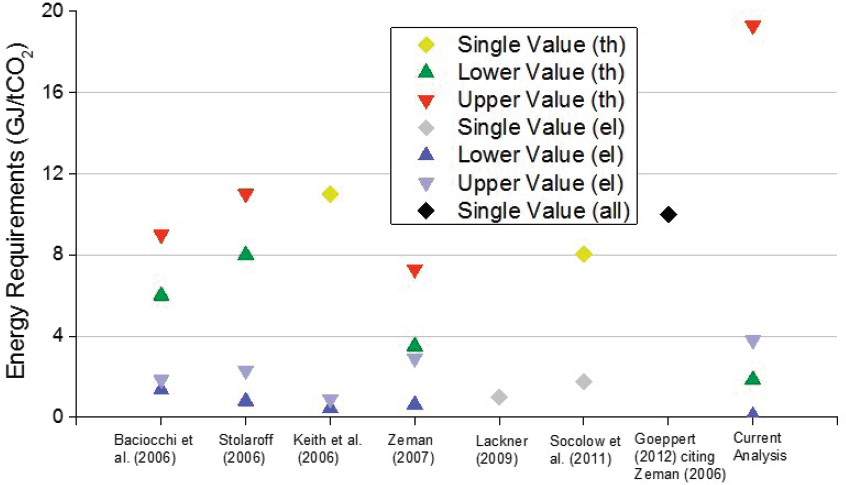

Estimated process energy intensities for the generic solid sorbent direct air capture system were obtained by varying each parameter within the range provided in Table 5.6. The calculated thermal and electrical energy requirements are reported in Table 5.7, with the associated CO2 emissions if the energy were provided by coal, natural gas, nuclear, wind, or solar reported in Table 5.8 (NREL, 2013). The electrical energy consumption was costed at an average grid price ($0.06/kWh) and the thermal energy cost was derived by considering the extra steam that would have to be produced to replace the electrical energy delivered from the condensing turbine of a power plant (Sinha et al., 2017). The estimated energy consumption falls in a similar range reported for other processes in the literature (Figure 5.5, Broehm et al., 2015).

Because of the possibility for wide variation in parameters, the committee considered five scenarios that represent different degrees of process optimization and performance (i.e., best case, low, mid, high, and worst case). The combination of every best-case parameter results in the lower bound (1-best), a scenario that may be unachievable because of correlations among various parameters, where optimizing one may move another away from an optimum (using currently known materials and approaches). Similarly, there are many ways to design a poor process with very high energy consumption. This scenario (5-worst) is presented here as an example where all the most pessimistic values were used. These two cases are shown for completeness, although the committee does not expect practical operation at either extreme. More realistically, three estimates using parameters in the middle of the range are provided (2-low, 3-mid, 4-high), where the descriptive words refer to anticipated carbon emissions and energy consumption. The approach used for these calculations is described in Appendix H, along with the specific parameters for each case.

An advantage of many recent solid sorbent–based direct air capture processes is that they do not require high temperature thermal energy. In an ideal scenario, the electrical energy needs should be met with renewable energy, and the thermal energy

___________________

12 For many sorbents, water uptake should be minimized to minimize the amount of water that must desorbed from the sorbent in each cycle, and its associated energy penalty. However, some adsorbents may benefit from co-adsorbing water, because CO2 uptake may increase, in which case water uptake must be managed advantageously. Water adsorption can also be managed to balance the production of fresh water as a coproduct.

used should be acquired from low temperature waste heat when such heat sources are suitable and available. Doing so helps to maximize net CO2 removal. Furthermore, use of waste heat could provide important stepping stones for early installations to operate with more privileged economics, potentially offsetting the disadvantage of being early on the technology learning curve. Nonetheless, because deployment that impacts negative emissions on a global scale will require heat and power, in all scenarios considered in this chapter, the energy used is sourced exclusively for the direct air capture process, and no assumption of waste heat use is made.

For each step in the solid sorbent direct air capture process, the CO2 emissions were evaluated under several scenarios, including providing the electrical energy from wind, solar thermal, nuclear, natural gas, or coal and thermal energy from solar thermal, nuclear, coal, or natural gas (Table 5.7). The calculated energy requirements suggest

TABLE 5.6 Model Parameters That Affect Estimated Performance of a Solid Sorbent Direct Air Capture Process

| Parameter | Units | Range |

|---|---|---|

| Inputs | ||

| Contactor to adsorbent ratio | kg/kg | 0.10-4.0 |

| Adsorbent purchase cost | $/kg | 15-100 |

| Adsorbent lifetime | y | 0.25-5.0 |

| Sorbent total capacity (at 400 ppm) | mol/kg | 0.5-1.5 |

| Desorption swing capacitya | mol/mol | 0.75-0.90 |

| Air velocity | m/s | 1-5 |

| Desorption pressure (VSA) | bar | 0.2-1.0 |

| Desorption final temperature (TSA) | K | 340-373 |

| Heat of adsorption (CO2) | kJ/mol | 40-90 |

| Outputs | ||

| Adsorption time | min | 8-50 |

| Desorption time | min | 7-35 |

| Mass transfer coefficientb | 1/s | 0.01-0.1 |

| Pressure drop | Pa | 300-1,400 |

aFraction of CO2 adsorbed that is desorbed and recovered as product.

bLumped linear driving force coefficient accounting for all resistances, see Appendix D.

NOTE: Some parameters (inputs) were varied within a physically realistic range, based on literature reports, and outputs were calculated from the model.

TABLE 5.7 Estimated Unit Operation Energy Requirements for Solid Sorbent Direct Air Capture Systems

| Step | Type | Energy Required (GJ/t CO2) | |

|---|---|---|---|

| Mid-Range (low-high, 2-4) | Full-Range (best-worst, 1-5) | ||

| Desorption heat (100°C sat. steam) | Thermal | 3.4-4.8 | 1.85-19.3 |

| Air contactor fans | Electrical | 0.55-1.12 | 0.08-3.79 |

| Desorption vacuum pump | Electrical | (110-140) x 10-4 | (4–910) x 10-4 |

| Total | 3.95-5.92 | 1.93-23.09 | |

Like liquid solvent systems, solid sorbent systems have a minimum work rate of 0.45 GJ/tCO2 to capture 60-75 percent CO2 from air to a 99 percent pure CO2 stream. Based on the energy requirements outlined for solid sorbent systems, the “real” work rate is 1.9-23.1 GJ/tCO2, leading to an exergy efficiency range of 2-24 percent, with the middle-range scenarios (2-low to 4-high) being 7.6-11.4 percent.

that the worst-case scenario (5-worst) would be unable to provide negative emissions under any scenario where fossil energy was used, even those that use renewable energy for electricity, because of the extensive thermal energy requirements provided by fossil energy. However, even the worst-case scenario that provided negative emissions uses solar thermal or nuclear energy for operation. By contrast, most other scenarios are substantially carbon negative, with the more realistic estimates (2-low to 4-high) being negative even when coal was used to provide all the energy (0.47-0.74 Mt CO2 emitted per Mt CO2 captured). While the use of coal to power a solid sorbent direct air capture system is not likely, it provides a useful worst-case emissions scenario, providing an upper bound to the problem. In the near term, one could envision rapid deployment using natural gas to provide thermal energy. Such a scenario yields a process with acceptable negative emissions (0.29-0.44 Mt CO2 emitted per Mt CO2 captured). Negative emissions drop further when renewable electricity is used (Table 5.7) and further still when thermal energy is generated from renewable sources. Nuclear energy provides another low emissions option.

Process Economics

As noted above, the cost estimates presented here are for the separation and capture of CO2 from ambient air from modestly optimized, generic direct air capture systems operating at 65-75 percent capture with highly concentrated CO2 product (~99 percent purity). These cost estimates reflect the total annual economic penalty incurred for removing 1 Mt CO2 from air on a per ton CO2 captured basis. Because additional CO2 emissions can be generated in several of the steps required in direct air capture systems, the net costs of CO2 removed are also presented. The cost estimates presented vary by energy source and do not account for compression, transportation, injection, and sequestration (see Chapter 7 on geologic sequestration). The estimated costs of CO2 capture for the range of scenarios considered are provided in Tables 5.9 and 5.10.

The two main phases of the cyclic adsorption process are shown above in Figure 5.4. In the adsorption phase, air is contacted with a solid structure that contains a suitable CO2-adsorbing material, with air depleted in CO2 being the exit stream from the process. In this step, key contributors to the process cost include (1) the energy required to pass the air over or through the adsorbing material, (2) the cost of the adsorbent, and (3) the cost of the contactor and other equipment, such as the fans that provide airflow. For routine equipment, such as the blowers and vacuum pumps, a factor of 4 was applied to the purchase cost to represent the total installed cost. For more innovative components, such as the gas-solid contactor, a factor of 6 was applied. It is instructive to compare the capital cost for the air-sorbent contactor between the solvent and solid sorbent cases. For the former, the total capital cost for the contactor ranges from $210 million to $420 million. For the latter, the total cost ranges from $13 million to $84 million. Considering that the solid sorbent case has a 10-fold higher surface area per volume, the order of magnitude of these costs is similar.

In the desorption phase of the process, heat (TSA) or heat and vacuum (TSA/VSA) are applied to the system to induce CO2 desorption and recover a concentrated product. This second step incurs substantially more operating costs, including costs associated with the energy needed to induce desorption (ΔHads), energy required to heat the sorbent, contactor, and other equipment (ΔHsens), and energy necessary to operate the vacuum pump, if such a pump is employed. Among capital costs, the costs of the pump and condenser are assigned to this step, whereas other costs are assigned to the first step. Adapting the methodology described by Realff and Kawajiri (Sinha et al., 2017), the committee estimated the individual contributors to the cost of CO2 capture for different parameter sets.

TABLE 5.8 Estimated CO2 Emissions Generated by a Solid Sorbent Direct Air Capture System That Removes 1 Mt/y CO2 Depending on Energy Source

| Step | Energy Source | Carbon Emissions (Mt/y CO2) | |

|---|---|---|---|

| Mid-Range (low-high, 2-4) | Full-Range (best-worst, 1-5) | ||

| Desorption heat | Solar | 0.008-0.01 | 0.004-0.04 |

| Nuclear | 0.004-0.005 | 0.002-0.02 | |

| Natural gas | 0.22-0.30 | 0.12-1.2 | |

| Coal | 0.32-0.44 | 0.17-1.7 | |

| Air contactor fans | Solar | 0.0004-0.008 | 0.0005-0.026 |

| Wind | 0.002-0.003 | 0.0002-0.012 | |

| Nuclear | 0.002-0.004 | 0.0002-0.013 | |

| Natural gas | 0.07-0.14 | 0.01-0.47 | |

| Coal | 0.15-0.3 | 0.019-1 | |

| Vacuum pump | Solar | (0.93-1.9) x 10-6 | (0.0015-2.8) x 10-5 |

| Wind | (0.47-0.7) x 10-6 | (0.0059-13) x 10-6 | |

| Nuclear | (0.47-0.93) x 10-6 | (0.0059-14) x 10-6 | |

| Natural Gas | (1.6-3.3) x 10-5 | (0.029-50) x 10-5 | |

| Coal | (0.35-0.7) x 10-4 | (0.0056-10.8) x 10-4 | |

| Total | Solar/solar | 0.0084-0.018 | 0.0045-0.066 |

| Nuclear/nuclear | 0.006-0.009 | 0.0022-0.032 | |

| Solar/natural gas | 0.22-0.30 | 0.12-1.2 | |

| Wind/natural gas | 0.22-0.30 | 0.12-1.2 | |

| Natural gas/natural gas | 0.29-0.44 | 0.13-1.67 | |

| Coal/coal | 0.47-0.74 | 0.19-2.7 | |

Note: Emission factors for different energy sources are referenced near the start of this chapter (NREL, 2013).

For a generic solid sorbent system, with all parameters varied within the ranges listed in Table 5.5, the committee calculated carbon capture costs ranging from $18/tCO2 to over $1,000/t CO2. The combination of every best-case parameter resulted in the lower bound (1-best), a scenario that is likely unachievable due to correlations among various parameters, where optimizing one may move another away from an optimum (using currently known materials and approaches). There are many ways to design a poor process with costs that exceed $1,000/tCO2, with the calculated upper bound in this parameter space designated as the worst case (5-worst). As noted above, three other, more realistic scenarios were also considered (2-low, 3-mid, 4-high). A description of the approach used for the calculations is provided in Appendix D, and the specific parameter used in each case are provided in Table 5.9. A sensitivity analysis of the impact of the various parameters is provided in Table 5.10. All five scenarios are shown, making it clear that the adsorbent CAPEX dominates the overall cost. In comparison, no other capital and operating costs are substantial cost drivers. This demonstrates the importance of adsorbent cost and lifetime, as well as the potential for adsorbent material innovations to further reduce costs.

As noted above, the cost estimates span a wide range. Disregarding the lower bound as not realistically achievable and the upper bound as prohibitively expensive, the middle range of scenarios is perhaps most instructive. These estimates yielded capture

costs of $88-228/t CO2 for a generic solid sorbent direct air capture system. It is plausible that these costs could be reached within the next decade, considering that Climeworks has reported a capture cost of about $600/tCO2 for its first generation commercial plant. From this point, costs should decline as process design and process operation improve, falling into the range calculated above.

This analysis of solid sorbent direct air capture systems reveals the following observations. First, processes that are not specifically optimized for direct air capture will generate costs that fall within the range estimated by House et al. (≥ $1,000/tCO2, 2011). Second, direct air capture processes that employ physically realistic process parameters designed for direct air capture systems can generate costs in the range of $100-600/tCO2. Third, large-scale processes (over 1 Mt/y CO2) employing known materials and gas-solid contactors in the most promising scenarios could generate costs close to $100/tCO2, though no such large-scale, continuously operating installation exists at this time.

Summary of Analysis of Solvent and Solid Sorbent Direct Air Capture Systems

Table 5.11 presents the estimated energy required for direct air capture, along with the CO2 footprint and net CO2 removal assuming a plant designed to capture 1 Mt/y CO2. Both liquid solvent and solid sorbent cases have been considered, with scenarios that vary to meet the electric and thermal needs of the direct air capture plant.

TABLE 5.9 Input Parameters Used for Cost Estimates for the Generic Solid Sorbent Direct Air Capture System, with Selected Outputs

| Parameters | 1-Best | 2-Low | 3-Mid | 4-High | 5-Worst |

|---|---|---|---|---|---|

| Adsorbent purchase cost ($/kg) | 15 | 50 | 50 | 50 | 100 |

| Adsorbent life (y) | 5 | 0.5 | 0.5 | 0.5 | 0.25 |

| Sorbent total capacity (mol/kg) | 1.5 | 1.0 | 1.0 | 1.0 | 0.5 |

| Desorption swing capacity (mol/mol) | 0.90 | 0.8 | 0.8 | 0.8 | 0.75 |

| Contactor to adsorbent ratio (kg/kg) | 0.1 | 0.1 | 0.2 | 1.0 | 4.0 |

| Desorption pressure (bar) | 0.2 | 0.5 | 0.5 | 0.5 | 1.0 |

| Outputs | |||||

| Final desorption temperature (K) | 340 | 360 | 360 | 360 | 373 |

| Cycle time (min) | 39 | 16 | 28 | 42 | 26 |

TABLE 5.10 Estimated Annualized Capital (CAPEX) and Operating (OPEX) Costs for a Generic Solid Sorbent Direct Air Capture System with a Capacity of 1 Mt/y CO2 Removal

| Parameters | 1-Best | 2-Low | 3-Mid | 4-High | 5-Worst |

|---|---|---|---|---|---|

| Adsorbent CAPEX | 3.6 | 70 | 122 | 186 | 988 |

| Adsorption OPEX | 1.3 | 9 | 12 | 19 | 4.3 |

| Blower CAPEX | 3.6 | 2.1 | 3.7 | 6.7 | 13.7 |

| Vacuum pump CAPEX | 4.5 | 2.6 | 4.7 | 8.5 | 17.4 |

| Steam OPEX | 2.5 | 2.2 | 2.4 | 3 | 43 |

| Condenser CAPEX | 0.03 | 0.07 | 0.075 | 0.1 | 0.4 |

| Contactor CAPEX | 2.2 | 1.3 | 2.3 | 4.1 | 8.4 |

| Vacuum pump OPEX | 0.3 | 0.2 | 0.2 | 0.24 | 0.3 |

Energy Requirements

The thermal component of the energy required to operate a direct air capture plant dominates the electric component because of the need for strong CO2-binding chemistry. The electricity required is used to operate fans and pumps and can be minimized through the design of a shallow contactor to minimize pressure drop through the system. The strong-binding chemistry is necessary to produce high-purity CO2 from dilute CO2 in the air, that is, approximately 400 ppm. The thermal requirement for regeneration of the material used for capture may be satisfied by burning natural gas directly, with the generated heat used for regeneration directly or indirectly through the production of steam. Another option for meeting the thermal requirement is H2 combustion, which results in zero CO2 emissions. It is clear from Table 5.10 that the thermal requirement for the liquid solvent system13 is significantly larger than that for the solid sorbent system. This is because the liquid solvent approach involves heating CaCO3 up to 900°C to produce high-purity CO2, while the temperature required for solid sorbent regeneration is much lower at approximately 100°C. The table presents a range of energy estimates for the solid sorbent–based approach.

The electric requirement is similar regardless of the approach. For the solvent-based approach, H2 combustion was also considered, with H2 produced through electrolysis. If using the grid mix of electricity, this approach increases that component

___________________

13 Solvent systems are not inherently disadvantaged compared to solid sorbent systems, and both can operate in high- or low-temperature regimes if the sorption/desorption chemistry is designed to do so.

TABLE 5.11 Summary of Estimated Energy Requirements, CO2 Footprint, and Carbon Capture for 1 Mt/y CO2 Liquid Solvent and Solid Sorbent Direct Air Capture Systems

| Direct Air Capture System | Energy Source | Energy Required (GJ/t CO2) | CO2 Generated (Mt/y CO2) | Net CO2 Avoided | Capture Cost ($/t CO2) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Electric | Thermal | Electric | Thermal | Electric | Thermal | (Mt/y CO2) | Captured | Net Removeda | |

| Liquid Solvent | NG | NG | 0.74-1.7 | 7.7-10.7 | 0.11-0.23 | 0.47-0.66 | 0.11-0.42 | 147-264 | 199-357 |

| coal | NG | 0.74-1.7 | 7.7-10.7 | 0.18-0.38 | 0.47-0.66 | 0-0.35 | 147-264 | 233-419 | |

| wind | NG | 0.74-1.7 | 7.7-10.7 | 0.004-0.009 | 0.47-0.66 | 0.34-0.53 | 141-265 | 156-293 | |

| solar | NG | 0.74-1.7 | 7.7-10.7 | 0.01-0.03 | 0.47-0.66 | 0.31-0.52 | 145-265 | 165-294 | |

| nuclear | NG | 0.74-1.7 | 7.7-10.7 | 0.01-0.02 | 0.47-0.66 | 0.32-0.52 | 154-279 | 173-310 | |

| solar | H2b | 11.6-19.8 | 7.7-10.7 | 0.01-0.03 | 0 | 0.99 | 317-501 | 320-506 | |

| Solid Sorbentc | solar | solar | 0.55-1.1 | 3.4-4.8 | 0.0004-0.008 | 0.008-0.01 | 0.892-0.992 | 88-228 | 89-256 |

| nuclear | nuclear | 0.55-1.1 | 3.4-4.8 | 0.002-0.004 | 0.004-0.005 | 0.91-0.994 | 88-228 | 89-250 | |

| solar | NG | 0.55-1.1 | 3.4-4.8 | 0.0004-0.008 | 0.22-0.30 | 0.70-0.78 | 88-228 | 113-326 | |

| wind | NG | 0.55-1.1 | 3.4-4.8 | 0.002-0.003 | 0.22-0.30 | 0.70-0.78 | 88-228 | 113-326 | |

| NG | NG | 0.55-1.1 | 3.4-4.8 | 0.07-0.14 | 0.22-0.30 | 0.56-0.71 | 88-228 | 124-407 | |

| coal | coal | 0.55-1.1 | 3.4-4.8 | 0.15-0.3 | 0.32-0.44 | 0.26-0.53 | 88-228 | 166-877 | |

a Assuming the use of an oxy-fired kiln to provide heat from natural gas in the calcination process, leading to greater CO2 production and hence lower cost of net CO2 removal, using a basis of 1.3 Mt CO2 for NG/NG, 1.2 Mt CO2 for coal/NG. (NG = natural gas).

b Assuming all hydrogen is produced via electrolysis using near zero-carbon power.

c Scenarios range from 2-low to 4-high.

significantly; however, the electricity could be sourced from carbon-free nuclear, wind, or solar, which would maximize the impact of this pathway to direct air capture.

Carbon Footprint

If the electricity or thermal energy requirements are met using fossil fuels, then significant CO2 emissions will result, thereby reducing the effect of a direct air capture plant in terms of CO2 removal from the air. The committee assumed a grid mix, carbon-free paths such as nuclear, wind, and solar thermal, and fossil-intensive paths such as coal and natural gas. The CO2 emitted from meeting the energy requirements increases as expected—from nuclear, wind, or solar thermal, to natural gas, and finally to coal as the source with the greatest CO2 emissions. Because the solvent-based approach regenerates CaCO3 in an oxy-fired kiln, it can easily capture the CO2 generated from burning natural gas to meet the thermal requirements in addition to maximizing the removal of CO2 from the air (Keith et al., 2018). In fact, on average, an additional 0.5 Mt/y CO is produced and captured along with the CO2 from air by condensing the exhaust mixture of CO2 and water vapor. In principle, any process can employ fossil energy with carbon capture from the energy emissions to reduce its carbon footprint, although at additional capital and operating costs. Such a scenario was considered here for the solvent case because it is an inherent part of the Carbon Engineering design.

Carbon Removal Cost

If fossil-based energy resources are used to provide the energy requirements of a direct air capture system, then an accurate estimate of the cost to removing CO2 from the air requires consideration of the net CO2 removed because burning fossil fuels produces CO2. On average, the costs for net CO2 removed for the solid sorbent–based approach range from $89 to $877/tCO2, depending on the adsorption scenario, while the costs range for the solvent-based approach range from $156 to $506/tCO2, depending on the use of natural gas or renewable H2 for the thermal source.

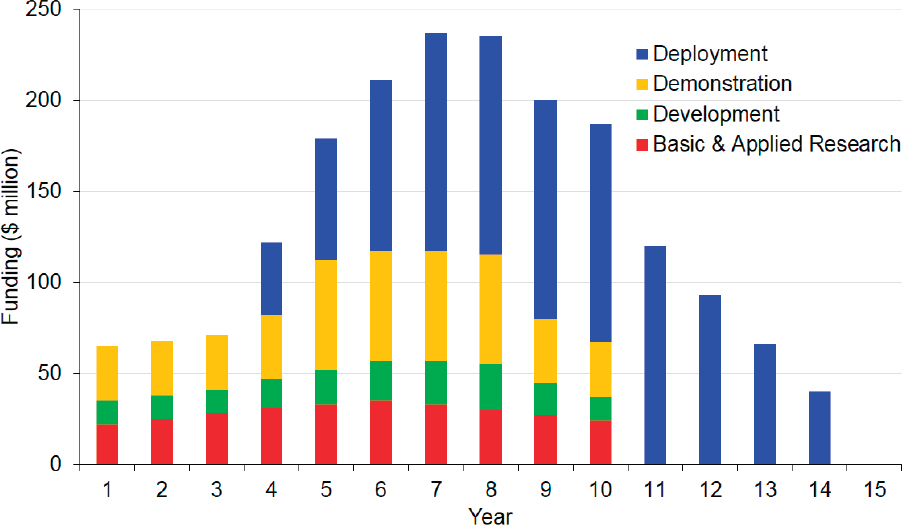

IMPACT POTENTIAL

The potential for direct air capture flux and capacity has no fundamental physical limit, making its primary limitation financial. The potential impact is limited by the investment required to scale direct air capture as well as the availability of geologic