APPENDIX C

AN ILLUSTRATIVE SENSOR TAXONOMY

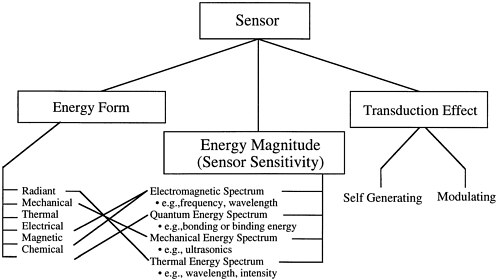

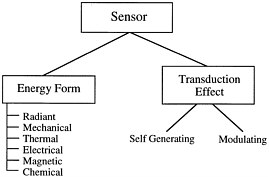

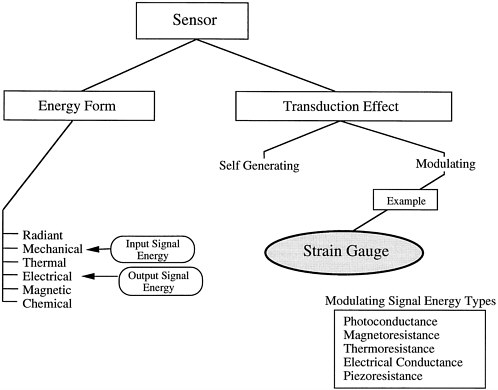

The discussion of a taxonomy for sensors that was presented in Chapter 1 was necessarily brief. This appendix applies those somewhat theoretical concepts to specific examples drawn from past reports of the National Research Council's National Materials Advisory Board that addressed various sensor applications (NRC, 1986a,b,c, 1987, 1989a,b, 1992). For example, Figure C-1, based on a 1989 report (NRC, 1989a) graphically depicts the classification, presented in Chapter 1, in which sensors are classified on the basis of the energy form in which signals are received and generated (mechanical, thermal, electrical, magnetic, radiant, or chemical) and by the nature of the transduction effect (self-generating or modulating).

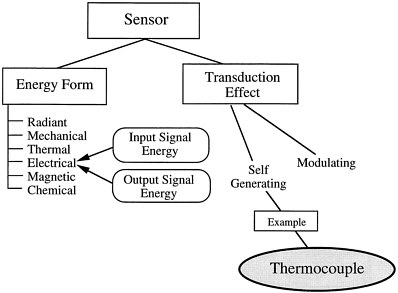

Figure C-2 applies the example taxonomy to a thermocouple. The figure indicates that in the general case, both input and output signals can be in any one of these six forms of energy, giving rise to a six-by-six matrix of primary (input) and secondary (output) signals, as summarized in Table 1-3. Following the approach of Middlehoek and Noorlag (1982), self-generating and modulating signals may be treated as fundamental transduction principles, creating a third dimension to the six-by-six matrix. As discussed in Chapter 1, some confusion then arises from the use of the terms "passive" and "active" for modulating sensors. For this reason, the designations "self-generating" and "modulating" are preferred to describe, respectively, sensors that do and do not require an auxiliary energy source to produce an output signal. For example, as shown in Figure C-2, a thermocouple is a self-generating transducer, since a change in temperature is converted directly into an electrical signal that can be measured. In contrast, the mechanical energy input to a strain gauge is modulated or converted to an electrical signal (Figure C-3) through the use of a piezoresistive element made of wire or metal foil. Deformation of this element as a result of a tensile or compressive force results in a change in electrical resistance. The various signal energies that are used in modulating transducers include photoconductive, magnetoresistive, thermoresistive, electrically conductive, or piezoresistive ones.

Figure C-4 illustrates the correlation between the form of the sensor signal and sensor sensitivity,

FIGURE C-1 Basic sensor taxonomy.

FIGURE C-2 Example of thermocouple transducer.

based on the magnitude of the energy change to be detected. For example, the detection of chemical signals is generally less than the measurement of chemical bonding or binding energies, which are likely to be in the range of 0.025 volt. In contrast, the energies associated with thermal signals are significantly greater, corresponding to wavelengths and intensities in the thermal energy spectrum. Similarly, sensing of radiant, electrical, and magnetic signals requires the detection of energies in the relevant parts of the electromagnetic spectrum. For example, the long-wavelength infrared detectors discussed in Chapter 5 depend upon the use of semiconductor materials that can efficiently absorb radiation in the wavelength band of 8 to 14 microns; this requirement necessitates the use of sensor materials with band gaps less than about 130 MeV.

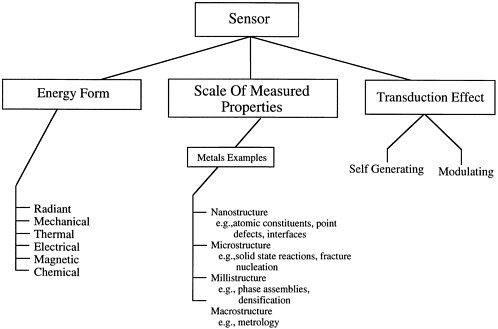

Figure C-5 shows that sensitivity requirements for sensors used in materials processing depend not only upon the signal energy magnitude and form, as discussed above, but also on the scale of the material property to be measured. In the case of metal processing, the properties of interest can range from nanostructural features, such as point defects and dislocation densities, through microstructural features (phase transformations, grain size) to millistructural and macrostructural properties such as tensile strength. The selection and design of an appropriate sensor depends upon an understanding of the scale of measurement and sensitivity required for the proposed application. The communication tool presented in Chapter 2 offers an effective means for matching the measurement scale of the application with the capabilities of candidate sensor technologies. In the polymer matrix composite processing example discussed in Chapter 3, sensing requirements to determine part quality are based on the determination of bulk properties. In contrast, the in situ diagnostic techniques under development to monitor the fabrication of band-structure-engineered semiconductor materials depend on the determination of materials properties at nanostructural and microstructural scales.

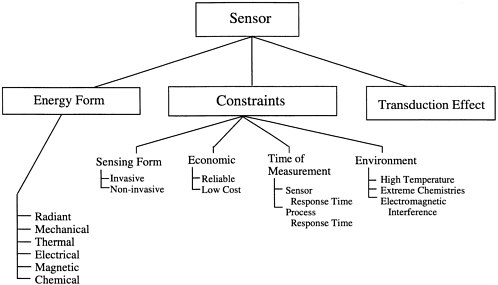

Figure C-6 illustrates some of the practical constraints associated with sensor applications for materials processing. These constraints apply regardless of the signal form or transduction type. For example, there is frequently a requirement for sensing

FIGURE C-3 Example of strain gauge transducer.

to be conducted in a noninvasive fashion such that the presence of a sensor does not perturb the fabrication process. Applications of this type are discussed in Chapter 3 in the context of intelligent processing of polymer matrix composites, and the requirement for noninvasive monitoring of composite cure is identified as a major driver for the development of new sensor types. The use of optical sensing technologies is particularly promising for such noninvasive sensing applications.

Another important constraint for sensing applications is the availability of reliable, low-cost sensors. As noted in Part II of the report, the availability of such sensors is critical in order to accelerate the incorporation of advanced sensors in practical applications, including materials and component manufacture. Low-cost, reliable sensors are also needed for structural control and health monitoring and for environmental sensing applications, such as personal health monitoring. In the case of structural health monitoring, practical requirements for long-term reliability may be far more challenging than those associated with materials manufacture.

The issue of measurement time and sensor response time (Figure C-6) is considered in Chapter 3 in the context of intelligent processing of structural polymer matrix composites. It is noted that, in practical applications, sensors with short time constants are required in order to detect very rapid, localized changes in the matrix resin system during composite cure or to detect large gradients in material

FIGURE C-6 Illustration of typical constraints on sensor applications.

properties over a processing time of several hours. Thus, the sensor response time must be short enough to provide an accurate and "instantaneous" representation of the material during processing, thereby permitting modifications to be made to the composite cure parameters in real time in order to optimize the process for final material quality and efficient use of processing facilities. If the sensor response time is long compared with the process response time, changes to the material processing parameters cannot be achieved effectively on-line, and intelligent processing is not feasible.

A further constraint on sensors for materials processing arises from the hostile manufacturing environment in which such sensors must operate. Processing is frequently performed at elevated temperatures (up to 900 °F or 480 °C for advanced thermosetting polymer matrix composites), and the chemical environment associated with processing may tend to attack the material of the sensor (exposure to polymer resins and their precursors may result in degradation of sensor performance). Thus, the sensors used to monitor process changes must be robust and capable of performing reliably under elevated temperature and chemically aggressive conditions. In addition, sensors must be insensitive to electromagnetic interference effects, for example, in an autoclave during processing. Some of the major constraints associated with monitoring the temperature of polymer-matrix composite resin during cure are summarized in Appendix D, Table D-1.

REFERENCES

Middlehoek, S., and D.J.W. Noorlag. 1982. Three-dimensional representation of input and output transducers. Sensors and Actuators 2(1):29–41.

NRC (National Research Council). 1986a. Bioprocessing for the Energy-Efficient Production of Chemicals. NMAB-428. National Materials Advisory Board, NRC. Washington, D.C.: National Academy Press.

NRC (National Research Council). 1986b. New Horizons in Electrochemical Science and Technology. NMAB-438-1. National Materials Advisory Board, NRC. Washington, D.C.: National Academy Press.

NRC (National Research Council). 1986c. Automated Nondestructive Characterization and Evaluation in Metal and Ceramic Powder Production. NMAB-442. National Materials Advisory Board, NRC. Washington, D.C.: National Academy Press.

NRC (National Research Council). 1987. Control of Welding Processes. NMAB-421. National Materials Advisory Board, NRC. Washington, D.C.: National Academy Press.

NRC (National Research Council). 1989a. On-Line Control of Metals Processing. NMAB-444. National Materials Advisory Board, NRC. Washington, D.C.: National Academy Press.

NRC (National Research Council). 1989b. Intelligent Process Control Systems for Materials Heat Treatment. NMAB-457. National Materials Advisory Board, NRC. Washington, D.C.: National Academy Press.

NRC (National Research Council). 1992. Opportunities in Attaining Fully-Integrated Processing Systems. NMAB-461. National Materials Advisory Board, NRC. Washington, D.C.: National Academy Press.