3

Emission Sources Subject to New Source Review and Technology Options

INTRODUCTION

The purpose of this chapter is to address the following key questions:

-

What source categories account for a substantial portion of permitting activity pertaining to modifications under New Source Review (NSR)?

-

Are modifications an important part of all NSR permitting?

-

What is the current status of state permitting programs and availability of permit data?

-

What is the correct status of state permitting programs and availability of permit data?

-

What are the most common kinds of repairs and replacements in selected industries?

-

What are the typical technology options or considerations regarding those source categories?

The answers to those questions provide insight into the emissions, energy use, and other implications of technological choices regarding preventive measures, repairs, and replacements. In this chapter, we use language that implies the colloquial meanings, as opposed to the “legal” terminology of maintenance and modification as these terms are used in NSR permitting. It is common in many industries to refer to repair and replacement activities as maintenance (in a nonlegal sense) and for maintenance costs to be considered a routine part of the annual operating cost of a facility. To avoid

confusion with legal terminology, in this chapter we use the terms repair and replacement instead of maintenance and modification.

The main focus here in terms of pollutants is on selected criteria pollutants, especially sulfur dioxide (SO2) and oxides of nitrogen (NOx) but also including carbon monoxide (CO), particulate matter (PM) with an aerodynamic diameter smaller than about 10 µm (PM10), and PM with an aerodynamic diameter smaller than about 2.5 µm (PM2.5). Volatile organic compounds (VOCs), which are ozone precursors, are also included.

With respect to identifying technology options, the focus here is on the current status of emission-source technologies and current options for repair and replacement. However, because technology changes, explicit consideration is given to the process of technology change and the implications for technology change in the future. Furthermore, we consider both pollution control and pollution prevention. Typically, pollution control refers to “end-of-pipe” techniques for removing pollutants from an exhaust gas after they have been formed in an upstream process. For example, in a coal-fired power plant, NOx, SO2, and PM are formed during combustion. Postcombustion control technologies—such as selective catalytic reduction, flue-gas desulfurization, and electrostatic precipitation, respectively—can be used to reduce or capture those pollutants. In contrast, pollution prevention is aimed at reducing or eliminating sources of pollution, typically through feedstock substitutions or process alterations. For example, in the case of a coal-fired power plant, methods that control and stage mixing of fuel and air more carefully can prevent the formation of a portion of NOx that otherwise would have been created, and evaporative VOC emissions can be prevented by substituting water-based solvents for VOC-based solvents in a manufacturing facility. In addition, cost is always a consideration in evaluating and choosing options for repair and replacement. Therefore, cost implications of alternatives for repair and replacement are summarized.

OVERVIEW OF NEW SOURCE REVIEW PERMITS

The purpose of this section is to identify and evaluate the frequency of NSR permitting activity with respect to industrial categories for the purpose of determining which emission sources represent the highest priority for assessment. However, a substantial challenge is that there is not a readily available database that summarizes NSR permitting activity. For example, an Environmental Protection Agency (EPA) database1 (EPA 2004d) containing case-specific information on best available control technology (BACT) and lowest achievable emission rate (LAER) does not readily distinguish

between permits for new sources and permits for modifications. In principle, such data could be obtained individually from each state, but the availability of such data varies among states.

An overview of permitting activity was gleaned from information provided by EPA during preparation of the committee’s interim report (NRC 2005), supplemented with information obtained in the intervening period. We provide here a summary based on the interim report followed by a summary of the additional information.

In its interim report, the committee obtained data provided by EPA as the basis of a summary of permitting activity. That information is included in Appendix D. The data provided by EPA are unpublished, were not subjected to review, and have not been distributed outside EPA. The data were based on information collected internally by EPA from its regional offices that were obtained from state and local permitting authorities. They were summarized by EPA for the committee in terms of the NSR permitted emissions (in tons) by two-digit Standard Industrial Classification (SIC) code and by number of permits. Permits were categorized as “greenfield,”2 new at existing sources, and modifications. The main focus here is on modifications. The data do not include information on facilities that made modifications but did not obtain permits via the NSR program. Although the information presented in the table is sorted by pollutant, it is possible for a modification to involve more than one pollutant.

For NOx, the largest share of modification permits—in both number of permits (46%) and NSR permitted emissions (35%)—was for SIC type 49 (electric, gas, and sanitary services).3 SIC type 49 includes electricity-generating plants of all types, and most of the permits and permitted emissions were for SIC code 4911, electric services. SIC types 32 (stone, clay, and glass products) and 26 (paper and allied products) also had a large share of the reported NSR permitted emissions for modifications (27% and 10%, respectively) but substantially fewer than for SIC type 49. For SIC type 32, the most important source category was SIC code 3241, hydraulic cement. Pulp mills (SIC code 2611) were the most commonly permitted source for modifications under SIC type 26. NOx emission sources at these types of facilities are typically industrial or electricity-generating-plant furnaces but can include a variety of other combustion-based sources, such as heaters, kilns, and ovens.

For SO2, the key emission-source category in number of modification

permits (31%) and NSR permitted emissions for modifications (27%) was SIC type 49 (electric, gas, and sanitary services), for which SIC code 4911 (electric services) was the most important subcategory. Other source categories with large totals for NSR-permitted emissions for modifications included SIC types 28 (chemicals and allied products, particularly industrial inorganic chemicals and phosphatic fertilizers) (24%), 32 (stone, clay, and products, particularly hydraulic cement) (22%), and 26 (paper and allied products, particularly pulp, paper, and paperboard mills) (14%). SO2 emissions typically are associated either with combustion of sulfur-bearing fuels or with processing of sulfur-bearing feedstocks or ores (such as crude oil and metal ores).

For CO, the largest number of permits for modifications was issued to SIC types 49 (which includes electric, gas, and sanitary services) and 33 (which includes primary metal industries). With respect to NSR permitted emissions for modifications, the largest categories (in descending order) were SIC types 26 (paper and allied products, primarily paperboard mills), 32 (stone, clay, and glass products, primarily hydraulic cement and concrete block and brick), 33 (primary metal industries), 20 (food and kindred products, primarily cane sugar), and 49 (electric, gas, and sanitary services, primarily electricity-generating facilities).

For PM, the highest frequency of NSR permits for modifications was for SIC types 49 (electric, gas, and sanitary services) and 33 (primary metal industries). Although both those types also contributed to the NSR permitted emissions for modifications, these emissions are widely distributed among six categories, including SIC types 28 (chemical and allied products, primarily carbon black, phosphatic fertilizers, and industrial organic chemicals), 26 (paper and allied products, primarily paperboard mills, pulp mills, and coated and laminated paper), and 20 (food and kindred products, primarily cane sugar).

For VOCs, the highest frequency of permits for modifications was for SIC types 49 (electric, gas, and sanitary services), 33 (primary metal industries), and 24 (lumber and wood products). The largest share of NSR permitted emissions for modifications was for SIC types 26 (paper and allied products, with a large contribution from coated and laminated paper), 20 (food and kindred products, with a large contribution from soybean oil mills), and 24 (lumber and wood products).

The summary above is subject to several key limitations. Complete permit data were not available for every permit issued. The survey was for a specific period (1997-1999); more-recent data were not available. Some sources accept limits on their emissions by state permits when modifications are made and so are not included in the EPA database. There is some uncertainty in estimated NSR permitted emissions because emission rates are often reported on a short-term basis and had to be converted to an

estimate of annual emissions. Actual emissions are typically less than what is allowable. During the survey period, there was a noticeable increase in the number of new natural-gas-fired turbines permitted, which would affect totals for greenfield sites and new facilities at existing locations. However, that probably does not substantially affect the frequency of permits issued for modifications. The data do not include situations in which NSR permits for major modifications were not issued, such as for facilities that considered but decided against making a modification or facilities that made modifications but did not get an NSR permit for a major modification, whether because of noncompliance or because the source agreed to reduce emissions and obtained a state permit. Despite the limitations of the data, they are among the most comprehensive available.

The summary of permitting activity from the interim report is updated here on the basis of data from EPA that include the period 1997-2002. These data are similar to those provided in summary form by EPA for the interim report, with the same caveats and limitations except that the update includes additional years (2000-2002) and the committee had access to the underlying data and so could generate its own summary tables. The information presented also includes Census data on the number of facilities in each state and EPA data on the number of emitting facilities and their total emission amounts. The information is summarized here with respect to the following two objectives: (1) determine the overall permitting activity when comparing electricity-generating and other sectors, and (2) for the SIC codes of sectors other than electricity generating that have the most permitting activity, identify the states with the largest share of this activity occurring. Table 3-1 compares NSR permitting activity by pollutant, selected states, and manufacturing vs electricity-generating sectors; and Table 3-2 compares permitting activity by pollutant, selected states, and selected manufacturing industries.

Although the general conclusions are the same, the updated summary enables more specific insights regarding permitting activity on a state level and regarding the relative importance of electricity generation versus manufacturing sectors.

On the basis of Table 3-1, in general, the emissions associated with permits for modifications are about 1.5-2.3% of the total emissions for a given pollutant for the manufacturing sector (including facilities not granted a permit in that period). For the electricity-generating sector, the emissions associated with permits for modifications are 0.1-1.1% of total emissions except for CO, for which they are 3.6% of total emissions. Overall, therefore, the amount of emissions associated with permits for modifications are about 1-2% of total emissions for most pollutants and types of industrial facilities.

In general, 33.1-41.2% of all NSR permits issued in the manufactur-

TABLE 3-1 NSR Permit Activity Pollutant, 1997-2002, Manufacturing versus Electricity Generationa

|

Manufacturing Sector |

||||||||||

|

Number of Permits |

Permitted Emissions (tpy) |

Census |

Emissions |

|||||||

|

State |

Tot |

Grn |

New |

Mod |

Grn |

New |

Mod |

Plants |

Plants |

tpy |

|

Carbon monoxide |

||||||||||

|

AL |

24 |

2 |

12 |

7 |

385 |

6,729 |

5,353 |

5,444 |

386 |

190,106 |

|

WI |

13 |

2 |

6 |

5 |

240 |

1,831 |

2,875 |

9,936 |

907 |

56,427 |

|

AR |

12 |

1 |

5 |

6 |

3,694 |

3,054 |

12,206 |

3,316 |

96 |

93,876 |

|

LA |

11 |

0 |

7 |

5 |

- |

8,360 |

3,315 |

3,545 |

198 |

592,306 |

|

NC |

10 |

0 |

4 |

5 |

- |

14,067 |

4,470 |

11,306 |

886 |

63,506 |

|

FL |

9 |

1 |

4 |

2 |

490 |

2,894 |

15,697 |

15,992 |

234 |

48,569 |

|

IL |

8 |

0 |

4 |

4 |

- |

5,701 |

515 |

17,953 |

1,644 |

114,147 |

|

TX |

6 |

0 |

4 |

2 |

- |

1,059 |

6,422 |

21,808 |

466 |

386,465 |

|

OH |

5 |

0 |

2 |

5 |

- |

7 |

5,589 |

17,974 |

342 |

701,527 |

|

TN |

5 |

0 |

2 |

2 |

- |

2,271 |

338 |

7,407 |

211 |

91,929 |

|

IN |

5 |

1 |

3 |

1 |

135 |

1,180 |

272 |

9,303 |

341 |

237,363 |

|

Total |

148 |

10 |

71 |

59 |

5,813 |

72,785 |

73,750 |

363,753 |

12,949 |

4,351,945 |

|

Nitrogen oxides |

||||||||||

|

AL |

25 |

3 |

13 |

6 |

287 |

5,206 |

2,258 |

5,444 |

382 |

66,693 |

|

LA |

18 |

1 |

11 |

5 |

186 |

3,442 |

2,504 |

3,545 |

214 |

146,447 |

|

FL |

16 |

1 |

7 |

5 |

394 |

3,428 |

622 |

15,992 |

270 |

44,255 |

|

AR |

10 |

1 |

3 |

4 |

406 |

86,700 |

2,936 |

3,316 |

102 |

31,170 |

|

IL |

10 |

0 |

5 |

4 |

- |

5,875 |

1,486 |

17,953 |

2041 |

102,435 |

|

WI |

10 |

2 |

6 |

2 |

1,842 |

916 |

360 |

9,936 |

951 |

43,953 |

|

NC |

8 |

1 |

3 |

3 |

767 |

1,127 |

4,175 |

11,306 |

912 |

43,718 |

|

TX |

6 |

0 |

4 |

2 |

- |

2,093 |

8,329 |

21,808 |

470 |

280,741 |

|

PA |

6 |

0 |

2 |

1 |

- |

4,889 |

916 |

17,128 |

476 |

110,514 |

|

TN |

6 |

0 |

3 |

3 |

- |

4,013 |

487 |

7,407 |

232 |

60,711 |

|

IN |

6 |

1 |

3 |

2 |

75 |

1,022 |

2,102 |

9,303 |

358 |

43,912 |

|

OH |

6 |

0 |

3 |

5 |

- |

138 |

1,637 |

17,974 |

345 |

69,263 |

|

MN |

6 |

0 |

3 |

1 |

- |

1,194 |

106 |

8,091 |

278 |

20,808 |

|

CA |

5 |

0 |

0 |

2 |

- |

- |

1,577 |

49,418 |

1,804 |

73,855 |

|

Total |

181 |

13 |

85 |

60 |

6,463 |

133,659 |

36,343 |

363,753 |

14,515 |

1,803,675 |

|

Particulate matter (PM10) |

||||||||||

|

AL |

27 |

2 |

12 |

11 |

86 |

913 |

1,605 |

5,444 |

535 |

35,287 |

|

FL |

26 |

2 |

12 |

10 |

24 |

1,401 |

2,561 |

15,992 |

351 |

13,846 |

|

WI |

19 |

2 |

11 |

8 |

126 |

466 |

243 |

9,936 |

812 |

9,748 |

|

LA |

18 |

1 |

9 |

7 |

14 |

1,223 |

447 |

3,545 |

202 |

30,334 |

|

NC |

12 |

1 |

4 |

4 |

177 |

474 |

877 |

11,306 |

1,222 |

19,405 |

|

IL |

9 |

0 |

4 |

4 |

- |

736 |

132 |

17,953 |

2,615 |

45,727 |

|

AR |

8 |

1 |

4 |

3 |

247 |

568 |

477 |

3,316 |

101 |

13,485 |

|

KY |

8 |

0 |

4 |

2 |

- |

172 |

734 |

4,218 |

511 |

10,773 |

|

OH |

7 |

0 |

4 |

5 |

- |

30 |

3,375 |

17,974 |

516 |

34,887 |

|

TN |

7 |

0 |

3 |

3 |

- |

658 |

169 |

7,407 |

164 |

2 |

|

Electricity-Generating Sector |

|||||||

|

Number of Permits |

Permitted Emissions (tpy) |

Emissions (tpy) |

|||||

|

Tot |

Grn |

New |

Mod |

Grn |

New |

Mod |

|

|

31 |

10 |

12 |

1 |

7,970 |

14,664 |

4,545 |

12,005 |

|

18 |

0 |

9 |

3 |

- |

3,729 |

444 |

7,856 |

|

16 |

6 |

3 |

0 |

5,687 |

1,705 |

- |

12,413 |

|

19 |

4 |

3 |

3 |

3,151 |

674 |

1,780 |

35,071 |

|

13 |

5 |

2 |

2 |

2,285 |

625 |

235 |

13,848 |

|

61 |

29 |

11 |

8 |

8,119 |

2,636 |

5,563 |

23,297 |

|

36 |

4 |

3 |

0 |

5,688 |

9,153 |

- |

16,536 |

|

62 |

5 |

2 |

0 |

3,850 |

887 |

- |

101,286 |

|

12 |

0 |

3 |

0 |

- |

2,563 |

- |

15,868 |

|

3 |

1 |

2 |

0 |

1,284 |

433 |

- |

10,935 |

|

17 |

8 |

1 |

0 |

5,444 |

221 |

- |

16,930 |

|

557 |

166 |

104 |

39 |

119,977 |

63,637 |

24,090 |

677,206 |

|

33 |

15 |

11 |

1 |

5,349 |

5,236 |

892 |

235,480 |

|

18 |

4 |

1 |

3 |

1,962 |

559 |

929 |

178,812 |

|

66 |

29 |

12 |

13 |

22,507 |

3,214 |

20,826 |

310,279 |

|

16 |

6 |

3 |

0 |

4,431 |

1,418 |

- |

65,935 |

|

37 |

4 |

2 |

0 |

1,666 |

4,379 |

- |

330,587 |

|

19 |

0 |

13 |

4 |

- |

5,231 |

886 |

120,543 |

|

13 |

5 |

2 |

0 |

5,389 |

2,040 |

- |

274,309 |

|

62 |

5 |

2 |

0 |

4,149 |

346 |

- |

502,201 |

|

27 |

3 |

3 |

0 |

650 |

142 |

- |

275,072 |

|

3 |

1 |

2 |

0 |

2,032 |

643 |

- |

311,678 |

|

17 |

9 |

1 |

0 |

4,287 |

132 |

- |

402,124 |

|

13 |

0 |

3 |

0 |

- |

3,462 |

- |

557,700 |

|

4 |

1 |

2 |

0 |

782 |

737 |

- |

127,232 |

|

14 |

8 |

0 |

1 |

1,498 |

- |

247 |

34,541 |

|

572 |

180 |

108 |

46 |

120,370 |

45,036 |

31,234 |

7,193,141 |

|

28 |

14 |

11 |

1 |

2,407 |

2,237 |

259 |

9,080 |

|

55 |

30 |

9 |

7 |

2,706 |

672 |

1,125 |

11,419 |

|

14 |

0 |

8 |

2 |

- |

1,250 |

164 |

5,968 |

|

10 |

5 |

4 |

2 |

1,230 |

252 |

352 |

3,850 |

|

11 |

6 |

4 |

2 |

882 |

281 |

87 |

14,357 |

|

10 |

6 |

3 |

0 |

1,700 |

1,389 |

- |

12,090 |

|

8 |

5 |

3 |

0 |

1,966 |

676 |

- |

1,930 |

|

8 |

4 |

2 |

0 |

2,017 |

511 |

- |

19,393 |

|

3 |

0 |

3 |

0 |

- |

458 |

- |

16,562 |

|

1 |

1 |

1 |

0 |

214 |

54 |

- |

33,764 |

|

Manufacturing Sector |

||||||||||

|

Number of Permits |

Permitted Emissions (tpy) |

Census |

Emissions |

|||||||

|

State |

Tot |

Grn |

New |

Mod |

Grn |

New |

Mod |

Plants |

Plants |

tpy |

|

Particulate matter (PM10) continued |

||||||||||

|

VA |

7 |

0 |

3 |

4 |

- |

161 |

90 |

5,986 |

854 |

13,514 |

|

IN |

6 |

0 |

4 |

2 |

- |

472 |

253 |

9,303 |

456 |

14,689 |

|

MS |

6 |

2 |

1 |

3 |

111 |

13 |

116 |

3,008 |

103 |

7,712 |

|

TX |

5 |

0 |

3 |

2 |

- |

219 |

1,497 |

21,808 |

419 |

34,010 |

|

IA |

5 |

0 |

1 |

3 |

- |

197 |

628 |

3,749 |

32 |

7,379 |

|

SC |

5 |

3 |

3 |

0 |

282 |

86 |

- |

4,450 |

172 |

8,137 |

|

GA |

5 |

0 |

2 |

2 |

- |

55 |

236 |

9,083 |

145 |

29,335 |

|

CA |

5 |

0 |

0 |

2 |

- |

- |

222 |

49,418 |

1,520 |

15,891 |

|

Total |

207 |

14 |

99 |

80 |

1,067 |

11,656 |

13,936 |

363,753 |

15,397 |

606,681 |

|

Sulfur dioxide |

||||||||||

|

FL |

20 |

1 |

7 |

11 |

37 |

3,161 |

21,247 |

15,992 |

237 |

7,3497 |

|

AL |

14 |

0 |

7 |

6 |

- |

2,137 |

3,319 |

5,444 |

327 |

84,797 |

|

IL |

8 |

0 |

3 |

4 |

- |

16,392 |

2,747 |

17,953 |

1,130 |

240,356 |

|

WI |

8 |

2 |

4 |

2 |

82 |

685 |

104 |

9,936 |

637 |

80,598 |

|

LA |

7 |

0 |

5 |

2 |

- |

10,763 |

1,995 |

3,545 |

132 |

151,246 |

|

NC |

7 |

1 |

2 |

3 |

244 |

5,661 |

5,837 |

11,306 |

755 |

72,180 |

|

AR |

7 |

1 |

2 |

3 |

791 |

232 |

10,401 |

3,316 |

86 |

54,095 |

|

OH |

6 |

0 |

2 |

5 |

- |

1,590 |

2,719 |

17,974 |

334 |

330,991 |

|

IN |

6 |

1 |

3 |

2 |

39 |

384 |

2,400 |

9,303 |

330 |

125,434 |

|

TX |

5 |

0 |

3 |

2 |

- |

93 |

12,600 |

21,808 |

369 |

233,257 |

|

IA |

5 |

0 |

1 |

3 |

- |

5,913 |

2,132 |

3,749 |

30 |

67,285 |

|

TN |

5 |

0 |

2 |

3 |

- |

902 |

585 |

7,407 |

107 |

122,658 |

|

VA |

5 |

0 |

2 |

2 |

- |

612 |

117 |

5,986 |

664 |

97,063 |

|

Total |

131 |

8 |

58 |

54 |

1,206 |

53,725 |

68,349 |

363,753 |

9,776 |

2,914,441 |

|

Volatile organic compounds |

||||||||||

|

WI |

36 |

2 |

23 |

10 |

93 |

2,934 |

743 |

9,936 |

1,233 |

56,490 |

|

AL |

27 |

3 |

8 |

10 |

2,023 |

1,308 |

1,843 |

5,444 |

566 |

88,546 |

|

LA |

13 |

1 |

8 |

5 |

12 |

2,702 |

3,188 |

3,545 |

235 |

90,490 |

|

AR |

12 |

0 |

7 |

3 |

- |

1,696 |

837 |

3,316 |

117 |

33,988 |

|

FL |

12 |

1 |

5 |

3 |

16 |

420 |

1,990 |

15,992 |

507 |

18,622 |

|

NC |

11 |

0 |

7 |

3 |

- |

2,372 |

1,148 |

11,306 |

1,156 |

78,718 |

|

GA |

11 |

0 |

3 |

5 |

- |

448 |

1,316 |

9,083 |

227 |

32,111 |

|

IL |

10 |

0 |

4 |

7 |

- |

6,645 |

2,443 |

17,953 |

1,741 |

136,081 |

|

SC |

10 |

3 |

5 |

0 |

844 |

1,504 |

- |

4,450 |

187 |

46,631 |

|

KY |

9 |

1 |

2 |

4 |

107 |

609 |

4,116 |

4,218 |

559 |

57,951 |

|

MI |

8 |

0 |

5 |

2 |

- |

2,935 |

103 |

1,6045 |

765 |

71,594 |

|

MS |

8 |

1 |

4 |

3 |

678 |

501 |

1,148 |

3,008 |

188 |

39,079 |

|

OH |

8 |

0 |

2 |

5 |

- |

3 |

2,251 |

17,974 |

820 |

77,781 |

|

TX |

8 |

0 |

5 |

3 |

- |

405 |

1,451 |

21,808 |

568 |

192,080 |

|

VA |

8 |

0 |

3 |

4 |

- |

991 |

301 |

5,986 |

822 |

55,460 |

|

Electricity-Generating Sector |

|||||||

|

Number of Permits |

Permitted Emissions (tpy) |

Emissions (tpy) |

|||||

|

Tot |

Grn |

New |

Mod |

Grn |

New |

Mod |

|

|

17 |

8 |

5 |

1 |

1,547 |

417 |

115 |

4,825 |

|

8 |

7 |

1 |

0 |

1,436 |

22 |

- |

13,307 |

|

11 |

8 |

3 |

0 |

1,497 |

848 |

- |

1,964 |

|

5 |

3 |

2 |

0 |

702 |

139 |

- |

23,372 |

|

3 |

1 |

2 |

0 |

213 |

93 |

- |

3,020 |

|

2 |

2 |

0 |

0 |

266 |

- |

- |

7,208 |

|

10 |

8 |

2 |

1 |

1,296 |

353 |

438 |

8,519 |

|

4 |

3 |

1 |

0 |

452 |

38 |

- |

3,283 |

|

303 |

156 |

85 |

34 |

30,119 |

11,358 |

3,822 |

35,1410 |

|

53 |

27 |

11 |

7 |

5,991 |

616 |

20457 |

698,288 |

|

15 |

8 |

5 |

1 |

945 |

9,365 |

324 |

568,542 |

|

7 |

4 |

2 |

0 |

383 |

5,632 |

- |

833,311 |

|

14 |

0 |

9 |

2 |

- |

1,588 |

148 |

238,313 |

|

3 |

1 |

1 |

1 |

215 |

3 |

21 |

131,565 |

|

9 |

4 |

3 |

0 |

1,125 |

576 |

- |

478,640 |

|

7 |

3 |

2 |

0 |

198 |

137 |

- |

85,554 |

|

3 |

0 |

2 |

0 |

- |

10,503 |

- |

1,491,039 |

|

7 |

7 |

0 |

0 |

771 |

- |

- |

986,065 |

|

5 |

3 |

2 |

0 |

312 |

122 |

- |

684,100 |

|

1 |

0 |

1 |

0 |

- |

0 |

- |

173,424 |

|

2 |

1 |

1 |

0 |

428 |

95 |

- |

546,745 |

|

14 |

7 |

5 |

1 |

657 |

357 |

14 |

215,026 |

|

244 |

126 |

68 |

22 |

43,919 |

37,075 |

25,334 |

13,421,975 |

|

16 |

0 |

10 |

3 |

- |

344 |

185 |

942 |

|

22 |

11 |

7 |

1 |

1,983 |

853 |

598 |

2,991 |

|

7 |

3 |

3 |

1 |

94 |

97 |

97 |

14,964 |

|

8 |

5 |

3 |

0 |

733 |

857 |

- |

1,390 |

|

51 |

27 |

8 |

5 |

1,224 |

211 |

313 |

4,279 |

|

11 |

5 |

3 |

2 |

177 |

73 |

23 |

3,504 |

|

9 |

4 |

3 |

0 |

303 |

114 |

- |

1,236 |

|

7 |

4 |

3 |

0 |

792 |

252 |

- |

6,198 |

|

2 |

2 |

0 |

0 |

607 |

- |

- |

524 |

|

5 |

4 |

1 |

0 |

1,245 |

24 |

- |

1,541 |

|

15 |

6 |

7 |

3 |

873 |

454 |

65 |

3,819 |

|

10 |

7 |

3 |

0 |

731 |

797 |

- |

3,355 |

|

2 |

0 |

1 |

0 |

- |

39 |

- |

2,089 |

|

6 |

3 |

2 |

0 |

441 |

55 |

- |

22,749 |

|

15 |

8 |

5 |

1 |

956 |

98 |

83 |

1,519 |

ing sector and 9.0-25.6% in the electricity-generating sector were issued for modifications, depending on the pollutant. Thus, in both sectors, the number of permits issued for modifications is less than the number issued for either new facilities at existing locations or new and greenfield facilities combined.

Typically, only a few states contribute substantially to the national total emissions associated with permits for modifications for a given pollutant and sector. For example, for NOx, five states (Florida, Arkansas, Texas, Ohio, and Alabama) contribute 61.4% of the total emissions associated with such permits in the manufacturing sector, whereas a different set of five states (Alabama, Illinois, Wisconsin, Florida, and Ohio) contribute 47.8% of the total permitted emissions associated with modifications in the electricity-generating sector. For SO2, only three states (Florida, Texas, and Arkansas) contribute 64.7% to emissions associated with modification permits in the manufacturing sector, and Florida alone contributes 80.7% to the total emissions for modification permits in the electricity-generating sector. In general, in the manufacturing sector, the top five states shown in Table 3-1 contribute 55.4-78.1% of the national emissions associated with permits for modifications. Similarly, the top five states contribute 47.8-82.8% of the emissions associated with modification permits in the electricity-generating sector. Therefore, in general, a substantial portion of the total emissions associated with permits for modifications can be attributed to a relatively small number of states.

|

Electricity-Generating Sector |

|||||||

|

Number of Permits |

Permitted Emissions (tpy) |

Emissions (tpy) |

|||||

|

Tot |

Grn |

New |

Mod |

Grn |

New |

Mod |

|

|

7 |

7 |

0 |

0 |

573 |

- |

- |

2,712 |

|

4 |

1 |

1 |

0 |

42 |

20 |

- |

2,788 |

|

2 |

1 |

1 |

0 |

99 |

58 |

- |

7,393 |

|

1 |

1 |

0 |

0 |

59 |

- |

- |

613 |

|

279 |

133 |

79 |

29 |

17,087 |

5,187 |

1,667 |

160,666 |

|

ABBREVIATIONS: Census plants = number of establishments in manufacturing industries in state, taken from 1997 Economic Census; emissions = 1997 EPA point-source emission data (unpublished, not 1996 National Emissions Inventory [NEI] data), includes number of plants with any emissions of this pollutant and total emissions; Grn = Greenfield; Mod = modification; New = new unit at existing plant; Tot = total; tpy = tons per year. |

|||||||

Alabama, Arkansas, Florida, Ohio, North Carolina, and Texas have substantial permitting activity in the manufacturing sector for modifications for three or more of the five pollutants listed in Table 3-1. Alabama, Florida, Louisiana, and Wisconsin have substantial permitting activity for modifications in the electricity-generating sector for three or more pollutants.

Table 3-2 provides examples of the distribution of NSR permits among selected industries and states for five pollutants in the manufacturing sector. For example, for NOx, the paper and allied products industry contributed about 21.7% to the emissions associated with permits for modifications, and the largest share of the activity for this industry was in North Carolina. For SO2, the chemical and allied products industry and the paper and allied products industry combined for 57.5% of the total emissions associated with permits for modifications in the manufacturing sector. Most of that activity was in Florida, Arkansas, and North Carolina. For PM10, the two industries combined account for about half the total emissions associated with permits for modifications in the manufacturing sectors, with only a handful of states (e.g., Alabama, North Carolina, Kentucky, and Florida) contributing substantial shares. The primary metal industries and the paper and chemical industries had substantial permitting activity for CO, including permits for modifications totaling 1,000 tons/year or more in six states. VOC emissions tend to be dispersed among many industries. The paper and allied products industry contributed 28.3% of the total emissions associated with permits for modifications; a large share of the industry total was in

TABLE 3-2 NSR Permit Activity by Pollutant, 1997-2002, Selected Manufacturing Industriesa

|

State |

Number of Permits |

Permitted Emissions (tpy) |

Census |

Emissions |

Emissions |

|||||

|

Tot |

Grn |

New |

Mod |

Grn |

New |

Mod |

Plants |

Plants |

||

|

Carbon monoxide |

||||||||||

|

|

SIC 26: Paper and Allied Products |

|||||||||

|

AL |

5 |

1 |

2 |

2 |

215 |

2,811 |

1,555 |

19 |

21 |

5,3208 |

|

AR |

3 |

0 |

1 |

2 |

- |

917 |

3,920 |

8 |

7 |

3,2977 |

|

NC |

3 |

0 |

1 |

2 |

- |

8,678 |

3,920 |

14 |

29 |

1,7926 |

|

WI |

3 |

0 |

3 |

0 |

- |

1,305 |

- |

51 |

89 |

24,496 |

|

GA |

2 |

0 |

2 |

1 |

- |

707 |

185 |

25 |

21 |

142,217 |

|

Total |

20 |

1 |

12 |

8 |

215 |

25,626 |

9,148 |

543 |

722 |

552,075 |

|

|

SIC 28: Chemicals and Allied Products |

|||||||||

|

LA |

5 |

0 |

4 |

1 |

- |

464 |

263 |

16 |

90 |

448,938 |

|

AL |

3 |

0 |

2 |

1 |

- |

239 |

578 |

12 |

27 |

46465 |

|

KY |

2 |

0 |

1 |

0 |

- |

473 |

- |

11 |

45 |

1,125 |

|

MI |

2 |

0 |

1 |

1 |

- |

865 |

863 |

48 |

47 |

1,289 |

|

TX |

2 |

0 |

2 |

0 |

- |

334 |

- |

94 |

184 |

265,755 |

|

Total |

20 |

0 |

13 |

7 |

0 |

2,761 |

7,719 |

1,733 |

1,518 |

1,255,846 |

|

|

SIC 20: Petroleum and Coal Products |

|||||||||

|

LA |

3 |

0 |

1 |

2 |

- |

297 |

1,828 |

54 |

25 |

78,071 |

|

IL |

2 |

0 |

0 |

2 |

- |

- |

38 |

93 |

152 |

2,945 |

|

TX |

2 |

0 |

2 |

0 |

- |

725 |

- |

194 |

38 |

41,077 |

|

Total |

9 |

0 |

4 |

4 |

0 |

1,070 |

1,866 |

2,074 |

1,500 |

460,508 |

|

|

SIC 33: Primary Metal Industries |

|||||||||

|

WI |

8 |

0 |

3 |

5 |

- |

526 |

2875 |

6 |

77 |

14,067 |

|

AL |

3 |

0 |

2 |

1 |

- |

2,239 |

37 |

11 |

45 |

38,900 |

|

AR |

3 |

1 |

1 |

1 |

3,694 |

753 |

3,942 |

7 |

10 |

6,055 |

|

IN |

2 |

0 |

1 |

1 |

- |

585 |

272 |

18 |

54 |

193,361 |

|

NC |

2 |

0 |

1 |

1 |

- |

4,380 |

436 |

1 |

20 |

6,568 |

|

OH |

2 |

0 |

1 |

2 |

- |

5 |

4,201 |

29 |

52 |

572,213 |

|

OR |

2 |

0 |

0 |

2 |

- |

- |

2,521 |

5 |

15 |

5,947 |

|

TN |

2 |

0 |

0 |

1 |

- |

- |

192 |

9 |

14 |

12,386 |

|

VA |

2 |

0 |

1 |

1 |

- |

3,473 |

341 |

4 |

21 |

2,340 |

|

Total |

35 |

2 |

13 |

19 |

3,880 |

15,843 |

16,820 |

287 |

893 |

1,658,200 |

|

|

SIC 37: Transportation Equipment |

|||||||||

|

AL |

3 |

1 |

2 |

0 |

171 |

482 |

- |

6 |

8 |

409 |

|

Total |

3 |

1 |

2 |

0 |

171 |

482 |

0 |

355 |

593 |

1,7434 |

|

Nitrogen oxides |

||||||||||

|

|

SIC 26: Paper and Allied Products |

|||||||||

|

AL |

5 |

1 |

2 |

2 |

129 |

1,715 |

1,723 |

19 |

19 |

31,516 |

|

WI |

3 |

0 |

3 |

0 |

- |

324 |

- |

51 |

90 |

28,858 |

|

State |

Number of Permits |

Permitted Emissions (tpy) |

Census |

Emissions |

Emissions |

|||||

|

Tot |

Grn |

New |

Mod |

Grn |

New |

Mod |

Plants |

Plants |

||

|

Nitrogen oxides |

||||||||||

|

|

SIC 26: Paper and Allied Products |

|||||||||

|

AR |

2 |

0 |

1 |

1 |

- |

86,264 |

711 |

8 |

7 |

18,523 |

|

GA |

2 |

0 |

2 |

1 |

- |

386 |

125 |

25 |

21 |

34,011 |

|

NC |

2 |

0 |

0 |

2 |

- |

- |

4,071 |

14 |

30 |

13,897 |

|

Total |

21 |

1 |

11 |

9 |

129 |

92,724 |

7,903 |

543 |

786 |

318,804 |

|

|

SIC 28: Chemicals and Allied Products |

|||||||||

|

LA |

8 |

1 |

6 |

0 |

186 |

1,813 |

- |

16 |

93 |

73,815 |

|

FL |

7 |

0 |

3 |

3 |

- |

226 |

180 |

69 |

36 |

8,974 |

|

AL |

5 |

0 |

3 |

1 |

- |

405 |

251 |

12 |

35 |

8,022 |

|

AR |

2 |

0 |

0 |

1 |

- |

- |

1,091 |

8 |

14 |

4,688 |

|

KY |

2 |

0 |

1 |

0 |

- |

229 |

- |

11 |

48 |

5,564 |

|

TX |

2 |

0 |

2 |

0 |

- |

236 |

- |

94 |

182 |

109,926 |

|

Total |

34 |

1 |

20 |

8 |

186 |

4,038 |

2,023 |

1,739 |

1,638 |

416,235 |

|

|

SIC 29: Petroleum and Coal Products |

|||||||||

|

LA |

8 |

0 |

3 |

4 |

- |

201 |

2,499 |

54 |

29 |

47,242 |

|

CA |

2 |

0 |

0 |

0 |

- |

- |

- |

205 |

171 |

29,212 |

|

IL |

2 |

0 |

0 |

2 |

- |

- |

151 |

93 |

163 |

29,361 |

|

MN |

2 |

0 |

1 |

1 |

- |

109 |

106 |

29 |

59 |

5,540 |

|

TX |

2 |

0 |

2 |

0 |

- |

1,857 |

- |

194 |

38 |

102,101 |

|

Total |

18 |

0 |

7 |

7 |

0 |

2,258 |

2,756 |

2,074 |

1,600 |

321,098 |

|

|

SIC 33: Primary Metals Industries |

|||||||||

|

WI |

5 |

0 |

3 |

2 |

- |

592 |

360 |

6 |

85 |

3,577 |

|

AL |

3 |

0 |

2 |

1 |

- |

1,019 |

37 |

11 |

40 |

5,984 |

|

OH |

3 |

0 |

2 |

2 |

- |

37 |

384 |

29 |

54 |

13,659 |

|

TN |

3 |

0 |

1 |

2 |

- |

197 |

338 |

9 |

13 |

3,239 |

|

AR |

2 |

1 |

0 |

1 |

406 |

- |

749 |

7 |

11 |

1,728 |

|

IN |

2 |

0 |

1 |

1 |

- |

54 |

36 |

18 |

58 |

16,871 |

|

OR |

2 |

0 |

0 |

2 |

- |

- |

571 |

5 |

16 |

1,367 |

|

SC |

2 |

1 |

1 |

0 |

2 |

347 |

- |

11 |

8 |

757 |

|

VA |

2 |

0 |

1 |

1 |

- |

798 |

296 |

4 |

24 |

1,001 |

|

Total |

31 |

2 |

14 |

15 |

409 |

4,154 |

3,063 |

287 |

1033 |

150,948 |

|

|

SIC 37: Transportation Equipment |

|||||||||

|

AL |

4 |

2 |

2 |

0 |

158 |

342 |

- |

6 |

6 |

168 |

|

Total |

7 |

2 |

3 |

0 |

158 |

1,422 |

0 |

355 |

669 |

2,6754 |

|

Particulate matter (PM10) |

||||||||||

|

|

SIC 26: Paper and Allied Products |

|||||||||

|

AL |

6 |

1 |

2 |

3 |

46 |

284 |

1,078 |

19 |

22 |

10,367 |

|

WI |

5 |

0 |

5 |

0 |

- |

211 |

- |

51 |

75 |

1,307 |

|

State |

Number of Permits |

Permitted Emissions (tpy) |

Census |

Emissions |

Emissions |

|||||

|

Tot |

Grn |

New |

Mod |

Grn |

New |

Mod |

Plants |

Plants |

||

|

Particulate matter (PM10) |

||||||||||

|

|

SIC 26: Paper and Allied Products |

|||||||||

|

GA |

3 |

0 |

2 |

1 |

- |

55 |

17 |

25 |

17 |

12,643 |

|

LA |

3 |

0 |

2 |

1 |

- |

994 |

4 |

12 |

14 |

8,631 |

|

KY |

2 |

0 |

0 |

1 |

- |

- |

603 |

9 |

17 |

716 |

|

NC |

2 |

0 |

0 |

2 |

- |

- |

801 |

14 |

34 |

4,608 |

|

Total |

28 |

1 |

15 |

11 |

46 |

2,399 |

3,027 |

543 |

728 |

85,440 |

|

|

SIC 28: Chemicals and Allied Products |

|||||||||

|

FL |

15 |

0 |

7 |

7 |

- |

651 |

587 |

69 |

42 |

1,306 |

|

LA |

6 |

1 |

4 |

0 |

14 |

184 |

- |

16 |

82 |

6,882 |

|

AL |

4 |

0 |

1 |

2 |

- |

13 |

262 |

12 |

50 |

1,762 |

|

KY |

4 |

0 |

2 |

1 |

- |

111 |

131 |

11 |

59 |

1,563 |

|

Total |

36 |

1 |

18 |

13 |

14 |

1,044 |

3,524 |

1,733 |

1,769 |

80,166 |

|

|

SIC 29: Petroleum and Coal Products |

|||||||||

|

LA |

8 |

0 |

3 |

5 |

- |

46 |

419 |

54 |

26 |

5,337 |

|

IL |

2 |

0 |

0 |

2 |

- |

- |

18 |

93 |

196 |

5,999 |

|

TX |

2 |

0 |

2 |

0 |

- |

207 |

- |

194 |

38 |

8,954 |

|

Total |

14 |

0 |

6 |

7 |

0 |

280 |

437 |

2,074 |

1,709 |

53,767 |

|

|

SIC 33: Primary Metal Industries |

|||||||||

|

WI |

11 |

0 |

6 |

7 |

- |

255 |

230 |

6 |

90 |

3,185 |

|

TN |

4 |

0 |

1 |

2 |

- |

475 |

160 |

9 |

16 |

3,096 |

|

AL |

3 |

0 |

2 |

1 |

- |

132 |

6 |

11 |

72 |

8,513 |

|

AR |

|

1 |

1 |

1 |

247 |

4 |

108 |

7 |

10 |

424 |

|

OH |

3 |

0 |

2 |

2 |

- |

21 |

389 |

29 |

92 |

13,296 |

|

VA |

3 |

0 |

1 |

2 |

- |

135 |

64 |

4 |

23 |

1,426 |

|

IN |

2 |

0 |

1 |

1 |

- |

24 |

22 |

18 |

69 |

9,363 |

|

NC |

2 |

0 |

2 |

0 |

- |

238 |

- |

1 |

24 |

391 |

|

SC |

2 |

1 |

2 |

0 |

2 |

84 |

- |

11 |

7 |

368 |

|

Total |

43 |

3 |

20 |

21 |

354 |

1,429 |

1,391 |

290 |

1,134 |

114,932 |

|

|

SIC 37: Transportation Equipment |

|||||||||

|

AL |

2 |

1 |

1 |

0 |

41 |

37 |

- |

6 |

10 |

225 |

|

Total |

4 |

2 |

1 |

1 |

47 |

37 |

13 |

342 |

695 |

7,424 |

|

Sulfur dioxide |

||||||||||

|

|

SIC 26: Paper and Allied Products |

|||||||||

|

AL |

6 |

0 |

1 |

4 |

- |

799 |

2,660 |

19 |

18 |

33,294 |

|

NC |

3 |

0 |

1 |

2 |

- |

5,277 |

5,729 |

14 |

26 |

20,766 |

|

FL |

2 |

0 |

1 |

1 |

- |

241 |

40 |

10 |

11 |

26,260 |

|

GA |

2 |

0 |

2 |

1 |

- |

203 |

5 |

25 |

17 |

55,075 |

|

State |

Number of Permits |

Permitted Emissions (tpy) |

Census |

Emissions |

Emissions |

|||||

|

Tot |

Grn |

New |

Mod |

Grn |

New |

Mod |

Plants |

Plants |

||

|

Sulfur dioxide |

||||||||||

|

|

SIC 26: Paper and Allied Products |

|||||||||

|

WI |

2 |

0 |

2 |

0 |

- |

435 |

- |

51 |

76 |

66,055 |

|

Total |

22 |

0 |

9 |

10 |

0 |

8,346 |

9,107 |

543 |

592 |

496,155 |

|

|

SIC 28: Chemicals and Allied Products |

|||||||||

|

FL |

13 |

0 |

4 |

8 |

- |

2,787 |

18,219 |

69 |

30 |

35,453 |

|

AR |

2 |

0 |

0 |

1 |

- |

- |

10,085 |

8 |

11 |

11,525 |

|

LA |

2 |

0 |

2 |

0 |

- |

8,516 |

- |

16 |

60 |

56,819 |

|

Total |

22 |

0 |

10 |

11 |

0 |

12,299 |

30,207 |

1,715 |

1,174 |

532,117 |

|

|

SIC 29: Petroleum and Coal Products |

|||||||||

|

LA |

4 |

0 |

2 |

2 |

|

874 |

1,995 |

54 |

22 |

76,080 |

|

CA |

2 |

0 |

0 |

0 |

|

- |

- |

205 |

95 |

29,875 |

|

IL |

2 |

0 |

0 |

2 |

|

- |

305 |

93 |

125 |

125,222 |

|

TX |

2 |

0 |

2 |

0 |

|

91 |

- |

194 |

37 |

90,754 |

|

Total |

11 |

0 |

5 |

4 |

|

1,005 |

2,300 |

2,074 |

1,444 |

569,478 |

|

|

SIC 33: Primary Metal Industries |

|||||||||

|

WI |

4 |

0 |

2 |

2 |

- |

251 |

104 |

6 |

77 |

1,360 |

|

AL |

3 |

0 |

2 |

1 |

- |

734 |

0 |

11 |

48 |

19,169 |

|

OH |

3 |

0 |

1 |

2 |

- |

685 |

77 |

29 |

51 |

190,521 |

|

TN |

3 |

0 |

1 |

2 |

- |

122 |

560 |

9 |

9 |

6,419 |

|

AR |

2 |

1 |

0 |

1 |

791 |

- |

296 |

7 |

9 |

31,981 |

|

IN |

2 |

0 |

1 |

1 |

- |

39 |

20 |

18 |

68 |

33,368 |

|

SC |

2 |

1 |

1 |

0 |

0 |

193 |

- |

11 |

8 |

3,597 |

|

VA |

2 |

0 |

1 |

1 |

- |

596 |

100 |

4 |

22 |

5,590 |

|

Total |

27 |

2 |

11 |

13 |

792 |

3,486 |

1,224 |

287 |

767 |

610,893 |

|

|

SIC 37: Transportation Equipment |

|||||||||

|

AL |

1 |

0 |

1 |

0 |

- |

3 |

- |

6 |

3 |

354 |

|

Total |

1 |

0 |

1 |

0 |

0 |

3 |

0 |

342 |

427 |

40,094 |

|

Volative organic compounds |

||||||||||

|

|

SIC 26: Paper and Allied Products |

|||||||||

|

WI |

11 |

0 |

6 |

4 |

- |

537 |

299 |

51 |

108 |

14,534 |

|

AL |

5 |

1 |

1 |

3 |

637 |

140 |

327 |

19 |

26 |

25,541 |

|

AR |

3 |

0 |

2 |

0 |

- |

593 |

- |

8 |

7 |

9,333 |

|

GA |

3 |

0 |

0 |

0 |

- |

- |

- |

25 |

23 |

10,913 |

|

LA |

3 |

0 |

2 |

1 |

- |

957 |

2,624 |

12 |

15 |

14,325 |

|

MN |

3 |

0 |

2 |

0 |

- |

543 |

- |

11 |

19 |

5,530 |

|

NC |

3 |

0 |

1 |

2 |

- |

24 |

817 |

14 |

38 |

10,001 |

|

FL |

2 |

0 |

1 |

0 |

- |

64 |

- |

10 |

13 |

4,203 |

Louisiana and Kentucky. In general, permitting activity for modifications is distributed among a number of industries and states. The key inferences from the available data suggest that the following industries have substantial NSR permitting activity for modifications, whether measured in terms of the number of permits or permitted emissions: electricity generation; paper and allied product; and chemicals and allied products. Other industries that appear to be of secondary importance with respect to permitting activity include stone, clay, and glass products; primary metal industries; and food and kindred products.

Although the mix of industries appears to be widely different, the emission processes are often qualitatively similar across industries. For example, many industries use common unit operations, such as industrial furnaces, to generate steam for process use. Some industries—such as stone, clay, and glass products—use tunnel or rotary kilns, which are specialized combustion-based equipment for heating specific types of materials (EPA 1995a). Thus, although the specific design and duty cycle may differ, there are similarities in combustion principles and factors that govern pollutant formation and control. For example, the NOx formation mechanisms and control strategies are similar for cement kilns, glass melting, and industrial boilers and include thermal and fuel NOx formation (if a nitrogen-bearing fuel is used), combustion-based controls, and postcombustion controls (EPA 1994a,b,c). Of course, not all the emission sources are combustion based. To provide a more-thorough assessment of specific emission technologies, later sections of this chapter review specific types of process facilities and their unit operations.

Several states provided summary information to the committee regarding NSR, but the summaries typically did not distinguish among permits for new sources and permits for modifications of existing sources, so permitting activity for modifications cannot be readily inferred from the information. For example, in Louisiana, the largest share of all permits was issued for chemical manufacturing, power generation, refining, paper and allied products, and inorganic-chemical industries. The industrial mix in Louisiana is somewhat unusual because of the large industrial presence in such areas as those around the lower Mississippi River and Lake Charles. In New Jersey, permits have been issued for power generation, chemical and allied industries, petroleum refining, and others. The sources permitted in New Jersey have included combustion turbines, boilers, engines, and fluidized catalytic cracker units. However, the industries identified in the Louisiana and New Jersey surveys as being of greatest importance with respect to permitting activity are qualitatively consistent with those identified in the EPA summary.

The use of data such as in Appendix D is one approach to identifying priorities among industries subject to NSR for modifications. However,

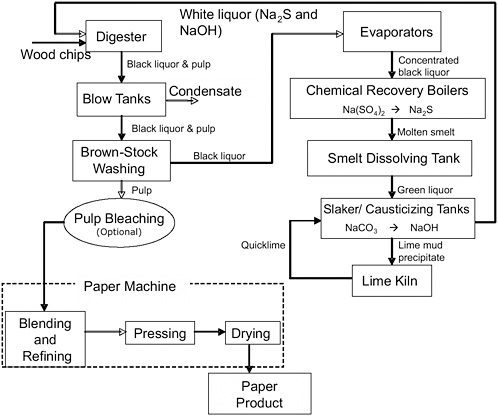

another approach is to select industries that illustrate the complexity of the technology choices that are associated with decisions regarding common repairs and replacements. Furthermore, some industries are regionally important. For example, the petroleum-refining and pulp and paper industries provide useful case studies regarding the myriad of unit operations that are subject to repairs and replacement. Such industries also illustrate that many unit operations or processes are common to multiple industries. For example, industrial boilers are commonly used to boil water to produce steam in many industries. In addition to industrial boilers, industrial process heaters are used to heat raw materials, such as crude oil or intermediate products for processing or distillation. Industrial heaters often exhibit emissions that are similar to those from industrial boilers. The fuel used for industrial heaters and boilers differs among industries. Natural gas is predominant in the chemical industry, fuel gas and natural gas in petroleum refining, and coal, tire chips, “bark” (waste wood, such as stumps), and “black liquor” (lignin that has been separated from cellulose) in the pulp industry. On the basis of review of available summaries of data on permits and the evaluation of other factors, such as representativeness of the complexity of technology characteristics and options, several industries and emission sources were identified as having high priority for characterization and evaluation, including electricity generation, petroleum refining, and paper and allied products. Furthermore, because industrial boilers are common to many industries, they are also characterized.

Systematic data are not available from which to assess the claim of foregone opportunities for facilities that are claimed to have refrained from making modifications for fear of triggering a requirement to obtain an NSR permit. Anecdotal examples were presented to the committee, but there are often inadequate details on the examples. Furthermore, the committee cannot use anecdotes as the basis of generally valid inferences.

The committee also considered use of the generating availability data system (GADS) produced by the North American Electric Reliability Council (NERC). The GADS includes design data, and performance and event data. The former are publicly available, and the latter are available only with special permission. The publicly available design data provide information regarding overall average rates of the forced and scheduled outages, as well as deratings, for power plants. Also, summary data regarding the top 25 individual “cause codes,” which briefly indicate the reason or purpose of the outage, are available. That information provides insight regarding failures or replacement activities at power plants (for example, the largest sources of average megawatt (MW) hours lost per outage for fossil-fuel-fired power plants of 300-399 MW capacity included major turbine overhaul, major boiler overhaul, and various forms of generator overhaul) but does not

directly provide insight regarding choices to forego opportunities that might have prevented or reduced the frequency of some of these occurrences.

There are several key conclusions from the review of permitting activity. Most permits are for greenfield facilities or new facilities at existing locations. Permits for modifications involve only 1-2% of total emissions for most pollutants in either the manufacturing or electricity-generating sector (including facilities that did not receive a permit in that period). There is somewhat more permitting activity for modifications, as measured by emissions and number of permits, in the manufacturing sector, but the activity in the two sectors is often of a similar order of magnitude. Although there are systematic data available from which to make assessments of permitting activity, no systematic data available from which to assess the opportunity costs of facility decisions not to make modifications.

STATE PERMITTING PROGRAMS—STATUS OF NEW SOURCE REVIEW IMPLEMENTATION

The purpose of this section is to provide an overview of the current status of NSR implementation. Because there is no national clearinghouse on NSR permitting activity or the status of the NSR permitting programs in each state, the committee asked the State and Territorial Air Pollution Program Administrators and the Association of Local Air Pollution Control Officials (STAPPA/ALAPCO—referred to in this report as STAPPA) about the current state of NSR implementation. STAPPA provided the following types of information from state and local agencies:4

-

Format in which data are archived for major and minor air permits, including NSR. Formats include paper files, electronic databases, and others.

-

Key industries in the state in terms of emissions and permitting activity.

-

Descriptions of electronic databases of emission and permit data, such as data categories and the period over which records are kept.

-

Status of NSR implementation, including whether the state is implementing the NSR reforms, implementing the prerevision NSR, or implementing a hybrid that includes combinations of both. Furthermore, comment was requested as to the state’s future plans.

There are several key findings from the information provided by STAPPA. There is no consistency in how permits are archived or how such information can be retrieved. For example, some states, such as Alabama

and Iowa, have primarily a paper-based system, and other states, such as Alaska, Mississippi, and Maryland, have various types of electronic approaches. Some of the latter involve converting permit files to electronic format and posting them on the internet, and others involve the use of electronic databases to store permit tracking data or emission data. It would be difficult and time consuming to do a systematic survey of the permits themselves given the lack of uniformity of the archival method and the format in which information is stored.

The states that reported the status of their NSR programs essentially confirmed information provided in Chapter 2 regarding how the “unapproved” versus “approved” states handle their NSR programs. Unapproved here refers to states that are either “not approved but delegated” (often referred to simply as delegated) or “not approved and not delegated.” For an approved state, the NSR program is approved as part of the state implementation plan (SIP), so the state fully administers the NSR program. For a “not approved but delegated” state, EPA allows the state to do the day-by-day work of running the program, but the state is ultimately subject to EPA supervision.

For example, Alaska has adopted the new federal NSR rules by reference, whereas Alabama continues to use the prerevision NSR rules. Many states reported that they are awaiting finality on the federal rules given the uncertainty caused by litigation pertaining to the NSR reforms. In short, there is wide variation in the current status of NSR among the states. Because many states have not fully implemented the NSR reforms and because the reforms are relatively recent, there is little or no track record of permitting under the reforms. In turn, there is little empirical basis on which to assess the effect of the reforms. The available information is anecdotal and incomplete. A key logistical aspect of permitting under the reform is to require companies to provide data to support their claims regarding use rates under the baseline part of the rule.

As a followup, several members of the committee obtained additional information from permitting officials in several states, including Illinois, Kentucky, Michigan, New Jersey, New Hampshire, Ohio, and Washington.5 It appears from the comments of those officials that the NSR rule changes have not yet had a substantial effect. In many cases, the same or similar outcome is reported under the prerevision and revised NSR rules. In some cases, state regulators have advised industries to apply under the prerevision rules or the industry has preferred to do so because of the greater familiarity and certainty associated with the prerevision process. Some companies voluntarily retrofit emission controls to make them similar to what would

be required under NSR or agree to restrictions to avoid emission increases associated with a modification that would trigger NSR. The uncertainty about the legal status of the new rules may also be inhibiting their use and causing a preference for the prerevision rules where possible. One state commented that the equipment replacement provision (ERP) would be difficult to implement because it would require financial accounting capabilities that the state environmental agencies typically do not have.

In many states, facilities need to get a minor state permit for construction even if they do not need an NSR permit. The minor permits often include requirements for control technology similar to that required under NSR, such as BACT. Thus, it is possible in some states that facility changes that might not trigger NSR could trigger the need for a minor permit, which in some cases might be of equivalent stringency. Getting a minor permit instead of an NSR permit appears to be generally more desirable to facilities because of the greater delays and expense associated with the NSR permit process, which can involve long public comment and greater documentation than a minor permit.

Some states are using a common electronic database system that assists in processing permit applications, tracking permits, and filing documents. Seven states are using it or considering using it: Kentucky, Mississippi, New Mexico, Louisiana, New Jersey, Indiana, and Maryland.

In summary, there is substantial variation among states regarding the implementation status of NSR reforms, the existence of a minor permitting program that might cover modifications that are not covered under the NSR reforms, experience with reforms where they have been implemented, and the recording and archiving of information. There is some promise that several states are adopting a common framework for electronic management of permits. There appears to be some reluctance by some states and even some facilities to conduct permitting under the new rules until the uncertainty associated with litigation over the reforms subsides. Thus, a complicated context surrounding the state of evidence regarding the effects of NSR revisions makes it difficult to conduct a systematic empirically based assessment.

PROCESS TECHNOLOGIES OF EMISSION SOURCES: PROCESS DESCRIPTION, REPAIRS AND REPLACEMENT, AND POLLUTION-PREVENTION AND -CONTROL APPROACHES

The purpose of this section is to describe the major components of emission sources that are most relevant to NSR permitting decisions pertaining to repair and replacement. An understanding of the typical facilities in several key industries is needed to assess the effect of changes in NSR on emissions and energy use from these sectors. Thus, the focus is on

components that are most commonly subject to common repair and the potential for more substantial replacements. Typical pollution-prevention and -control strategies are also identified. Because the number of industries affected by NSR is potentially large, it was deemed infeasible to provide a comprehensive survey of all industries. However, selected industries that either represent a high frequency of permitting activity or contain emission processes typical of many industries are reviewed here. For example, electricity-generating power plants are among the source categories for which there is a relatively high frequency of NSR permits associated with modifications. Other industries, such as petroleum refining and paper, are important in selected regions of the country. However, those types of industries include emission processes, such as industrial furnaces, that are common to many industries. Thus, the review provided here is intended to furnish a technical foundation for identifying issues pertaining to typical repair and replacement and their implications for cost, emissions, and other effects.

There are no standard ways among industries of reporting process design, repair, and replacement practices, and performance and cost information. Classification schemes may differ among industries because of differences in feedstocks, process configurations, and constituent unit operations and because of industry-specific practices and metrics. Thus, in presenting information regarding specific industries in later sections of this chapter, we tend to adhere to terminology, flowsheets, repair and replacement practices, and technology options that are tailored to these industries. For each of the industries described here, there is a representative flowsheet of the process technologies and a narrative that highlights key NSR-relevant technological characteristics.

Electricity-Generating Facilities

According to 2002 national emission estimates, electricity-generating facilities each year emit about 4.7 million tons of NOx, 10.3 million tons of SO2, 52,000 tons of VOCs, 499,000 tons of CO, and 582,000 tons of PM2.5 (EPA 2004e). Most electricity-generating facilities’ NOx emissions are from coal-fired power plants, including bituminous- and subbituminous-coal plants, and natural-gas-fired plants. SO2 emissions are primarily from bituminous-coal-fired plants, with smaller contributions from other ranks of coal and from other fuels. VOC emissions from power plants tend to be lower than from other sources because of the high combustion efficiency relative to other types of energy-conversion systems (such as internal-combustion engines) and because evaporative emissions at other sources contribute to national totals. Similarly, CO emissions from electricity-generating facilities are a small fraction (<1%) of national emissions and are associated mostly with coal and natural gas. Coal accounts for most of the estimated PM2.5

emissions from electricity-generating facilities, which in turn represent less than 10% of the estimated national PM2.5 emissions. However, these data are for primary emissions and do not include formation of secondary PM2.5 in the atmosphere. Key pollutants of concern for electricity-generating facilities from a health perspective tend to be NOx and SO2 because they are important contributors to concentrations of airborne PM2.5 and ozone (see Chapter 7). Coal and natural gas are the fuels of greatest interest with respect to this mix of key pollutants. Therefore, this section focuses on identifying the characteristics of typical coal-fired and natural-gas-fired electricity-generating facilities for purposes of identifying the typical repair and replacement issues for such facilities.

Typical Electricity-Generating Power-Plant Designs

There are many varieties of power-plant design for both coal- and natural-gas-fueled systems. For example, for coal-fired power plants, the choice of an appropriate furnace design and the design of other plant components often depends at least to some extent on the rank of the coal and its properties. The choice of furnace design can influence baseline emission rates. For example, tangentially fired furnaces promote the formation of a rotating fireball in a furnace, so their NOx emissions are different from those from a wall-fired boiler. Operational practices, such as optimization of fuel and air ratios, also influence emissions; a well-tuned furnace can have substantially lower NOx emissions than one that is not well tuned.

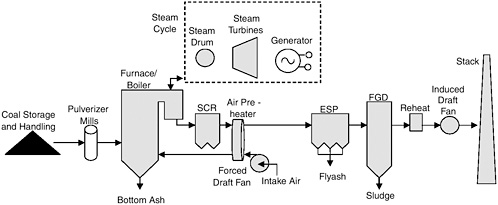

Figure 3-1 illustrates a generic power plant burning pulverized coal that is equipped with postcombustion controls for NOx, PM, and SO2. The

FIGURE 3-1 Simplified flowsheet for generic pulverized coal-fired electricity-generating power plant with postcombustion controls for NOx, PM, and SO2.

plant includes coal storage and handling facilities and pulverizer mills that typically deliver finely pulverized coal to the burners via a pneumatic transport system. The furnace, also often referred to as a boiler, is the structure where combustion of the coal takes place. The burner design and methods for staging combustion affect the formation of NOx.

The walls of the furnace structure typically are composed of steam tubes, so most of the surfaces in the furnace are actually heat exchangers. Therefore, the flue-gas temperatures decrease as the fuel gas leaves the flame zone and travels past the heat-exchanger tubes. The topmost portion of the boiler is referred to as the “convective pass” and includes the heat exchangers for producing superheated steam. The temperature window in portions of the convective pass can be appropriate for selective noncatalytic reduction (SNCR), which is an NOx-control technique involving injection of ammonia or urea to promote conversion of NOx in the flue gas to molecular nitrogen (e.g., EPA 2002d). After the convective pass, at which point the flue-gas temperature has been reduced because of heat exchange, the flue gas reaches the economizer, which is also a heat exchanger.

The flue gas leaving the economizer is typically about 367ºC, which is compatible with the desired temperature window for selective catalytic reduction (SCR) for postcombustion NOx control (e.g., EPA 2002d). Flue gas leaving the SCR, if present, or the economizer, if SCR is not present, flows through the air preheater, which is a heat exchanger. A typical air-preheater design is a slowly rotating basket, portions of which are exposed to the hot flue gas and then the cooler inlet air. An intake-air fan is typically used to force air into the furnace. In some power-plant designs, an induced-draft fan downstream pulls gas through the system.