The Shape of Things to Come: Frontiers in Additive Manufacturing

HOD LIPSON

Cornell University

Additive manufacturing technologies—machines that can automatically fabricate arbitrarily shaped parts, pixel by pixel, layer by layer, from almost any material—have evolved over the past three decades from limited and expensive prototyping equipment in the hands of few, to small-scale commodity production tools available to almost anyone. It has been broadly recognized that this burgeoning second industrial revolution will transform every aspect of our lives. Clearly, we will see the usual improvements we have come to expect of any burgeoning technology: more material options, better resolution, faster printing, easier and more reliable operation, and lower costs. But where will this technology go next?

3D printing is only the tip of a much larger phenomenon. We can look at the evolution of additive manufacturing technologies’ past, present, and future as a series of milestones in humans’ increasing control over physical matter.

PRINTING FORM: PROGRAMMING THE SHAPE OF MATTER

The first episode of this journey, maturing today, has been the unprecedented control over the shape of objects. Machines today can fabricate objects of almost any material—from nylon to glass, from chocolate to titanium—and with any complex geometry. This ability is transforming many fields to a degree that few inventions ever have—not just engineering, but many others, from biology to archeology, and from education to culinary arts.

Complexity for Free

Perhaps the most dramatic impact of 3D printing is the ability to manufacture objects without factoring their complexity. Fabricating a solid block costs almost the same as fabricating an oddly shaped object with curved surfaces and notches. In either case, the printer will still scan back and forth, depositing one layer at a time, and only the material deposition pattern will change. In the same way that printing a picture of a circle takes no longer than printing a picture of the map of the world, printing a mousetrap does not take more time, resources, or skill than printing a paperweight. Regardless of how you want to measure cost—in production time, material weight, energy waste, or in production planning effort—adding more features hardly changes the cost. In some cases, added complexity can even reduce cost; printing a block with a hole is cheaper and faster than a solid block without a hole. The marginal cost of added complexity is therefore near zero, in stark contrast with conventional manufacturing where every new feature—every additional hole, surface, protrusion, and corner—takes more planning effort, requires longer production time, and consumes more energy and possibly more raw material.

Why do we care about the marginal cost of complexity? It is easy to understand that lowering the cost of manufacturing complex products is a good thing, but the reason is more profound. Industrial revolutions are triggered when a fundamental cost associated with production drops dramatically, essentially taking that factor out of the equation. The industrial revolution of the 19th century occurred when the cost of power dramatically declined, as steam engines replaced horses and waterwheels. As a consequence, these power sources were not only replaced, but the range and types of work that machines could perform greatly expanded, leading to a cascade of innovation, such as railroads and factory automation. The Internet similarly reduced the cost of disseminating information and, as a consequence, expanded the range and types of media that could be distributed—not just online newspapers, but also Wikipedia, blogs, and user-generated content. One could argue that 3D printing has drastically reduced the cost of making complexity. Initially, this simply implies that this technology will gradually replace the old way of making the things we once made in more expensive ways. But in the longer term, the range and types of objects being manufactured will greatly expand.

The Personalization of Manufacturing

Alongside the vast new design possibilities, however, is the personalization of manufacturing. This trend has profound economic implication on how we will design and consume products in the future, who designs them, and where they are made (Lipson and Kurman, 2010). Most important, the ability of anyone to design and make complex products without the barriers of resources and skills of traditional manufacturing will democratize innovation and unleash the long

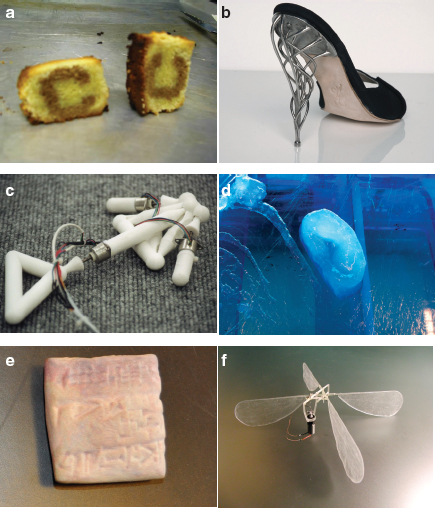

tail of human creativity. Look online right now and you will see thousands of objects for sale ready to be printed on demand, from custom-shaped hearing aids, to flapping-hovering micro air vehicles, to authentic-looking replicas of ancient cuneiforms (Figure 1).

FIGURE 1 From chocolate to titanium, from biology to archeology, and from robotics to avionics, 3D printing is a universal technology that will impact every industry and discipline. Sources: Figures 1a, 1c, 1d, 1e, and 1f courtesy of Cornell University and http://creativemachines.cornell.edu. Figure 1b courtesy of WTWH Media.

PRINTING COMPOSITION: SHAPING THE INTERNAL STRUCTURE OF MATERIALS

The second episode of this journey, which we are beginning to experience now, is the control over the composition of matter—going beyond shaping just the external geometry to shaping the internal structure of materials with unprecedented fidelity. Using multimaterial additive manufacturing technologies, we can make materials within materials, embed and weave multiple materials into complex patterns, and cofabricate entangled components. For example, we can print hard and soft materials in patterns that create bizarre and new structural behaviors, like materials that expand laterally when pulled longitudinally. We are shedding the traditional limitations imposed by conventional manufacturing where each part is made of a single material. Instead, microstructure can be specified with micron-scale precision. With such possibilities, you will be able to print a custom tennis racket that cleverly enhances your unique backhand, or a replacement spinal disc implant tailored for your aching back. While the possibilities are vast, however, few theories can predict properties of these new materials and few designers can exploit the new design space, so new design tools will be needed to augment human creativity.

From Bioprinting to Food Printing

There is literally no discipline that will remain unaffected by this unprecedented control over the shape and composition of matter. It is easy to imagine the implication for any field that involves the design and fabrication of physical objects, from mechanical engineering to art and architecture. But the technology can also change fields that have no immediate connection to engineering or to manufacturing. Consider an example: the emerging field of 3D printing for medical applications.

Custom-shaped prostheses. One of the earliest applications of 3D printing to health-related applications was the fabrication of custom-shaped, complex prosthetic limbs and devices. A key challenge in many prosthetic devices is the interface point with the body. For example, the ability to match the socket of a limb prosthesis to a patient’s bony prominences or muscular tissue can greatly improve both functionality and comfort. In many cases where the aesthetic appearance of a prosthetic is also a factor, the ability to custom shape the exterior to blend with its surrounding or match symmetrical features is an important advantage as well. The ability to further shape internal cavities, add strengthening girders, and shave material off non-load-bearing components can also help improve the weight-to-strength ratio of the device, making it both stronger and lighter. With more sophisticated multimaterial fabrication, one could imagine that the mechanical performance of such devices could be tailored even further, improving their elasticity, shock bearing, and energetic performance. A second example of shaped

prostheses is hearing aids. A major factor in the comfort and effectiveness of hearing aids is their fit in the aural canal. With 3D printing, the patient’s canal can be optically scanned and a tailored soft prosthesis fabricated almost instantly.

Custom implants. One size fits all is not a good compromise when it comes to your hip-replacement implant. The idea of using 3D printing to fabricate custom-shaped implants dates back to the earliest days of free-form fabrication. Custom-shaped titanium or platinum implants can be fabricated at exactly the right size and shape, either parametrically scaled to fit the patient or even produced directly from a computed tomography (CT) scan geometry of the original bone to be replaced or a symmetrical healthy bone. Since complexity is free, printed implants can go beyond the standard bone shape and include various cavities and connection points that make the bonding with existing tissue more compatible, reliable, and effective.

Bioprinting. Instead of using titanium and other engineering materials, bioprinting involves fabricating implants (and other constructs) from biological materials directly. Early experiments involved 3D printing of biocompatible scaffolds, which were later infused with live cells and incubated before implantation. The live cells gradually replaced the scaffold, resulting in a custom-shaped live tissue-engineered implant. While the use of printed scaffolds is still prevalent, a further advance involves printing with biological cells directly with no scaffold at all. In this case, the cells are first immersed in a biocompatible hydrogel ink—a bioink—and then printed into their target form. The bioink has two key, contradicting properties that make it tricky to develop: On the one hand, it needs to be fluid enough to be printed—to flow through the nozzle while not harming the cells that experience severe shear forces as they come out of the printhead. On the other hand, the bioink needs to be stiff enough to hold its shape after printing or else the material will ooze into a shapeless mass. Solving that challenge using a variety of chemical and optical cross-linking agents, we were able to fabricate cartilage implants in the shape of a meniscus directly from CT data. Unlike scaffold infusion techniques, however, the ability to print with live cells directly opens the door to fabrication of heterogeneous tissue implants. Imagine the fabrication of something as complex as a spinal disk or a heart valve, which involves multiple cell types in a complex spatial arrangement that is critical to proper functionality (Cohen et al., 2006).

Drug screening models. The ability to fabricate complex, multicell heterogeneous tissue arrangements in three dimensions has many applications beyond implants. One such exciting opportunity is the fabrication of models for drug screening. Traditionally, drugs and other treatments are tested first in simple petri dish-like environments that tries to replicate the anticipated target environment where the actual drug or treatment will be in use. These petri dishes or test tubes are relatively

simple compared to the real environment, both in the range of cell types and in their spatial distribution. This mismatch often necessitates the use of animal models and other more sophisticated high-throughput testing procedures. The use of 3D bioprinting, however, opens the door to fabrication of 3D, spatially heterogeneous tissue models that more closely resemble the target application of a drug. One could imagine, for example, that cancer cells in the shape and distribution of a tumor could be fabricated directly and then the effectiveness of treatments tested directly in vitro. Such experiments could provide a more realistic prediction of drug effectiveness and shorten the cycle of drug development.

Surgical planning. A somewhat less obvious but equally important application of 3D printing is for preparation for surgery. Nonroutine, complex surgical procedures often involve manipulation of tissue and tools through an intertwined and unknown environment. Some operations also require the preparation and attachment of permanent or temporary plates and other devices within the patient’s body. Just as it is easier to put a puzzle together the second time around, surgeons can substantially reduce the time and improve the reliability of an operation if they get a chance to practice it beforehand. This is especially true when a complex and nonroutine procedure is executed for the first time. For example, we have often been requested to three-dimensionally print a set of shattered or deformed bones produced from a CT scan of an injured dog coming into emergency surgery at the veterinary school. The surgeons will receive the printed bones and practice the surgery—learning to identify the fragments, optimize the reconstruction process, and prepare any necessary plates and jigs in advance. Informally, surgeons have reported that surgery time can be reduced by half, not to mention the increase in quality of care.

Surgical training. Surgeons in training often get access to state-of-the-art surgical equipment and tools, but rarely do they get a chance to practice on realistic cases. It is unlikely that a training surgeon will get to practice removing a brain tumor, for example, because it is unlikely that an animal model or a human cadaver will be found with such a case or that a synthetic training model happens to available for purchase. With 3D printing, however, relevant and typical cases from real patients can be recorded and reproduced on demand for practice. With some modeling, it is even possible to combine cases and adjust the severity of cases on demand in order to challenge training surgeons at exactly the right level for the best learning experience. With multimaterial bioprinting, the training models could be fabricated with biological materials to provide an even more realistic training experience that also provides the feel and the responsiveness of the real wet tissue.

Custom medication. An excellent example of an application of 3D printing where composition control is key is the fabrication of medical pills on demand.

A growing challenge for both doctors and patients is the administration of multiple medications simultaneously. Instead of keeping track of a dozen pills daily, a printer can now fabricate a single, custom-made pill for each patient. That pill contains the exact amount, combination, and arrangement of medication that a patient needs that day. The pill could have a special identification marking, eliminating much of the confusion and uncertainty associated with conventional delivery methods.

Food printing. Perhaps the unforeseen killer app, food printing is for 3D printing as video gaming is for computers. Based on the very same technology as bioprinting, food printing involves the fabrication of edible items from raw edible inks. The term “edible inks” does not quite do justice here: We are talking about chocolate and peanut butter, cookie dough and frosting. And it does not have to be all bad: You can even print with organic pesto and locally made goat cheese. Download the recipe, load in the frozen food cartridges, and hit print. The recipe dictates which material goes where and what in-line cooking procedure is applied during deposition and after. We have printed with all the materials above and more, creating chocolate confections with frosted decorations and vanilla cookies with vertical text lettering in chocolate inside. Imagine a cookie printer with sliders to adjust the crispiness, flavor, color, and texture in any arbitrary way. How about a checkerboard lasagna? Your imagination is the limit. While some find the idea of printed foods the epitome of processed foods, others find the whole idea fascinating in its vast new opportunities to innovate. Download and share recipes, tailor variants to your liking, and have freshly made dishes just for you.

PRINTING FUNCTION: PROGRAMMING BEHAVIOR OF ACTIVE MATERIALS

The third and final episode of this journey, of which we are only beginning to see early signs, is the control over behavior. In this section we go beyond controlling just the shape of matter, past controlling just its composition; we will now be able to program these materials to function in arbitrary ways—to sense and react, to compute and behave. This last step entails a blurring between material and code (Gershenfeld, 2005), leading to what is essentially programmable matter—moving from an object’s mechanical functionality to controlling how it processes information and energy as well. When this day comes, you will be able to print virtually anything, from a cellphone to a robot that will walk out of the printer, batteries included. But that robot will not look at all like today’s robots because it will not be limited by the constraints imposed by conventional manufacturing, nor will it be designed directly by humans. The ability to manufacture such arbitrary active systems comprising both passive and active substructures will have opened the door to a new space of designs and a new paradigm of engineering, one that is not unlike biology.

THE NEW CAD

For the past four decades, computer-aided design (CAD) tools have played a critical role in the product design process, but to a large extent, CAD tools have remained relatively unchanged in their role and format. User interfaces have improved, geometric manipulations have become faster and more reliable, and graphics have become three-dimensional and photorealistic. But conceptually, CAD software remains today merely a passive 3D drawing board that records our intentions but offers little insight or ideas of its own.

As 3D printing technologies become more abundant, the traditional barriers of resources and skill for manufacturing have all but vanished. The limit is now our imagination, and our imagination is, unfortunately, limited. I have seen over and over how fresh students faced with the blank page of CAD and the unlimited capability of a 3D printer design nothing more than a rectangular object with a few linear notches. To a large extent, this is a cultural blindness evolved out of years of observing mass-produced objects made subject to traditional manufacturing constraints. But on the other hand, this is also due to the design thinking imposed by conventional CAD tools and the lack of new design tools that take advantage of the vast new design space offered by 3D printing capabilities.

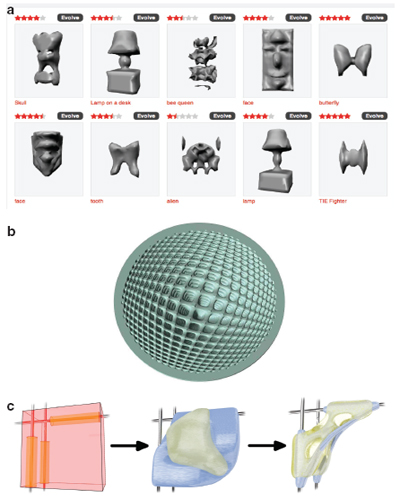

It is clear that while the classical CAD paradigm will remain dominant for the foreseeable future, new paradigms for design tools are beginning to emerge (Figure 2).

Function Representations

As our ability to control the shape, composition, and behavior of materials advances, it becomes more appropriate to think about geometry and material specification as programming rather than as drawing. For example, say you would like to fabricate a helical surface with elliptical perforations at some semiperiodic pattern. Making something like that would be a complicated and expensive nightmare using traditional manufacturing techniques, so that kind of capability is buried deep down the advanced CAD options menu, if it can be found at all. It would involve multiple steps and would bring the CAD software to its knees. But unencumbered by traditional manufacturing constraints, a growing number of designers would want to explore exactly those kind of geometries, easily and quickly. And why not? There are, in fact, many more crazy shapes than regular shapes, but they are just currently difficult to explore. The helical perforated shape might be more easily described using a procedural construction process rather than a target geometry (Pasko et al., 2011)—in other words, algorithmic rather than descriptive geometry—much like biology describes phenotypes using a developmental process, or like a software engineer describes the appearance of a dynamic web page.

FIGURE 2 The New CAD. Beyond geometric modeling, products are described by interactive evolution, through procedural construction algorithms, or by compiling highlevel requirement and constraints automatically. Sources: Figure 2a courtesy of Cornell University and http://endlessforms.com. Figure 2b: Pasko et al., 2011. Courtesy of Turlif Vilbrandt. Figure 2c designed by Jon Hiller. Reprinted courtesy of Cornell University and http://creativemachines.cornell.edu.

Matter Compilers

An alternative approach to design is to specify what the design needs to accomplish rather than what it needs to look like and then to let the machine compile the design to your specification. Some products, especially those that have a purely functional role, would fit well into such a design process. Consider, for example, the task of designing a supporting bracket. We know the geometric constraints of the load and support contact points, the weight to be carried, and the material properties. Specify those requirements, hit the design button, and watch how the optimal design emerges automatically. The optimal design will not be a block with rectangular notches and holes. Instead, an organic-looking optimal structure with beautifully shaped cavities will emerge—something that would take a human designer years to come up with manually. Now say the bracket cannot be installed because of a pipe protruding into the bracket’s location. No problem—add the pipe protrusion constraint and recompile. Programming by specifying the target behavior and constraints, then compiling it into functional geometry, can address complex requirements as well as optimally exploit the new manufacturing capabilities afforded by multimaterial 3D printing as they become available. In a way, the designer becomes the customer, and the CAD software becomes the designer.

Interactive Evolution

What happens when the desired object cannot be described quantitatively? Such situations occur frequently in the design of objects that have an aesthetic component that defies quantification. Imagine you need to design a perfume bottle. While some aspects of the design can be specified quantitatively, such as the desired volume and size, others, such as the look and feel, are more difficult to describe. Moreover, those skilled at the art of assessing perfume bottles may have no inclination to dabble in CAD speak. Instead, a new type of CAD software can display a range of initial design concepts and can allow an expert to indicate which ones they like, or to put it in perhaps less gentle terms, which they least dislike. Armed with this information, the machine can begin to infer automatically a sense of aesthetic that the designer has in mind and can generate a new set of solutions. These solutions will still obey the quantitative requirements—the bottle volume and size, say—but they will more closely match the designer’s aesthetic preferences. Repeating this process through a sequence of solutions and selections, the designer might be able to design what might be a complex perfume bottle with relatively little CAD expertise. Importantly, the designer might actually come across new ideas and be provoked into new corners of the design space where no person has been before. Using this process, visitors to the EndlessForms website (Clune and Lipson, 2011) have collaboratively designed objects from furniture to faces, and from bottles to butterflies.

FabApps

What if I want to design a toothbrush to print on my 3D printer today? It is unlikely that I will be able to design a good, ergonomic, and safe toothbrush. Even though a toothbrush seems like a simple product, it takes years of experience and know-how to design a successful one. Yet with the advent of 3D printers, it is likely that people will want to do exactly that—design their own products with almost no experience and little patience to learn. The solution may be in the form of simple CAD applications dedicated to a narrow product and which encapsulate all the relevant knowledge, yet expose just the right level of flexibility to the user. Such FabApps (term coined by Daniel Cohen and Jeffrey Lipton), similar to the iPhone apps that you can download for 99 cents, specialize in the design of one particular product. In contrast with general-purpose CAD, FabApps use extensive built-in know-how to guide a user through the design of one item and ensure the resulting product will be successful. A toothbrush app can ask for dimensions of your hand and mouth, process pictures of your face and palm, walk you through fifty different options and ask twenty more questions, and then produce the perfect toothbrush that uniquely fits your needs and is guaranteed to be a success.

CONCLUSION

3D printing is only the tip of a series of milestone in humans’ increasing control over physical matter. If humans distinguished themselves from their evolutionary ancestors by making tools, then additive manufacturing represents the ultimate tool—perhaps changing human culture forever in ways we can hardly anticipate.

REFERENCES

Clune, J., and H. Lipson. 2011. Evolving three-dimensional objects with a generative encoding inspired by developmental biology. Proceedings of the 2011 European Conference on Artificial Life, Paris, France, August 8–12, 2011. Available at http://EndlessForms.com.

Cohen, D. L., E. Malone, H. Lipson, and L. Bonassar. 2006. 3D direct printing of heterogeneous tissue implants. Tissue Engineering 12(5):1325–1335.

Gershenfeld, N. 2005. FAB: The Coming Revolution on Your Desktop—From Personal Computers to Personal Fabrication. New York: Basic Books.

Lipson, H., and M. Kurman. 2010. Factory@Home: The emerging economy of personal fabrication. White House Office of Science and Technology Policy. Available at http://web.mae.cornell.edu/lipson/FactoryAtHome.pdf.

Pasko, A., O. Fryazinov, T. Vilbrandt, P.-A. Fayolle, and V. Adzhiev. 2011. Procedural function-based modelling of volumetric microstructures. Graphical Models 73(5):165–181.

ADDITIONAL READING

Carrabine, L. 2009. Explore the range of DMLS of titanium. Available at http://www.makepartsfast.com/2009/12/828/explore-the-range-of-dmls-of-titanium/.

Hiller, J., and H. Lipson. 2009. Design automation for multi-material printing. Paper presented at the Solid Freeform Fabrication Symposium (SFF’09), Austin, Texas, August 3–5, 2009. Available at http://creativemachines.cornell.edu/sites/default/files/SFF09_Hiller2.pdf.

Knapp, M., R. Wolff, and H. Lipson. 2008. Developing printable content: A repository for printable teaching models. Paper presented at the 19th Annual Solid Freeform Fabrication Symposium, Austin, Texas, August 2008. Available at http://creativemachines.cornell.edu/papers/SFF08_Knapp.pdf.

Lipson, H., and J. B. Pollack. 2000. Automatic design and manufacture of robotic lifeforms. Nature 406:974-978. Available at http://creativemachines.cornell.edu/papers/Nature00_Lipson.pdf.

Lipton, J.I., D. Arnold, F. Nigl, N. Lopez, D.L. Cohen, N. Noren, and H. Lipson. 2010. Multi-material food printing with complex internal structure suitable for conventional post-processing. Paper presented at the 21st Solid Freeform Fabrication Symposium (SFF’10), Austin, Texas. Available at http://creativemachines.cornell.edu/sites/default/files/69-Lipton-Mutlimaterial%20food%20printing%20Final.pdf.

Richter, C., and H. Lipson. 2010. Untethered hovering flapping flight of a 3D-printed mechanical insect. 12th International Conference on Artificial Life (Alife XII), Odense, Denmark, August 2010, Pp. 797–803. Available at http://creativemachines.cornell.edu/sites/default/files/Alife10_Richter.pdf.