3

Input of Oil to the Sea

|

HIGHLIGHTS This chapter points out that:

|

Petroleum hydrocarbons enter the marine environment from numerous sources. The 1985 National Research Council report Oil in the Sea: Inputs, Fates, and Effects (National Research Council, 1985) was a benchmark report and basically updated the original 1975 National Research Council report Petroleum in the Marine Environment. Inputs from maritime transportation activities were once again updated in 1990 in a study conducted by the U.S. Coast Guard in cooperation with the National Academy of Sciences (International Maritime Organization, 1990). Increased petroleum production and consumption by industry and the public in the past 15 years warrants an updated analysis of the quantity and varied inputs of petroleum hydrocarbons into the marine environment.

Significant differences in a variety of conditions exist between those in 1985 and the present. The major differences include:

Petroleum production. In 1970, the world oil production was 7.0 million tonnes per day and by 1985, it had increased to 8.5 million tonnes per day (www.eia.doe.gov, 2001). By the end of 2000 the production had increased to 11.0 million tonnes per day, an increase of about 30 percent over the 16 years. The average annual rate of growth in production has been approximately 1.6 percent and a rate of growth of 1.9 percent has been forecast for the first decade of the 21st century. In 1985, there were only a few thousand offshore oil and gas platforms and by 1999 there were about 8,300 fixed/ floating offshore platforms (DeLuca and LeBlanc, 1997). Worldwide offshore production has grown by 45 percent from 1985 to 1995, the latest year of record (API, 2001).

Volume of petroleum products transported. Since 1985, significantly higher volumes of petroleum hydrocarbons are being transported by various methods on the world’s oceans.

For example, exports to the U.S. from the Middle East grew by nearly a factor of three to 346,900 tonnes/day in 1999. For the world as a whole, the growth in exports from the Middle East increased by a factor of two (API, 2001).

Databases. Since the NRC 1985 report, significant new databases that contain more accurate information have been generated by public, governmental, and private agencies. These databases have become much more accessible with the advent of the worldwide web. In the present report, data bases existed that allowed a) dividing oil and gas operations into four categories (platforms, outer continental shelf (OCS) pipelines, coastal pipelines, and produced waters), b) estimating atmospheric deposition of petroleum hydrocarbons, and c) estimating recreational/small craft inputs. In general, the international databases for spills are neither as comprehensive nor as carefully maintained as those for U.S. and Canadian waters, and therefore the worldwide estimates have a greater uncertainty.

Regulations. Since 1981, a number of regulations intended to reduce petroleum hydrocarbon inputs into the oceans have been implemented. The 1978 Protocol of the International Convention for the Prevention of Pollution from Ships (MARPOL 73/78) was implemented in the U.S. in June 1981, and went into effect worldwide in 1983. These regulations mandate segregated ballast tanks (SBT) for new tankers and set limits on the oil content of overboard discharges. The Oil Pollution Act of 1990 (OPA 90; Appendix K) and the 1992 amendments to MARPOL 73/78 mandate double-hull requirements or equivalent protection for all new tankers, and establish phase-out schedules for existing single-hull tankers. Other relevant regulations include restrictions on produced water discharges into coastal waters of the United States, the elimination of oil-based drilling cutting into the North Sea, and limits on the average oil and grease content of produced water discharge. These and other regulatory changes have contributed to a significant reduction in both operational discharges and accidental spills.

Identification of geographic distribution of inputs. In 1985, data did not exist to accurately pinpoint the geographic area of the major sources of input of hydrocarbons to the oceans. Since then, new reporting databases contain the location of major spills, and it is now possible to subdivide the input of hydrocarbons to relatively small geographic zones in North American waters. Although similar databases exist for only a few other worldwide areas, they are still not refined enough to allow specific allocation of inputs by geographic zones.

Increase in urban population. In the fifteen years since the last NRC report, there has been a significant increase in urban population, particularly in the coastal zone. Current trends indicate that by the year 2010, 60 percent of the U.S. population will live along the coast. This is consistent with the worldwide profile in which two-thirds of the urban centers, defined as cities with populations of 2.5 million or more, are near tidal estuaries. This increased population has resulted in a considerable increase in land-based runoff of petroleum hydrocarbons.

Increase in number of two- and four-stroke engines. In 1985, the NRC report Oil in the Sea did not discuss petroleum hydrocarbon inputs from operation of recreational marine vehicles. In 1990, heightened awareness about the large number and design inefficiencies of these engines led the US EPA to begin regulating the “non-road engine” population under the authority of the Clean Air Act. The average hours of use nationwide for two-stroke personal watercraft engines is 77.3 hours per year and for outboard engines is 34.8 hours per year (EPA, in preparation). This increased use of two-stroke engines has proven to be a major contribution to discharge of petroleum hydrocarbons to marine waters, especially in coastal waters from recreational marine vehicles.

In the 1985 NRC report, inputs were categorized into five major sources: Natural, Offshore Production, Transportation, Atmospheric, and Municipal and Industrial. Subcategories were delineated within several of these major input areas (Table 3.1). In the present report, inputs were organized into four major sources, with subcategories within each of the major sources (Table 3-1).

Although the categories are organized slightly differently in the two reports, the major input sources are the same. In

TABLE 3-1 Input Sources in 1985 and Present Report

|

1985 Report |

Present Report |

|

Natural Sources Marine seeps Sediment erosion Offshore production Transportation Tanker operations Dry-docking Marine terminals Bilge and fuel oils Tanker accidents Non-tanker accidents Atmosphere Municipal & Industrial wastes Municipal wastes Refineries Non-refining industrial wastes Urban runoff River runoff Ocean dumping |

Natural seeps Extraction of Petroleum Platforms Atmospheric deposition Produced waters Transportation of Petroleum Pipeline spills Spills (tank vessels) Operational discharges (cargo oil) Coastal facility spills Atmospheric deposition (tanker VOC) Consumption of Petroleum Land-based (river and runoff) Recreational vessel discharge Spills (commercial vessels ≥100 GT) Operational discharges (vessels ≥100 GT) Operational discharges (vessels <100 GT) Atmospheric deposition Aircraft dumping |

|

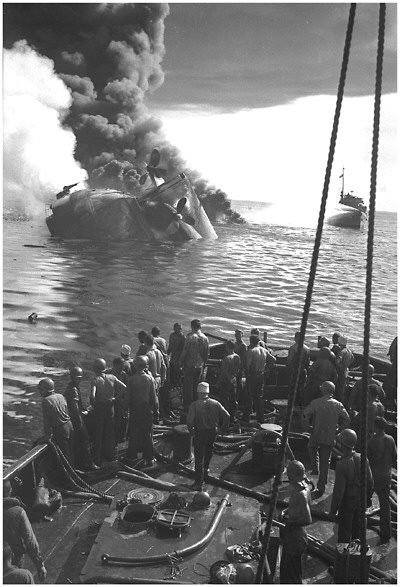

the present report, databases existed that allowed a) breaking oil and gas operations into three categories (platforms, pipelines, and produced waters), and b) separating out various types of recreational/small craft inputs (see Table 2-3 for more complete discussion of the intercomparibility of the two reports and the significance of any changes in the estimates for the various categories of input). Three known sources of petroleum, erosion of petroleum-bearing sediment, offshore disposal of urban wastewater or sewer sludge, and abandoned vessels (shipwrecks still containing petroleum or refined products) were not directly included in calculations for North America of the world. All three of these sources may be locally significantly, however, when compared to volumes generated from the more commonly recognized sources; their significance at worldwide, continental, and even regional scales is minimal. Of the three, it was felt that greater attention should be paid to potential risks posed by abandoned vessels. The vast majority of these are sunken World War II vessels, and corrosion and other factors working over the last 60 years may pose risk to increased leakage rates or catastrophic failure of the structure and sudden release of large volumes of refined product. An in-depth examination of this issue was beyond the scope and resources of the study, but greater attention may need to be paid to this potential source in the near future (Box 3-1).

PETROLEUM HYDROCARBON INPUTS

Petroleum hydrocarbon inputs into North American and worldwide marine waters were computed, based on various databases, for four major categories. These include a) natural seeps, b) extraction of petroleum, c) transportation of petroleum, and d) consumption of petroleum. Details of the methodology utilized, and discussion of the computation and distribution of sources are discussed in Appendixes C through I, the databases are explained in Appendix D. In order to further pinpoint the source of these discharges, North American waters were divided into 17 zones (Figure 2-3; see Appendix B for description). Table 3-2 summarizes the sources of inputs for North American and worldwide waters.

NATURAL SEEPS

Crude oil that seeps naturally into the marine environment establishes a contaminant “background” that needs to be measured in order to determine the extent of pollution resulting from human activities, such as oil spills. This new assessment places the current global rate of natural seepage of crude oil at 600,000 tonnes per year, with a range of 200,000 to 2,000,000 tonnes per year. These estimates take into account two previous studies of the National Research

|

BOX 3-1 Grounded and Abandoned Vessels Grounded and abandoned vessels pose a significant threat of oil spills, and releases of other pollutants by becoming sites for illegal dumping of waste oils and hazardous materials. This may impede navigation, and could result in physical crushing and smothering of habitats, leading to wildlife entrapments and public health hazards. There are two different types of abandoned vessels that pose the greatest oil pollution risks:

Existing U.S. and international laws and regulations provide limited authority to promptly remove grounded or abandoned vessels that are causing harm to natural resources but which are not otherwise obstructing or threatening to obstruct navigation, or threatening a pollution discharge. With the exception of the Oil Pollution Act (OPA), no federal statute provides a source of funds other than appropriated agency monies for use in removing grounded or abandoned vessels, and the OPA fund has not been made broadly available for these purposes. |

TABLE 3-2 Average, Annual Releases (1990-1999) of Petroleum by Source (in thousands of tonnes)

|

|

North America |

Worldwide |

|||||

|

|

Best Est. |

Regionsa |

Min. |

Max. |

Best Est. |

Min. |

Max. |

|

Natural Seeps |

160 |

160 |

80 |

240 |

600 |

200 |

2000 |

|

Extraction of Petroleum |

3.0 |

3.0 |

2.3 |

4.3 |

38 |

20 |

62 |

|

Platforms |

0.16 |

0.15 |

0.15 |

0.18 |

0.86 |

0.29 |

1.4 |

|

Atmospheric deposition |

0.12 |

0.12 |

0.07 |

0.45 |

1.3 |

0.38 |

2.6 |

|

Produced waters |

2.7 |

2.7 |

2.1 |

3.7 |

36 |

19 |

58 |

|

Transportation of Petroleum |

9.1 |

7.4 |

7.4 |

11 |

150 |

120 |

260 |

|

Pipeline spills |

1.9 |

1.7 |

1.7 |

2.1 |

12 |

6.1 |

37 |

|

Tank vessel spills |

5.3 |

4.0 |

4.0 |

6.4 |

100 |

93 |

130 |

|

Operational discharges (cargo washings) |

nab |

na |

na |

na |

36 |

18 |

72 |

|

Coastal Facility Spills |

1.9 |

1.7 |

1.7 |

2.2 |

4.9 |

2.4 |

15 |

|

Atmospheric deposition |

0.01 |

0.01 |

tracec |

0.02 |

0.4 |

0.2 |

1 |

|

Consumption of Petroleum |

84 |

83 |

19 |

2000 |

480 |

130 |

6000 |

|

Land-based (river and runoff) |

54 |

54 |

2.6 |

1900 |

140 |

6.8 |

5000 |

|

Recreational marine vessel |

5.6 |

5.6 |

2.2 |

9 |

ndd |

nd |

nd |

|

Spills (non-tank vessels) |

1.2 |

0.91 |

1.1 |

1.4 |

7.1 |

6.5 |

8.8 |

|

Operational discharges (vessels ≥100 GT) |

0.10 |

0.10 |

0.03 |

0.30 |

270 |

90 |

810 |

|

Operational discharges (vessels<100 GT) |

0.12 |

0.12 |

0.03 |

0.30 |

nde |

nd |

nd |

|

Atmospheric deposition |

21 |

21 |

9.1 |

81 |

52 |

23 |

200 |

|

Jettisoned aircraft fuel |

1.5 |

1.5 |

1.0 |

4.4 |

7.5 |

5.0 |

22 |

|

Total |

260 |

250 |

110 |

2300 |

1300 |

470 |

8300 |

|

a“Regions” refers to 17 zones or regions of North American waters for which estimates were prepared. bCargo washing is not allowed in U.S. waters, but is not restricted in international waters. Thus, it was assumed that this practice does not occur frequently in U.S. waters (see Chapter 3 and Appendix E). cEstimated loads of less than 10 tonnes per year reported as “trace” dWorld-wide populations of recreational vessels were not available (see Chapter 3 and Appendix F). eInsufficient data were available to develop estimates for this class of vessels (see Chapter 3 and Appendix E). NOTES: 1.Totals may not equal sum of components due to independent rounding. 2. Generally assumes an average specific volume of oil at 294 gallons per tonne (7 barrels per tonne). Where the specific commodity is known, the following values are applied when converting from volume to weight: Gasoline: 333 gallons per tonne Light Distillate: 285 gallons per tonne Heavy Distillate: 256 gallons per tonne Crude Oil: 272 gallons per tonne 3. Numbers reported to no more than 2 significant figures using rules: http://web.mit.edu/10.001/Web/Course_Notes/Statistics_Notes/Significant_Figures.html#SignificantFigures |

|||||||

Council (NRC, 1975; NRC, 1985) and new information on the natural seepage of crude oil into the marine environment (detailed in Appendix C). Not considered in the new or previous studies is the contribution to the marine environment of hydrothermally-derived petroleum at oceanic spreading axes (see summary by Kvenvolden and Simoneit, 1990). Although it is clear that hydrothermal petroleum occurs in the sea, the rates of seepage are unknown, but are believed to be very small, and therefore are not included in the new global assessment.

In 1975, the estimated worldwide rate of natural seepage of oil into the marine environment ranged widely from 200,000 to 6,000,000 tonnes per year, with a “best estimate” of 600,000 tonnes per year. These rates were based on a comprehensive global survey incorporating extensive geological considerations, but used extrapolations from only a few known seeps. In 1985, little new information had become available, and estimates of individual oil-seep rates had not changed significantly. Thus a revised estimate of the global seepage rate was calculated based on assumptions concerning the amount of crude oil known to be present that could seep over reasonable periods of geologic time. This theoretical approach was first developed by Kvenvolden and Harbaugh (1983) and incorporated into NRC (1985). The

new estimates ranged between 200,000 and 2,000,000 tonnes per year, with a “best estimate” of 600,000 tonnes per year. This revised estimate does not imply that seep rates decreased during the intervening years between 1975 and 1985, but rather reflect a difference in approaches to making the global estimates.

Although only a few new seeps have been identified and estimates of known crude-oil deposits throughout the world have not changed greatly from about 300,000 million tonnes, new technologies, particularly remote sensing techniques, have provided better means of natural seep detection and assessment. Studies in parts of the Gulf of Mexico (MacDonald et al., 1993; MacDonald, 1998; Mitchell et al., 1999), using these new technologies, have resulted in an estimated seepage rate for the entire Gulf of Mexico of 140,000 tonnes per year (range of 80,000 to 200,000 tonnes per year). For offshore southern California, a new estimate of rate of oil seepage is 20,000 tonnes per year (range of 2,000 to 35,000 tonnes per year), based on considerations of work by Fischer (1978), Clester et al. (1996), and Hornafius et al. (1999). The rate of oil seepage for offshore Alaska is also estimated, based mainly on a report by Becker and Manen (1988), to be about 400 tonnes per year (range of 200 to 800 tonnes per year). The North American best estimate is 160,000 tonnes per year, with a minimum of 80,000 tonnes per year (50 percent of best estimate), and a maximum of 240,000 tonnes per year (best estimate + 50 percent1).

The new North American estimate of 160,000 tonnes per year is only 40,000 tonnes less than the 1985 global estimate of 200,000 tonnes per year, suggesting that the 1985 value was grossly underestimated. To accommodate the new information now available, the “best estimate” of the global crude oil seepage rate has been revised to 600,000 tonnes per year, reviving an estimate made originally in 1975. The estimated range of 200,000 tonnes per year to 2,000,000 tonnes per year was developed based on the approach applied in NRC (1985). These limits are set by the amount of crude oil seepage estimated for North American waters and the amount of crude oil ultimately available for natural seepage during geologic time.

Extraction of Petroleum

Global production of petroleum (crude oil and natural gas plant liquids) increased by 1.0 million tonnes per day (7.1 million barrels per day) between 1990 and 1999, an average annual rate of growth of 1.0 percent (International Energy Review, 1999; www.eia.doe.gov). Saudi Arabia, the United States, and Russia were the three largest producers of petroleum in 1999. Together, they produced 31.4 percent of the world’s petroleum. Production from Iran and Mexico accounted for an additional 9.7 percent.

Oil and gas operations include discharges from platforms and other offshore facilities in both federal waters and state waters, produced waters, and atmospheric deposition from the volatile organic compounds (VOC) generated from offshore production platforms. Details concerning data sources, methodology, and computations can be found in Appendix D.

Platforms

Volumes of petroleum hydrocarbons introduced into North American waters from accidental discharge on offshore platforms are relatively well known for the U.S. Outer Continental Shelf and Canada, but data from offshore Mexico and state waters in the United States are generally lacking or scattered and incomplete. There are an estimated 4,900 platforms in North American waters. As of 1993, there were 3,182 offshore oil and gas facilities located in non-North American waters (International Association of Oil and Gas Producers, 2000). Thus in the world’s oceans, slightly in excess of 8,000 platforms and offshore facilities provide the source of petroleum hydrocarbon input into marine waters.

In North American waters, the input of petroleum hydrocarbons from platforms is 146 tonnes per year. Platforms in the OCS account for 39 percent of the discharge, while platforms in state waters account for the remaining discharge (61 percent). As these data are based on relatively good data bases (Appendix D) accumulated over the past ten years, the committee’s best estimate of inputs by offshore facilities is 153 tonnes per year (minimum plus 5 percent2). The committee estimated that the maximum input would probably be on the order of 20 percent3 higher than the calculated amount or 175 tonnes per year. Based on the distribution of accidental spills identified in the databases, it was possible to further pinpoint geographically the sources of inputs. The central and western Gulf of Mexico accounted for roughly 90 percent of the total discharge in North American waters.

In marine waters worldwide (including North American waters), the calculated amount of discharge is 290 tonnes per year, a figure computed on the assumption that the vol

ume of spills/platform/year for foreign platforms is similar to those in North American waters. However, because not all foreign platforms are subject to the same stringent anti-pollution guidelines under which U.S. oil platforms operate, it is generally agreed that their spills/platform/year exceed the estimates for North American waters. The 1985 report estimated that foreign spills/platform/year exceeded those in the United States by 300 percent, or 860 tonnes/year and these figures were used in this report as well. The maximum is estimated to be 1,400 tonnes per year or five times the calculated amount. These latter two estimates (best and maximum) are based on the lack of any reliable databases of measured discharges from platforms in the world’s oceans.

Atmospheric Deposition

During the production, transport, and refining of hydrocarbons, volatile compounds escape to the atmosphere. Some, like methane, are light and mix or degrade rapidly. Heavier compounds, like hexadecane, react more slowly and may deposit to the sea surface. These heavier hydrocarbons are labeled as volatile organic compounds (VOC) and are defined in the U.S. Clean Air Act to include all volatile hydrocarbons except methane, ethane, a wide range of chlorofluorocarbons (CFC), hydrochlorofluorocarbons (HCFC), and a few others, e.g., acetone. VOC from production facilities were not estimated in the 1975 or 1985 NRC reports. With the increased number of offshore oil and gas platforms, the committee decided to evaluate the existing databases, and make estimates of this input. Appendix D describes the methodology, databases, and calculations.

The methodology used was to take estimates from regulators or producers from the four regions where these were available (North Sea, Norwegian Sea, California, and Gulf of Mexico). For the other regions, an estimate was made by multiplying the regional production volume by an average VOC rate per unit produced based on the average of the rates for the four regions mentioned above. Lower (upper) bound VOC estimates were calculated using the same technique except that the minimum (maximum) VOC rate of the four regions was used.

Equilibrium calculations as described in Appendix D indicate that less than 0.2 percent of the released VOC are deposited to surface waters. Based on the best estimate of VOC emissions of 60,000 tonnes (VOC heavier than butane) to North American coastal waters from production platforms, 120 tonnes of VOC enter the coastal oceans from production platforms. The minimum is 72 tonnes or 60 percent of the best estimate, and the maximum is 450 tonnes or 375 percent of the best estimate4. Worldwide, the best estimate is 1,300 tonnes, the minimum estimate is 380 tonnes (29 percent of the best estimate), and the maximum estimate is 2,600 tonnes (200 percent of the best estimate). The significance of these VOC inputs to the marine environment are not known and will be explored to some degree in Chapter 5. However, the size of the loads suggest that they may have an impact on local air quality. VOC is a known pollutant and has been the subject of many NRC studies (NRC 1992, 1995, 1999a,b).

Produced Waters

During oil or gas production, water from the reservoir is also pumped to the surface. Under current industry practices, this “produced water” is treated to separate free oil and either injected back into the reservoir or discharged overboard. Produced water is the largest single wastewater stream in oil and gas production. The amount of produced water from a reservoir varies widely and increases over time as the reservoir is depleted. For example, in the North Sea, a maturing oil production area, the volume of produced water has increased at a rate of 10 to 25 percent per year over the period 1993-1997 in Norway (NOIA, 1998) and the United Kingdom (UKOOA, 1999).

Produced water discharges are permitted as operational discharges. The oil and grease content is regulated by permit, and the allowable maximum concentrations vary by region and nation. For the U.S. Gulf of Mexico offshore oil and gas industry, the limit is a monthly average of 29 mg/L (USEPA, 1996a); in the North Sea and Canada, it is 40 mg/L (PARCOM, 1986, PanCanada, 1999). Conventional treatment consists of gas flotation and/or membrane filtration to separate oil and water, and there will have to be major technological advances before significant improvements in treatment efficiencies can be expected.

In the United States, operators are required to routinely monitor the volumes and oil content of produced water discharges and to submit reports to regulatory authorities to demonstrate compliance with discharge permits. For Canada, Texas Territorial Seas, California, and Alaska, compiled data were available on the volume and oil content of produced water discharges, and the best estimates were calculated using these reported data for selected time periods (usually the late 1990s). Petroleos Mexicanos published an annual report (PEMEX, 2000) reporting a total amount of oil discharged in tonnes. For discharges to the Gulf of Mexico OCS and the Louisiana Territorial Seas, only produced water volumes were available. Therefore, a default value of 29 mg/L, which is the maximum amount allowed on a monthly basis for the Gulf of Mexico discharges, was used as the maximum amount of oil and grease in produced water for these areas. Many operators are able to achieve levels below 20 mg/L (long-term average for California was 18 mg/L and for Alaska was 15 mg/L). Thus, 20 mg/L was used to calculate the best estimate, and 15 mg/L was used to calculate the minimum estimate for this region.

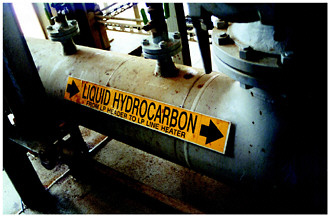

PHOTO 6 Surface water disposal of produced water discharge in estuary of south Louisiana. Water from petroleum-bearing strata (referred to as “produced water”) is recovered when crude oil is pumped to the surface. Although direct disposal is no longer permitted in sensitive coastal habitats in the United States, similar practices continue in other parts of the world. (Photo courtesy of Nancy Rabalais).

The calculated minimum value of the inputs into North American waters is 2,100 tonnes per year. The best estimate is 2,700 tonnes per year and the maximum is 3,700 tonnes per year (Table D-8, Appendix D).

In the North Sea, operators sample twice each day and prepare annual summaries that report the total produced water volumes, average oil content, and total amount of oil discharged to the sea. These reports are posted on web sites by the offshore operator associations for each country. The best estimate of 8,200 tonnes of oil discharge into the North Sea was derived directly from the annual summaries by operators in the United Kingdom, Norway, The Netherlands, and Denmark (Table D-8, Appendix D). The minimum and maximum estimates for the North Sea were calculated using a low oil and grease concentration of 15 mg/L (same as for North America) and a high concentration of 40 mg/L (the maximum allowed monthly average concentration in the North Sea). The exception is Denmark, where no range estimates were made because the oil and grease content was not reported. For other international areas, where discharge summaries could not be obtained, a rough estimate was made as outlined in Appendix D.

The best estimate of the worldwide total amount of oil discharged with produced water during the late 1990s is 36,000 tonnes per year, with a minimum estimate of 19,000 tonnes per year and a maximum estimate of 58,000 tonnes per year. These volumes cannot be compared with the estimates made in the NRC 1985 report because of the different methods used to make the two estimates.

There have been some major changes in permitted discharges for the oil and gas production industry during the 1990s that are not included in Table 3-2. In the United States, produced water discharges into estuarine areas landward of the shoreline (prohibited in 1996) in Louisiana were estimated to include 1,170 tonnes per year of oil and grease (Boesch and Rabalais, 1989b). Before the prohibition of discharge of drilling muds in 1997, oil discharges with drilling cuttings were about 4,000 tonnes/year and accounted for 40 percent of the total oil releases to the North Sea by the United Kingdom.

Overall

In the NRC 1985 report, the best estimate of petroleum hydrocarbons into the world’s oceans from oil and gas operations was 50,000 tonnes per year, with minimum and maximum of 40,000 and 60,000 tonnes per year, respectively. The estimates computed in this report for inputs during extraction processes are lower than the 1985 estimates, with the best estimate being 38,000 tonnes per year, with a minimum of 20,000 tonnes per year and a maximum of 62,000 tonnes per year. The concern of offshore safety and environmental compliance, differences in computing techniques, and the existence of better databases are probably responsible for the differences. In North American waters, the best estimate of petroleum hydrocarbons discharged during extraction processes is 3,000 tonnes per year, while the minimum is 2,300 tonnes per year and the maximum is 4,300 tonnes per year.

Transportation of Petroleum

Significant petroleum hydrocarbon inputs into the oceans from petroleum transportation activities include oil spills and operational discharges from tankers and pipelines, atmospheric deposition of volatile organic compounds (VOC) vented from tankers, and coastal facility spills. Details concerning data sources, methodology, and computations can be found in Appendix E.

Pipelines

Minerals Management Service indicates that there are 21,000 miles of pipelines in U.S. Outer Continental Shelf area (www.mms.gov/stats/), and DeLuca and LeBlanc (1997) estimate that there are 23,236 miles of offshore pipelines in North America. This represents a significant increase in petroleum hydrocarbons being transported during the past decade. In OCS waters, some 75 accidental spills occurred from 1990 to 1999, discharging a total 5,674 tonnes of petroleum hydrocarbons in the marine environment (Box 3-2). Based on the databases from Minerals Management Service on OCS spills and databases from coastal waters, the average annual discharge is calculated as 1,700 tonnes per year. Even though the database is fairly complete, there is always the uncertainty of estimating the volume of the discharges. The committee’s best estimate is 1,900 tonnes per year (minimum + 10 percent) with a maximum value of 2,100 tonnes per year (minimum +20 percent).5 An estimated 99 percent of the pipeline spills occurred in the central and western Gulf of Mexico, 66 percent (1,200 tonnes per year) of the spills occurred in state waters, while 34 percent (650 tonnes per year) occurred in OCS waters.

Estimating the volumes of discharge from pipelines worldwide is more difficult and uncertain. The number of miles of offshore pipelines in the world’s oceans (including North America OCS waters) has been estimated to be 82,748 miles (DeLuca and LeBlanc, 1997). This estimate is prob

|

BOX 3-2 Lake Barre Pipeline Break, Louisiana In May 1997 an underwater pipeline rupture released 940 tonnes (280,000 gallons) of south Louisiana crude oil into Lake Barre, Louisiana. Lake Barre is part of a shallow coastal estuarine system separated from the Gulf of Mexico by barrier islands. Rates of subsidence in this area are among the highest in Louisiana, which among other factors results in extensive erosion of the marsh and creation of a very complex shoreline with isolated patches of sparse salt marsh and large expanses of open water. There had been such rapid change that aerial photographs taken in 1995 (two years before) were useless as base maps, and new aerial photographs had to be obtained. Water depth is about 2 m, and the tidal range is less than 1 m, and water-level changes are mostly wind-driven. South Louisiana crude is a medium crude oil (API gravity of 31), and approximately 36 percent of the oil was estimated to have evaporated or dispersed within 48 hours. Steady onshore winds during the spill raised water levels in the marsh, and oil slicks and sheens eventually spread over 1,750 hectares (4,327 acres) of wetlands (Lorentz et al., 2001). With the high water levels and the sparse vegetation in the marsh, pockets of heavy oil trapped along the outer marsh fringe generated silver to rainbow sheens that dispersed north (downwind) through the marsh for over 6.5 km. Because of the high water levels, there was very little sediment contamination, and only 0.1 hectares (0.3 acres) of salt marsh died back. The oil left a black band a few tens of centimeters high on the vegetation on about 65 hectares (162 acres) of marsh. The widely spread sheens affected 1,685 hectares (4,165 acres) of wetlands over a two week period; two months later there was no evidence of oil or oil effects in these lightly oiled areas. Response efforts focused on recovery of floating black oil pooled in the edges of the marsh. Of greatest concern was that cleanup should not cause more damage to the vegetation, thus a rule was instituted, and strictly enforced, that responders were to remain in boats while working in the marsh. Water samples collected five days after the release contained 0.6-2.2 ppb total PAH, dominated by naphthalenes. Limited sediment sampling indicated no large-scale contamination of bottom sediments. Residual petroleum hydrocarbons in sediment samples collected one year later were characterized as significantly weathered, with degradation of nearly all n-alkanes. The only reports of dead fish or shellfish were three dead juvenile blue crabs (although adult crabs and fish were alive) in a total of seven crab pots inspected, some dead brown shrimp in a survey trawl, and a few dead forage fish in the marsh. An oil fates and effects model was used to estimate that 7,500 kg of fish and invertebrates were lost (Kern et al., 2001). Estimating impacts to birds was difficult because the summer residents are mostly rails, small shorebirds, and similar birds that hide in marsh grass. Only two birds were found oiled and dead; 58 live oiled birds were observed but not captured. The bird impacts would have been significantly different if the spill had occurred in winter when very large numbers of wintering waterfowl are present. Key factors that limited the biological impacts of this spill were: a crude oil that was highly degradable; rapid weathering of the oil because it spread over a large surface area; calm sea conditions so there was little mixing of oil into the water column or contamination of bottom sediments; time of year when relatively few birds were present; and little intertidal sediments so the oil did not strand onto the marsh substrate. |

PHOTO 7 Crude oil is heated to maintain low viscosities, thereby making pipeline transport from offshore easier. Low temperatures can also lead to the formation of gas hydrates in pipelines crossing the sea bed. (Photo courtesy of Environmental Research Consulting.)

ably too low by as much as 30 percent, but these are the only published figures available.

The computed minimum volume spilled is 6,100 tonnes/year and is based on the volume of petroleum hydrocarbons spilled per mile of pipeline per year in North American waters. Because of the uncertainty of the number of miles of pipelines existing in non-North American waters and the lack of adequate databases, the best estimate is 12,000 tonnes per year or two times the calculated amount, while the maximum spillage is estimated to be 37,000 tonnes per year or six times the calculated amount.

Spills (Tank Vessels)

During the period from 1980 to 1999, the size of the tanker fleet has been relatively stable, with the number of

PHOTO 8 Even a relatively small spill (one gallon) can generate a visible slick that extends for some distance from the source. Additional research is needed to evaluate the cumulative impact of such small releases that occur regularly in a given area, especially when they occur in sensitive areas such as coastal wetlands. (Photo courtesy of Nancy Rabalais.)

tankers increasing from 7,112 to 7,270, and the deadweight of the tanker fleet decreasing from 340 million tonnes to 299 million tonnes. Due to the phase-out schedule of OPA 90 and MARPOL Regulation 13G, the fleet is becoming younger, such that in 1999 more than 50 percent of the tanker fleet was less than 15 years of age. In recognition of the fundamental changes that took place after the Exxon Valdez accident, spill data from 1990 onward were used as the basis for estimating the amount of oil spilled from tankers (tank ships and tank barges). The U.S. Coast Guard consistently collected data on oil spills during the 1990s. These data are considered reliable, particularly for the larger spills, and they serve as the basis for the estimated spills in U.S. waters. The data were sorted geographically to remove inland spills. During the period from 1990 to 1999, there were 513 spills from tankers and tank barges in U.S. coastal waters of at least 100 gallons in size, and the average annual spillage was 4,000 tonnes. Of the recorded spills, 64 were greater than 10,000 gallons (34 tonnes) in size, and these accounted for over 95 percent of the total spillage. One single spill of 13,000 tonnes (3.9 million gallons) from the Mega Borg in 1990 accounted for 36 percent of the total spillage during this ten-year period.

Because comprehensive spill databases for Canadian and Mexican waters are not available, spill volumes for these waters were estimated by adjusting the U.S. figures by the relative movements of petroleum. On this basis, the calculated oil spillage to North American waters, from tankers is 4,000 tonnes per year (see Table 3-2). This calculated value was taken as the minimum estimate. Recognizing the completeness of the U.S. data set, the spill quantities were increased by 5 percent to 5,300 tonnes to obtain the best estimate, and by 20 percent to 6,400 tonnes to obtain the maximum estimate.6

International spill data were obtained from the Environmental Research Consulting database and includes information gleaned from the International Maritime Organization, ITOPF, and other national and regional agencies. These international data are not consistently collected and do not include spills under 10,000 gallons (34 tonnes) in size, and are therefore regarded as underestimates. The international spill quantities were increased by 25 percent to obtain the minimum estimate, by an additional 10 percent to obtain the best estimate, and further increased by 25 percent to obtain the maximum estimate. The international and North American figures were then combined to produce the worldwide estimates of spillage from tankers. The best estimate is 100,000 tonnes; the minimum and maximum estimates are 93,000 tonnes and 130,000 tonnes, respectively.

The NRC 1985 report and the 1990 study (IMO, 1990) both used data from the International Tanker Owners Pollution Federation Ltd. (ITOPF) to estimate the quantity of oil entering the marine environment from tanker accidents. In the NRC 1985 report, the spillage from tankers was averaged over the 7-year period from 1974 to 1980, establishing a best estimate of 390,000 tonnes per year. In the 1990 study, the spillage from tankers was averaged for the 10-year period from 1981 to 1989, establishing a best estimate of 114,000 tonnes per year. It is believed that the collection of international data prior to 1990 was even less consistent than it is today. Also, in the 1985 and 1990 reports no adjustments were made for the deficiencies in the database, and therefore care should be taken when comparing these estimates. In U.S. waters where the spill data have been more consistently recorded since 1980, spillage from tankers during the period 1990-1999 was less than one-third of the spillage recorded during the period 1980-1989.

Operational Discharges (Cargo Oil)

During normal operations, certain tankers may discharge into the sea an amount of oil contained in the ballast and tank washings. Under regulation 13 of MARPOL 73/78, tankers of 20,000 tonnes deadweight and above are required to have segregated ballast tanks (SBT), dedicated clean ballast tanks (CBT), and/or crude oil washing systems (COW), depending on the vessel type, when they were built, and their size. Regulation 13F adopted in 1992 requires all new tankers to have double-hull or equivalent protection of all oil tanks within the cargo block. MARPOL Regulation 13G requires mandatory retirement for single hull tankers at 30 years of age. A revision to regulation 13G requires phase-out of all single hull tankers above 20,000 tonnes deadweight by 1 January 2007.

Generally, crude oil carriers of 20,000 deadweight tonnes (DWT) and above and product tankers of 30,000 tonnes deadweight and above delivered since 1983 must have SBT. Segregated ballast tanks are ballast tanks that are completely separated from the cargo oil and fuel oil systems, and are permanently allocated to the carriage of water ballast. SBT greatly reduces the likelihood of oily ballast discharge, because there are sufficient segregated ballast tanks for normal operation in ballast. For these vessels, ballast may be allocated to cargo tanks only when needed to ensure the safety of the vessel in particularly severe weather. Unlike SBT, the piping systems for CBT may be common or connected with the cargo oil pump and piping systems. There are few CBT tankers operating today.

Regulation 9 of MARPOL limits the amount of oil that may be discharged into the sea to 1/15,000 of the total cargo oil volume for tankers built prior to the implementation of

MARPOL73 (commonly referred to as Pre-MARPOL tankers), and 1/30,000 of the total cargo oil volume for MARPOL tankers. The requirement that the oil content of discharged effluent cannot exceed 15 ppm has the practical effect of limiting operational discharge to amounts much less than these maximum values.

Discharge of oily water within 50 nautical miles from shore is prohibited. Therefore, operational discharges from tankers in North American waters were presumed to be zero. Intentional discharges within U.S. and Canadian waters are believed to be small due to rigorous enforcement programs, and such intentional discharges are considered as part of the input from spills.

By 1999, approximately two-thirds of the tankers operating worldwide had either SBT or double-hull arrangements. SBT and double-hull crude oil carriers will water wash 3 to 4 cargo tanks twice a year for inspection purposes. Assuming full compliance with MARPOL and an oil content of 15 ppm for the discharged effluent, the total discharge per year from SBT and double-hull tankers is estimated as 95 tonnes per year.

The remaining one-third of the crude oil carriers are Pre-MARPOL vessels, and they carry ballast in their cargo tanks. For MARPOL compliant operations, the committee estimated that 1/200,000 of the cargo oil moved on these Pre-MARPOL vessels is discharged with the ballast. This assumes that 30 percent of the deadweight is discharged as ballast with an oil content of 15 ppm. If all Pre-MARPOL tankers operate in compliance with MARPOL, the total estimated discharge is 5,000 tonnes per year.

The outflow factor (oil discharge expressed as a fraction of the oil moved) is estimated as 1/2,000,000 for SBT and double-hull product tankers, and 1/200,000 for Pre-MARPOL product tankers. Assuming all vessels are MARPOL compliant, the estimated operational discharge is 380 tonnes per year for SBT and double hull product tankers, and 1,900 tonnes per year for non-SBT product tankers.

Thus, if all tankers operate in strict compliance with MARPOL, the total operational discharge from cargo washings and ballast discharge is estimated to be 7,400 tonnes per year. It is recognized that not all vessels comply with the regulatory requirements, and the following levels of compliance were assumed when calculating worldwide operational discharges:

|

Greater than 125,000 DWT |

99 percent compliance |

|

20,000 to 125,000 DWT |

95 percent compliance |

|

Less than 20,000 DWT |

90 percent compliance |

The rationale for this degree of non-compliance is that: 1) not all tankers fly the flag of a State that is party to MARPOL 73/78; 2) not all tankers that fly the flag of a State party to MARPOL 73/78 operate in compliance with the discharge criteria; 3) there will be equipment failures on board ships; and 4) there are not adequate reception facilities worldwide. The higher degree of compliance allocated to the larger tankers was justified on the basis that the majority of the larger tankers fly the flag of a State party to MARPOL 73/78, and the majority of larger tankers are on longer voyages that facilitates compliance with MARPOL 73/78.

When these levels of compliance were factored into the analysis, the best estimate for total operational cargo oil discharge from tankers was calculated to be 36,000 tonnes per year. Due to the uncertainty in estimating the frequency of non-compliance and the expected discharge in the event of non-compliance, the minimum estimate is 18,000 tonnes (one-third of the best estimate), and the maximum estimate is 72,000 tonnes (twice the best estimate).7

In the 1975 NRC, 1985 NRC, and 1990 IMO reports, the best estimates for operational discharges from tankers were 1,080,000 tonnes/year, 710,000 tonnes/year, and 158,600 tonnes per year, respectively. The new estimate of 36,000 tonnes/year follows this trend of reduced operational discharges from tankers. Further reductions are anticipated in future years when the tanker fleet is fully double-hulled.

Atmospheric Deposition (from Tankers)

Tankers emit volatile organic compounds (VOC) during loading, during crude oil washing operations, and during the course of the voyage. The amount of VOC emissions depends on many factors, including the properties of the cargo oil, the degree of mixing and temperature variations experienced during the voyage, and whether a vapor recovery system is employed during loading operations. Precise measurement of VOC loss from tankers is difficult. Cargo insurance companies will typically exclude coverage for loss of 0.5 percent of a crude oil cargo as normal variation between loading and unloading ports. This is the upper range of potential uncovered loss.

INTERTANKO conducted an extensive research program to investigate the behavior of crude oil during transport (INTERTANKO, 2000). About 2,024 crude oil and VOC samples were taken during a total of 361 voyages. On the basis of CRUCOGSA study and further theoretical analysis, INTERTANKO estimates that total VOC emissions is approximately 0.20 percent of the crude oil movements, roughly half of these emissions occurring during transport and half during the loading process. In an information paper submitted to IMO MEPC 47 by INTERTANKO, they note that for the more volatile types of crude oil, the loss rate is between 0.4 percent and 0.6 percent. A loss rate of 0.2 percent is applied in this study.

Approximately 3.3 million tonnes of petroleum products were moved by tanker vessels in 1999, including about 2.4

million tonnes of crude oil. The estimated VOC emissions is 0.2 percent of 3.3 millions tonnes or 6.6 million tonnes per year. This is considered a conservative assumption, as the heavier products will emit significantly lower levels of VOC as compared to crude oils.

Based on the CRUCOGSA program sampling and analysis of the volatile components of approximately 1000 samples of crude oil, the VOC in the hullage space of a tanker is broken down as follows: roughly 7 percent ethane, 45 percent propane, 45 percent butane, and the remaining 3 percent of the components within the VOC emissions are heavier than butane. When released into the atmosphere, the lighter hydrocarbons will not deposit, and while it may be a “greenhouse gas” concern, does not appreciably impact the volume of oil entering the sea. Of the remaining VOC, only a small fraction is likely deposited to the sea.

To assess the potential loading of hydrocarbons from fugitive emissions of VOC, this analysis considers the following conservative calculation. The calculated value assumes that: (1) the 97 percent of the VOC released from tankers consists of light hydrocarbons that do not deposit to the sea surface; (2) the remaining VOC mix (3 percent of total VOC emitted from tankers) has a Henry’s law constant equal to that of decane (which certainly underestimates its volatility and, therefore, overestimates deposition); (3) the released VOC do not react in the atmosphere or in surface waters (which ignores the substantial degradation due to hydroxyl radical attack in the troposphere); and (4) the released VOC rapidly partition between the atmosphere, which is well mixed to 1000 m altitude, and the surface ocean, which is well mixed to 100 m depth.

Assuming 3 percent of the VOC are heavier than pentane, and that 0.2 percent of these heavier compounds are deposited into the oceans, the calculated atmospheric deposition of VOC from tankers worldwide is (6.6 million tonnes) × (.03) × (.002) or approximately 400 tonnes per year. The minimum value is 200 tonnes (50 percent of the best estimate), and the maximum value is 1,000 tonnes (see Table 3-2); (300 percent of the best estimate).8

Within North American waters, the total cargo oil movement in 1999 was approximately 0.9 billion tonnes. In recognition of the shorter voyage lengths within coastal waters and the extensive use of vapor recovery at load ports, a loss rate of 0.01 percent is assumed, resulting in estimated VOC emissions of 90,000 tonnes. The calculated atmospheric deposition of VOC from tankers in North American waters is 5 tonnes per year. The minimum value is 2.5 tonnes (50 percent of the best estimate), and the maximum value is 15 tonnes (300 percent of the best estimate).9 Calculation of atmospheric deposition of VOC was not included in the prior NRC reports. Given the size of the loading they may have an impact on air quality. VOC is a known pollutant and has been the subject of many NRC studies (NRC, 1992, 1995a, 1999).

Coastal Facility Spills (refined products)

Coastal facilities are defined for this report as point sources of spills that are not vessels or oil and gas exploration and production facilities (including crude oil pipelines). Table G-1 of Appendix G lists the types of facilities included in this discussion. The U.S. Coast Guard database of spills greater than 100 gallons for the ten-year period from 1990-1999 was used to estimate the amount of oil spilled from facilities. The U.S. Coast Guard data were sorted geographically to remove spills to inland waters. Also, only spills of refined petroleum products from pipelines in coastal areas were included (so as to exclude the crude oil pipeline spills from the USCG data base that were included in the section on oil and gas exploration and production). Facility spills greater than 100 gallons over the period 1990-1999 account for 9 percent of the number of spills and 98 percent of the spill volume. There was an average of 119 facility spills reported per year, with an average volume of 14.4 tonnes. Two types of facilities were the sources of 66 percent of the oil spilled over the 10-year period: coastal pipelines transporting refined products and marine terminals each were the sources of 33 percent of the spilled oil. Industrial facilities were the next largest source of spilled oil, with 14.4 percent. The pipeline spill volume was dominated by one spill event in 1994 where 5,500 tonnes of gasoline, crude oil, diesel, and jet fuel were spilled (the San Jacinto River spill in Texas). This one spill accounted for 30 percent of all the oil spilled from facilities in the 10-year period. This spill also demonstrates the problem of how to account for oil removal, since a very large fraction of the spilled oil burned.

The computed data from the U.S. Coast Guard data for North American waters resulted in estimating the minimum discharge as 1,700 tonnes per year. The best estimate is 1,900 tonnes per year (minimum + 10 percent), recognizing that spill reporting in the U.S. is very high. The maximum is 2,200 tonnes per year (minimum + 30 percent).10

International spill data were obtained from the Environmental Research Consulting database and includes information gleaned from the International Maritime Organization, ITOPF, and other national and regional agencies. The minimum computed discharge is 2,400 tonnes per year, while the best estimate is 4,900 tonnes per year (minimum + 100 percent). The maximum (see Table 3-2) discharge was estimated to be 15,000 tonnes per year (minimum + 500 percent).11

It is difficult to compare directly these numbers to those in the NRC 1985 report because of differences in definitions. The category, marine terminals, in the 1985 report included bunkering operations, but did not specifically indicate the type of facilities included in their computation. The present report defines coastal facilities in a very broad framework (see Table G-1, Appendix G). In the NRC 1985 report, the volume discharged into marine waters by “Marine Terminals” is 20,000 tonnes per year (best estimate), with a range of 10,000 to 30,000 tonnes per year. The best estimate in this report is 4,900 tonnes per year, a significant difference existing between the two estimates.

Overall

This report, based on the methodology described in Appendix E, reports a best estimate for imports from transportation of 160,000 tonnes per year, with a minimum of 120,000 and a maximum of 260,000 tonnes per year. The categories in the NRC 1985 report included major differences from those in the present report, so no overall comparison is possible. However, operational discharges from tankers (best estimate of 36,000 tonnes per year in this report compared to 710,000 tonnes per year in the NRC 1985 report) and oil spills from tankers (best estimate of 100,000 tonnes per year in this report compared to 390,000 tonnes per year in the NRC 1985 report) indicate very significant reductions in the amounts of petroleum hydrocarbons entering the oceans from transportation-related services. In North American waters, the best estimate of petroleum hydrocarbons discharged during the marine transportation of petroleum is 9,100 tonnes per year, while the minimum is 8,500 tonnes per year and the maximum is 11,000 tonnes per year.

Consumption of Petroleum

The world population increased from 4.5 billion in 1980 to 6.0 billion in 1999, an increase of 35 percent (U.S. Census Bureau, www.census.gov). The world’s merchant fleet of vessels greater than 100 gross tons (GT) increased by 18 percent, from 73,832 in 1980 to 86,817 in 1999 (Lloyds Register, 1999). There has also been a significant increase in the number and use of recreational vessels. From year 1985 to 2000, the global consumption of petroleum increased from 9.3 to 11.7 million tonnes per day, an increase of over 25 percent (www.eia.doe.gov, 2001).

Significant petroleum hydrocarbon inputs into the oceans related to consumption of petroleum include river and urban runoff, oil spills from cargo ships, operational discharges from commercial vessels and recreational craft, and atmospheric deposition of petroleum hydrocarbons. Details concerning data sources, methodology, and computations can be found in Appendix E.

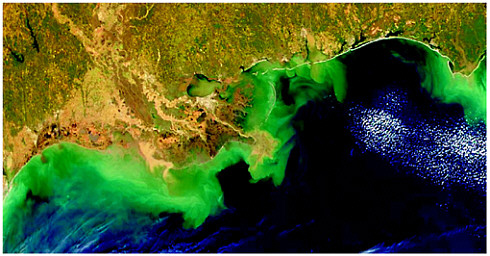

Land-based (river and runoff)

Because of the scarcity of available data for estimating loads from individual sources (i.e., municipal wastewaters, non-refinery industrial discharge, refinery discharges, urban runoff, river discharges, and ocean dumping), loading estimates presented in this analysis are based on loading from all land-based sources per unit of urban land area (see Box 3-3). These calculations assumed that most of the contributions of petroleum hydrocarbons to the sea from land-based sources were from urban areas. This approach accounted for loading from all of the sources in the United States and Canada, with the exception of Gulf coast loadings from coastal refineries, which were calculated separately. The overall calculations of hydrocarbon loadings from all land-based sources for the United States and Canada were then extrapolated to other regions of the world to form a world estimate.

For the calculations in the United States and Canada, the land-based sources were divided into two categories: inland basins and coastal basins. It was assumed that inland basins discharged into major river basins that drain to the sea along the coast of the United States and Canada. Coastal basins were assumed to discharge directly to the sea. Appendix I details the methodology and calculations utilized in determining the sources of petroleum hydrocarbons to the sea from land-based sources.

In order to compute the annual average load of petroleum hydrocarbon to the sea from land-based sources, it was decided to use oil and grease (O&G) as a surrogate measure, and consider TPH and PAH to be some fraction of the O&G. The reason for using O&G data is that these data have been measured historically in urban runoff, wastewater discharges, and rivers. There is no such database available for petroleum hydrocarbon. While some PAH data are available, there is no consistency from investigator to investigator, or study to study with respect to the PAH species that were defined as comprising PAH. The method for arriving at the fractions of O&G that are petroleum hydrocarbon and PAH is described in detail in Appendixes I and J.

|

BOX 3-3 Possible Monitoring Approaches to Determine Land-Based Input Recommendation for Monitoring Approach to Determine Land-based Inputs of Oil to the Sea The range of uncertainty in the estimated loadings to the sea of petroleum hydrocarbons from land-based sources is four orders of magnitude. This means that it could be the largest source of petroleum hydrocarbon by a wide margin. While it is questionable whether petroleum hydrocarbons from land-based sources poses an ecological threat in the sea, the PAH fraction does, so it is recommended that both be included in a monitoring program. It is recommended that all major rivers that have significant urban development in their watersheds be monitored for petroleum hydrocarbon and PAH at the first EPA water quality monitoring station upstream of the end of the reverse tidal flow zone. Samples should be taken monthly (or at minimum seasonally) at the bottom, mid-depth and surface of the river. It is desirable to keep the samples separate, but if cost does not permit that, they can be composited in proportion to the relative velocity of the river at the depth that each sample is taken. The river discharge must be measured at the time the samples are taken. These samples should be analyzed for the petroleum hydrocarbon and the PAH suite of compounds identified in Table 3-3, which are the compounds measured by Environment Canada. Further, these analyses should be performed on both the filtrate and residue of the filtered samples. In addition, urban runoff and municipal wastewater effluents should be monitored in several urban coastal cities. At least one full year of sampling should be done at each site. For urban runoff a flow weighted composite sample for each storm is adequate to determine an Event Mean Concentration for the site. It is recommended that at least the following types of land use be monitored: 1) typical residential, 2) typical shopping center, and 3) urban highway with high density, slow moving rush hour traffic. Runoff samples should be filtered and the filtrate and residue analyzed for TPH and the suite of PAH compounds identified in Table 3-3. Since not all PAH compounds are petroleum derivatives, it would be important to first determine the fraction of TPH that is PAH. Once that fraction is determined, it could be used to partition the PAH measurements in river, waste effluent and urban runoff samples into petroleum derived PAH and those derived by other sources. |

The average annual load in tonnes per year of O&G was then calculated for those rivers with reported O&G concentrations by multiplying the average O&G concentration of each river by corresponding average annual flow. The average annual load for each of these rivers was then converted

PHOTO 9 Diffuse sources of petroleum on land contribute to rivers and runoff polluted with petroleum. Although individual releases may be very small, the cumulative load from all land-based sources accounts for about half of the total average, annual load of petroleum to the marine environment from human related activities. Thus, in terms of volume these sources far exceed the contribution from activities associated with the extraction and transportation of petroleum, combined. (Photo courtesy of Larry Roesner.)

to unit loads per urban land area using U.S. Bureau of the Census (1998) data.

For the majority of the inland river basins, no usable O&G data were available, or observations were too few to be reliable. For these rivers, annual loading of O&G were calculated by multiplying the unit loads from the rivers for which data were available by the urban land area reported for the corresponding river watersheds in U.S. Bureau of the Census (1998) and Statistics Canada (2000).

A similar approach was used to calculate the annual loads of O&G from coastal basins. For the United States, metropolitan areas in U.S. Bureau of the Census (1998) were classified as contributing to coastal basins if they fell within one of the 451 coastal counties defined by Culliton et al. (1990).

TABLE 3-3 PAH Measured by Environment Canada

|

Naphthalene C0-N C1-N C2-N C3-N C4-N Phenanthrene C0-P C1-P C2-P C3-P C4-P |

Dibenzothiophene C0-D C1-D C2-D C3-D Fluorene C0-F C1-F C2-F C3-F Chrysene C0-C C1-C C2-C C3-C |

Other PAH Biphenyl Acenaphthalene Acenaphthene Fluoranthene Pyrene Benz[a]anthracene Benzo[b]fluoranthene Benzo[k]fluoranthene Benzo[e]pyrene Benzo[a]pyrene Perylene Indeno[1,2,3cd]pyrene Dibenz[a,h]nthracene Benzo[hi]erylene |

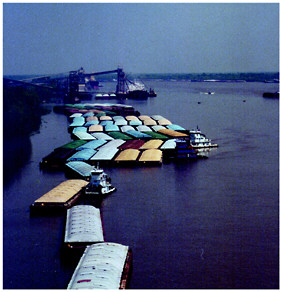

PHOTO 10 Barge traffic on the lower Mississippi River near New Orleans. Like other consumers of petroleum, container vessels and tug boats contribute to the chronic input of petroleum (Photo courtesy of Environmental Research Consulting.)

The individual coastal basin metropolitan areas, along with data from Statistics Canada (2000), were then aggregated into the appropriate coastal zones. The annual loads for each coastal zone were calculated by multiplying the unit loads from the rivers for which data were available by the urban land area in each coastal zone.

Because almost one-fourth of the crude oil distillation capacity of the United States is located along the Gulf coast (Radler, 1999), the petroleum refining industry discharges a substantial amount of additional O&G to coastal waters in that area. To estimate this contribution, the operating capacities for coastal refineries in Louisiana and Texas (Radler, 1999) were multiplied by an assumed rate of O&G loss that corresponded to effluent guidelines for refinery discharges. These loadings were added to the coastal discharge for the coastal zone for the western Gulf of Mexico.

The total inland river and coastal basin annual loads of O&G for the United States and Canada were summed (with the exception of coastal zones for Mexico) to give an overall estimate for North America, based on urban land area. The North American O&G loading was then extrapolated to world estimates based on the number of motor vehicles in different regions of the world (World Resources Institute, 1998).

Data on motor vehicles from the World Resources Institute (1998) were used to calculate the O&G loadings for Mexico because of a lack of data regarding urban land area for metropolitan areas in Mexico. The total load for Mexico was divided by partitioning urban areas in Mexico with populations of more than 100,000 inhabitants as of 1990 (United Nations, 1998) depending on whether urban drainage from those areas drained to the Gulf of Mexico or the Pacific Ocean.

The total petroleum hydrocarbon load was estimated as a fraction of the oil and grease load to the sea. The calculated value of land-based inputs of petroleum hydrocarbons to North American marine waters, using the unit loadings per urban land area, is 2,600 tonnes per year (minimum), while the best estimate is 54,000 tonnes per year and the maximum estimate is 1,900,000 tonnes per year (Table 3-2).12 The worldwide best estimate, as determined using the methodol

|

12 |

The factors used to develop maximum and minimum estimates are somewhat subjective and reflect the committee’s confidence in the data available and the methods and assumptions used to complete the calculation. As discussed in Appendix I, uncertainties regarding the percent of TPH in O&G measurements account for the vast majority of this uncertainty. |

ogy described in Appendix I, is 140,000 tonnes per year. The minimum estimate is 6,800 tonnes per year and the maximum estimate per year is 5,000,000 tonnes.

Recreational Marine Vessels

The 1985 NRC report Oil in the Sea did not discuss petroleum hydrocarbon inputs from operation of two- and four-stroke engines used in outboard motors and personal watercraft (PWC) (also know as jet skis) and small recreational vessels (<100 GT vessels). In both cases, there has been a significant increase in the use of recreational vessels, especially in marinas located in the coastal zone. In 1990, heightened awareness about the large number and the design inefficiencies of two-stroke engines led the U.S. EPA to begin regulating the “non-road engine” population under the authority of the Clean Air Act. Engines that fall under this category include lawn mowers, grass trimmers, chain saws, as well as outboard engines for boats. EPA has issued regulations to decrease the exhaust emissions from small marine engines by 75% by 2005 through new design features (see below). In the 1990 EPA regulations, there were only preliminary data on hydrocarbon inputs into surface water from two-stroke engines. Since then, many more studies have better quantified the inputs of hydrocarbons and gas additives such as MBTE into the air and water from two- and four-stroke engines (Jüttner et al. 1995; Barton and Fearn, 1997; M.S. Dale et al., 2000; Gabele and Pyle, 2000).

Design Features of Two- and Four-Stroke Engines

There is no pump or oil circulation system in a standard two-stroke engine, so oil is added to the gasoline to lubricate the moving parts in the engine. There is no extra valve mechanism to operate, as the piston acts as the valve, opening and closing the necessary ports. These features make these engines powerful and lightweight and therefore very popular as outboard engines on small boats.

Fuel and fuel additives that are not combusted, can enter the surface water directly with the exhaust gases through the exhaust port. Depending on how the fuel is introduced to the combustion chamber, two-strokes may emit unburned fuel and fuel additives. Before 1998, conventional two-stroke engines used either carburetors or injectors to mix fuel with air as it entered the crankcase. Since 1998, marine outboard manufacturers have been producing new, direct injected (DI) two-strokes, although the technology is still in its infancy. While there are various techniques used in DI, they all inject the fuel directly to the cylinder after or nearly after the exhaust ports close. Direct injected two-stroke engines generally have 80 percent less hydrocarbon emissions than their predecessors. In DI two-strokes, oil is introduced directly to the crankcase to lubricate the moving parts and not mixed with the fuel. As the name implies, four-stroke engines use four piston strokes for each combustion cycle including an intake stroke where fuel and air enter the combustion chamber a compression stroke combustion or power stroke and

PHOTO 11 Recreational vessels, especially those with older, two-stroke engines contribute about 6 percent of the total load of petroleum entering North American waters each year. Tri-level “boat racks” along Falmouth Harbor, in Falmouth, Massachusetts, emphasize how enjoyment of recreational marine boating has expanded, leading to a shortage of slips and vessel storage facilities. (Photo courtesy of Paul Dery.)

exhaust stroke. These engines are designed with a separate oiling and mechanical system to operate the valves. This feature limits direct leakage of fuel, but also adds additional weight to the engine that puts them at a disadvantage as a lightweight outboard engine.

For this report, oil and gasoline inputs are calculated for standard (crankcase scavenging) two-stroke engines ranging in size from 16-175 horsepower (20-230 kW), that are fueled by a mixture of oil and gasoline. The population of engines used in recreational vessels is changing dramatically. In 1996 the EPA produced estimates on the potential impact on this changing population. However, four-stroke engines and direct-injection two-stroke engines were not included in this analysis because their populations are not adequately known. Population of other recreational vessels such as diesel outboard and inboard engines is known (EPA population model). However, aqueous fuel emissions studies have focused exclusively on gasoline engines and to our knowledge aqueous diesel emissions are not reported.

Overall, oil and gas inputs from two-stroke outboard motors are estimated to be between 0.6 to 2.5 million gallons per year (average 1.6 million gallons) or between 2,200 and 9,000 tonnes (average 5,300 tonnes) per year for coastal waters of the United States.13

Worldwide estimates of discharge of petroleum hydrocarbons by two-stroke engines were not estimated because of a lack of population databases. The number of two-stroke engines operational in non-North American waters, however is likely extremely large, and it is felt that this is a major source of petroleum hydrocarbons to the world’s oceans.

Spills (Non-Tank Vessels)

Similar to the evaluation of tank vessel spills, the U.S. Coast Guard database was used to estimate spills from non-tank vessels in U.S. waters. During the ten-year period from 1990 to 1999, there were 1,745 spills from non-tank vessels of at least 100 gallon size. Of the recorded spills, 45 were greater than 10,000 gallons (34 tonnes) in size, and these accounted for 53 percent of the total spill volume. The average annual spillage from non-tank commercial ships was 910 tonnes per year, about 23 percent of the spillage from tank vessels.

Because comprehensive spill databases for Canadian and Mexican waters were not available, spill volumes for these waters were estimated by adjusting the U.S. figures by the relative movements of dry cargo. On this basis, the calculated oil spillage from non-tank vessels into North American waters is 1,100 tonnes per year. This figure was applied as the minimum estimate. Recognizing the completeness of the U.S. data set, the spill quantities were increased by just 5 percent to 1,200 tonnes to obtain the best estimate, and by 20 percent to 1,400 tonnes to obtain the maximum estimate.14

International spill data were obtained from the Environmental Research Consulting database and includes information gleaned from the International Maritime Organization, ITOPF, and other national and regional agencies. The international data are not collected consistently and do not include spills under 10,000 gallons (34 tonnes) in size, and are therefore regarded as underestimates. The international spill quantities were increased by 25 percent to obtain the minimum estimate, by an additional 10 percent to obtain the best estimate, and further increased by 25 percent to obtain the maximum estimate.15 The international and North American figures were then combined to obtain the worldwide estimates of spillage from tankers. The best estimate is 7,100 tonnes; the minimum estimate is 6,500 tonnes per year and the maximum is 8,800 tonnes per year.

The NRC 1985 report used data from the International Tanker Owners Pollution Federation Ltd. (ITOPF) to estimate the quantity of oil entering the marine environment from tanker accidents. In the NRC 1985 report, the spillage from tankers was averaged over the 6-year period from 1974 to 1979, establishing a best estimate of 20,000 tonnes per year. In the IMO 1990 report, the spillage from non-tankers was not available, and a best estimate of 7,000 tonnes was made by assuming that the volume of non-tanker spills equaled 6 percent of tanker spillage. In U.S. waters, spillage from non-tankers during the period 1990-1999 was 57 percent of the spillage recorded during the period 1980-1989. It is likely that the IMO 1990 report underestimated the spills from non-tankers, and that spills from non-tankers have declined worldwide during the 1990s.

Operational Discharges (Vessels ≥100 GT)

Machinery Space Bilge Oil Discharge From Tankers

The NRC 1985 study assumed a typical motor ship with a 20,000 HP propulsion plant generated 15 gallons of bilge oil

|

13 |

The factors used to develop maximum and minimum estimates are somewhat subjective and reflect the committee’s confidence in the data available and the methods and assumptions used to complete the calculation. As discussed in Appendix F, uncertainties regarding the size of coastal populations of recreational vessels, the percent of marine vs freshwater use, and the percent of the population using new, more efficient two-stroke engine designs. |

|

14 |

Roughly 5 percent of the spills reported in the available databases did not have adequate geographic information to place them in any region with confidence. The 5 percent factor applied to develop the best estimate reflects the committee’s confidence in the reporting of spills, the completeness of available databases, and a recognition that 97 percent of the total spill volume captured by these databases comes from spills that exceed 100 gallons. The likelihood that a spill much larger than that will go unobserved is, in the committee’s opinion, rather small. |

|

15 |

The factors used to develop maximum and minimum estimates are somewhat subjective and reflect the committee’s confidence in the data available for international waters and the methods and assumptions used to complete the calculation. |

per day. Advancements in the design of engines and pumps and the fitting of containment has reduced the quantity of bilge oil generation in modern ships, and a rate of 5 gallons per day was applied for this evaluation. The number of tankers was taken from the Lloyd’s Register data for 1999, and the installed power was estimated based on the distribution of tanker sizes. Assuming 350 days per year operation, the estimated total bilge oil generation from the world’s tanker fleet is 19,200 tonnes per year. MARPOL requires that the oily water effluent be discharged overboard through an oil-water separator and oil discharge monitoring system, that is set to alarm and shut down when the oil content exceeds 15 ppm. Assuming a 15 ppm oil content for bilge discharges, it is estimated that less than 0.2 percent of bilge oil is discharged overboard. Thus, if all tankers comply with MARPOL regulations, the total worldwide bilge oil discharge would be (19,200 tonnes) × (0.002), or 38 tonnes per year.

Assumed compliance with MARPOL regulations is as follows: 99 percent of tankers greater than 125,000 DWT, 95 percent of tankers 20,000 to 125,000 DWT, and 90 percent of tankers less than 20,000 DWT. Assuming non-compliant tankers discharge 100 percent of the bilge oil into the oceans, the total calculated bilge oil discharge for both MARPOL compliant and non-compliant tankers is 1,130 tonnes per year.

Machinery Space Bilge Oil Discharge From Non-Tankers

According to Lloyd’s Register data there were 79,547 non-tankers above 100 GT in size operating commercially worldwide in 1999. These consisted of 38,732 commercial vessels with the main propulsion plants averaging 7,500 HP, and 40,815 other vessels with an average power of about 500 HP. Similar to tankers, a bilge oil generation rate of 5 gallons/20,000 HP was applied. Vessels between 100 GT and 400 GT, that comprise 54 percent of the non-tanker fleet, are not required to have oily water discharge equipment installed. Although these vessels are not permitted to discharge bilge effluent, it is believed that there is a significant level of non-compliance. Therefore, 15 percent of the commercial vessels and 30 percent of the other vessels were assumed not to comply with the MARPOL requirements. The total calculated worldwide bilge oil discharge for both non-compliant and compliant vessels other than tankers is 15,600 tonnes per year.

Fuel Oil Sludge From All Vessels

Based on 1998 data collected by INTERTANKO (unpublished), the world annual use of fuel oil for marine applications is estimated to be 130 million tonnes of heavy residual fuel oil and 40 million tonnes of distillate fuel. Heavy fuel oils contain between 1 percent and 5 percent sludge or waste oil, which cannot be burned as fuel and therefore must be disposed of by other means. A value of 1.5 percent is applied for these calculations. Diesel fuel oil does not produce any appreciable quantity of sludge and therefore is discounted from further consideration here. Thus, the total production of sludge from ships is estimated as (130 million tonnes) × (0.015), or 1,950,000 tonnes per year.