3

Investigating Current Challenges and Acquisition Process Changes with USAF Sustainment Planning

Sustainment challenges exist in the Air Force because it is comprised of individual program-unique sustainment activities. Program offices typically plan, resource, staff, and execute sustainment activities without coordination at the enterprise level. This approach frequently results in incompatible and redundant sustainment systems, increased costs, and nontransferrable technical expertise. When cross-program or enterprise level sustainment modernization initiatives are identified, they often face fiscal, organizational, procedural, and operational barriers toward scaling and adoption.

Based on expert testimonies presented at the data-gathering workshop, committee meetings, and site visits, the committee identified challenges in five areas: workforce, expertise, authority, leadership, and enterprise. Simply increasing investments in total workforce may not be the solution to addressing these sustainment challenges. Instead, adopting institutional or organizational changes, revised policies, improved training with an emphasis on workforce competencies, and resource reallocations may yield more expeditious and positive sustainment outcomes.

WORKFORCE CHALLENGES

In discussions with product support managers (PSMs) and sustainment personnel, the committee learned that many technical staff peak at the General Schedule-13 or -14 level. There do not appear to be many opportunities for professional development or upward mobility, particularly for software or systems engineers working at software engineering groups located at Air Logistic Com-

plexes (ALCs).1 As a result, many of these deeply technical experts opt to depart the Air Force and transition to the private sector. The effect is that the Air Force loses much of its technical expertise at a crucial juncture in the system’s life cycle: refresh or upgrades of mission-critical software systems.

A second challenge that the committee learned relates to co-location of PSMs with program managers (PMs). During the visit to Wright-Patterson Air Force Base, the committee met and heard from eight PSMs, who highlighted varying degrees of success in their planning efforts. Those who were geographically co-located with their PMs appeared to have the greatest involvement in shaping sustainment requirements and planning early in the development life cycle. They were also consulted and actively involved throughout the program’s development and operation.

However, several PSMs who were not geographically co-located with their PMs highlighted the challenges of being involved only when the PMs needed them. They were frequently “forgotten” and excluded from important planning meetings. While some of these PSMs indicated that they were willing to relocate to be closer to the PMs, they were told that the lack of physical workspace prevented them from being moved and co-located.2

A third challenge relates to the grade structures for sustainment positions. The committee learned that sustainment position grade structures tended to be lower than development position grade structures. This inequity reinforces the impression that product support and sustainment are less important functions than development, which only makes the inclusion of sustainment expertise in programs early in development all the more difficult to achieve.

Finding 3-1: The Air Force Life Cycle Management Center’s Logistics Directorate (AFLCMC/LG) has piloted a workforce development rotational program for new hires with the intent of providing experience and exposure to the experienced sustainment workforce.

The program is only being tested with a small group of candidates, but the goal is to expand the rotational program for new hires across all ALCs. Additionally, several Software Maintenance Groups (SMXGs) have embedded software engineers with original equipment manufacturers (OEMs) both to develop Air Force technical expertise and to leverage industry best practices. At the present time, both of these efforts appear to be limited in scope and have not been adapted across the Air Force sustainment enterprise.

___________________

1 Interviews and discussions with Air Force Software Maintenance Group members at Tinker and Hill Air Force Bases, April 2019.

2 Interviews and discussions with PSMs at Wright-Patterson Air Force Base, December 2018.

Recommendation 3-1: The Air Force Materiel Command should expand the Air Force Life Cycle Management Center Logistics Directorate’s workforce development program in size and scope, add the Air Force Sustainment Center (AFSC) as a full partner, and include AFSC personnel in the program.

In doing so, the Air Force will ensure that the workforce development rotational program can be applied across the sustainment enterprise. The Air Force may also want to designate career-broadening positions that do not encumber limited AFSC authorizations and assign sustainment professionals working at the Air Force Life Cycle Management Center (AFLCMC) and in program offices with titles and responsibilities commensurate with their experience and expertise independent of standard local grade structure practice. A positive outcome of this approach would be to better equalize the grade structures between sustainment professionals at the AFLCMC and the AFSC.

Recommendation 3-2: The Air Force should consider co-locating all of the product support managers with their respective program managers.

Co-location appears to be an essential characteristic of successful PMs. For the few PSMs who are geographically dispersed from the program management offices (PMOs), they are less engaged and effective in shaping positive sustainment outcomes. The committee recognizes that some government civilians may be reluctant to relocate or that workspaces may be limited at certain PMOs. However, in order to ensure that sustainment planning is considered both early in development and throughout the program’s life cycle, the Air Force needs to address these challenges directly.

EXPERTISE CHALLENGES

In discussions with PSMs, the committee learned that they are typically comprised of former military with operational, but not necessarily acquisition, experience. While the committee recognizes that operational experience is crucial toward understanding weapons system development and sustainment, a lack of expertise on acquisition requirements and planning hampers the PSM’s ability to shape sustainment planning throughout the program’s life cycle.

Finding 3-2: PSMs also appear to lack a structured professional development and career management track typically associated with the program management, engineering, and contracting officer functional tracks.

The absence of a structured professional development and career management track for PSMs limits their ability to gain the knowledge and expertise required to broaden their career opportunities, as well as contribute to a positive outcome for their assigned programs. Moreover, it contributes to morale and retention challenges.

Recommendation 3-3: The Air Force Materiel Command should proactively manage the product support manager workforce, similar to more established communities like engineering and contracting, for continuous improvement and increased professionalism.

Establishing and maintaining a professional cadre of PSMs would enable the Air Force to adopt an enterprise approach toward sustainment planning, management, and execution. PSMs would also benefit from a clear career management track aided by professional development opportunities to enhance their acquisition and operational expertise. The transparency and dedicated support to helping PSMs in their career development would correspondingly improve retention, particularly in crucial technical disciplines.

The Air Force may want to consider the following questions in identifying the proper mix of strong operational and sustainment-focused acquisition backgrounds:

- Are the right authorities in place to assist in streamlining the recruiting and hiring of PSMs with former operational and sustainment experience?

- Does the Air Force have existing career broadening opportunities for other functional disciplines that may be adapted to support PSMs?

AUTHORITY CHALLENGES

Relative to other functional leads, such as engineering and contracting, sustainment leaders and PSMs do not currently possess adequate authorities to drive product support focused outcomes in program decision making. For example, the committee learned that they are unable to incentivize sustainment modernization initiatives. One reason given is that they lack an authoritative documented source for decision-making support, such as Air Force Materiel Command (AFMC) Instruction 63-1201, “Implementing Operational Safety, Suitability, and Effectiveness (OSS&E) and Life Cycle Systems Engineering (LCSE)”—the Federal Management Regulation, or the Federal Acquisition Regulation that provides necessary authorities and guidance to other functional personnel.

Even when the Air Force issues guidance regarding the roles and functions of the PSMs, they are limited in their roles and are tasked to “take program direction

from the [program manager].”3 This is in stark contrast to other functional leads, such as the Chief Engineer, who has full authority to “Develop and implement a comprehensive systems engineering (SE) strategy that addresses the total life cycle of the system and documents that strategy.”4Box 3.1 lists the responsibilities of the PSM and the Chief Engineer.5 The contrast in authorities is notable.

Recommendation 3-4: The Air Force should identify specific product support manager authorities needed to be compatible with Air Force sustainment expertise modernization plans and higher-level (i.e., higher/other than the program manager) Air Force sustainment policy.

___________________

3 Air Force Instruction 63-101/20-101, “Integrated Life Cycle Management,” May 9, 2017.

4 Ibid.

5 Ibid., p. 21.

As an example of the PSMs’ potential impact on later sustainment outcomes, the Air Force may consider establishing a requirement for the PSM to approve early design decisions that impact enterprise sustainment direction, including any changes that depart from the default sustainment modernization strategies.

LEADERSHIP CHALLENGES

Within the Air Force, there is currently no single, authoritative functional leader to drive systemic improvements and modernization across the Air Force sustainment enterprise. Responsibilities and authorities appeared to be dispersed between the headquarters level and at the depots.

While the committee routinely heard during our conversations with Air Force leaders that a strength of Air Force acquisition is the PM’s singular authority to speak for his/her program, the lack of an enterprise-level functional leader prevents the Air Force from developing and benefiting from an effective corporate sustainment strategy. Unlike development and production, which are conducted primarily by OEMs, the bulk of sustainment activities are largely performed within the Air Force. This set of activities presents the Air Force with an opportunity to coordinate, streamline, and perform sustainment activities and modernization across multiple programs.

Recommendation 3-5: The Air Force should designate a sustainment and modernization functional leader, with appropriate authorities, staff, and resources.

The role of the functional leader is to plan, budget, coordinate, and identify cross-program capabilities for sustainment activities across the Air Force enterprise. The committee is not recommending where the sustainment and modernization functional leader should reside within the Air Force corporate structure. However, it is essential that the individual is given necessary authorities and resources to achieve enterprise-level sustainment solutions for the total force.

The Air Force has taken positive steps in the past decade to realign and streamline organizational roles and responsibilities and to strengthen the Service Acquisition Executive (SAE)/program executive office (PEO)/PM alignment for sustainment. Nevertheless, there remains opportunities for improvements in readiness levels, costs, technology insertion, and downtime with enterprise level sustainment results.

One example is the creation of the Office of the Deputy Assistant Secretary of the Air Force for Logistics and Product Support (SAF/AQD) that addresses product support requirements and equities as part of the Air Force’s Integrated Life Cycle Management process. A Senior Executive Service (SES), who possesses extensive

experience in Air Force sustainment, heads the office. SAF/AQD is responsible for the following activities:6

Weapons System Life Cycle Support

- Participates in key weapon system strategy planning decisions to ensure fielding, modification, and sustainment issues are resolved

- Advocates appropriate resource priority to field, modify, and sustain weapons systems

- Facilitates and supports efforts that transform and posture our product support strategy with regard to cradle-to-grave sustainment

Supply Chain Management

- Endorses policies/programs that produce integrated supply chains for the warfighting customer

- Advocates implementation of new or improved business initiatives

- Facilitates and expedites supply chain improvement and innovation through advocacy for appropriate resources

Depot Maintenance

- Ensures Depot Maintenance Strategy and Master Plan provide properly sized depot level maintenance and repair capability

- Advocates within the corporate structure for appropriate resources consistent with Depot Maintenance Strategy and Master Plan

- Facilitates and expedites continuous improvement and innovation

Sustainment Transformation

- Ensures superior warfighting forces through agile and proactive sustainment through retirement phase of the life cycle

- Advocates implementation of new or improved business initiatives

- Provides integration and management of maintenance/supply chain capabilities to meet the needs of the warfighter

Finding 3-3: In interviews and discussions with both the current and former AQD leaders, the committee found that the organization is inadequately resourced and staffed.

___________________

6 Retrieved from ww3.safaq.hq.af.mil/Organizations/SAF-AQD on October 17, 2019.

Only nine sustainment/logistics professionals are assigned to the organization. Given the scope and magnitude of their responsibilities for supply chain management, depot maintenance, sustainment transformation, and weapon system life cycle support, AQD is significantly under-resourced to execute their core functions effectively.

Resourcing AQD should be consistent with both the oversight in its charter and the opportunity to harvest savings from the sustainment portfolio. Driving enterprise-level efficiencies requires resources to identify opportunities, drive change, and measure performance. For example, how might AQD provide integration and oversight of maintenance and supply chain capabilities to meet the needs of the warfighter while advancing enterprise value? Similarly, does AQD possess the necessary expertise and authority to facilitate and accelerate supply chain improvements and innovation across the Air Force enterprise?

Recommendation 3-6: The Assistant Secretary of the Air Force for Acquisition, Technology, and Logistics (SAF/AQ) should reassess the appropriate role of Deputy Assistant Secretary of the Air Force for Logistics and Product Support (SAF/AQD) in support of the Service Acquisition Executive and the Air Force.

This reassessment should include determining the adequacy of organizational staffing, policy scope, and required authorities for AQD to effectively execute its core functions and responsibilities. The assessment should perhaps consider the following questions:

- What authorities are required to enable AQD to issue authoritative enterprise level guidance for sustainment?

- If the committee’s recommendation to establish a functional lead for Air Force enterprise sustainment and modernization is adopted, what should be the role and corresponding resources and authorities of AQD?

ENTERPRISE CHALLENGES

The committee observed that the Air Force seldom provides cross program direction for early sustainment planning. The Air Force does not currently offer a consistent set of expectations or direction regarding how program managers or OEMs should structure their programs, including sustainment modernization plans, to fit within an Air Force enterprise view of sustainment. As a result, industry is not incentivized or required to focus on enterprise sustainment compatibility during proposal and development phases.

Evidence of the lack of incentives is found in conformance with existing and planned logistics support systems and architectures, established cybersecurity approaches to logistics management systems, adaptation of modernization initiatives such as capability-based maintenance, data analytics requirements, compatibility with planned additive manufacturing capitalization, or compatibility with laser paint removal. Program offices and prime contractors are largely independent, and even indirectly incentivized, to design program unique sustainment features and approaches.

Recommendation 3-7: The Air Force should develop forward-looking sustainment modernization strategies and implement them across multiple programs.

As part of this approach, the Air Force should direct that compatibility with planned sustainment modernization be the default approach in new acquisitions. Examples include strategies for provision for additive manufacturing, coherent guidance on technical data rights, use of “smart components,” condition-based maintenance, among others.

Recommendation 3-8: The Air Force and original equipment manufacturers should consider using new supply chain optimization algorithms to replace traditional supply chain forecast models that will significantly improve availability and reduce supply chain costs.

To accomplish this, the Air Force should consider incentivizing innovation in sustainment modernization through the source selection process, which could take into account both the instant program benefit and the broader applicability of new sustainment technologies.

The committee also learned that Air Force acquisition is currently focused on fast delivery of capability. The use of rapid acquisition tools such as Section 804 Middle Tier Acquisition, Joint Capability Technology Demonstration, and Other Transaction Authority, high concurrency between development and production, and reduced or eliminated risk reduction phases focuses too much on schedule at the expense of other priorities. This creates incentives to increase risk in designing and verifying important sustainment features. In short, these rapid acquisitions trade speed of acquisition and fielding for long-term efficient sustainment. It also discourages sustainment innovation that could increase development time and cost.

While these authorities may be beneficial by accelerating certain capabilities to delivery, it is likely they may add risk to product support and total life cycle cost. PMs may opt to truncate the time allocated to addressing vital activities associated

with requirements refinement, risk reduction, design iterations, and testing activity in order to meet shortened schedules and field capabilities sooner.

Recommendation 3-9: The Air Force should issue guidance that indicates the minimum sustainment considerations for rapid acquisition programs, including sustainment modernization compatibility. The committee recommends the Air Force incorporate sustainment costs and considerations in the Section 804 program planning and decision-making processes.

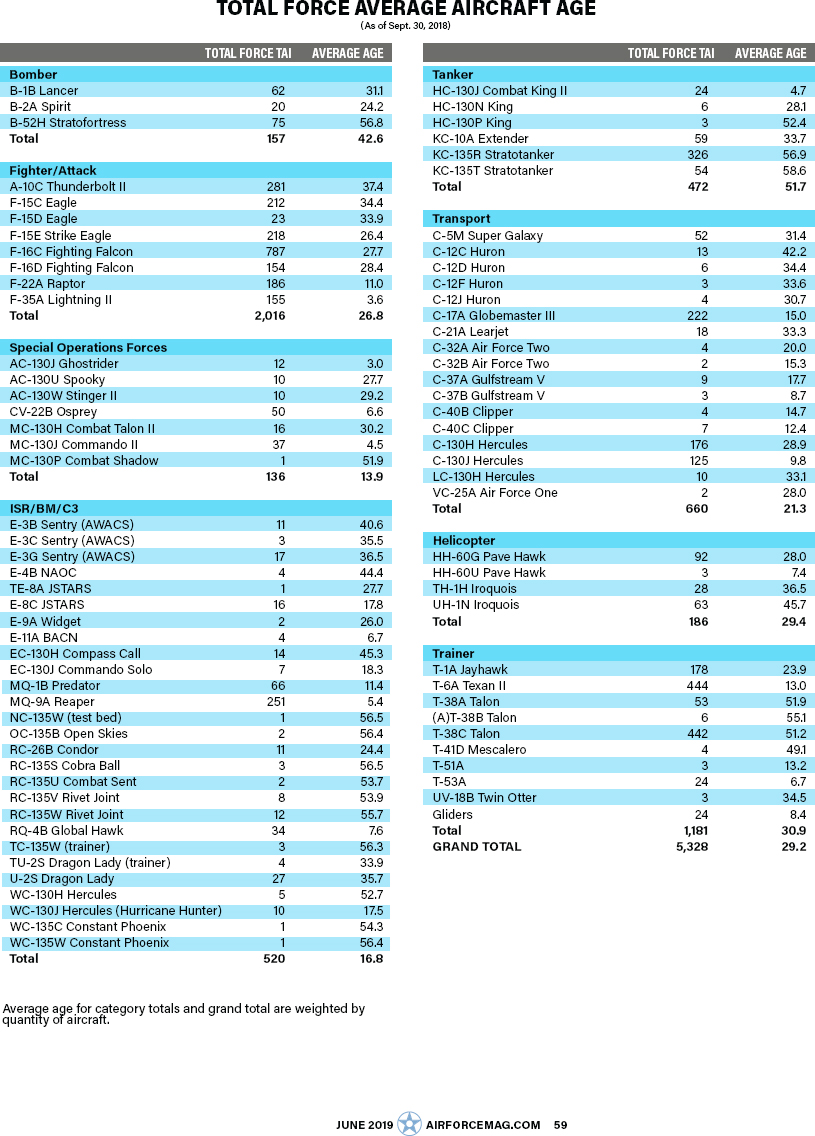

Lastly, the Air Force faces a major challenge with extended service life. Figure 3.1 shows the average age of current inventory aircraft.7 Aircraft flying well beyond expected service life create unanticipated sustainment issues. Examples include fatigue, wear, and corrosion failure of components and parts originally expected to last only for the life of the platform. The Air Force is taking action to address these problems, but appears to be largely in a reactive mode as problems associated with this development emerge. In addition (and possibly as a result of the extended service life issue), Air Force resources are exposed to growing degrees of budget risk, as sustainment costs rise precipitously at the tail-end of the extended service life.

Recommendation 3-10: The Air Force needs to proactively address the problem of dramatically extended service life from both a holistic enterprise-level approach, as well as a program-by-program approach.

This should involve evaluating cross-program actions that may mitigate this problem and to addressing it in a cost-effective manner. For example, the Air Force may want to consider incorporating an ongoing and routine assessment of extended service life sustainment needs and requirements and use the results to develop a long-term strategy, plans, and resource allocations. Data analytics, artificial intelligence/machine learning ontologies may also provide enterprise sustainment insight into billions of Department of Defense (DoD) weapon system maintenance and supply chain transactions.

___________________

7 Air Force Magazine, USAF Almanac 2019, June 2019.