2

Energy for Electricity

BACKGROUND

This chapter considers sources of energy used for the generation of electricity. The committee’s analysis includes utilities, independent power producers, and commercial, and industrial sources. The generation data that we used are available at the Web site of the Energy Information Administration (EIA) (www.eia.doe.gov) of the U.S. Department of Energy, and are the official energy statistics from the U.S. government.

The Current Mix of Electricity Sources

The total electricity generation1 in the United States during 20082 was 4.11 million gigawatt hours (GWh), down very slightly from 2007. In terms of usage, the residential sector consumed the most electricity (36.6% of the total), followed by the commercial sector (36.3%). The industrial sector (26.9%), and transportation (0.2%) accounted for the rest.

The energy sources and the amount of electricity they contributed are given in Table 2-1.

The two largest classes of “other renewables” were wind, which produced 52,026 GWh or 1.3% of the 2008 electricity-generation total; and

TABLE 2-1 Net Electricity Generation by Energy

|

Energy Source |

Net Electricity Generation (GWh) |

Percent of Total Net Generation |

|

Coal |

2,000,000 |

48.5 |

|

Petroleum liquidsa |

31,200 |

0.8 |

|

Petroleum coke |

14,200 |

0.4 |

|

Natural gas |

877,000 |

21.3 |

|

Other gasesb |

11,600 |

0.3 |

|

Nuclear |

806,000 |

19.6 |

|

Hydroelectric |

248,000 |

6.0 |

|

Other renewablesc |

124,000 |

3.0 |

|

NOTE: Net electricity-generation numbers reported by the Energy Information Administration are rounded to three significant figures. aDistillate fuel oil, residual fuel oil, jet fuel, kerosene, and waste oil. bBlast furnace gas, propane gas, and other manufactured and waste gases derived from fossil fuels. cWind, solar thermal, solar photovoltaic (PV), geothermal, wood, black liquor, other wood waste, biogenic municipal solid waste, landfill gas, sludge waste, agricultural by-products, and other biomass. SOURCE: Data from EIA 2008, 2009a. |

||

wood and wood-derived energy sources (38,789 GWh, or 0.9%). Other renewable sources individually amounted to less than 0.5% each; the largest was other biomass, (16,099 GWh, or 0.4%. Generation from solar PV was approximately 600 GWh.

Rationale for Choice of Fuel Sources to Analyze

This chapter provides detailed analyses of electricity generation from coal, natural gas, nuclear fission, wind, and solar. The first three sources were chosen because they together account for 88% of all electricity generated in the United States; moreover they feature prominently in current policy discussions about energy sources. Wind energy also is prominent in policy discussions concerning electricity, and it appears to have the largest potential among all renewable sources to provide additional electricity in the medium term according to current projections (see discussion later in this chapter). Solar energy for electricity (photovoltaics) also is discussed, although not in detail, because of recent legislative and public interest and because of the rapid increase in use over the past 10 years. For the above reasons, the committee concluded that analyzing the external costs and benefits associated with these sources would be of the greatest value to policy makers.

We mention biomass (briefly) because it is such a dispersed source of

electricity (many very small generators). We did not focus on hydropower generation of electricity, even though its current contribution is far greater than that of all other renewable sources combined, because the potential use of hydropower to increase significantly is modest, and hydropower currently receives little attention in energy-policy discussions.

Describing the Effects Caused by Life-Cycle Activities

In its analyses, the committee describes externalities—indeed, all effects caused by life-cycle activities—as being upstream or downstream. By “up-stream,” in the context of energy for electricity, the committee means effects that occur before electricity is generated at an electricity-generating unit (EGU) (such effects as EGU; steam turbine, wind turbine, and solar cell). For fossil-fuel and nuclear EGUs, the largest upstream effects are associated with obtaining and transporting fuel. They include effects of exploration, development, and extraction of geologic deposits of fuel or ore, refining and processing, and transportation of primary energy sources (for example, coal and natural gas). For solar, wind, and hydropower EGUs, the main upstream effects are associated with obtaining, fabricating, and transporting materials required for the EGU and with the construction of the EGU, including road building and other activities. Fossil-fuel and nuclear EGUs also have these effects, but they typically are smaller than those associated with the ongoing production and transportation of the primary energy sources. The committee’s upstream limit for consideration of effects was exploration for fuel. Although effects even further upstream can occur, such as reactions to the announcement of a lease sale for oil, gas, or even the announcement of a proposed mine (for example, see NRC 2003a), those effects are generally unquantified. By “downstream” the committee means effects that are associated with generation of electricity and the subsequent transmission and distribution of electricity to end users. In other words, effects associated with the operation of an electricity-generating facility or with electricity transmission and distribution (that is, delivery to the end user) are considered downstream effects.

General Approach Taken

The goal of this chapter is to describe and, when possible, to quantify the monetary value of the physical effects3 (that is, the “damages”) of electricity production. For electricity generation from nuclear fission, wind power, solar power, and biomass, our analysis summarizes effects reported

from previous studies, but does not monetize damages from externalities. For electricity generation from coal and natural gas we are able to quantify and monetize the externalities associated with local and global air pollution, both upstream and downstream. We express these externalities in costs per kWh of electricity generated and also in costs per ton of pollution generated.

As summarized in Chapter 1, this study is preceded by a large literature on the social cost of electricity. Two notable studies are those by Oak Ridge National Laboratory and Resources for the Future (ORNL-RFF) (1992-1998) and the ExternE project (EC 2003). The goal of each study was to estimate the life-cycle externalities associated with electricity production from various fuel types. Externalities were expressed in monetary terms per kWh to permit comparisons across fuel types. The social costs of electricity generation, together with the private costs of electricity generation, could thus be used to inform choices among fuel types when expanding or replacing generation capacity. Both studies conducted their analyses using representative plants in two geographic locations. Both studies were exhaustive in their descriptions of, and attempts to quantify, various categories of externalities throughout the fuel cycle.

In addition to literature on social costs of electricity, there have been studies on the environmental effects of electricity production. The National Research Council recently (2007b) reported on environmental effects of wind-energy projects, and the New York State Energy Research and Development Authority recently (NYSERDA 2009) reported on effects and risks to vertebrate wildlife in the northeastern United States from six types of electricity generation.4 Both reports included assessments of all life-cycle stages, but did not quantify or monetize the effects.

This chapter builds on and extends these studies. We have attempted to describe externalities and other effects broadly, and to analyze them wherever possible. However, we have focused our efforts to monetize external costs for the categories of externalities that earlier studies found to be a significant component of damages. We extend the studies by measuring the externalities associated with local and global air pollution—a significant component of the costs of electricity generation—for individual coal-fired and gas-fired power plants in the United States. This allows us to characterize the diversity in the damages of electricity generation from fossil fuel across plants and to relate damages per kWh to the pollution intensity of the plant (that is, to pounds of sulfur dioxide [SO2] or particulate matter [PM] emitted per kWh) and the location of the plant, which affects the size of the human and other populations exposed to pollution generated by the plant. We also express damages per ton of pollution emitted. While

a comparison of damages per kWh may (together with information about private costs) help inform the choice of fuel type, it is not particularly useful if the goal is to internalize the externalities associated with pollution emissions.5 Economic theory suggests that the most economically efficient policy to address air-pollution externalities is a policy that targets the externality itself rather the output associated with it. We therefore present information on damages per ton of emissions from coal and natural gas plants that contribute to the concentrations of criteria pollutants.6

The core of our analysis of local air-pollution damages uses an integrated assessment model (the Air Pollution Emissions Experiments and Policy, or APEEP model) (Appendix C), which links emissions of SO2, oxides of nitrogen (NOx), PM2.5, PM10,7 ammonia (NH3), and volatile organic compounds (VOCs) to ambient levels of SO2, NOx, PM2.5, PM10, and ozone (see Box 2-1). The model calculates the damages associated with population exposures8 to these pollutants in six categories: health, visibility, crop yields, timber yields, building materials and recreation. Health damages include premature mortality and morbidity (for example, chronic bronchitis, asthma, emergency hospital admissions for respiratory and cardiovascular disease), and are calculated using concentration-response functions employed in regulatory impact analyses by the U.S. Environmental Protection Agency (EPA). Damages to crops are limited to major field crops, and recreation damages are those associated with pollution damages to forests. A description of the concentration-response functions used in the model is in Appendix C, which also provides details on the choice of unit values used to monetize damages. Damages associated with carbon dioxide (CO2) emissions are computed based on a review of the literature, and are described in Chapter 5. Not all impacts and externalities associated with electricity production have been quantified and monetized in this study. Table 2-2 summarizes which impacts are quantified, monetized, or qualitatively discussed within this chapter.

|

BOX 2-1 Airborne Particulate Matter PM is a heterogeneous collection of solid and liquid particles that can be directly emitted from a source (primary pollutants) or can be formed in the atmosphere by interaction with other pollutants (secondary pollutants). Secondary PM can be formed by oxidation of NOx and SOx to form acids that can be neutralized by ammonia to form sulfates and nitrates. Organic PM may be chemically transformed by oxidants in the air to form secondary pollutants. Soot particles can be altered by adsorption of other pollutants on their surface. PM is monitored for both mass and size. Ultrafine particles (less than 0.1 micron in aerodynamic diameter) can be emitted from combustion sources or can be formed by nucleation of atmospheric gases, such as sulfuric acid or organic compounds. Fine particles (less than 2.5 microns) are produced mainly by combustion of fossil fuels, either from stationary or mobile sources. Coarse particles (sometimes called PM102.5) are mainly primary pollutants that may come from abrasive or crushing processes or the suspension of soil. PM larger than 10 microns is not of great concern for this report because they are not readily respirable and do not have a long half-life in the atmosphere. Current research on PM is exploring the influence of particle composition (in addition to mass and size) on its toxicity, as recommended by the National Research Council (NRC 1998, 1999, 2001, 2004b). However, enough data are not yet available from this research to inform the estimation of damages in this report. |

Regulations

As noted in Chapter 1, the externalities examined in this study are those that have not been eliminated by regulation. Most stages of electricity production are subject to regulations at the federal, state, and local levels. Surface mining of coal, for example, is regulated under the 1977 Surface Mining and Control Act. Air-pollution emissions from electricity-generating facilities are regulated under the Clean Air Act. The U.S. Nuclear Regulatory Commission regulates and licenses nuclear power plants.

Relevant regulations for upstream and downstream activities related to electricity generation are varied and extensive. Their details are not necessarily of great import for this study, although they obviously are important for other reasons. For this study, though, the existence of regulations is of great importance, because in large part regulations are an attempt to reduce upstream and downstream damages from electricity generation, and they have substantially reduced these damages over time. We discuss only those damages that remain, with emphasis on those that can be quantified and monetized. Most of the committee’s quantitative analyses of damages in

TABLE 2-2 Energy for Electricity: Impacts and Externalities Discussed, Quantified, or Monetized

|

|

Energy Sources for Electricity |

|||||

|

Impact or Burden |

Coal |

Natural Gas |

Nuclear |

Wind |

Biomass |

Solar |

|

Upstream |

||||||

|

Air pollutant emissions (SOx, NOx, PM) |

|

|

q |

q |

|

q |

|

CO2-eq (carbon dioxide equivalent) emissions |

|

|

q |

q |

q |

|

|

Metals, radionuclides, and other air pollutants |

q |

q |

q |

q |

q |

|

|

Effluents |

q |

q |

q |

|

|

|

|

Solid wastes |

q |

q |

q |

|

|

|

|

Land cover/footprint |

q |

q |

q |

q |

q |

|

|

Ecological effects |

q |

q |

q |

|

||

|

Occupational and transport injuries |

† |

† |

|

|

|

|

|

Downstream |

|

|

|

|

|

|

|

Air pollutant emissions (SOx, NOx, PM) |

$ |

$ |

|

|

|

|

|

CO2-eq emissions |

|

|

|

|

|

|

|

Metals, radionuclides, and other air pollutants |

q |

q |

|

|

|

q |

|

Effluents |

q |

q |

q |

|

|

|

|

Solid wastes |

q |

q |

q |

q |

||

|

Land cover/footprint |

q |

q |

q |

q |

q |

|

|

Ecological effects |

q |

|

|

†, q |

|

|

|

q = qualitative discussion.

† = impacts quantified. $ = impacts monetized. |

||||||

this chapter focus on emissions from electricity-generating facilities that are fired by coal or natural gas. Under the Clean Air Act, electric utilities are regulated at both the state and federal levels. The Clean Air Act requires states to formulate state implementation plans (SIPs) to pursue achievement of the National Ambient Air Quality Standards (NAAQS) (NRC 2004c). Under SIPs, electricity-generating units (EGUs) are assigned emissions limits for SO2, NOx, PM, and other pollutants, usually stated as performance standards (for example, maximum annual average tons of SO2 that may be emitted per million British thermal units [MMBtu] of heat input). These performance standards vary widely across states. In addition, EGUs are subject under the Clean Air Act to “new source review,” a series of regula-

tions that pertain to newly constructed facilities and to modifications of existing facilities.9 Coal-fired power plants built after 1970 are also subject to “new source performance standards” (NSPS), which impose strict limits on emissions that contribute to the formation of criteria air pollutants. For example, the 1978 NSPS for coal-fired power plants requires the installation of flue gas desulfurization units (scrubbers) on all new coal-fired EGUs.

Emissions of SO2 and NOx are also regulated under various cap-and-trade programs. The goal of Title IV of the 1990 amendments to the Clean Air Act was to reduce SO2 emissions from EGUs to 8.95 million tons by 2010. That goal has been achieved by issuing SO2 permits (allowances) to EGUs equal to 1.2 pounds of SO2 per MMBtu (based on 1985-1987 heat input) and allowing utilities to trade allowances, which may not violate the NAAQS. In 1998, EPA issued a call for SIPs to reduce emissions of NOx. The rule provided the option for states to participate in a regional NOx Budget Trading Program. This program operated from 2003 to 2008, when it was replaced by a NOx ozone season trading program.

The net effect of the environmental regulations described above, as well as others, is that emissions per megawatt-hour (MWh) that contribute to criteria air pollution vary greatly among plants. Newer power plants have, on average, much lower emissions rates. As discussed later in this chapter, SO2 (and NOx) emissions per MWh are much lower for units installed after 1979 than for units installed before that date.

ELECTRICITY PRODUCTION FROM COAL

Current Status of Coal Production

Coal, a nonrenewable fossil fuel, accounts for approximately one-third of total U.S. energy production, and nearly half of all electricity produced. Coal is classified into four types based upon the relative mix of carbon, oxygen and hydrogen: lignite, sub-bituminous, bituminous, and anthracite (Table 2-3). The greater the carbon content, the greater the energy (heating) value of coal. Sub-bituminous and bituminous coal account for more than 90% of coal produced in the United States. Sub-bituminous coal has as much lower sulfur content but also as much lower energy content than bituminous coal. In electricity generation, replacing a ton of bituminous coal requires about 1.5 tons of sub-bituminous coal (NRC 2007c).

The United States has more than 1,600 coal-mining operations that pro-

|

9 |

New source review applies to facilities in areas of pristine air quality where the goal is to prevent significant deterioration of air quality and also to facilities in areas that have not attained the NAAQS. Regulations governing each facility are determined on a case-by-case basis. See the regulatory overview in Chapter 2 of NRC 2006a. |

TABLE 2-3 Coal Classification by Type

|

Type |

Carbon Content (%) |

Heating Value (Thousand Btu/lb) |

U.S. Production (%) |

|

Lignite |

25-35 |

4.0-8.3 |

6.9 |

|

Sub-bituminous |

35-45 |

8.3-13.0 |

46.3 |

|

Bituminous |

45-86 |

11.0-15.0 |

46.9 |

|

Anthracite |

86-97 |

~15.0 |

<0.1 |

|

ABBREVIATION: Btu/lb = British thermal unit per pound. SOURCE: EIA 2008a, Table 7.2; NEED 2008; EIA 2009b. |

|||

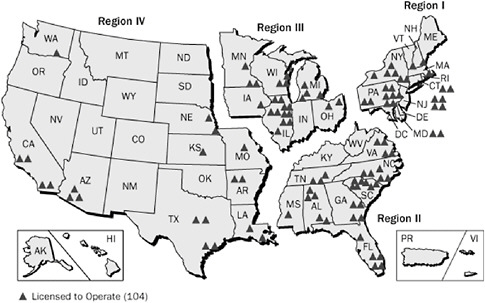

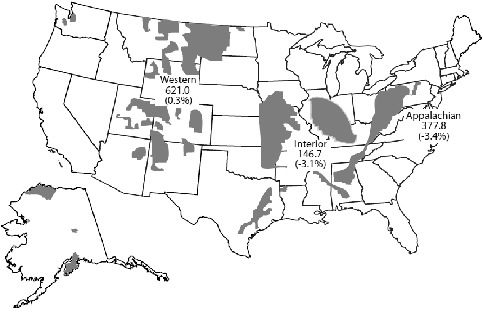

duced more than 1.18 billion short tons10 in 2008. Major coal-producing regions are shown in Figure 2-1. The EIA estimates that 70% of coal production comes from surface mines, the majority of which are in Wyoming, Montana, West Virginia, Pennsylvania, and Kentucky. Large mining operations in the Powder River Basin (PRB) in Wyoming and Montana accounted for more than 50% of surface-mine coal production and 40% of nationwide coal production in 2007. Coal in the PRB is mainly sub-bituminous; coal in Appalachia is mainly bituminous (NRC 2007c). The top five coal-producing states in 2007 are listed in Table 2-4.

On average, more coal is produced in the United States than is consumed. The EIA estimates that nearly 95% of U.S.-mined coal is consumed domestically. In 2008, the United States exported 23.0, 7.0, and 6.4 million short tons to Canada, the Netherlands, and Brazil, respectively.

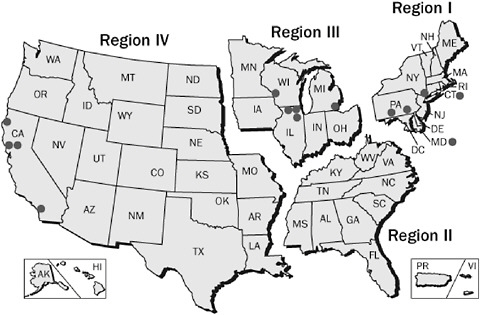

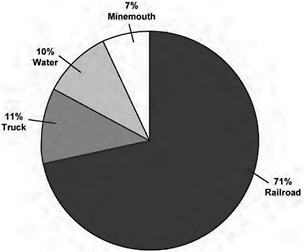

U.S. coal production is focused in a relatively small number of states, but coal is consumed throughout the country. As a result, coal is transported by all major surface transportation modes (Figure 2-2). Once mined, coal is typically transported to power plants, steel mills, and other commercial and industrial companies by rail. In 2007, approximately 70% of coal production was distributed by rail. The remaining 30% was transported by barge, tramway and pipelines, or truck.

Looking forward, it can be expected (barring shifts in current coal consumption trends) that western states will increase their production relative to other states (EIA 2008a). Table 2-5 below lists the ten states with the largest Estimated Recoverable Reserves (ERR). The ERR is derived by the Energy Information Administration (EIA) for each state by applying coal mine recovery and accessibility factors to the Demonstrated Reserve Base (NRC 2007c).

FIGURE 2-1 Major coal-producing regions in the United States (million short tons and percent change from 2006). SOURCE: EIA 2009c, p. 2.

TABLE 2-4 Five Leading Coal-Producing States, 2007, by Mine Type and Production (Thousand Short Tons)

|

State |

Number of Mines |

Production |

|

Wyoming |

20 |

453,568 |

|

Underground |

1 |

2,822 |

|

Surface |

19 |

450,746 |

|

West Virginia |

282 |

153,480 |

|

Underground |

168 |

84,853 |

|

Surface |

114 |

68,627 |

|

Kentucky |

417 |

115,280 |

|

Underground |

201 |

69,217 |

|

Surface |

216 |

46,064 |

|

Pennsylvania |

264 |

65,048 |

|

Underground |

50 |

53,544 |

|

Surface |

214 |

11,504 |

|

Montana |

6 |

43,390 |

|

Underground |

1 |

47 |

|

Surface |

5 |

43,343 |

|

Total, Top Five States |

989 |

830,766 |

|

Underground |

421 |

210,483 |

|

Surface |

568 |

620,284 |

|

Total, United States |

1,358 |

1,145,480 |

|

SOURCE: Adapted from EIA 2009c, p. 11, Table 1. |

||

FIGURE 2-2 Methods of U.S. coal transport. NOTE: Data exclude a small unknown component. SOURCE: EIA in AAR 2009.

Brief History of Coal Production

Coal was the predominant source of U.S. energy from the late 19th century through the mid 20th century. Coal was used for electricity, space heating, industrial process heating for iron, steel, and other commodities, and fuel to power ship and train steam engines. During the latter 20th

TABLE 2-5 Estimated Recoverable Reserves for the 10 States with the Largest Reserves by Mining Method for 2005 (million short tons)

|

State |

Underground Minable Coal |

Surface Minable Coal |

Total |

|

Montana |

35,922 |

39,021 |

74,944 |

|

Wyoming |

22,950 |

17,657 |

40,607 |

|

Illinois |

27,927 |

10,073 |

38,000 |

|

West Virginia |

15,576 |

2,382 |

17,958 |

|

Kentucky |

7,411 |

7,483 |

14,894 |

|

Pennsylvania |

10,710 |

1,044 |

11,754 |

|

Ohio |

7,719 |

3,767 |

11,486 |

|

Colorado |

6,015 |

3,747 |

9,762 |

|

Texas |

— |

9,534 |

9,534 |

|

New Mexico |

2,801 |

4,188 |

6,988 |

|

Total, Top 10 States |

137,031 |

98,896 |

235,927 |

|

Total United States |

152,850 |

114,705 |

267,554 |

|

SOURCE: EIA 2006a. Adapted from NRC 2007c, p. 51, Table 3.2. |

|||

century, however, coal was rapidly replaced by petroleum and natural gas for fuel and space heating, respectively. Today, approximately 7% of coal is consumed to generate heat for a variety of industrial processes, including paper, concrete, and steel production.

Upstream Impacts and Externalities of Electricity Production from Coal

Injuries and Illnesses in Coal-Mining Operations

Although the gravity of occupational injuries and illnesses cannot be underestimated, the tradition in economics is to treat occupational injuries and deaths as job characteristics that are traded in labor markets rather than to treat them as externalities. In general, miners receive compensating wage differentials for the higher risks that they face on the job (Viscusi 1993).11 In addition, some proportion of injuries and deaths are compensated after the fact through workmen’s compensation, insurance, or court judgments. We also note that previous studies of the social cost of electricity (for example, ORNL-RFF 1994b) did not count occupational injuries and illnesses as externalities. However, occupational injuries are briefly discussed because they are an important societal concern related to energy production.

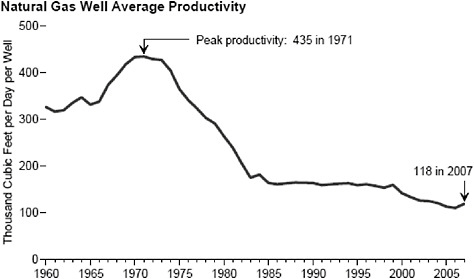

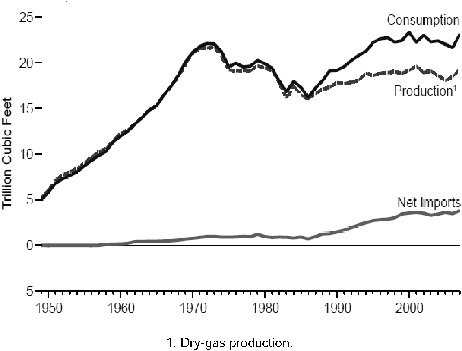

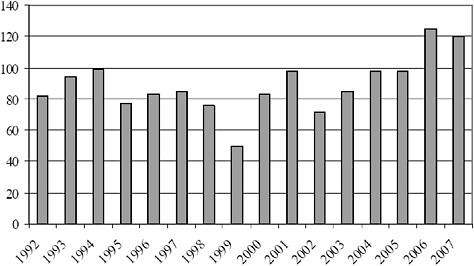

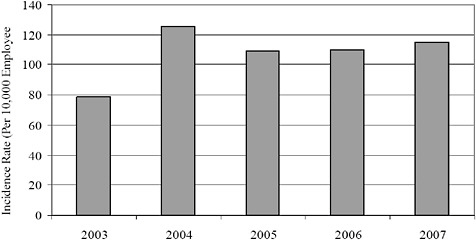

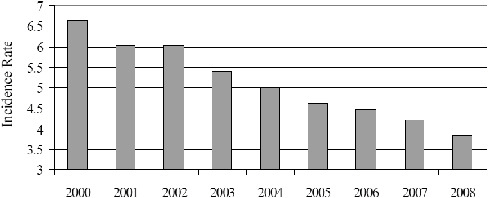

Coal-mining-related fatalities and nonfatal injuries have generally decreased over time, even though employee hours have not steadily declined (Figure 2-3). This is the result of increased regulation and safer mining technology. In 2008,12 29 fatal injuries (corresponding to 2 deaths per 10,000 workers) and 4,760 nonfatal injuries (an incidence rate of 3.83 per 100 workers) were reported.13 This marked a 27% decrease from 2000 to 2007 in the incidence of both fatal and nonfatal injuries and, more dramatically, 35% and 54% decreases, respectively, in the incidence of fatal and nonfatal injuries from the previous decade. The majority of both fatal and nonfatal injuries occur in underground mines (67% in 2008), followed by strip mines (19%) and processing plants (8%).14

FIGURE 2-3 Injuries in U.S. coal-mining operations from 2000 to 2008. SOURCE: Data from MSHA 2008, Table 08; MSHA 2009.

Most injuries in coal-mining operations result in workdays lost (WDL). In 2007, nonfatal injuries accounted for 220,284 WDL. Injuries classified as strain/sprain, cut or puncture, and fracture accounted for 76% of all injuries (31%, 24%, and 18%, respectively) but only 67% of nonfatal WDL and 6% of fatalities. Multiple injuries and bruises or contusions accounted for 79% and 12%, respectively, of fatalities, while accounting for only 3% and 11%, respectively, of total injuries. Coal-mining operations also reported a total of 159 occupational illnesses in 2007, 80 being disorders associated with repeated trauma and 40 being dust-related diseases of the lungs.

Injuries and Fatalities in Coal Transport

Coal transport introduces risks to the public and to employees of the transportation industry (primarily railroad, truck, and barge), which we describe below. As discussed above, occupational injuries and fatalities are not considered externalities. However, nonoccupational injuries and fatalities probably are externalities—that is, one could argue that the railroad operator might not take the full risk of death or injury to another person into consideration when choosing driving speed or safety equipment unless required to do so by law.

Domestic coal shipments represented 730 billion ton-miles in 2006, a 47% increase from 498 billion ton-miles in 1996. According to the Energy Information Administration, 71% of these U.S. coal shipments were delivered to their final domestic destinations by rail, followed by truck (11%) and barge (10%, mainly on inland waterways). Rail’s share, along with the average length of haul for rail coal movements, has been increasing over

the past 15 years (from 57% in 1990 to 71% in 2006). This is largely due to the growth of western coal. Waterborne traffic’s share of coal shipments has been declining, while the share of coal shipped by truck has fluctuated. Trucks transport coal over short distances, thus accounting for a small proportion of coal ton-miles (less than 2% in 2002) but a more substantial amount of tonnage (12% that same year). The average distance traveled by truck per shipment of coal increased from 51 miles in 1997 to 88 miles in 2002.

Coal is by far the most significant commodity carried by rail. In 2007, coal transport accounted for almost 44% of tonnage, 24% of carloads, and 21% of gross revenue for U.S. Class I railroads as well as a significant portion of non-Class I railroad freight. The commodity dominates originated rail traffic in major coal-producing regions. For example, coal accounted for 79% of total rail tons originated in Kentucky, 95% in West Virginia, and 96% in Wyoming in 2006. Coal (not including coal coke) is also a significant commodity in waterborne commerce, accounting for approximately 9% of tonnage. Large trucking, by contrast, only owes 0.2% of vehicle miles traveled to coal transport. For these reasons, we focus on the externalities associated with the shipment of coal by rail.

Over the past several decades, rail transportation has seen considerable drops in accident/incident rates, thanks in part to numerous initiatives on grade crossings and trespasser prevention. In 2008, there were 571 freight rail fatalities and 4,867 nonfatal injuries, indicating a 9% decline in fatalities and 11% decline in nonfatal injuries since 2007, and, more notably, 48% and 76% declines, respectively, since 1990. Ninety-seven percent of fatalities occur among the public, while, in contrast, the majority of nonfatal injuries and illnesses are borne by employees.

To estimate fatal and nonfatal injuries attributable to coal transport via rail, we use revenue ton-miles15 as a quantifiable proxy for risk of rail-associated injury. The reasoning for using revenue ton-miles as a proxy for risk of injury to railroad employees is that the number of employee hours, and hence the number of injuries, is more closely correlated with the revenue ton-miles measure than with train-miles or carloads. The reason for using revenue ton-miles as a proxy for risk of injury to the public is based on availability of information. A train-miles measure of coal transport would be the preferred metric for assessing risk to the public, but no such recent measure is available. We chose ton-miles of coal transport as the “next-best” measure for assessing risk to the public because it includes distance.

Our estimate of the number of fatal and nonfatal rail injuries attribut-

able to shipping coal for electric power generation appears in Table 2-6. The estimate is computed by multiplying the total number of occupational and public injuries occurring on freight railroads16 in 2007 by the proportion of ton-miles of commercial freight activity on domestic railroads accounted for by coal (43%).17 This estimate is then multiplied by the percent of coal transported that is used for electric power generation (91%).

By analogy with coal mining, we assume that occupational deaths and injuries are not externalities. A key issue is whether deaths among the public constitute externalities. One can argue that they are externalities (most are people struck by a moving train); however, based on the magnitude of the resulting damages, we have not monetized them, and they are not included in our aggregated damages. Valuing the 241 lives lost in 2007 by using a value of a statistical life (VSL) of $6 million 2000 U.S. dollars (USD) (about $7.2 million 2007 USD) would result in damages less than $2 billion annually.

Land-Use and Runoff Externalities from Surface and Underground Mines

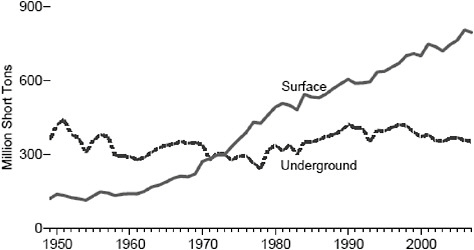

This section describes, but does not quantify or monetize, environmental effects of coal mining. Over the past 58 years there has been a relative shift to surface mining and to coal from western states (Figures 2-2 and 2-4). Surface mining is used for shallow deposits. Techniques range from area strip mining more typical in the West to contour strip mining and mountaintop mining/valley fill (also known as “mountaintop removal”) more typical in the East. Underground mining techniques range from drift mines and slope mines for deposits relatively near the surface to shaft mines for deposits deep underground.

Wyoming’s Powder River Basin (PRB) has near-surface deposits of coal that are more than 100 feet thick, making surface mining easy and productive, and the coal is almost always shipped to market “raw” (that is, without processing). A single PRB surface mine can yield more than 90 million tons annually. In contrast, coal in Appalachia, whether from surface or underground mining, is generally produced at smaller, lower-yield mines, and the coal often is processed in order to lower ash and moisture content (NRC 2007c).

The negative environmental externalities of coal mines, both during operation and after closure, depend in part on the mining method:

TABLE 2-6 Estimated Injuries, Illnesses, and Fatalities During Rail Transport of Coal for Electric Power, 2007

|

|

Fatalities |

Nonfatal Cases |

Total Cases |

||||

|

Injuries |

Illnesses |

NFDL |

NDL |

Total NF |

|||

|

Employees on duty |

5 |

1,408 |

36 |

991 |

453 |

1,444 |

1,449 |

|

Other (such as the public) |

241 |

— |

— |

— |

— |

698 |

939 |

|

Total |

246 |

— |

— |

— |

— |

2,142 |

2,388 |

|

ABBREVIATIONS: NFDL = nonfatal days lost; NDL= no days lost; NF = nonfatal. SOURCE: FRA 2008. |

|||||||

-

Underground mining. In addition to its threats to human health and safety, underground mining can also have environmental externalities. Collapses or gradual subsidence above the mined void can affect surface and subsurface water flows. Mine fires can occur, especially in abandoned mines. The disposal of mine wastes, especially wastes resulting from coal processing, can present environmental problems (NRC 2002b, 2007c). As much as 50% of the material fed to a process for treating raw coal can result in waste, often in the form of slurry, which usually is pumped into an impoundment. Impoundments can give way, as in the October 2000 breakthrough of a 72-acre coal waste impoundment near Inez, Kentucky (NRC 2002b). Environmental problems also can be triggered by acid mine

FIGURE 2-4 U.S. coal production 1949-2007, by mining method. SOURCE: EIA 2008a, p. 224, Figure 7.2.

-

drainage caused primarily by pyrite (FeS2), which is found in coal, coal overburden, and mine waste piles (USGS 2009a).

-

Surface mining (area and contour). Surface mining shares with underground mining the problem of mine waste disposal and acid mine drainage. It also poses the environmental challenge of reclaiming large tracts of land. The 1977 Surface Mining Control and Reclamation Act was intended to address surface-mining effects. It requires that sites be returned to their prior condition or to a condition that supports “higher and better uses.”

-

Mountaintop mining/valley fill (MTM/VF). MTM/VF is a type of surface mining used on steep terrain. Since its inception in the 1970s, this mining method has become widespread in Appalachia. Mountaintop mining often generates a large volume of rock, or “excess spoil,” that cannot be returned to its original locations and typically is placed in adjacent valleys. MTM/VF shares the negative externalities of other types of surface mining (see above) and has other externalities as well.

A Final Programmatic Environmental Impact Statement (FPEIS) on MTM/VF was released in October 2005 to consider developing agency policies regarding the adverse environmental effects of MTM/VF. Prepared by the U.S. Army Corps of Engineers, EPA, the U.S. Department of Interior’s Office of Surface Mining and Fish and Wildlife Service, and the West Virginia Department of Environmental Protection, the FPEIS focused on approximately 12 million acres encompassing most of eastern Kentucky, southern West Virginia, and western Virginia as well as scattered areas of eastern Tennessee. About 6.8% of the study area (816,000 acres) has been or may be affected by recent and future (1992-2012) mountaintop mining (EPA 2002, 2005a).

The study area is largely forested and contains about 59,000 miles of streams, most of which are considered headwater streams. The FPEIS comments that “headwater streams are generally important ecologically” and that “the study area is valuable because of its rich plant life and because it is suitable habitat for diverse populations of migratory songbirds, mammals, and amphibians” (EPA 2005a, p. 3).

The EPA Region 3 Web site on MTM/VF and the FPEIS note that valley fills generally are stable, but “based on studies of over 1,200 stream segments affected by mountaintop mining and valley fills, the following environmental issues were noted:

-

An increase of minerals in the water—zinc, sodium, selenium, and sulfate levels may increase and negatively impact fish and macroinvertebrates leading to less diverse and more pollutant-tolerant species.

-

Streams in watersheds below valley fills tend to have greater base flow.

-

Streams are sometimes covered up.

-

Wetlands are, at times inadvertently and other times intentionally, created; these wetlands provide some aquatic functions, but are generally not of high quality.

-

Forests may become fragmented (broken into sections).

-

The regrowth of trees and woody plants on regraded land may be slowed due to compacted soils.

-

Grassland birds are more common on reclaimed mine lands as are snakes; amphibians such as salamanders, are less likely….

-

Cumulative environmental costs have not been identified…(EPA 2009a).

The Web site also notes that there may be social, economic, and heritage issues with MTM/VF. Similarly, a USGS study of the Kanawha Basin (Paybins et al. 2000) shows significant degradation in the biotic communities of this mid-Atlantic river basin as a result of coal-mining operations, and other USGS studies show similar effects elsewhere (see USGS 2009b).

A possible benefit of coal mining can be the roads, utilities, and other infrastructure that accompany a mining operation. With proper planning, especially integration of the mine decommissioning and closure plan with local master plans, this infrastructure can be used for other economic enterprises following mine closure (NRC 2007c).

Upstream Emissions of Greenhouse Gases and Other Pollutants

The upstream life cycle of power generation from coal includes many relevant activities such as construction of infrastructure and power plants (see, for example, Pacca and Horvath 2002), but the most significant, from a perspective of greenhouse gas (GHG) emissions and criteria-pollutant-forming emissions, are surface and underground mining and transportation of coal. Mining and transport are fuel- and energy-intensive, requiring combustion of fossil fuels for cutting, moving, and preparing the coal from the mine and delivering it to power plants and other industrial facilities. Beyond emissions from engines, there are also significant emissions of methane, a GHG that exists within coal seams and is released as the seams are cut to extract the coal. As methane is a much more potent GHG than CO2, methane emissions are a significant concern.

In surface mining, the overburden (layers of rock and earth above the coal) is broken and removed to get to the underlying coal. The breaking and removal of both overburden and coal, and its movement from mine to transportation network is done with enormous machinery and engines that operate mostly by burning liquid fuels that release GHG emissions and criteria-pollutant-forming emissions. Underground mining uses similar

technologies, but shafts need to be drilled down to the seam depth, and the subsurface coal cutting and moving equipment is generally less energy efficient due to its smaller size since it has to fit beneath the surface.

Prior studies have assessed the relative contribution of air emissions from mining and transport of coal in the life cycle of coal-fired power generation (Jaramillo et al. 2007, Spath et al. 1999, ORNL/RFF 1992-1998). While not negligible, these studies found that upstream activities lead to relatively small life-cycle air emissions because of the dominance of GHG emissions and criteria-pollutant-forming emissions on site at coal-fired power plants. For example, Jaramillo et al. (2007) report that the mid-point GHG emission factors for coal combustion (at the power plant) and the entire coal life cycle are 2,100 lb CO2 equivalent (eq)/MWh and 2,270 lb CO2-eq/MWh, respectively.

Downstream Externalities of Electricity Production from Coal

Analysis of Current Air-Pollution Damages from Coal-Fired Power Plants

The air-pollution emissions from fossil-fueled power plants constitute a significant portion of the downstream damages associated with electric power generation. In this section, we quantify the impacts on human health, visibility, agriculture, and other sectors associated with coal-fired powerplant emissions contributing to criteria pollutant formation. The effects of those emissions on ambient air quality are modeled using the APEEP model (Muller and Mendelsohn 2006) and are calculated for each of 406 coal-fired power plants for the year 2005. We use the APEEP model to calculate the damages associated with emitting a ton of each of four pollutants (SO2, NOx, PM2.5, and PM10) at each power plant. Damages per ton are multiplied by the tons of each of the four pollutants emitted by the plant in 2005. This produces an estimate of aggregate damages associated with criteria-pollutant-forming emissions from each plant. Damages are also expressed per kWh.

Choice of Modeling Platform

Calculating the damages associated with air-pollution emissions involves three steps: (1) translating changes in emissions into changes in ambient air quality; (2) using concentration-response functions to calculate health impacts, environmental impacts, and others; and (3) valuing those impacts. This section describes the choices the committee made along each of these dimensions and discusses their strengths and limitations.

Approach to Air-Quality Modeling

There are two general approaches one can take to air-quality modeling: process-based modeling and reduced-form modeling. A process-based model captures the complexities of environmental processes by including exhaustively detailed representations of each mechanism in the atmosphere. Process-based models attempt to reflect the natural processes that govern the relationship between emissions and concentrations. The models are often applied to simulations with very fine spatial and temporal scales. The Community Multiscale Air Quality (CMAQ) model is widely considered the state of the science in process-based air-quality modeling (Byun and Schere 2006).

Despite these advantages, there are downsides to process models. Because of their exhaustive embodiment of a multitude of atmospheric processes, such models are time-intensive and expensive to operate. The implied cost of running process models limits the number of times researchers can run these models for a particular application. This constraint forces policy analyses using these models to make other compromises. For example, process models cannot be used to conduct large numbers of experiments. As a result, national applications of CMAQ and other process models feature a relatively small number of modeling runs in which many sources have their emissions modified at once. This approach may be appropriate for simulating a national or regional policy, but the simulation design is fundamentally unable to isolate the impact of emissions from individual sources over a large modeling domain. If that is the objective of the research, which is the objective in this study, then a simpler, reduced-form air-quality model.18

The reduced-form modeling approach depicts the environment with a simple representation that mimics the overall behavior of the entire system. Reduced-form models do not include all the complex relationships of the process-based models. Their advantages are that they are relatively fast, inexpensive to operate, and easy to interpret. The most critical drawback of reduced-form models is that they may omit or misrepresent a key element in the environmental process. The model used in this analysis, APEEP, uses a source-receptor matrix with county-level sources and receptors that are derived from a Gaussian air-quality model. The cells of the matrix, which are generated by the Gaussian model, represent estimates of the concentrations of a given pollutant (per unit of emission). The cells were systematically adjusted to implicitly represent the spatial effects of the dispersion and

transformation processes embodied in the CMAQ model. An alternative approach to develop a reduced-form model is to fit a “response surface” to CMAQ output, which has been used by EPA. The latter is a purely statistical approach.

APEEP has been carefully calibrated to CMAQ to reflect the relationships between emissions and concentrations that CMAQ estimates. However, APEEP has some drawbacks: It cannot effectively represent episodic events because of the use of annual and seasonal average meteorologic data. Although its use of county-level resolution is quite fine-grained for a national study, a preferred approach would be grid-cell-level resolution for large western counties.

Our choice of air-quality modeling approach in this study is motivated by the desire to model the impact of emissions from individual power plants. Power plants vary greatly in the amount of pollution they emit and, by virtue of their location, in the impact of the pollution on human health and on ecosystems. Exploring the heterogeneity of pollution impacts across space is important from a policy perspective because it provides regulators with a means to set priorities for emissions abatement by identifying the relative damage caused by emissions from different sources. To explore these effects, many model runs must be conducted. Reduced-form models are the optimal modeling choice in such a context.

Choice of Concentration-Response Functions

In analyses of air-pollution damages and the benefits of reducing them (for example, the Benefits and Costs of the Clean Air Act, 1990-2010 [EPA 1999]), impacts on human health constitute the vast majority of monetized damages, with premature mortality constituting the single largest damage category. The concentration-response functions for human health end points (including premature mortality, chronic bronchitis, and hospital admissions) used in APEEP are listed in Table C-1 of Appendix C. They are the same concentration-response functions as those used in the EPA regulatory impact analyses; therefore, those functions have been vetted by the EPA Clean Air Science Advisory Committee. In particular, the impact of PM on premature mortality is calculated using the relationship between PM2.5 and all-cause mortality in Pope et al. (2002).19 The concentration-response functions used to calculate impacts on agriculture, forestry, and

other sectors are listed in Appendix C and further described in Muller and Mendelsohn (2006).

One limitation of the APEEP model as used in this analysis is its limited treatment of ecosystem damages. For example, the model does not measure the impacts of acid rain associated with NOx and SO2 emissions either on tree canopy or on fish populations. It also fails to capture eutrophication of fresh-water ecosystems from nitrogen deposition.

Valuation

As in most analyses of damages associated with criteria-pollutant-forming emissions, health damages figure prominently in aggregate monetized damages—especially premature mortality associated with PM2.5. The value of monetized damages is particularly sensitive to the VSL used to monetize cases of premature mortality. The value that we use for our central case analysis is $6 million 2000 USD. This value is supported by recent meta-analyses of the literature on the VSL as well as by values used in EPA regulatory impact analyses. In their 2003 meta-analysis, Viscusi and Aldy (2003) reported a mean value of $6.7 million (2000 USD), and Kochi et al. (2006) reported a value of $5.4 million based on an empirical Bayes estimator. These values are in line with values used in recent EPA regulatory impact analyses: The Clean Air Interstate Rule (CAIR) regulatory impact analysis (RIA) uses a value of $5.4 million (1999 USD), and the EPA National Center for Environmental Economics recommends using a $7.4 million VSL (2006 USD). (This amount is equivalent to $6.3 million in 2000 USD.) A $6 million VSL (2000 USD) is also used by other researchers (for example, Levy et al. 2009) who recently examined the health impacts of power-plant emissions.

We applied the same VSL to persons of all ages. Although there is some evidence that willingness to pay for changes in mortality risks varies with age, the EPA Environmental Economics Advisory Committee of the Science Advisory Board judged in 2007 that the literature on this issue was not sufficiently mature to determine exactly how the VSL varies with age. The practice of valuing lives lost by multiplying the number of life years lost by the value of a statistical life year (VSLY) was also rejected. The empirical evidence on the impact of age on the VSL does support the use of the VSLY approach, which assumes that the VSL is proportional to remaining life expectancy (EPASAB 2007).

In calculating the value of premature mortality, we treated the lives lost due to changes in PM2.5 concentrations as occurring in the same year as the change in the concentrations. EPA (1999, Appendix D) assumed that the impact of a reduction in PM2.5 concentrations was spread over 5 years, with 25% of the change in deaths occurring in same year as the change in

concentrations, 25% occurring the next year, and one-sixth occurring in each of the following 3 years. At a 3% discount rate, the present discounted value of damages using EPA’s lag structure would be 95% of the mortality damages that we calculated. At a discount rate of 7%, the damages would be 89% of the mortality damages that we calculated. However, selecting a particular lag structure is associated with great uncertainty. In its review of the NAAQS for PM, EPA indicated that it is difficult to assess the time between the occurrence of a cause and its purported effect based on the studies it reviewed of PM exposures, given that airborne PM concentrations are generally correlated over time in any given area. For all-cause mortality and cardiovascular mortality, EPA observed that the greatest effect size is generally reported for the 0-day lag and 1-day lag. The effect generally tapered off for longer lag periods (EPA 2005b).

Treatment of Uncertainty

The version of APEEP used in our analysis does not provide error bounds that reflect either statistical uncertainty in the concentration-response functions used in the model or in the range of VSL estimates in the literature. The relationship between emissions and ambient air quality is likewise treated as certain, as is the case in regulatory impact analyses of air-quality regulations. Due to the importance of the VSL in determining the size of air-pollution damages, we used a value of $2 million (2000 USD) as a sensitivity analysis. The likely impact of using alternative concentration-response functions (for example, Dockery et al. 1993) is discussed below.

Methodology The APEEP model calculates the damages associated with emitting an additional ton of each of six pollutants (SO2, NOx, PM2.5, PM10, NH3, and VOCs) as a function of the county in which the pollutant is emitted and the effective stack height of the emissions. The categories of damages covered by APEEP and reflected in our estimates include premature mortality associated with PM2.5, cases of chronic bronchitis and respiratory and cardiovascular hospital admissions associated with PM2.5 and PM10, changes in crop and timber yields associated with ozone, damage to building materials from SO2, impairments to visibility associated with PM2.5 and recreation damages associated with ozone-related changes in forest canopy. As described in more detail in Appendix C, APEEP calculates the impact of a ton of emissions of each pollutant on ambient air quality, and the effect of the change in ambient air quality on population-weighted exposures to PM, ozone, SO2, and NOx. The impact of changes in exposure on health, crop yields, visibility, and other categories of damages is estimated using concentration-response functions from the literature. Damages are monetized using unit values from the literature. (Appendix C lists the

concentration-response functions used in the analysis and the unit values used to monetize damages.)

We calculated damages associated with each power plant by multiplying the damages per ton of each pollutant by the number of tons of each pollutant emitted by the plant in 2005, implying that we calculated the damages associated with 2005 emission levels compared with zero emissions. In practice, installing additional pollution control devices (or switching to low-sulfur coal) could reduce emissions very close to zero at most plants. We could have calculated damages relative to some estimate of the lowest emissions levels achievable by using existing control technologies; however, a zero baseline is more transparent. This approach implies that the damages calculated at each plant are an upper bound to the benefits from additional pollution controls.20

Results The monetized damages associated with emissions of SO2, NOx, PM2.5, and PM10 in 2005 are calculated for each of 406 coal-fired electricity-generating facilities by combining damages per ton from APEEP with emissions data from the 2005 National Emissions Inventory (NEI).21 Estimates of the damages associated with a ton of each of four kinds of emissions (SO2, NOx, PM2.5, and PM10) that form criteria air pollutants are obtained from APEEP as a function of the county in which the pollutant is emitted and the effective stack height of the emissions. These are combined with data on emissions of these pollutants, by stack, from the 2005 NEI.22 This allows us to calculate the monetized damages associated with each pollutant at the plant level. Data from the Energy Information Administration on net generation of electricity from coal were used to compute monetized damages per kWh.

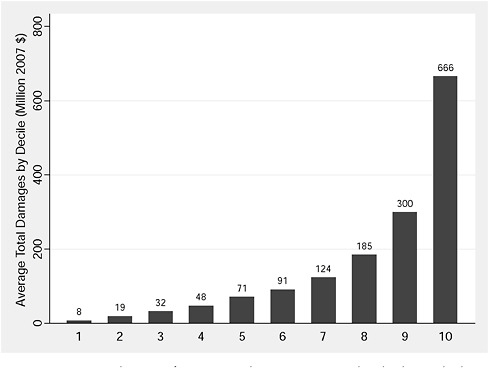

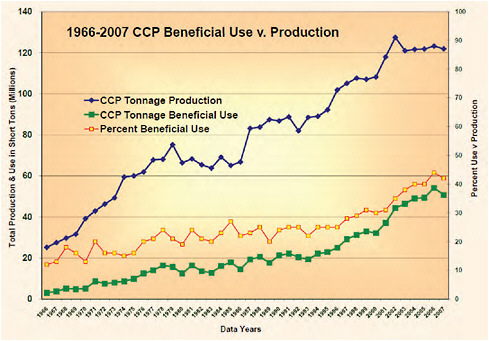

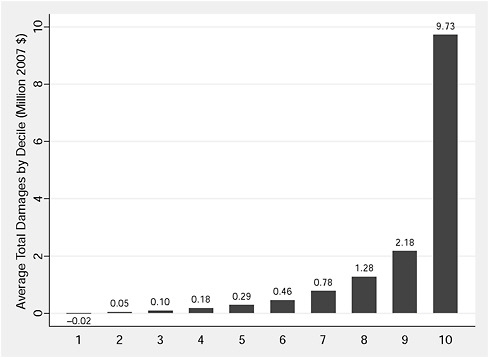

Damages from the criteria-pollutant-forming emissions were calculated, as described above, for each of 406 plants that generated electricity from coal in 2005.23 Table 2-7 and Figure 2-5 present the distribution of monetized damages across plants. (In Table 2-7 all plants are weighted equally, hence the mean figures are arithmetic means of damages across all plants.) As Table 2-7 makes clear, most damages come from SO2 (85%), followed by NOx (7%), PM2.5 (6%) and PM10 (2%). This reflects the size of SO2 and NOx emissions from coal-fired power plants and the damages associated with fine particles formed from SO2 and NOx.24 Directly emitted PM2.5 has very high damages per ton (see Table 2-8), but very little PM2.5 is emitted directly by power plants; most is formed from chemical transformations in the atmosphere.

Table 2-8 shows how the damages per ton of pollutant vary across plants, again weighting all plants equally. Variation in damages per ton reflects differences in the size of the populations (human and other) exposed to pollution from each plant, as well as differences in effective stack heights across plants. The assumption implicit in our calculations—that the damage per ton of pollutant emitted is independent of the number of tons emitted at the plant—is consistent with the epidemiological literature and with the calculation of air-pollution damages by EPA and other agencies.25

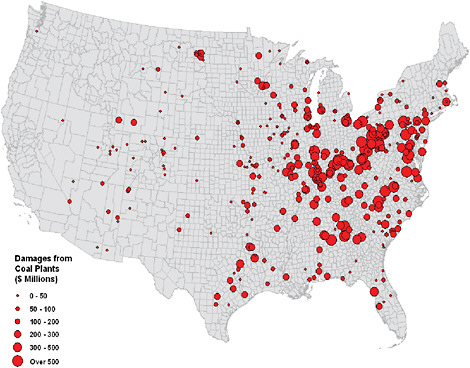

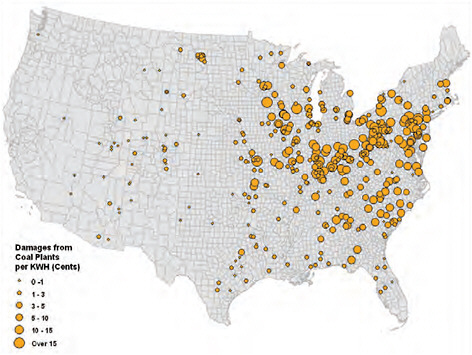

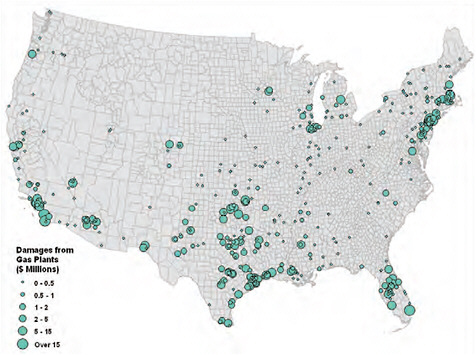

Damages from the criteria-pollutant-forming emissions in 2005 averaged $156 million per plant, but the range of damages across plants was wide—the 5th and 95th percentiles of the distribution are $8.7 and $575 million dollars, respectively (2007 USD). As Figure 2-5 shows, the distribution is highly skewed. After ranking all the plants according to their damages, we found that the most damaging 10% of plants produced 43% of aggregate air-pollution damages from all plants, and the least damaging 50% of the plants produce less than 12% of aggregate damages.26 Where are the plants with the highest damages located? The map in Figure 2-6 shows the size of damages created by each of the 406 plants, by plant location. Plants with large damages are concentrated to the east of the Mississippi, along the Ohio River Valley, in the Middle Atlantic and the South.

Some of the variation in damages across plants occurs because plants that generate more electricity tend to produce greater aggregate damages;

|

23 |

Each of our plants is classified as SIC 4911. Together they accounted for 94.6% of electricity generated from coal and sold to the grid (EIA 2009d, Table 1.1). |

|

24 |

Approximately 99% of the damages associated with SO2 come from secondary particle formation, that is, the transformation of SO2 into PM10 and PM2.5. |

|

25 |

The concentration-response functions in the air pollution literature are approximately linear in ambient concentrations. The unit values assigned to health and other endpoints are likewise assumed to remain constant over the relevant ranges of the endpoints. |

|

26 |

Each set of plants—the most damaging 10% and the least damaging 50%—account for approximately one quarter of electricity generated by the 406 plants. |

TABLE 2-7 Distribution of Criteria-Air-Pollutant Damages Associated with Emissions from 406 Coal-Fired Power Plants in 2005 (2007 U.S. Dollars)

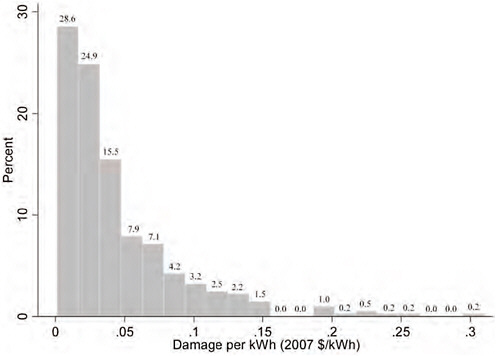

FIGURE 2-5 Distribution of aggregate damages in 2005 by decile: coal plants (U.S. dollars, 2007). NOTE: In computing this graph, power plants were sorted from smallest to largest based on aggregate damages. The lowest decile represents the 40 plants with the smallest aggregate damages. The figure on the top of each bar is the average, across all plants, of damages associated with SO2, NOx, PM2.5, and PM10.

TABLE 2-8 Distribution of Criteria-Air-Pollutant Damages per Ton of Emissions from Coal-Fired Power Plants (2007 U.S. Dollars)

FIGURE 2-6 Air-pollution damages from coal generation for 406 plants, 2005 (U.S. dollars, 2007). Damages related to climate-change effects are not included.

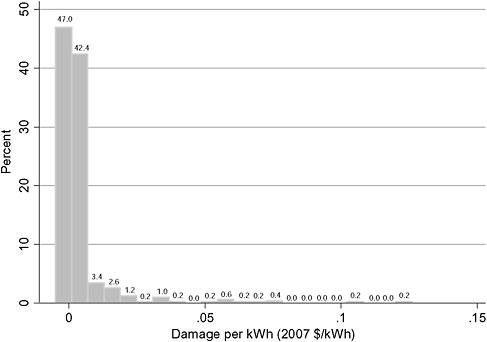

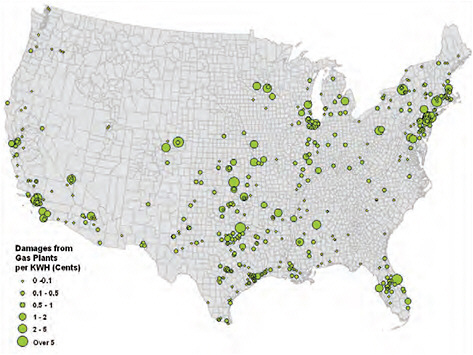

hence we also report damages per kWh of electricity produced.27 Table 2-9 and Figures 2-7 and 2-8 show damages per kWh for all four pollutants. Mean damages per kWh (2007 USD) from four criteria-pollutant-forming emissions are 4.4 cents per kWh if all plants are weighted equally and 3.2 cents per kWh if plants are weighted by the electricity they generate. The lower figure reflects the fact that larger plants are often less damaging per kWh.28 What is equally important as mean damages is the distribution of damages across plants. As Table 2-9 indicates the 95th percentile of the distribution—damages of 12 cents per kWh—is more than an order of magnitude larger than the 5th percentile. The distribution of damages per kWh (Figure 2-7) is very skewed: There are many coal-fired power plants with low damages per kWh as well as a small number of plants with high damages. Using generation-weighted figures, the damages per kWh from the least damaging 5% of plants were very small: 94% lower than the average coal-fired plant and almost as low as the average damage per kWh at natural gas power plants (0.16 cents). Figure 2-8 maps damages per kWh for each power plant. As in the case of aggregate damages, the plants with lowest damages per kWh are in the West. Plants with the largest damages per kWh are concentrated in the Northeast and the Midwest.

What explains variation in damages per kWh across plants? Damages per kWh associated with a criteria air pollutant (for example, SO2) are the product of emissions per kWh and the damage per ton of pollutant emitted. For the 406 plants examined, variation in damages per kWh is primarily due to variation in pollution intensity (emissions per kWh) across plants, rather than variation in damages per ton of pollutant, which varies with plant location. In the case of SO2, emissions per kWh reflect the sulfur content of the coal burned, adoption of control technologies (for example, scrubbers), as well as the vintage of the plant. Pounds of SO2 emitted per MWh (see Tables 2-10 and 2-11) vary greatly across plants, and this variation explains approximately 83% of the variation in damages attributed to SO2 emissions per kWh. As Table 2-11 indicates, pounds of SO2 and NOx emitted per MWh vary significantly with plant vintage, reflecting the fact that newer plants are subject to more stringent pollution controls. Variation in damages per ton of SO2 emitted (see Table 2-8) accounts for only

TABLE 2-9 Distribution of Criteria-Air-Pollutant Damages per Kilowatt-Hour Associated with Emissions from 406 Coal-Fired Power Plants in 2005 (2007 Cents)

24% of the variation in damages per kWh.29 A ton of pollution emitted by plants located closer to population centers does more damage than the same ton emitted in a sparsely populated area; however, while plant location is important, coal plants are not located in counties with the highest damages per ton of SO2 in the United States.

To summarize, the aggregate damages associated with criteria-pollutant-forming emissions from coal-fired electricity generation in 2005 were approximately $62 billion (USD 2007), or 3.2 cents per kWh (weighting each plant by the fraction of electricity it produces); however, damages per plant

FIGURE 2-7 Distribution of air-pollution damages per kWh for 406 coal plants, 2005 (U.S. dollars, 2007). NOTE: All plants are weighted equally rather than by the electricity they produce.

varied widely. The lowest-damage 50% of plants, which accounted for 25% of net generation, produced 12% of damages, and the highest-damage 10% of plants, which also accounted for 25% of net generation, produced 43% of the damages. Although damages are larger for plants that produce more electricity, less than half of the variation in damages across plants is explained by differences in net generation.

Damages per kWh also varied widely across plants: from approximately half a cent (5th percentile) to over 13 cents per kWh (95th percentile). (These are unweighted figures.) Most of the variation in damages per kWh can be explained by variation in emissions intensity across plants. In the case of SO2, which accounts for 85% of the damages associated with SO2, NOx and PM, over 80% of the variation in SO2 damages per kWh is explained by variation in pounds of SO2 emitted per kWh. Damages per ton of SO2 emitted, which vary with plant location, are less important in explaining variation in SO2-related damages per kWh. (They are, by themselves capable of explaining only 24% of the variation in damages per kWh.)

FIGURE 2-8 Regional distribution of air-pollution damages from coal generation per kWh in 2005 (U.S. dollars, 2007). Damages related to climate change are not included.

Of the 14 categories of criteria-air-pollutant damages included in APEEP, 6 relate to human health and the remainder to physical impacts (materials damage, ozone damage to crops and forests, the cost of foregone recreation due to SO2, NOx, ozone, and VOCs, and the cost of reduced visibility due to airborne particulate matter).

Sensitivity Analysis and Comparison with the Literature

The results of any analysis of the damages associated with air-pollution emissions depend critically on (1) the size of the emissions reduction analyzed; (2) the air-quality model used to translate emissions into ambient air quality; (3) the choice of concentration-response function for premature mortality and (4) the VSL used to monetize premature mortality. Premature mortality constitutes 94% of the damages reported above. When a VSL of $2 million is used (Mrozek and Taylor 2002), premature mortality constitutes 85% of total damages, and the weighted-average cost per kWh falls to 1.2 cents. If we had chosen to use Dockery et al. (1993) as the

TABLE 2-10 NOx and SO2 Emissions (2002) from Coal-Fired Electricity Generation by Age of Power Plant

|

a. 2002 NOx Emissions and Share of Generation of Coal-Fired Capacity by Vintage |

|||||||||||||

|

Power Plant Established |

Avg. NOx Emission Rate (lb/MWh) |

% Total NOx Emitted |

% of Coal-Fired Electricity Generation |

% of NOx Emitted per % of Electricity Generateda |

% of Coal-Fired Electricity Capacity |

||||||||

|

Pre-1950 |

5.51 |

0.65 |

0.50 |

1.31 |

0.92 |

||||||||

|

1950-1959 |

5.07 |

15.11 |

12.56 |

1.20 |

14.32 |

||||||||

|

1960-1969 |

4.56 |

21.27 |

19.65 |

1.08 |

20.51 |

||||||||

|

1970-1979 |

4.28 |

39.31 |

38.76 |

1.01 |

38.13 |

||||||||

|

1980-1989 |

3.53 |

21.74 |

25.97 |

0.84 |

23.84 |

||||||||

|

Post-1990 |

3.15 |

1.92 |

2.56 |

0.75 |

2.27 |

||||||||

|

b. 2002 SO2 Emissions and Performance of Coal-Fired Capacity by Vintage |

|||||||||||||

|

Power Plant Established |

Avg. SO2 Emission Rate (lb/MWh) |

% of Total SO2 Emitted |

% of Coal-Fired Electricity Generation |

% of SO2 Emitted per % of Electricity Generateda |

Average Capacity Factor (%)b |

Average Heat Rate (Btu/kWh generated) |

|||||||

|

Pre-1950 |

20.58 |

1.02 |

0.50 |

2.04 |

36.35 |

12,549 |

|||||||

|

1950-1959 |

15.78 |

19.64 |

12.56 |

1.56 |

58.93 |

10,668 |

|||||||

|

1960-1969 |

13.92 |

27.12 |

19.65 |

1.38 |

64.37 |

10,150 |

|||||||

|

1970-1979 |

9.31 |

35.75 |

38.76 |

0.92 |

68.29 |

10,270 |

|||||||

|

1980-1989 |

6.02 |

15.49 |

25.97 |

0.60 |

73.17 |

10,401 |

|||||||

|

Post-1990 |

3.88 |

0.98 |

2.56 |

0.38 |

75.80 |

9,982 |

|||||||

|

c. 2002 NOx Emissions and Share of Generation of Coal-Fired Capacity by NSPSc |

|||||||||||||

|

NSPS Status According to EIA 767 |

Avg. NOx Emission Rate (lb/MWh) |

% Total NOx Emitted |

% of Coal-Fired Electricity Generation |

% of NOx Emitted per % of Electricity Generateda |

% of Coal-Fired Electricity Capacity |

||||||||

|

Unknown |

2.93 |

0.16 |

0.23 |

0.69 |

0.27 |

||||||||

|

Not Affected by NSPS |

4.67 |

65.90 |

59.51 |

1.11 |

62.62 |

||||||||

|

Subject to Aug. 1971 Standards (D) |

3.57 |

26.73 |

31.58 |

0.85 |

29.56 |

||||||||

|

Subject to Sept. 1978 Standards (Da) |

3.50 |

7.21 |

8.68 |

0.83 |

7.56 |

||||||||

|

d. 2002 SO2 Emissions and Performance of Coal-Fired Capacity by NSPSc |

||||||

|

|

Average SO2 Emission Rate (lb/MWh) |

% of Total SO2 Emitted |

% of Coal-Fired Electricity Generation |

% of SO2 Emitted per % of Electricity Generateda |

Average Capacity Factorb (%) |

Average Heat Rate (Btu/kWh Generated) |

|

**Unknown |

4.56 |

0.10 |

0.23 |

0.45 |

56.58 |

11,247 |

|

Not Covered by NSPS |

12.93 |

76.25 |

59.51 |

1.28 |

63.85 |

10,250 |

|

Subject to Aug. 1971 Standards (D) |

6.66 |

20.86 |

31.58 |

0.66 |

71.79 |

10,519 |

|

Subject to Sept. 1978 Standards (Da) |

3.23 |

2.78 |

8.68 |

0.32 |

77.17 |

10,185 |

|

NOTES: All quantities, including percentages of emissions and generation capacity, are calculated with reference only to coal-fired generating units. Percentages (taking account of rounding) add to 100% because other types of generating capacity are not considered. These tables and the associated dataset were constructed by David Evans of Resources for the Future. Data used to make these tables come from three sources: emission data are from EPA’s CEM system database; generation and capacity data are from EIA’s 767 dataset; and information on vintage of generating units is from EIA’s Form 860 dataset. aIf the generators of a particular vintage (or in a particular NSPS category) emitted a particular pollutant in proportion to its share of total electricity generation, the value would be 1. bCapacity factor of units that operated that are strictly associated with boilers in CEM system database. cThe Subpart D standards apply to fossil-fuel-fired steam boilers for which construction began after August 17, 1971. The Subpart Da standards affect those boilers that began construction after September 18, 1978. For boilers not covered by NSPSs construction began before August 17, 1971. A new NSPS for NOx was promulgated in 1998, but no new coal-fired generating facilities have been permitted since this new standard was issued. ABBREVIATIONS: SO2 = sulfur dioxide; NOx = oxides of nitrogen; lb/MWh = pound per megawatt-hour; Btu/kWh = British thermal unit per kilowatt-hour; CEM = continuous emission monitoring; NSPS, new source performance standards. SOURCE: EIA 2004a,b; EPA 2004a. As presented in NRC 2006a. |

||||||

TABLE 2-11 Distribution of Pounds of Criteria-Pollutant-Forming Emissions per Megawatt-Hour by Coal-Fired Power Plants, 2005

|

|

Mean |

Standard Deviation |

5th Percentile |

25th Percentile |

50th Percentile |

75th Percentile |

95th Percentile |

|

SO2 |

12 |

11 |

1.5 |

5.4 |

8.9 |

16 |

33 |

|

NOx |

4.1 |

2.3 |

1.3 |

2.6 |

3.7 |

4.9 |

9.0 |

|

PM2.5 |

0.59 |

0.58 |

0.092 |

0.20 |

0.35 |

0.81 |

1.8 |

|

PM10 |

0.72 |

0.67 |

0.12 |

0.28 |

0.48 |

0.94 |

2.1 |

|

ABBREVIATIONS: SO2 = sulfur dioxide = NOx, oxides of nitrogen; PM = particulate matter. |

|||||||

concentration-response function for premature mortality instead of Pope et al. (2002), our damages would have been approximately three times as large as what is reported above.

How do our estimates of damages compare with the literature? Levy et al. (2009) estimated the criteria-air-pollutant damages associated with individual coal-fired power plants using a methodology similar to what is used here; however, their estimates of damages are much higher, ranging from $0.02 to $1.57 per kWh, with a median estimate of 14 cents per kWh (1999 USD).30 Converting the results of Levy et al. to 2007 USD, their median estimate is almost 6 times as high as our median estimate of 2.9 cents per kWh (Table 2-9).31 It is, however, possible to reconcile the two sets of estimates. Two notable differences are that Levy et al.’s estimates are based on emissions data for 1999 rather than 2005 and their estimates depend on a concentration-response function for premature mortality based on Schwartz et al. (2008) rather than Pope et al. (2002).32 Emissions of NOx from coal-fired power plants were approximately 50% higher in 1999 than in 2005; emissions of SO2 were approximately one-third higher. The concentration-response function in Schwartz et al. (2008) yields about three times more deaths associated with a microgram of PM2.5 than those estimated using Pope et al. (2002)—the concentration-response function used in APEEP. These differences lead to much higher estimates of mortality associated with PM2.5, and over 90% of the damages associated with air emissions in our study come from PM2.5 mortality. Levy et al. (2009) also performed uncertainty propagation involving asymmetric triangular distributions, which would contribute modest upward bias to the median

damage estimates. In short, if Levy et al. (2009) had used the same mortality concentration-response function and the same emissions as APEEP, and had not done uncertainty propagation, the results would have been nearly identical to ours.

Estimates of the benefits of reducing SO2 and NOx emissions under the Clean Air Interstate Rule (CAIR) (EPA 2005b) are also higher than ours because of differences in air-quality modeling. The regulatory impacts analysis of CAIR examined the benefits of reducing emissions of SO2 and NOx at power plants in 28 states in the eastern United States. The analysis predicted that in 2015 a reduction in SO2 emissions of approximately 4 million tons and a reduction in NOx emissions of approximately 1.5 million tons would reduce premature mortality by 17,000 deaths. Our analysis, in contrast, estimates that in those states a reduction in SO2 and NOx that is approximately twice as large would result in 10,000 fewer deaths in 2005. This result is due to differences in air-quality modeling: The use of CMAQ in the CAIR regulatory impact analysis (EPA 2005b) leads to an estimate of 1.15 μg/m3 reduction in population-weighted PM2.5 exposure, a much larger effect than is predicted by APEEP.33 A study evaluating the performance of the version of CMAQ used in the CAIR study (version 4.3) found that it overestimated sulfate PM concentrations at sample locations in the eastern United States by 9% in one sample of largely rural sites (the Interagency Monitoring of Protected Visual Environments) and by 6% in another sample of largely urban sites (Speciated Trends Network) (EPA 2005c). This estimation bias was higher in the summer months, when sulfate concentrations are higher—14%. However, the estimation bias still does not fully account for the difference between the CMAQ and APEEP predictions.

Air-quality modeling results from APEEP agree well with other studies that use Gaussian plume models to model dispersion of pollutants from power plants (Nishioka et al. 2002; Levy et al. 2009), but concentrations of PM2.5 from power plants are lower in APEEP than in CMAQ (EPA 2005c; Fann et al. 2009).34 One of the advantages of APEEP is better spatial resolution in urban counties, but it may still lack the necessary level of spatial detail in urban areas, giving rise to some uncertainty about results.

In contrast to Levy et al. (2009), Muller et al. (2009) report estimates of criteria air-pollutant damages from coal-fired power plants that are slightly lower than those presented here (mean damages of approximately 2 cents

per kWh, on the basis of 2007 USD), using a value of a statistical life year (VSLY) approach.

Downstream CO2Emissions of Electricity Generation from Coal

The emissions of CO2 from coal-fired power are the largest single source of GHG emissions in the United States. The heat rate (energy of coal needed to generate 1 kWh of electricity) varies widely among coal-fired plants; thus the CO2 emissions vary (with an average of about 1 ton of CO2 per MWh of power generated [the 5th-95th percentile range is 0.95-1.5 tons]). The main factors affecting differences in the CO2 generated are the technology used to generate the power and the age of the plant. The effect of CO2 and other GHG emissions on global warming are discussed in Chapter 5.

Externalities Associated with Heavy-Metal Emissions of Electricity Generation from Coal

Heavy metals are toxic both to the environment and to public health. The combustion of coal to produce electricity results in emissions of heavy metals, depending on the source of the coal, the conditions of combustion, and the cleanup technologies used. Among the heavy metals found in coal-combustion wastes are antimony (Sb), arsenic (As), beryllium (Be), cadmium (Cd), chromium (Cr), cobalt (Co), copper (Cu), lead (Pb), manganese (Mn), mercury (Hg), molybdenum (Mo), nickel (Ni), selenium (Se), silver (Ag), thallium (Tl), vanadium (V), and zinc (Zn). To determine the risks for human health and for the environment associated with particular heavy metals, one must consider both the toxicity of the metal and the potential for exposure to the metal.

Information on the toxicity of individual metals and their various metallic species can be found in the Integrated Risk Information System (IRIS) database at the EPA Web site (epa.gov/IRIS). Highly toxic metals for humans and the environment include Hg, As, Cd, Pb, and Se. Major routes of exposure are through air emissions and through leaching of contaminants from landfills or surface impoundments of wastes.

Trace metals, including heavy metals, have been classified according to how they partition among waste streams from coal combustion (EPA 1995):

Class 1. Elements that are approximately equally concentrated in the fly ash and bottom ash or that show little or no small particle enrichment (that do not contain many small particles). Examples include manganese, beryllium, cobalt, and chromium.

Class 2. Elements that are enriched in fly ash relative to bottom ash, or show increasing enrichment with decreasing particle size. Examples include arsenic, cadmium, lead, and antimony.

Class 3. Elements emitted in the gas phase (primarily mercury and in some cases, selenium).