5

Breakout Sessions: Feedback and Future Directions for the DoD Manufacturing USA Institutes

The workshop was a highly interactive, collaborative activity designed to solicit honest feedback from a variety of institute stakeholders. During three lengthy breakout sessions, participants were split into groups and asked to respond to specific prompts related to their experiences with the institutes and potential priorities for future changes.

BREAKOUT SESSION 1: VALUE AND COST OF PARTICIPATION IN THE DOD MANUFACTURING USA INSTITUTES

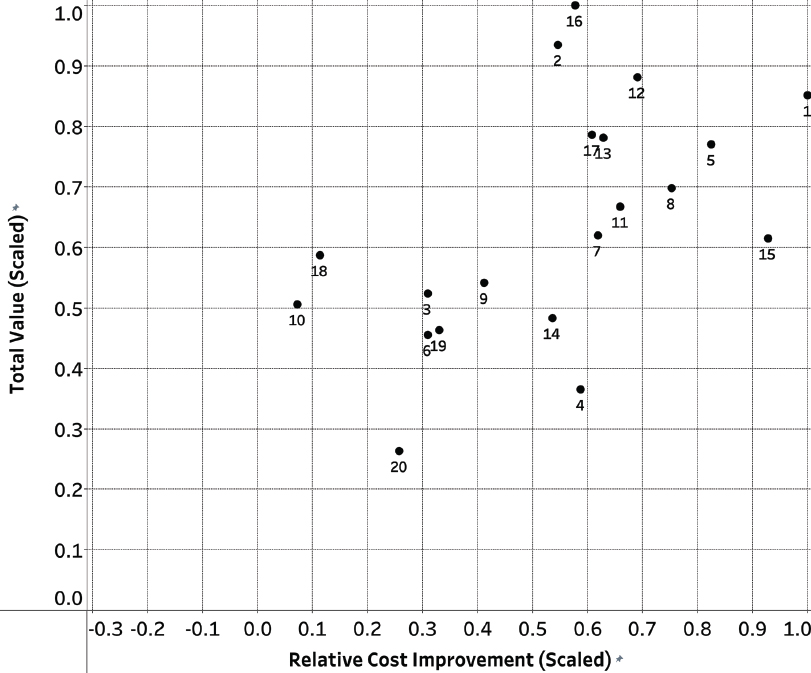

For the first breakout session, participants were divided into groups by sector: Department of Defense (DoD) institutes, industry, academia, and other government agencies or stakeholders. Participants were given a list of 20 offerings of the DoD Manufacturing USA institutes as focal points for group discussions (see Table 5.1; note that offerings were referred to by number throughout the workshop). Each group chose a representative; identified attributes of the offerings that delivered the greatest value to them as a group; assessed each individual offering in terms of technology development, technology diffusion, and education and workforce development (EWD); and then ranked offerings on a value-and-cost map. Workshop participants then reconvened and shared the outcomes of their breakout group discussions.

TABLE 5.1 Offerings of the Department of Defense (DoD) Manufacturing USA Institutes

| Offering | Generic Offering | Description | Funding Type |

|---|---|---|---|

| 1 | Technology R&D Roadmaps | Member and customer workshops to create and maintain R&D roadmaps | Core |

| 2 | Member-Driven R&D Projects—Shared Cost, Risk, and Results (IP) | Projects defined and executed by participating institute members | Project |

| 3 | Contracted DoD Customer R&D Projects with Cost Share | Projects defined by DoD and executed by selected institute members | Project |

| 4 | Contracted Customer R&D Projects with No Cost Share | Projects defined by DoD and executed by selected institute members | Project |

| 5 | Technology Standards Roadmaps and Coordination | Member and customer workshops to create and maintain technology standards development roadmaps | Core |

| 6 | Technology Consulting Services | Technology consulting provided by the institute to members and nonmembers | Core or Project |

| 7 | Rapid Prototyping/Pre-production Services | Contracted rapid prototyping/preproduction services executed by the institute | Project |

| 8 | Use of Institute Equipment | Contracted use of institute equipment by members and nonmembers | Project |

| 9 | Updates on SOA Technology | Technology SOA updates via member meetings, webinars, and online website | Core |

| 10 | Technical Papers and Publications | Project technical reports, professional journal publications, trade magazine articles | Core or Project |

| 11 | Data Coordination and Dissemination | Coordinate creation and collection of R&D findings using a data management and repository system accessible online by members | Core |

| 12 | Networking and Collaboration Opportunities Amongst Industry, Academia, and Government Members and Other DoD Institutes | Includes member meetings, conferences, workshops and member visits, and coordination/collaboration meetings with other DoD institutes | Core |

| 13 | Creation of Regional Institutes/Hubs and Technology Ecosystems | Create and oversee regional institutes/institute hubs to develop technology ecosystems in multiple regions | Core |

| 14 | Use of NIST MEP Program to Reach SMEs | Partner with MEP Program network of centers to transition institute technology to SMEs | Core |

| Offering | Generic Offering | Description | Funding Type |

|---|---|---|---|

| 15 | Education and Workforce Development Roadmaps | Member and customer workshops to create and maintain technology education and workforce standards development roadmaps | Core |

| 16 | Institute Internships and Apprenticeships | Coordinate and execute technology internship and apprenticeship programs with members and within the institute | Core |

| 17 | Technology Hands-on Training and On-Site Courses (K-12, Veterans, DoD, Industry) | Develop and execute technology hands-on training and education courses at the institute or customer site (No charge for K-12 tours) | Core and Project |

| 18 | Technology Education Online Courses | Develop and manage online technology education courses | Core and Project |

| 19 | Technology Overview Courses for Government and Industry Executives and Leaders | Develop and execute contracted technology overview courses for government and industry executives and leaders | Project |

| 20 | Job Postings | Online technology job postings and references | Core |

NOTE: IP, intellectual property; MEP, Manufacturing Extension Partnership; NIST, National Institute of Standards and Technology; R&D, research and development; SME, small and medium-size enterprise; SOA, state of the art.

OTHER INSTITUTE OPERATING COSTS (OVERHEAD AND G&A) THAT REQUIRE FUNDING:

- Facility rent/depreciation (building, furnishings, computer network, etc.)

- Equipment and software (office and technical) maintenance and depreciation

- Secure website and data storage

- Utilities

- Office indirect support staff

- Accounting

- Employee benefits (health insurance, vacations, etc.)

- Non-project travel

Overarching Trends

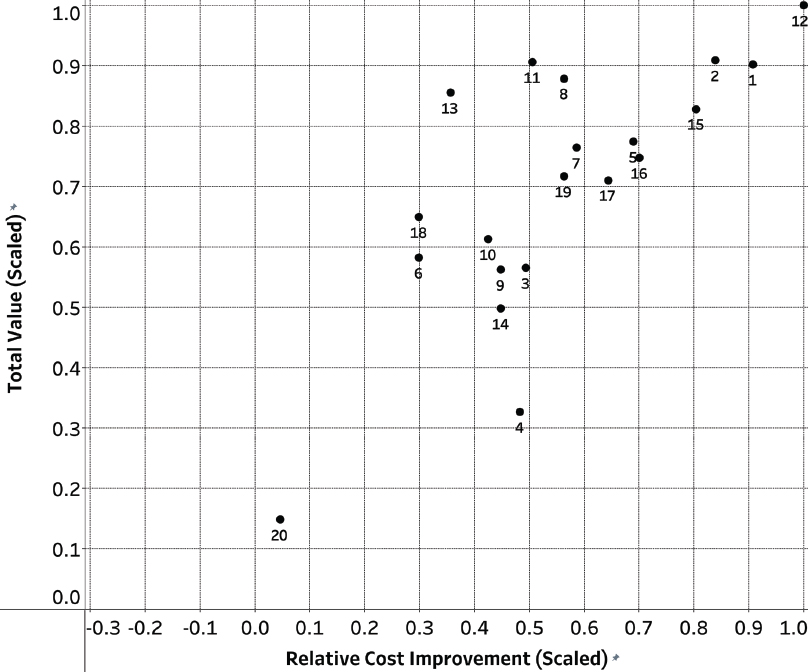

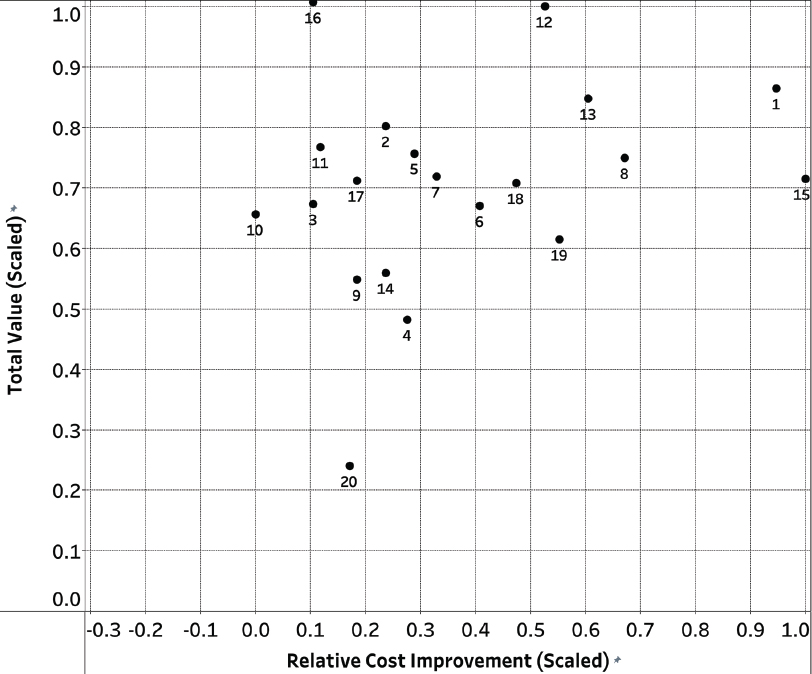

Offerings 1, 2, 7, 8, 9, 11, 12, 13, 15, 16, 17, and 19 were considered by many to achieve high value and high (or high-to-neutral) cost improvement1—the most desired category. Among these, the greatest level of agreement among groups was seen in the rankings of offerings 1, 12, and 15. Offerings 4, 9, 10, and 20 were generally designated as low value and low cost improvement, with the strongest level of agreement around the ranking of offering 20. There was much greater variation between groups with regard to ranking the other offerings.

In terms of value, all groups placed high value on offerings 1, 2, 5, 12, and 13, although they varied with regard to the perceived cost of these offerings.

Feedback by Sector

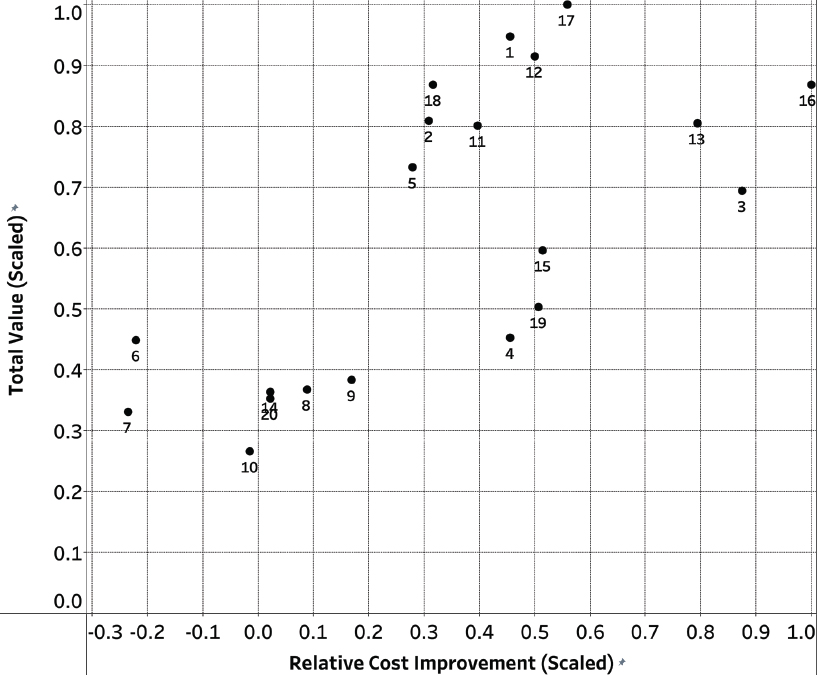

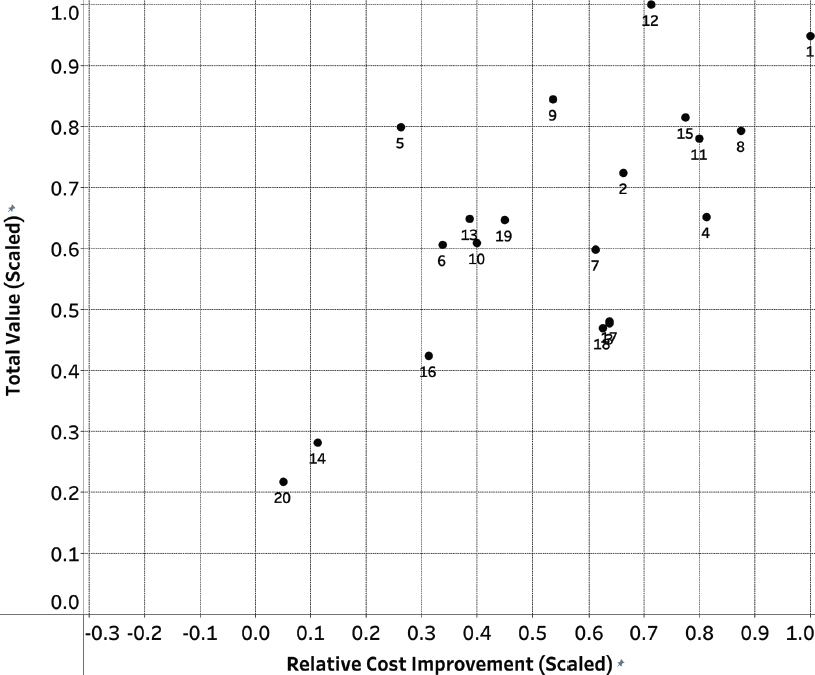

Breakout groups’ rankings of the 20 offerings in terms of cost and value are presented in Figures 5.1, 5.2, 5.3, 5.4, and 5.5.

From the perspective of increasing the acceleration of technology adoption, the breakout group representing DoD institutes rated offerings 5, 7, 8, and 9 to be important. Offerings 2, 3, 4, 7, and 8 are key to getting projects off the ground, de-risking development, and reducing the risk for small and medium-size enterprises (SMEs). The group noted that offerings 1, 2, 3, 4, and 12 are key to engaging diverse stakeholders as well as the creation of a sustainable supply chain. To advance EWD, which this group considered to be a foundational priority, offerings 15, 16, and 17 were identified as critical.

Like other groups, participants representing DoD ranked offerings 17 and 16 and their implementation highly. They emphasized that offerings 7 and 13 together can enhance technology advancement and adoption. While this group agreed that a roadmap is needed, they noted that creating one also requires creating a consistent, institute-wide vision to clarify funding sources and priorities. They also emphasized that offerings 5 and 3 are important to creating unity and consistency, with offering 5, standards development, being especially important to reduce fears related to intellectual property (IP) theft so that new technologies can make an economic impact.

The industry breakout group included a mix of large and small companies, a fact which they said influenced their approach to the rankings. Offerings they ranked as bringing the highest value were 1, 5, 9, 12, and 15. Offerings ranked lowest on the value scale were 16, 14, and 20. The group was struck by the fact that workforce-issue offerings were ranked so low, especially given that industry in general places great emphasis on workforce development. One possible explanation

___________________

1 More than two stakeholder groups put the offering in the top quadrant.

is that some companies may lack awareness of the institutes’ workforce development initiatives. Another is that while workforce is of high value to industry, it is not central to their motivation in engaging with the institutes. Shared best practices could help improve workforce issues at the institutes and evolve into standard practices across the industrial ecosystem, the group noted.

According to the academia breakout group, offerings 1, 2, 5, 11, 12, 13, and 16 were the highest value and highest relative cost improvement (see Tables 5.2 and 5.3). They noted that offering 1, technology research and development (R&D) roadmaps, allows the community to set goals and visions for investments. Offering 6, technology consulting services, enables SMEs, who have fewer resources, to take advantage of wider R&D developments. Member-driven R&D projects, offering 2, are valuable because they help universities have a larger role in technology readiness levels (TRLs), especially at the local level. Networking, offering 12, spurs new collaborations and innovations between universities and companies, which academia values highly. Offering 16, apprenticeships, are viewed as powerful workforce development programs. Finally, technology standards, offering 5, requires so much information and technological maturity that there is a strong need for the institutes to play a major advisory role. Most of the offerings rated in the high value, low cost improvement category had to do with education. While they are valued, they are not seen as improving costs very much because education is being pursued to a large extent outside the institutes.

The final breakout group encompassed attendees representing federal agencies other than DoD, as well as additional stakeholders that did not fit in the other four sectors (see Appendix B for the full attendee list). This group highlighted synergies among the offerings—for example, institute equipment (offering 8) may be used for rapid prototyping (offering 7) after consulting (offering 6) has ensured proper equipment handling. Large-scale systems require coordination and hands-on training, especially if they are to be shared with SMEs, which is why this group rated all of the education offerings highly. The group also saw roadmapping as high value, especially when viewed as an opportunity to unite the institutes and integrate services. Offering 2, de-risking investments, is especially important for any size company working with new technologies, they noted. In the group’s view, offering 13, creation of regional hub-and-spoke centers, can advance the creation and dissemination of certain technologies, such as composites, which need more heavy equipment than digital manufacturing. Last, the group noted that, while open IP and data sharing enables advancement in a precompetitive environment, IP and data also need strong protections, creating a tension.

TABLE 5.2 Offerings Ranked Highest (top right quadrant) and Lowest (bottom left quadrant) by Each Stakeholder Group

| # | Offering | Highest Quadrant Count (High Total Value-High Relative Cost Improvement) |

|||||

|---|---|---|---|---|---|---|---|

| Institutes | DoD | Industry | Academia | Others | Total Count | ||

| 1 | Technology R&D Roadmaps | 1 | 1 | 1 | 1 | 1 | 5 |

| 2 | Member Driven R&D Projects—Shared Cost, Risk, and Results (IP) | 1 | 1 | 1 | 3 | ||

| 3 | Contracted DoD Customer R&D Projects with Cost Share | 1 | 1 | 2 | |||

| 4 | Contracted Customer R&D Projects with No Cost Share | 1 | 1 | ||||

| 5 | Technology Standards Roadmaps and Coordination | 1 | 1 | 2 | |||

| 6 | Technology Consulting Services | 1 | 1 | ||||

| 7 | Rapid Prototyping/Pre-Production Services | 1 | 1 | 1 | 3 | ||

| 8 | Use of Institute Equipment | 1 | 1 | 1 | 1 | 4 | |

| 9 | Updates on State-of-the-Art Technology and Services | 1 | 1 | 1 | 3 | ||

| 10 | Technical Papers and Publications | 1 | 1 | 2 | |||

| 11 | Data Coordination and Dissemination | 1 | 1 | 1 | 1 | 4 | |

| 12 | Networking and Collaboration Opportunities Amongst Industry, Academia, Government, and other DoD Institutes | 1 | 1 | 1 | 1 | 1 | 5 |

| 13 | Creation of Regional Institutes/Hubs and Technology Ecosystems | 1 | 1 | 1 | 1 | 4 | |

| 14 | Use of NIST MEP Programs to Reach SMEs | 0 | |||||

| 15 | Education and Workforce Development Roadmaps | 1 | 1 | 1 | 1 | 1 | 5 |

| 16 | Institute Internships and Apprenticeships | 1 | 1 | 1 | 3 | ||

| 17 | Technology Hands-on Training and On-Site Courses (K-12, Veterans, DoD, Industry) | 1 | 1 | 1 | 3 | ||

| 18 | Technology Education Online Courses | 1 | 1 | ||||

| 19 | Technology Overview Course for Government and Industry Executives and Leaders | 1 | 1 | 1 | 1 | 4 | |

| 20 | Job Postings | 0 | |||||

NOTE: DoD, Department of Defense; IP, intellectual property; MEP, Manufacturing Extension Partnership; NIST, National Institute of Standards and Technology; R&D, research and development; SME, small and medium-size enterprise.

| Lowest Quadrant Count (Low Total Value-Low Relative Cost Improvement) |

|||||

|---|---|---|---|---|---|

| Institutes | DoD | Industry | Academia | Others | Total Count |

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 1 | 1 | 2 | |||

| 0 | |||||

| 1 | 1 | 2 | |||

| 1 | 1 | ||||

| 1 | 1 | ||||

| 1 | 1 | ||||

| 1 | 1 | ||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 1 | 1 | 2 | |||

| 0 | |||||

| 1 | 1 | ||||

| 0 | |||||

| 0 | |||||

| 1 | 1 | ||||

| 1 | 1 | 1 | 1 | 1 | 5 |

TABLE 5.3 Highest and Lowest Total Value Offerings by Each Stakeholder Group

| # | Offering | Highest Total Value (*0.75) | |||||

|---|---|---|---|---|---|---|---|

| Institutes | DoD | Industry | Academia | Others | Total Count | ||

| 1 | Technology R&D Roadmaps | 1 | 1 | 1 | 1 | 1 | 5 |

| 2 | Member Driven R&D Projects—Shared Cost, Risk, and Results (IP) | 1 | 1 | 1 | 1 | 1 | 5 |

| 3 | Contracted DoD Customer R&D Projects with Cost Share | 0 | |||||

| 4 | Contracted Customer R&D Projects with No Cost Share | 0 | |||||

| 5 | Technology Standards Roadmaps and Coordination | 1 | 1 | 1 | 1 | 1 | 5 |

| 6 | Technology Consulting Services | 0 | |||||

| 7 | Rapid Prototyping/Pre-Production Services | 1 | 1 | 2 | |||

| 8 | Use of Institute Equipment | 1 | 1 | 1 | 1 | 4 | |

| 9 | Updates on State-of-the-Art Technology and Services | 1 | 1 | ||||

| 10 | Technical Papers and Publications | 0 | |||||

| 11 | Data Coordination and Dissemination | 1 | 1 | 1 | 1 | 4 | |

| 12 | Networking and Collaboration Opportunities Amongst Industry, Academia, Government, and other DoD Institutes | 1 | 1 | 1 | 1 | 1 | 5 |

| 13 | Creation of Regional Institutes/Hubs and Technology Ecosystems | 1 | 1 | 1 | 1 | 1 | 5 |

| 14 | Use of NIST MEP Programs to Reach SMEs | 0 | |||||

| 15 | Education and Workforce Development Roadmaps | 1 | 1 | 2 | |||

| 16 | Institute Internships and Apprenticeships | 1 | 1 | 1 | 3 | ||

| 17 | Technology Hands-on Training and On-Site Courses (K-12, Veterans, DoD, Industry) | 1 | 1 | 2 | |||

| 18 | Technology Education Online Courses | 1 | 1 | ||||

| 19 | Technology Overview Course for Government and Industry Executives and Leaders | 0 | |||||

| 20 | Job Postings | 0 | |||||

NOTE: DoD, Department of Defense; IP, intellectual property; MEP, Manufacturing Extension Partnership; NIST, National Institute of Standards and Technology; R&D, research and development; SME, small and medium-size enterprise.

| Lowest Total Value ()0.25) | |||||

|---|---|---|---|---|---|

| Institutes | DoD | Industry | Academia | Others | Total Count |

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 0 | |||||

| 1 | 1 | 1 | 1 | 4 | |

BREAKOUT SESSION 2: WHAT SHOULD THE DOD MANUFACTURING USA INSTITUTES KEEP DOING, STOP DOING, START DOING?

The second breakout session gave the same stakeholder groups the opportunity to reconvene and identify institute strengths, weaknesses, opportunities, and threats (a “SWOT” report), looking at both overarching patterns and examples from individual institutes. They then built on the SWOT analyses by examining each institute offering in terms of what should be started, stopped, or continued. After the stakeholder discussions, the groups reconvened and again shared their results.

Overarching Trends

While there were small differences, groups were largely in agreement with regard to strengths, weaknesses, opportunities, and threats as well as what should be started, stopped, or continued. Overall, participants placed the highest value on networking and collaboration and saw funding uncertainties and a lack of inter-institute consistency as the biggest weaknesses. Commonly cited strengths included networking and collaboration opportunities, access to shared resources in a low-risk environment, and a better understanding of DoD needs. Several groups identified key weaknesses as a lack of consistent standards or established best practices across the institutes, especially for IP or contracting, and a lack of secured future funding or sustainability models. Key threats identified by several groups included funding instability, inadvertent knowledge transfer outside the United States, and foreign competition in general.

In identifying opportunities for the institutes, there was quite a bit of agreement among the groups. Many raised the possibility for more cross-institute collaboration, more precise roadmapping, improved data coordination and dissemination, better communication among the institutes and with SMEs and supply chain partners, and expanded workforce training programs across the institutes.

There were also significant commonalities in participants’ views on what to start, stop, or continue. Multiple groups agreed that the institutes should keep using and growing their valuable network; roadmapping; coordinating efforts with DoD; sharing resources, knowledge, and equipment, especially with SMEs; working with standards bodies; and offering prototyping and EWD. Several groups recommended starting to initiate a cross-institute Grand Challenge; publicize institute resources; and create consistent shared practices, EWD programs, and IP policies. Several groups recommended stopping posting jobs, duplicating other efforts, and allowing IP leaks or knowledge transfer abroad.

Feedback by Sector

DoD Institutes

Maureen Toohey, BioFabUSA, represented the institutes’ group. The strengths they identified were the ability to quickly find and fill gaps, DoD funding, cross-industry collaboration, talent development aligned with technology development, DoD as both a stakeholder and a customer, bleeding-edge technology, deeply embedded knowledge, a strong industrial commons, strong networking, and the ability to leverage DoD investment. The weaknesses they identified included a lack of stability, high operating costs, an unknown future, and the need for broad knowledge and resources for continued support. They saw key opportunities to build stronger, more formal DoD connections; to go faster and deeper with every technology; to bring collective influence on Congress to advocate for the institutes; to encourage more collaboration across institutes; to expand the talent base via marketing; and to better align with DoD priorities. The group saw threats from China (to both national and economic security) and from Europe (to economic security), funding instability, loss of a domestic industrial base, increased foreign manufacturing investment, continued use of Broad Agency Announcements (BAAs) instead of nimble institute processes, and loss of DoD backing.

The group recommended that the institutes should keep or start growing their network, which is valuable for the entire manufacturing base and for engaging SMEs, creating relevant EWD, collaborating across institutes, and deepening DoDinstitute engagement. The only “stop” this group highlighted was to stop focusing on group membership numbers and instead use the quality of those members and the impact the institutes are having as a better metric of success.

DoD

Anthony Holden, Army, represented the DoD group. Strengths this group identified were networking and collaboration; shared equipment, expertise, facilities, and projects for both large companies and SMEs; access to supply chains, DoD, and other customers; and shared risk in a precompetitive environment. Weaknesses were inconsistent policies across institutes, especially for IP; a lack of communication and coordination between the institutes; a lack of a broader public awareness of the institutes; contracting delays; and cost-share and funding uncertainties. They identified opportunities for creating roadmaps, improving cross-institute collaboration and communication, creating a talent pipeline, and increasing the involvement of supply chain members. They noted that threats can come from outside the United States, including data or IP leaks and increased foreign R&D

budgets, or from within, especially if government funding changes or companies lose interest, perhaps due to a lack of proper IP protections.

The group suggested that the institutes should keep roadmapping, coordinating and integrating with DoD efforts, and aligning with DoD investments, all of which helps the broader U.S. manufacturing ecosystem. The group also recommended keeping the cost-share program, although there was disagreement as to what a better ratio (instead of 1:1) might be; continuing to work with standards bodies; and continuing to share institute equipment, making sure to publicize the equipment and capabilities so that they are fully utilized. In addition, the group emphasized that the institutes should keep offering EWDs, EWD roadmaps, internships, online education, and leadership courses, ideally integrating and aligning these efforts across different technology areas where possible.

Several items were identified for potential improvements: simplifying acquisition, socializing funding processes (if cost sharing ends), offering consulting services, and creating better on-ramps for working with the institutes. The group suggested that the institutes should improve how they provide access to and publicize their capabilities, be more workforce-centered, have a well-defined foreign engagement strategy, improve service strategies and collaboration, and bring critical capabilities to certain facilities to increase innovation.

The group suggested stopping the dissemination of institute or manufacturing information beyond the United States, including through the publication of papers; stopping MEP program engagement in favor of leveraging MEP expertise for transitions; stopping online education from reaching foreign countries; stopping duplicative efforts, such as in consulting services or EWD; and discontinuing job postings.

Industry

Nancy Stoffel, GE Research, represented the industry group. Strengths identified were as follows: a wealth and variety of collaboration partners, increased technology development due to shared risk and reduced competition, sharing expensive infrastructure as de-risking, visibility of DoD product needs, and an ability to align those with commercial needs. The group saw weaknesses in administrative areas, especially in a confusing lack of consistency across the institutes in IP issues, bidding, contracts, cost sharing, and membership conditions. The threats identified were a lack of long-term funding as a threat to sustainability; knowledge transfer to foreign entities, whether from foreign graduate students or offshoring practices; and keeping up with foreign investments in manufacturing.

The group identified an opportunity for all institutes to create shared benchmarks, especially those recommended in the U.S. Manufacturing Council’s 2016

report, Shaping the Future of the National Network for Manufacturing Innovation.2 Benchmarks, Stoffel suggested, will help all institute stakeholders define progress, make decisions about future projects and funding structures, and encourage a better understanding of the global landscape, all of which can be used to create metrics for individual projects.

The group recommended continuing roadmapping and supporting all projects, whoever is driving them, because doing so increases collaboration, moves technology forward, and decreases risk. They recommended a continued focus on noncompetitive R&D and working with standards bodies, which will help get new products certified and ready for manufacturing. In addition, they believe that the institutes should continue to offer technology consulting, make equipment available, provide updates on state-of-the-art technology (perhaps even creating a cross-institute newsletter that could keep other institutes informed and facilitate collaboration), and produce publications.

In terms of activities to improve or start, the group noted opportunities related to broader supply chain involvement, shorter contracting time, an IP policy that encourages commercialization, working with the National Science Foundation on publications, and improved data coordination and dissemination, perhaps through a centralized database and regional hub-and-spokes centers (two initiatives that NextFlex has recently developed that could serve as models for other institutes). In particular, the institutes could start virtual hubs, with design or simulation equipment, and improve internships and training, perhaps creating an online repository for trainings and technical information. The group identified only two offerings to stop funding, which were lower TRL projects and posting jobs; it was also noted that the institutes should also be careful not to encourage competition between members.

Academia

Julie Chen, University of Massachusetts, Lowell, spoke for the academia group. According to this group, networking opportunities and diverse partnerships are key strengths of the institute model. They noted that academia benefits when researchers apply their expertise to an actual problem, helping to drive commercialization. Key weaknesses include a lack of shared best practices, which leads to administrative headaches; challenges to creating cross-institute programs; a lack

___________________

2 U.S. Manufacturing Council, 2016, Shaping the Future of the National Network for Manufacturing Innovation: MC Recommendations for National Network for Manufacturing Innovation Best Practiceshttps://www.trade.gov/manufacturingcouncil/documents/MC%20Recommendations%20for%20National%20Network%20for%20Manufacturing%20Innovation%20Best%20Practices%20-%20August%203,%202016.pdf.

of clarity about funding and self-sustainability, which can impact whether people are willing to continue participating; divergent timelines (given the slow pace of grant cycles); and the drive to prioritize short-term projects, which is counter to academia’s more long-term approach.

The group identified opportunities to tell the institute story better, in terms of value to SMEs, original equipment manufacturers, DoD, and the federal government, and opportunities to create shared best practices, standards, and databases across the institutes, something no one group can do alone. They also noted the importance of internships and apprenticeships for workforce development and suggested that these should be expanded across all the institutes.

The group suggested that institutes should start emphasizing IP releases to enable domestic competitiveness, harnessing the institutes’ collective strength to create a structure that can make critical improvements across the whole landscape, updating management about institute benefits, and creating more standardization of platforms and coordination for all EWD programs. They recommended that the institutes should keep reaching out to SMEs, providing technical assistance, and providing access to equipment and capabilities. Key things to stop include IP leaks, overly bureaucratic measures, and required cost sharing, which, in the group’s view, harms the institutes’ sustainability.

Other

Carolyn Fries, Doolittle Institute, and Raj Manchanda, American Society of Mechanical Engineers, together represented the “other” stakeholder group. The strengths they emphasized were networking and rapid prototyping. Networking in particular is seen as so valuable that the group recommended that institutes should remove any barriers to it, such as by removing requirements for applications or fees. Weaknesses identified include a lack of consistency for funding, contracting, and other administrative functions. Key opportunities include increasing access to shared resources; improving inter-institute communication, data coordination, and data dissemination; expanding and coordinating training; and strengthening the apprenticeship opportunities into major workforce improvement programs, similar to the Fraunhofer model. Threats, in the group’s view, come from foreign competition and from a lack of clear funding structures, the lack of a vision for future sustainability, and the lack of a properly trained workforce.

The group suggested that the institutes should start a cross-institute Grand Challenge to facilitate collaborative and roadmapping skills. They recommended that institutes should stop competing with private consultants, focusing instead on how the institutes are different, and stop posting jobs. They recommended

continuing online education activities, with the caveat that these activities should not duplicate or compete with established players in this space.

BREAKOUT SESSION 3: LONG-TERM ENGAGEMENT MODEL OPTIONS FOR THE DOD MANUFACTURING USA INSTITUTES

For the third breakout session, participants were re-sorted such that each group contained representation from all sectors, with the goal of initiating new discussions and integrating input from stakeholders with different perspectives. Each group was tasked with evaluating the actions and attributes under each of DoD’s five Manufacturing USA Strategy goals. After completing the assignment, participants reconvened and reported on the strategies they believed would bring the institutes closer to meeting the goals. Similar to the structure used in the second breakout session, the outcomes were framed in terms of what the institutes should start, stop, or continue doing.

Overall, the institutes were judged to be performing adequately, with few obvious or extreme course corrections needed. However, many participants agreed that the institutes have enormous potential and should be performing at a higher level. There was a great deal of overlap in what the groups judged to be most crucial to improving the institutes: careful roadmapping; funding clarity; stronger alignment with DoD needs; more cross-institute collaboration, communication, and shared learning, especially in terms of EWD; more engagement with outside entities; and consistent, streamlined processes, especially for contracting. While making these improvements, participants suggested that the institutes also craft a compelling narrative of their successes to increase the visibility of Manufacturing USA and buoy themselves, DoD, industry, and the entire domestic manufacturing ecosystem.

Goal 1: Drive Impactful Advanced Manufacturing R&D

There were many suggestions for how to better reach Goal 1. Participants suggested that the institutes should continue supporting TRLs and manufacturing readiness levels, create roadmaps that include sustainment, engage with current partners, and focus on DoD as the priority customer. They recommended that institutes stop following traditional, slow contracting processes; funding nonapplicable or nonrelevant R&D; and competing with other laboratories or private equity.

Participants suggested that the institutes should create fast, flexible, efficient, and consistent contracting and acquisition policies; initiate follow-on funding for successful projects; build capacities for technology transfer; improve industry participation (especially at the SME level); start friendly precompetitive and foreign engagements; and work together on a Grand Challenge. Together, participants

posited, these activities can help create cross-institute synchronicity, developing a compelling narrative that communicates the success of the institutes as centers for advancing technology and piloting capabilities that prioritize DoD needs for warfighter safety and lethality, are aligned with DoD’s end goals, and are in turn prioritized by DoD.

Goal 2: Encourage the Creation of Viable and Sustainable Institute Business Plans

The groups had several suggestions for meeting Goal 2. Participants agreed that the institutes should keep assessing their business plans for cooperative opportunities and shared learning and keep ensuring that their work is relevant, forward-looking, and meets DoD needs. Participants suggested that institutes stop making short-term plans and short-term assessments, stop focusing on “sustainability” and create a true business plan, stop forced partnering with MEP, and stop using irrelevant metrics.

Participants identified several activities to start or improve in order to bring the institutes closer to this goal. These include improving inter-institute communication, engaging with other technology-focused organizations, and ensuring sufficient DoD resources and consistent funding. Also, participants suggested that the institutes should reduce the expensive reporting burden, start sharing lessons learned, leverage technologies and their IP to sustain institute funding, fast-track business technologies, and connect funding to Small Business Innovation Research (SBIR) and BAAs. They suggested that institutes increase their focus on EWD costs and cost sharing, roadmapping, and meeting DoD, logistics, and supply chain needs; define success and sustainability; take a much longer-term view of success; determine criteria for launching new institutes or sunsetting ones that are no longer relevant; and identify core funding, project funding, and priority technologies.

Goal 3: Maintain an Optimal Program Design to Maximize Value Delivery

Participants agreed that the institutes are on the right track overall and should keep focusing on long-term goals and engaging directly with the government. In terms of what to stop, participants suggested eliminating the cost-sharing requirement, unnecessary overreporting, and difficult or inconsistent contracting processes and terms and conditions. They recommended that institutes start streamlining and harmonizing contracts, IP, and other policies across institutes; sharing best practices; examining alternative models; basing strategic goals on value propositions;

leveraging Other Transaction Authorities; and creating mechanisms to encourage more cross-institute collaborations.

Participants expressed support for better clarifying roles and decision-making responsibilities; greater flexibility when working with SBIR, foreign countries, or foreign companies; keeping short-term and long-term values in mind; increasing the initial funding phase to ensure an adequate foundation; and bringing prototyping and piloting out of the institutes directly to manufacturers. It may also be helpful, participants suggested, to convene an annual institute summit (perhaps co-located for increased participation and efficiency), create cross-institute working groups, and launch a campaign emphasizing the importance of advancing domestic manufacturing. It is also important, some suggested, for DoD staff and institute staff to be equally engaged in the institutes.

Goal 4: Maximize Stakeholder Understanding of DoD’s Manufacturing USA Institutes

The groups determined that to meet Goal 4, the institutes should keep convening stakeholders, linking entities with shared goals or collaborative opportunities, and attending relevant conferences. They emphasized the need to stop treating all the institutes as if they are the same, as they have very different commercialization and key technology profiles, and to stop chasing money instead of relevance.

To move forward, participants suggested that the institutes should align with DoD roadmaps and priorities, share overall lessons learned, start a Grand Challenge, and improve information dissemination and action. Understanding of the institutes will improve if they open up better communication venues, use industry partners as advocates, start sharing the positive missions of each institute, and initiate a marketing campaign to publicize their successes, participants posited. They also suggested that the institutes should foster better engagement and collaboration with the science and technology community, program executive officers, program management offices, all DoD units, senior government officials, and other federal personnel, perhaps creating a residency or an exchange program between the institutes and DoD or “Institute Days” for visitors.

Goal 5: Effectively Support a Capable Workforce

Participants urged the institutes to keep EWD as a core project with core funding, and stop underfunding it, blindly funding inadequate programs, and assuming that manufacturing is a compelling employment option. Instead, they

suggested, an “EWD Network Coordinator” should be hired to oversee an institute-wide, multiple-skill-level EWD-human capital focus that engages with universities, 2-year colleges, other military agencies, First Robotics programs, and K-12 administrators; emphasizes DoD priorities and workforce needs; and considers future skill requirements. Participants at this workshop suggested that industry and other institute participants could commit to sending a certain number of employees to the institutes for such training. The institutes, in turn, should also identify scalable, flexible, and transferable educational content or projects (such as Operation Next,3 co-ops, entrepreneurships, and internships), showcase EWD successes, and compile EWD best practices, all to elevate the national manufacturing conversation and meet workforce needs of industry and government, participants suggested.

___________________

3 See the Operation Next website at http://www.opnextjobs.com/.