The Digital Twin Concept

PAMELA A. KOBRYN

Air Force Research Laboratory at Wright-Patterson Air Force Base

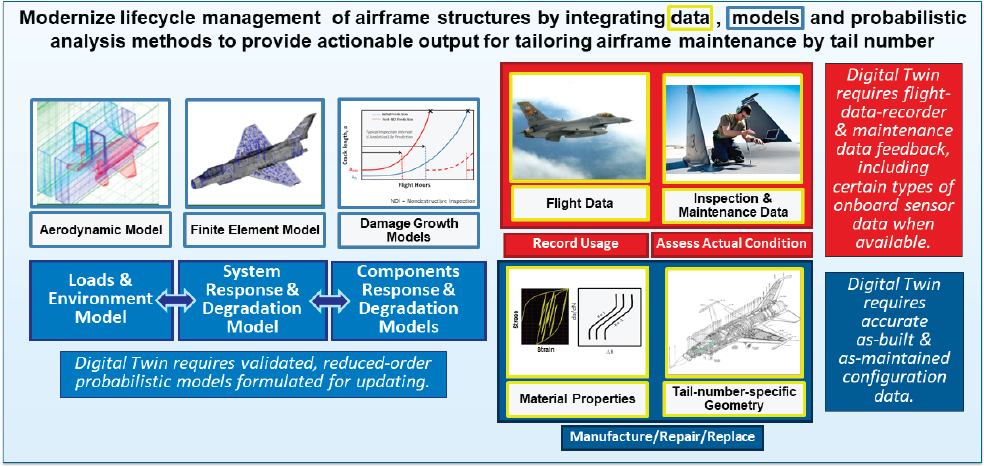

The digital twin concept involves simulating the future performance of a specific product or system based on current knowledge about the system and how it is operated. Key aspects of the concept include near- and long-term performance predictions individualized to both the particular product/system (e.g., by serial number) and its use; delivery of results in an intuitive, interactive, and affordable manner in a timeframe suitable for use; and timely and automated updating of results.

While the original concept focused on the health management of engineered systems with stringent reliability and safety requirements (e.g., airplanes), the scope of digital twin applications is rapidly expanding across the entire product/system lifecycle. Advanced computing, information system, network, and device technologies are being joined with advanced analytical methods to unlock new digital twin applications that bring value to enterprises, communities, and individuals across a broad spectrum of uses—in transportation and logistics, mining and construction, manufacturing and production, power generation and distribution, communication and computing networks, and medicine.

MOTIVATING FACTORS AND SIGNIFICANCE

An early motivation for the digital twin concept was the structural health management of military aircraft, which led to investment in Airframe Digital Twin (ADT) technologies by the Air Force Research Laboratory (AFRL) beginning in about 2009 (Tuegel et al. 2011). At the time, the US Air Force’s desire to reduce the impact of maintenance on aircraft availability and operating costs inspired AFRL engineers to devise new concepts for predicting structural maintenance

needs. These engineers sought to develop methods to increase the fidelity and timeliness of the analyses used to decide when to perform such maintenance (Tuegel and Babish 2014).

Newer applications have a similar motivation: delivering and sustaining the predictable, safe, reliable, and affordable operational capability of engineered products and systems to achieve the outcome desired or required by the end user. Recent advances—in high-performance computing capability; modeling, simulation, and analysis methods; data analytics and information technology; metrology and sensor technology; the internet of things/industrial internet of things (IoT/IIoT); and mobile and cloud computing—support the integration of these capabilities in a digital twin simulation framework for a variety of applications across the product lifecycle, including design, development, testing, and manufacturing, in addition to the original applications in system sustainment.

Several aspects of US Air Force aviation led the AFRL engineers to use the term “digital twin” for their new concept. The facts that every flight of each Air Force airplane is unique and that the types of missions for which the aircraft are used change periodically led to the idea of using flight simulation to predict airplane performance over time.

While the use of flight simulators is not new, the idea of using flight simulation to predict the engineering performance of an individual aircraft over time is novel. Because the physical configuration of different aircraft of the same make and model is unique and changes periodically,1 tailnumberspecific configuration data are used for the flight simulations.

A digital twin simulates the performance of its physical twin using current, periodically updated knowledge about the state and use of its physical twin. This is in contrast to typical engineering-level analyses that use a nominal physical configuration with average or worst-case initial conditions and boundary conditions and are updated only when major changes in configuration or usage occur.

The significance of the digital twin concept is derived from its key elements:

- Digital twins are designed to provide timely and actionable information about an asset to a decision maker.

- The output is tailored for the asset operator(s), based on both the known physical characteristics of the assets and the details of past, current, and planned use.

- The output of digital twin simulations is updated based on new information about the physical characteristics of the system and/or its past, current, and future use.

___________________

1 Configuration changes are due to (i) repairs associated with wear and other damage that can occur during manufacturing, operation, and maintenance; (ii) design updates to address newly identified performance deficiencies; (iii) design updates to add new capability to the aircraft; and (iv) the installation of missionized equipment (e.g., weapons, external fuel tanks, sensor pods).

AN EXAMPLE: AFRL’S AIRFRAME DIGITAL TWIN PROGRAM

For AFRL’s ADT program, the decision maker is the airframe structures engineer and the decision is when to require safety- and maintenance-critical structural inspections for each aircraft in the fleet. Because the engineer is not the owner or operator of the fleet, the decision of when to require inspections must include operational considerations such as an adequate planning horizon and minimized downtime and cost.

Better Maintenance and Planning

No operator wants an engineer to call for maintenance on short notice, particularly if that maintenance takes the aircraft out of service and/or is expensive. The operator typically wants to defer or eliminate maintenance actions as much as possible! ADT aims to provide information about operational and economic risks as a function of flight hours and/or calendar time for each aircraft to help the engineer justify inspection requirements to the operator. Furthermore, ADT enables the engineer to provide these requirements to the operator early enough for the inspections to be incorporated in the operator’s plans.

Because of the pressure to reduce maintenance requirements without compromising safety, engineers are always looking for ways to improve their ability to forecast system degradation. In the case of airframe structures, the primary degradation mechanism is fatigue cracking of metallic parts. Such cracking is very difficult to predict because it is driven by factors that are challenging or impossible to know a priori. Current engineering methods for forecasting fatigue cracking employ various safety factors that are uniformly applied to an entire fleet for the duration of its service life.

ADT aims to reduce or eliminate the use of uniform, fleetwide safety factors in favor of aircraft-specific probabilistic analyses. Individualized analyses can reduce some uncertainties in the factors of safety, making the analysis results more precise and reducing the likelihood of over- or underinspecting. ADT analyses of the physical characteristics of a given plane will account for differences induced by manufacturing, assembly, operation, and maintenance that influence fatigue cracking behavior based on data gathered throughout its life (figure 1).

Analysis Based on Actual Use

The other way ADT aims to refine analyses is by accounting for how an individual operator uses its aircraft. An operator at a training site flies differently than an operator at a forward operating site, and ADT accounts for such systematic differences to reduce analysis uncertainty. Hence, to forecast fatigue cracking, one must first forecast operations. For ADT, these forecasts are in the form of simulated future flights based on synthesized data from previous

use and assumptions about how the operator intends to fly its aircraft (Asher et al. 2017).

Finally, ADT aims to automatically update when the aircraft configuration is changed and when new flight or maintenance records become available. In this manner, ADT further reduces uncertainty, providing additional opportunity to tailor maintenance requirements.

Proof of Concept

While simulating the engineering performance of a physical aircraft and updating it over its lifetime is a simple concept, in practice it involves the synchronization of numerous models, analyses, and data elements. The time and cost of developing and validating a digital twin are not trivial, so proving that the concept is viable and can benefit both engineers and operators is a necessary early step. However, given the time scale of fatigue cracking in operations—typically thousands of flight hours—proving the concept using operational aircraft would simply take too long.

AFRL engineers therefore focused on developing a laboratory-based method for proof of concept. This effort resulted in a one-of-a-kind full-scale structural experiment in which the external aerodynamic loads from individual flights are applied to full-scale aircraft wings in a laboratory environment at the rate of 200 simulated flights per workweek. This experiment is currently running in AFRL’s Structures Validation Facility at Wright-Patterson Air Force Base.

EXCITING FRONTIERS

Since the early days of AFRL’s ADT program, the digital twin concept has become increasingly common and enabling technology has advanced. One exciting recent example comes from the US Food and Drug Administration’s Office of Science and Engineering Laboratories (FDA 2019), which solicited information on “the capability to perform whole human heart computations with a medically implanted device” and “to create ‘virtual patients’ and a ‘virtual population’ such that the FDA can conduct an in silico clinical trial with data that can be used to support a proposal for a real clinical trial.” While this project doesn’t use the term digital twin, many similarities exist, including decision support, tailoring for the individual, uncertainty quantification, and statistical model updating.

CURRENT LIMITATIONS AND CHALLENGES

Digital twin simulations have many potential applications, but significant technical, economic, and social limitations and challenges remain, including the need to

- determine what information to present to the decision maker and how often to update it

- determine the proper level of fidelity for the simulations

- develop methods to reduce the order of the underlying models to reduce computation time

- decide how much to tailor simulations to the individual asset/operator

- develop affordable, reliable means of collecting state and usage data

- develop computationally efficient methods of updating probabilistic simulations

- develop methods to validate probabilistic simulations

- develop methods to synthesize usage and state data

- protect personal privacy and intellectual property

- secure data and models

- address liability for operational failures.

SUMMARY

The concept of simulating engineering performance of physical assets and updating the simulations with state and usage data over time is a powerful idea that is becoming increasingly feasible as enabling technologies mature. Though challenges remain, engineers are envisioning new applications and finding ways to bring them to fruition.

REFERENCES

Asher I, Wang L, Khan G, Ling Y, Viana F. 2017. Developing a probabilistic load spectrum for fatigue modeling. AIAA SciTech Forum, Jan 9–13, Grapevine TX.

FDA [US Food and Drug Administration]. 2019. Computational human heart modeling software and services. Solicitation FDA-RFI-1215586, Aug 1. Rockville MD.

Tuegel EJ, Babish CA IV. 2014. Continuing airworthiness and the Airframe Digital Twin. Proceedings, NATO STO Workshop on Continuing Airworthiness of Ageing Aircraft Systems, STO-MP-AVT-222. Brussels: North Atlantic Treaty Organization.

Tuegel EJ, Ingraffea AR, Eason TG, Spottswood SM. 2011. Reengineering aircraft structural life prediction using a digital twin. International Journal of Aerospace Engineering 2011:154798.