2

Advanced Technologies for Offshore Oil and Gas Development: Resource Recovery, Environmental Stewardship, and Safety

The three keynote presentations and discussion summarized in this chapter provide an overview of practices and concerns associated with offshore development, well completion, and stimulation. Following the keynote presentations, Danenberger moderated a discussion between the panelists and workshop participants.

KEYNOTE PRESENTATIONS

From Exploration to Production: Offshore Oil and Gas Development and the Context of Unconventional Resources in the Offshore Environment

Evan Zimmerman, Offshore Operators Committee

Zimmerman explained that the primary impetus for offshore well completion design is sand control. He noted that high-volume hydraulic fracturing of unconventional formations, as is done, for example, for shales in the onshore, is not occurring offshore in the Gulf of Mexico. Offshore well completion activities are regulated extensively on both the operational and environmental sides. According to Zimmerman, because offshore completion operations occur by nature in remote areas, direct impact on public communities is minimized.

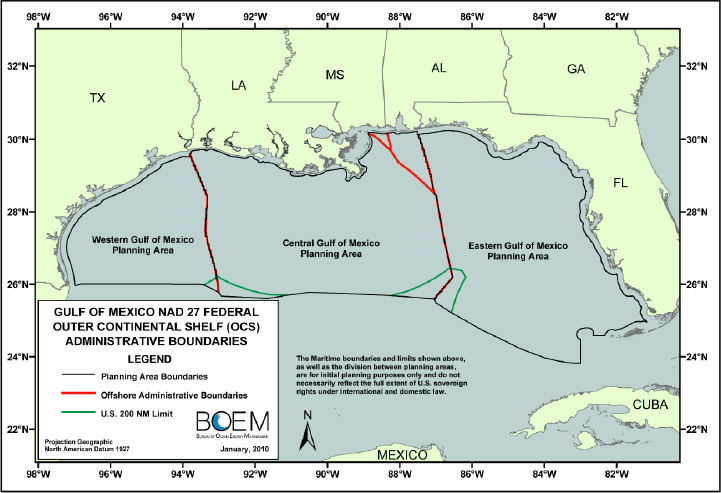

Zimmerman provided an overview of the Gulf of Mexico Outer Continental Shelf (OCS), which is divided into three regional planning areas: western, central, and eastern (see Figure 2.1). Overseen by several agencies,1 energy production in the Gulf of Mexico represents a significant portion of federally derived oil and gas production. As of 2014, the Gulf ’s production generated the second largest source of income to the U.S. Department of the Treasury behind tax revenues collected by the Internal Revenue Service, and, as of 2013, OCS activities have created approximately 700,000 jobs and generated $62 billion (DOI, 2014), he said.

___________________

1 Oversight agencies include the Bureau of Ocean Energy Management, the Bureau of Safety and Environmental Enforcement, the National Marine Fisheries Service, the Occupational Safety and Health Administration within the U.S. Department of Labor, the Office of Natural Resources Revenue, the U.S. Coast Guard, the U.S. Department of Homeland Security, the U.S. Department of Transportation, the U.S. Environmental Protection Agency, and the U.S. Fish & Wildlife Service.

He noted that offshore well completion activities for both consolidated and unconsolidated sands are governed by a number of environmental regulations and/or permits. For example, air emissions are regulated by the Bureau of Ocean Energy Management’s (BOEM’s) air quality review process or the U.S. Environmental Protection Agency’s (EPA’s) permitting process, depending on the location in the Gulf of Mexico in which the completion activities will take place. Emissions that fall under these reviews or permits include those from permanent and temporary engines, support vessels, flares, and other well completion activities.

Water discharges are regulated and permitted by the EPA through the National Pollutant Discharge Elimination System (NPDES). These permits contain specific testing requirements and limits for discharges from completion, treatment, or workover-type byproducts and are renewed every 5 years to incorporate changes or initiate industry studies, Zimmerman said. Waste disposal is regulated by the EPA (via the Resource Conservation and Recovery Act and the Solid Waste Program), the U.S. Department of Transportation, and the individual states. He added that if used completion or stimulation fluids fail to meet NPDES criteria for discharge, they are shipped to shore for disposal, reuse, or recycle under state regulations. Regulations from the Occupational Safety and Health Administration, the U.S. Coast Guard, and the Bureau of Safety and Environmental Enforcement (BSEE) protect the workers themselves.

In conclusion, Zimmerman explained that because human populations are located at some distance from the OCS, impacts to community health, and related issues such as noise, traffic, or light considerations are absent. OCS wellbores also do not affect onshore drinking water aquifers, he continued. Offshore operations comply with zonal isolation2 standards for water and hydrocarbon formations. Offshore operations primarily utilize seawater, although supplementary municipal water supplies from onshore Gulf States may be used occasionally.

___________________

2 Zonal isolation involves placing cement barriers in the wellbore to prevent fluids such as water or gas in one zone around the wellbore from mixing with fluids such as oil in another zone.

Overview of Well Completion and Stimulation Technologies in Offshore Settings

David Payne, Chevron Corporation

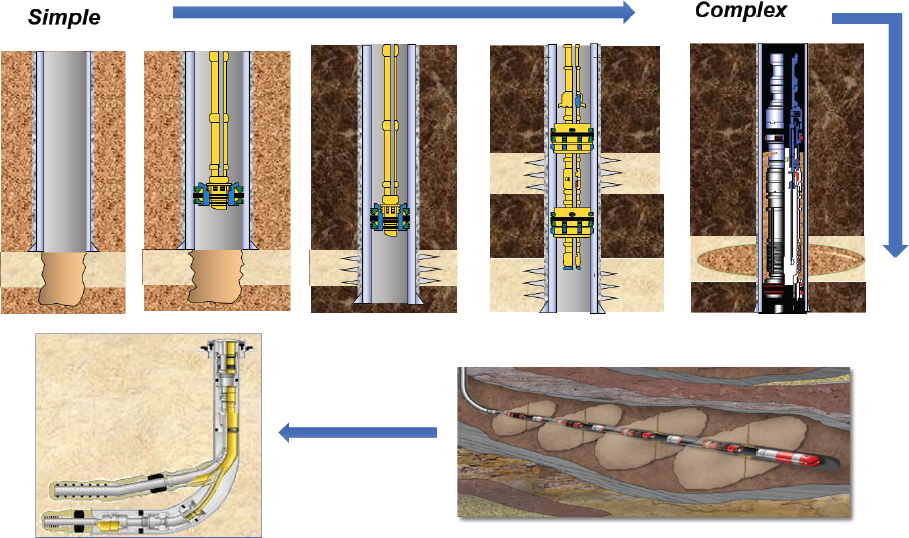

Payne discussed a variety of well completion activities. He emphasized that while drilling is important, if completions are not done correctly, it is impossible to deliver the OCS oil or gas production needed to make wells economically sustainable. He explained that many different types of completions exist to address the requirements of the individual wells (see Figure 2.2). The simplest approach, an open-hole completion, is utilized only occasionally. Perforation through casing is another simple approach, best used for competent formations that do not need artificial support to maintain a borehole and thus do not require sand control. Two complex approaches that are used for sand control are the gravel pack and the frac pack. A gravel pack uses sieved sand as a filter to prevent formation sand from entering the wellbore, while the frac pack combines the gravel pack with hydraulic fracturing to create wide fractures filled with sieved sand that aid in connecting the reservoir to the wellbore.

Payne mentioned that open-hole sand control can be performed in many ways, the simplest of which is to put a standalone screen into the wellbore. This screen can be made of mesh, sand, or a series of rods. Proppant is not used in open-hole sand control, and sand is not pumped into the formation; sand is only present to filter fine-grained formation materials and prevent them from entering the tubing and being produced with the fluid. This process works best in wells with uniformly sorted sands. More recently, the industry has developed expandable screens: placing a screen against the sandface stops all sand movement, thus preventing the collapse of sand into the wellbore. This approach facilitates production, Payne said.

Sand control for cased boreholes3 can be accomplished with the use of gravel packs, high-rate water packs, and frac packs. The gravel pack forces the gravel to remain in the wellbore and fill the perforations. This approach enhances productivity. High-rate water packs push the sand farther into the formation and allow pressure to rise to a level that improves the overall productivity of the wellbore, Payne remarked. The frac pack, one of the most commonly used completion techniques worldwide (particularly in deepwater wells), can create a 50- to 250-foot fracture to stimulate production in the well. He noted that although it is possible for such fractures to grow vertically, the preferred method is to keep the fracture inside of the reservoir. He explained that all of these completion techniques can also be used in the onshore environment.

Payne described another completion technique, hydraulic fracturing, that is most appropriate for use in sandstone, tight rock, and shales. In hydraulic fracturing, significant volumes of fluid are pumped to generate fractures (up to several hundred feet in length), which are then kept open with proppant. He noted that the high cost of this approach can be prohibitive, especially in the offshore environment. Acid stimulation, another type of completion that has been used for decades, can be used to stimulate the formation. Acid stimulation can be achieved through matrix acidizing (i.e., pumping acid into the formation below fracture pressure to dissolve minerals in the rock and create flow path channels) or acid fracturing (i.e., pumping a viscous fluid into the formation at or above fracture pressure and pumping acid into each fracture to create flow path channels).

Payne concluded by observing that industry has been completing wells offshore safely for decades. Although the techniques have evolved, there has not been a dramatic change in the primary approaches used to complete offshore wells. He noted that all aspects of drilling have been and remain highly regulated in the offshore environment and that collaboration among industry, regulators, and environmental nongovernmental organizations is necessary to continue to access these energy resources.

Regulatory and Environmental Considerations for Offshore Development

William Y. Brown, Bureau of Ocean Energy Management

Brown explained that BOEM, in cooperation with BSEE, manages energy and mineral resources for the approximately 2.2 billion-acre OCS. Of that area, about 1.7 billion acres falls within the oil and gas planning area under BOEM’s purview.

BOEM evaluates mineral resource availability and economics, handles permits, leases offshore blocks, approves plans for exploration and development on lease blocks, sets financial

___________________

3 A cased borehole is one that has had a pipe inserted into a section of the borehole and is typically cemented in place. The casing helps to isolate the oil or gas from communication with other fluids in the borehole or from contact with other fluids or rock formations along the wellbore.

responsibility for decommissioning facilities, and undertakes environmental research assessment and regulation. According to Brown, BOEM also provides environmental analysis to BSEE in support of its decisions and activities. BSEE, on the other hand, handles permits for drilling and authorizations for laying pipelines and decommissioning facilities at end of life; ensures that safety and environmental requirements are implemented fully by operators; and maintains engineering expertise needed to carry out inspection and enforcement duties.

Brown highlighted BOEM’s resource development programs: (1) oil and gas, which make up the largest share of its work; (2) renewable energy, which currently focuses on wind energy; and (3) marine minerals (e.g., sand and gravel) and response to storm beach erosion. BOEM also leads a program that conducts environmental studies on the impacts of BOEM-authorized activities and evaluates impact mitigation options. This program ensures that environmental protection is at the forefront of BOEM’s decision-making processes.

The Outer Continental Shelf Lands Act (OCSLA) serves as the foundation for BOEM’s governance, Brown said. BOEM uses OCSLA’s environmental standards, in addition to other statutes and directives, as a guide to informed decision making. BOEM also uses the National Environmental Policy Act as a framework to analyze its authorized activities, to evaluate alternative approaches, and to create scientifically motivated mitigation strategies. BOEM’s oil and gas program begins with a 5-year national program of lease sales, moves to individual lease sales, reviews exploration and production plans, and then approves site development. Brown clarified that while BOEM leases blocks to companies and approves exploration, development, and protection plans, BSEE handles requests for facilities whose plans have already been approved by BOEM but that seek a permit to modify their wells.

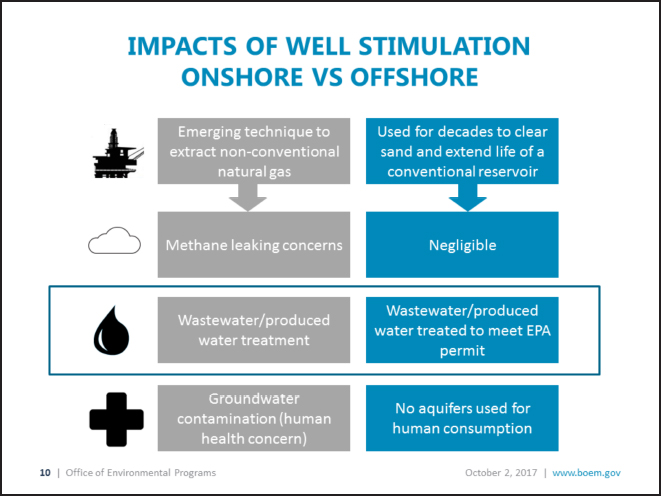

Brown defined well stimulation as any treatment of a well to enhance oil or gas production or recovery onshore or offshore, often involving fracturing by pressure from injected fluids or treatment with acid. He explained that well stimulation may affect air and water quality as well as people and biological resources, owing to the discharge of waste water containing small amounts of chemicals, release of greenhouse gases to the atmosphere, and induced seismicity. He explained that the potential for these impacts varies between the onshore and offshore environments (see Figure 2.3), emphasizing that well stimulation offshore, which has been in practice for decades, shows far fewer negative impacts than well stimulation onshore.

Brown shared some of the potential environmental impacts that BOEM considers before authorizing offshore activities, including oil spills, bottom disturbance obstructions, noise, air emissions, lighting, vessel traffic, and viewscape. While these are all valid concerns, he noted that BOEM has already developed mitigation strategies and that there are appropriate existing regulations to address these concerns. He emphasized that the addition of well stimulation with offshore oil and gas production generally lessens such environmental impacts—more energy can be recovered with less new infrastructure.

MODERATED DISCUSSION

A participant asked for clarification on the suggestion that methane emissions are negligible in the offshore environment and that completions onshore are the major source of methane emissions. The participant explained that the majority of methane emissions in the onshore environment correspond to the supply chain from production, not completion, and, with the addition of green completions, methane emissions have decreased overall in the on-

shore. He asked the keynote speakers if data have been collected in the offshore environment, using top-down or similar approaches that confirm that the emissions are actually negligible. Brown responded that data show fugitive methane emissions to be limited in the offshore environment, and that recent studies may suggest significant releases of methane in the onshore. Danenberger noted that there are clear differences in the offshore and onshore environments, adding that offshore production is much less dispersed than that onshore. He explained that in the offshore, production from a small group of large, modern facilities is managed effectively with careful inspection of potential release points. Brown acknowledged that the issue of emissions is worth further study and suggested the Gulfwide Offshore Activity Data System4 as a starting point for future discussions on pollutants, while Payne suggested that methane emissions could be the central focus of a future workshop.

Another participant asked about the differences in injection pressures between an offshore frac pack and an onshore shale gas well. Payne explained that, relative to the formations, injection pressures are generally higher in the onshore than in the offshore. In the offshore, the injection pressures are not as high relatively speaking because only small fractures, requiring lower pumping rates, are needed. Payne added that, depending on the depth of the offshore well, injection pressures can range from only a few thousand pounds per square inch (psi) to as high as 10,000 psi.

Another participant wondered how the panelists’ assessments might apply in Alaska where there are both fewer regulations than in the Gulf of Mexico and increasing opportunities for drilling in the Artic environment. The participant added that the use of fresh water for stimulation and hydraulic fracturing is a concern for Alaskans, especially in Cook Inlet.

___________________

4 Available at https://www.boem.gov/Gulfwide-Offshore-Activity-Data-System-GOADS (accessed November 22, 2017).

Payne responded that, from a completion perspective, the issues for Cook Inlet are similar to those in the western region of the Gulf of Mexico: it is important to ensure that discharges meet requirements of discharge permits and that contaminants are not being placed in the sea. OCS operations strive to use as much seawater as possible because the supply of fresh water is limited, and it would be too expensive to haul fresh water for stimulations. He encouraged industry to continue to identify approaches that use less fresh water. The participant noted that Cook Inlet has fewer discharge requirements than other coastal areas and suggested that there are areas in which industry could also strengthen standards.

Regarding active fracturing operations, a participant asked whether the operator or the drilling contractor bears responsibility. Payne emphasized that because decisions need to be made quickly during operations, the point of contact is identified before well stimulation begins. He explained that a drilling contractor is not responsible for decision making during the stimulation; the stimulation company makes decisions and, owing to the high costs and high impacts of such activities, OCS drilling and completion jobs are also monitored remotely. Danenberger added that Safety and Environmental Management System requirements make clear that operators are responsible and held accountable for everything that happens on a lease.

Another workshop participant asked the panelists to discuss how geological differences affect completions in the onshore and offshore environments. Payne noted that while there is no difference between the rocks onshore and those offshore, there is a difference in play types, especially in the consideration of shale plays, which generally are not seen offshore.

Continuing the discussion on the differences between the onshore and offshore environments, a participant asked whether there are different degrees for monitoring well completion quality. Payne responded that although quality may be monitored in different ways, the highest quality completion possible is desired in both environments. He added that the type of monitoring utilized depends on the size, cost, and setting of the well. To maximize production, for example, more money may be spent on a deepwater well than on an onshore shale well because the deepwater well itself was initially more costly. Wellbore integrity is a high priority in both environments, according to Payne, and decisions about monitoring center around the desire to avoid failure and prevent risk to the community and the environment. In response to the participant’s follow-up question about the regulatory role in monitoring well quality, Payne highlighted the high number of regulations in the offshore related to water discharge. Brown added that the OCS and the onshore environments are governed by different agencies and different laws, and Payne noted that onshore regulations can be especially difficult to navigate, owing to the high number of jurisdictions. Danenberger stated that BSEE reviews every completion program and reviews subsequent data, and he reiterated that quality control is an important and challenging issue in all environments.

Another participant asked about the future of offshore technologies, including possible innovations and their relationships to regulations. Zimmerman suggested that the current hydraulic stimulation and completion technologies and their corresponding regulations will still be valid in the future. Before new technologies are implemented offshore, a design technology review is completed. Thus far, Zimmerman explained, agencies have adjusted regulations appropriately based on potential risks of new technologies. He added that most new technology has proactively focused on safety and efficiency in the offshore—for example, offshore supply vessels run on natural gas to improve air quality and reduce emissions. Brown commented on the importance of performance-based innovation rather than design-based innovation,

given that performance relates most closely to risk. Payne added that outcome-based regulations may be more effective than prescriptive regulations, which could stifle innovation. He explained that the industry can also become more economically viable with innovations that limit infrastructure while increasing production efficiency, such as by joining remote fields into single hubs in the subsea infrastructure. Danenberger explained that the number of niche companies interested in taking advantage of oil and gas still in place is shrinking. For example, while there used to be approximately 4,000 platforms on the Gulf OCS, there are now approximately 2,000, only half of which are active. He added that because the industry functions more as a decommissioner (of old platforms) now, it is imperative to find new fields to tie back to existing production sites instead of creating new platforms.

In response to a participant’s inquiry about the use of desalination operations on platforms to generate fresh water, Payne explained that every rig operating in deep water has a desalination unit on board to generate its own fresh water, though the units are small and can generate only a limited volume each day. Most of this water will be used to support the rig, as opposed to sustaining drilling operations. When a larger volume is needed for drilling activities, Payne continued, water has to be hauled in from onshore at great expense. He reiterated that the rigs prefer to use seawater whenever possible.

Another participant asked the panelists to discuss how robotics, artificial intelligence, and remote sensing could impact the offshore environment. Zimmerman expressed confidence in the industry’s ability to find applications of such technologies as they mature and noted that drone technology is already regularly used to conduct offshore inspections. Payne suggested a better balance of regulation and innovation for the industry moving forward. He hypothesized that in the future drilling rigs could be run without people on board and that remote monitoring will improve safety and efficiency. Brown noted that the industry is especially interested in the use of remote sensing to reduce the cost of air quality monitoring in the offshore as well as the use of biological monitoring to better understand the environments. Danenberger recalled that the implementation of automation approximately 30 years ago significantly reduced the number of injuries from falls and falling objects in drilling operations, and he added that new technologies, such as the possibility of monitoring U.S. operations from abroad, raise broader questions about regulation and safety. Because information technology and big data stand to have the most substantial impact on the industry, Payne encouraged undergraduate programs to adapt curricula accordingly so as to better prepare future regulators and operators.