Taiwan’s Industrial Technology Research Institute: A Cradle of Future Industries

Taiwan’s Industrial Technology Research Institute (ITRI) is a not-for-profit research organization established in 1973 to provide applied industrial research for Taiwanese industry. ITRI draws upon research conducted all over the world in companies, research organizations and universities and uses the knowledge to develop product prototypes and the processes, equipment and materials necessary to manufacture those prototypes. It fosters not only the creation of companies that make new products, but of entire industry chains supporting the manufacturing process, including design, materials, equipment, testing, packaging, quality control and applications. ITRI “has played an integral role in transforming Taiwan’s economy from a low-tech, labor-intensive model to a high-tech, knowledge-based industrial core.”1 ITRI’s formation was the most important aspect of a broad national effort to develop Taiwan’s semiconductor industry, a spectacular success which has subsequently driven the growth of Taiwan’s capabilities in computers, lighting, displays, telecommunications, photovoltaics, and machinery.

ITRI is located in one of the most successful technology “clusters” in the world, grouped in and around Hsinchu Science Park (HSP), a research and high technology industrial zone established by the government in 1980.2 In addition to ITRI, two world class research universities, National Tsing Hua University (NTHU) and National Chiao Tung University (NCTU) adjoin the park, which is the site of research and manufacturing operations of over 400 high technology companies. Most points within this complex are within

________________

1Allen Hsu, “ITRI Pushes Technology Sector to New Frontier of Innovation,” Taiwan Journal (October 19, 2007).

2Michael Porter defines “clusters” as “geographic concentrations of interconnected companies, specialized suppliers, service providers, firms, in related industries and associated institutions … in particular fields that compete but also cooperate. Michael Porter, On Competition (Boston: Harvard Business School Printing, 1998) pp. 197-198.

walking distance of each other, a proximity which fosters personal interchange and cross-pollination of ideas. NCTU, NTHU and ITRI train large numbers of workers for the industries in HSP; company executives and ITRI officials teach in the two universities; and university professors turn to ITRI for assistance in developing practical applications of new ideas and sit on advisory boards of local companies. ITRI “has been praised as the incubator of Taiwan’s chief executive officers of publicly held companies and talents for industries,” and the same could be said of NCTU and NTHU. 3 The companies located in HSP account for about 15 percent of Taiwan’s GDP, making the park one of the most productive pieces of real estate on earth.4

The creation of ITRI, perhaps the most important milestone in the entire course of Taiwan’s industrialization, was the brainchild of an elite group of highly competent bureaucrats and business leaders, most of them holding degrees in engineering.5 They frequently had extensive experience working for multinational high technology companies and were in a position to apply their practical experience to the development of indigenous companies and industries.6 They were relatively unhindered by political pressure—the Kuomintang Party (KPT), which held a monopoly on political power until 1990, had a tradition of relying on “scientific” government planning when it arrived on Taiwan in 1949, and technocrats “had already won a large measure of independence from party and military control.”7 This pattern was maintained

________________

3As of late 2006 ITRI had cultivated over 60 CEOs and 18,000 specialists for Taiwan’s high tech industries. “ITRI Transforms Into a Value Creator from a Tech Follower,” Taiwan Economic News (October 24, 2006).

4Interview with Han-Ping David Shieh, National Chiao Tung University, Hsinchu, Taiwan, February 16, 2012. In 2007, the Geneva-based World Economic Forum ranked Taiwan in first place worldwide in industrial clustering competitiveness, a distinction “attributed mainly to the effect of the world-renowned Hsinchu Science Park.” “Taiwan Ranks 1st Place in Industrial-Clustering Competitiveness Worldwide: WEF,” Taiwan Economic News (December 26, 2007).

5Eleven of the first fourteen individuals to serve as Minister for Economic Affairs in Taiwan held degrees in engineering or science. K.Y. Lin, Taiwan’s chief economic planner in the 1950s and early 1960s, had a degree in electrical engineering, and of his two assistants, one was a physicist and the other a civil engineer. MOEA’s Industrial Development Bureau, which created ITRI, was dominated by engineers at the time. Robert Wade, Governing the Market: Economic Theory and the Role of Government in East Asian Industrialization (Princeton and Oxford: Princeton University Press, 1990), p. 98.

6Morris Chang, with 25 years of experience at Texas Instruments, is a former head of ITRI and when he moved to set up TSMC, he founded TSMC and “loaded TSMC’s ranks with American-trained managers such as Britt Brooks, Doug Chance (the successive general managers of TSMC) and other international professional manager. Among the managers, most of them are Chang’s former colleagues at TI.” Chang’s “excellent education and work experience established his professional knowledge in the semiconductor industry and contributed to the creation of the focused business model of the pure play foundry.” Similar observations could be made with respect to many members of the generation of leaders which oversaw Taiwan’s economic development. T. H. Liu, S. C Hung, S. Y. Wu, and Y. Y. Chu, “Technology Entrepreneurial Styles: A Comparison of UMC and TSMC,” International Journal of Technology Management Vo. 29 ½ (2005) p. 681. SEMI Oral History Interview, Morris Chang (August 24, 2007, Taipei, Taiwan).

7Chiang Kai-shek’s government, shaken by Japan’s seizure of Manchuria in 1931, came to believe that its survival depended on governing through a highly educated and professional bureaucracy.

during the decades of KMT rule but is eroding with the advent of democracy and challenges to KMT policies by the Democratic People’s Party (DPP).8

ITRI has deep American roots. Its founder, Y.S. Sun, formulated a developmental strategy for high tech industry in Taiwan based on discussions in the early 1970s with a colleague, Dr. Pan Wen-Yuan, an electrical engineer then employed in RCA’s David Sarnoff Laboratories in New Jersey. The two men determined that Taiwan should develop a semiconductor industry, that acquisition of U.S. technology would be required, and that Chinese engineers working in U.S. technology companies would be an important asset for such an effort.9 RCA trained the first cadre of ITRI engineers in semiconductor manufacturing technology, a number of whom were U.S. residents holding Ph.Ds. from U.S. universities. The Taiwanese development effort was advised by a “Science and Technology Advisory Group” (STAG), established in 1979, led by U.S. semiconductor executives, including Pat Haggerty, former CEO of Texas Instruments and former member of the National Academy of Sciences, and B.O. Evans, former VP for development at IBM.10 Hsinchu Science Park represented a deliberate effort by Kuo-Ting Li, a Taiwanese leader known to posterity as the “architect of Taiwan’s economic miracle,” to replicate the best features of California’s Silicon Valley in Taiwan. 11 HSP’s first director was an American, Dr. Choh Li, formerly a research director at Honeywell in

________________

Chiang promoted senior officials who believed in keeping economic policymaking insulated from political interference. Chiang’s philosophy was paraphrased by a KMT official as “governments and political forms are transitory, the problems facing a nation are not.” Chiang’s son, Chiang Ching-kuo, who succeeded him in 1972, believed in recruiting “the central economic decision-makers according to demonstrated technical abilities.” Wade, Governing the Market (1990) op. cit. pp. 247-248

8In 2006, Taiwan Premier Su Tseng-chang, a member of the KMT’s rival party, the Democratic People’s Party (DPP), visited ITRI, praised the organization for its achievements, and commented that he envied ITRI “because the researchers can commit themselves to professional studies without political interference.” “ITRI Has Contributed Greatly to Taiwan: Premier,” Asia Pulse (May 23, 2006). In fact the DPP tends to view ITRI as a KMT stronghold supporting business interests aligned with that party. Voices within the DPP reportedly suggest that if the government plans to spend money on industries, the funds would be better directed toward fisheries and agriculture.

9John A. Mathews and Dong-Sung Cho, Tiger Technology: The Creation of a Semiconductor Industry in East Asia (Cambridge: Cambridge University Press, 2000) p. 158.

10STAG initially consisted of two Technical Review Boards (TRBs), one for semiconductors and one for electronics, dominated by overseas Chinese selected by Evans or his staff. Morris Chang recalls that “Pat Haggerty was really the major figure at TI. It was he that made TI a big successful company. TI was a very small unknown and not all that successful company before him. He was the one that made the key decision of entering the semiconductor business.” “Oral History of Morris Chang,” recorded August 24, 2007 (Computer History Museum, 2007) p. 7.

11Li, a former Finance Minister, consulted with Frederick Terman on how Taiwan could replicate Silicon Valley. Terman served as Dean of Stanford’s School of Engineering and spearheaded the establishment of what is now Stanford Research Park. Together with William Shockley he is widely regarded as the father of Silicon Valley. Similarly, Li, the founder of Hsinchu Science Park, is credited with transforming Taiwan from an agrarian country to a high technology center. “Fred Terman, the Father of Silicon Valley,” Net Valley (October 21, 2010).

Minneapolis.12 Morris Chang, perhaps the most famous person to head ITRI and the founder of Taiwan Semiconductor Manufacturing Corporation (TSMC), holds two degrees from MIT, a doctorate from Stanford and served for over 20 years with Texas Instruments, including time as the company’s CEO. At present, four decades after its creation, a large proportion of ITRI’s total work force still holds bachelors and advanced degrees from leading U.S. universities.

THE TECHNOLOGY INTERMEDIARY

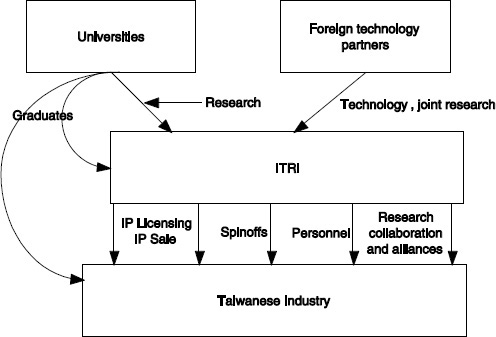

An industry analyst quoted in The Economist observed in 2010 that Taiwan was “the best place in the world to turn ideas into physical form.”13 That fact is substantially attributable to ITRI, which functions as the bridge between ideas and form, or as its managers express it, as a “technology intermediary” serving Taiwanese industry. Its primary function is not research but adaptation and transfer of technology from domestic and overseas laboratories to domestic companies. ITRI is “arguably the most capable institution of its kind in the world in scanning the global technological horizon for developments of interest in Taiwanese industry, and executing the steps required to import the technology—either under license or joint development— and then absorbing and adopting the technology for Taiwanese firms to use …”14 Technology is transferred to Taiwanese industry through a variety of channels, including licensing, patent auctions, co-development arrangements, spinoffs, migration of ITRI personnel to companies, and research consortia and alliances.

Strategic Direction

Although Taiwan’s National Science Council (NSC) is formally responsible for formulating the country’s science and technology policy, and ITRI is subordinated to the Ministry of Economic Affairs, strategic direction has determined through a consultation process involving foreign experts and ethnic Chinese with relevant experience in multinational companies:

“a distinctive feature of Taiwan’s technology policy making is the extensive participation of overseas technologists, mostly of ethnic Chinese origins, as advisers. Enjoying a varying level of access to the top policy circle, they help policymakers identify the industrial sectors with technological promise,

________________

12Constance Squires Meaney, “Taiwan’s Semiconductor Industry,”: in Joel D. Aberbach, David Dollar and Kenneth Sokoloff, (eds.) The Role of the State in Taiwan’s Economic Development (Armonk, NY: M.E. Sharpe, Inc., 1994) p. 178.

13“Hybrid Vigour,” The Economist (May 27, 2010).

14John A. Mathews and Dong-Sung Cho, Tiger Technology: The Creation of a Semiconductor Industry in East Asia (Cambridge: Cambridge University Press, 2000).

FIGURE APP-A3-1 ITRI as a technology intermediary.

suggest the strategies of technology transfer and adaptation, and provide technical expertise for the daily operation of research projects.”15

MOEA determines ITRI’s strategic direction in consultation with such experts and ITRI itself. The Technical Advisory Committee (TAC), originally an informal group of expatriate Taiwanese engineers working in the United States, evolved into a standing organization of Taiwanese with international education and work experience advising ITRI on relationships with multinational corporations. 16 The Science and Technology Advisory Group (STAG), which advises the Executive Yuan (cabinet) on science and technology policy, includes international experts (occasionally including Nobel Prize winners) as well as eminent Taiwanese academics and holds an annual Industrial Science and Technology Strategy Conference, which addresses themes in areas such as electronics, telecommunications, information technology and

________________

15Chen-Dong Tso, “State-Technologist Nexus in Taiwan’s High Tech Policymaking: Semiconductor and Wireless Communications Industries,” Journal of East Asian Studies (May 2004).

16Dr. Chintay Shih, former president of ITRI, commented in 2009 that “The TAC were our tutors and lighthouse. They have contributed the rest of their lives without any payback.” Thirty years after ITRI’s formation some of the original TAC members were still serving as consultants to ITRI. Cristina Chen, Jason Kao, Frans Nauta, Jan-Frens Van Giessel, Clement Goossens and Pipijn Veling, Excellent Government on a Far-East Silicon Island (December 2009).

biotechnology.17 STAG prepares developmental technology blueprints for specific industry sectors regarded as important.18 The Technical Review Board (TRB) of the National Science Council consists of foreign and domestic experts who concentrate on targeting particular technologies and adapting them at the operational and project level. A number of key Taiwanese experts have served in more than one capacity in such organizations.19 This multifaceted and cosmopolitan advisory system has been widely praised, but has fostered failures as well as successes.20

Ding-Yuan Yang, a former ITRI official who founded Winbond Electronics Corporation in 1987, explained in a 2011 oral history interview that the founder of ITRI, MOEA Minister Y.S. Sun, would use the conferences with experts to absorb opinions on the development of technology. MOEA would then draft formal minutes of the conferences, “and then the plans would start.” MOEA would give “suggestions” to ITRI for execution. ITRI would respond by proposing contracts with the Ministry, sign the contracts, and begin to execute them. “These kinds of national projects were all four-year contracts, which allowed it to have a certain continuity.”21

Organization

ITRI was formed through the combination of three existing research centers subordinated to MOEA which were relocated to a new site in Hsinchu in 1973.22 At its inception ITRI consisted of 400 employees and was funded by a

________________

17STAG was at one time headed by Frederick Seitz, former president of the U.S. National Academy of Sciences. “STAG Provides Policy Suggestions,” Taiwan Today (June 15, 2001). “The Science and Technology Advisory Group Must Take its Job Seriously,” United Daily News (Taipei, November 13, 2009). Arthur Carty, a Canadian nanotechnology who was invited to join STAG in 2008, recalled in 2010 that in a recent week-long STAG meeting, “government officials, industry professionals, research and development experts and academics reviewed and discussed a number of investment proposals before throwing out the bad ones. We don’t have anything like that in Canada,” Carty said. “Taiwan’s Technology Success Underappreciated: Canadian Scientist,” Focus Taiwan (July 24, 2010).

18“M-Taiwan Program and Objectives of WiMAX in Taiwan,” WiMAX360° (June 24, 2009).

19Dr. Hwa-Nien Yu, one of the world’s foremost experts on semiconductor device technology and design, has chaired the TAC for ITRI since 1993. He also served on the TRB and has been advising ITRI in various capacities since the 1970s. He is an emeritus member of IBM Research with B.S., M.S. and Ph.D. degrees in electrical engineering from the University of Illinois.

20Based on advice from STAG, in 1982 the Taiwanese government decided to place a priority on the development of a biotechnology industry. Major financial and institutional commitments were subsequently undertaken. Today, thirty years after this effort began, it is not at all clear that the modest results achieved to date represent an adequate return on Taiwan’s major investment. See generally Yu-Shan Wu, Academia Sinica, “Taiwan’s Developmental State: After the Economic and Political Turmoid,” Paper prepared for delivery at the Conference on A Decade After the Asian Financial Crisis, Thammasat University, Bangkok, February 23-24, 2007, p. 22.

21Interview with Ding-Yuan Yang, “Taiwanese IT Pioneers: D.Y. (Ding-Yuan) Yang,” recorded February 23, 2011 (Computer History Museum) p. 12.

22The research centers were the Uni-Chemical Research Centre, the Metal Research Centre, and the Mineral Industrial Research Centre, all of which became internal ITRI research laboratories.

government budget of $213 million. In 1974, the Electronics Industry Research & Development Centre was established within ITRI to create a domestic semiconductor industry, subsequently being renamed as the Electronics Research & Service Organization (ERSO). In 1990, new laboratories were established for computer and communications research and biomedical engineering.23

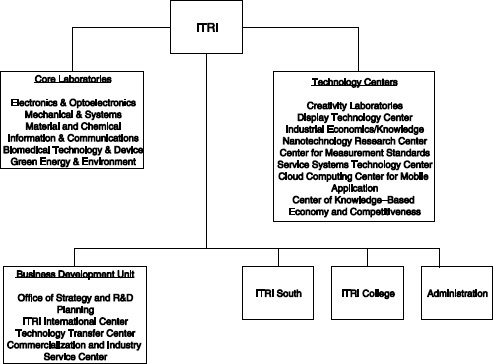

Currently, ITRI’s R&D activities are centered on six core laboratories pursuing “deeper and new” ideas and eight technology centers which focus on particular themes emphasizing a multidisciplinary approach and drawing on the specialized competencies of the core laboratories. ITRI’s Business Development Unit is responsible for commercializing research results, technology transfer, and relations with foreign research partners.

FIGURE APP-A3-2 ITRI’s organization.

________________

23Min-ping Huang, “The Cradle of Technology: the Industrial Technology Research Institute,” in Terence Tsai and Bor-Shiuan Cheng (eds.). The Silicon Dragon: High Tech Industry in Taiwan. (Cheltenham, UK and Northampton, MA: Edward Elgar, 2006) pp. 27-28. ITRI undertook a fundamental restructuring of its organization in 2006 with an eye toward “silo-breaking” among its research laboratories, which were seen as competing with each other for resources and not collaborating sufficiently. ITRI’s eight core laboratories were reduced to six through the merger of its semiconductor and optoelectronics labs and its materials and chemical labs. “Technology centers” were established and tasked with integrating the work of multiple ITRI core laboratories.

ITRI’s budget is currently about $600 million per year, half of which is provided by the government and half by the private sector. 24

ITRI employs 5,728 personnel, of which 1,163 hold Ph.Ds. and 3,152 masters’ degrees. ITRI’s staffing of research projects is “very bare bones,” even in technology areas regarded has having breakthrough potential.25

Technology Acquisition

In ITRI’s early years it relied almost entirely on the acquisition of technology and know-how from foreign high technology companies, which it disseminated to Taiwanese industry. In recent decades the research capabilities of Taiwan’s universities, including the Hsinchu-based National Tsing Hua and National Chiao Tung Universities, have emerged as increasingly important sources of technology. As ITRI’s reputation as an R&D powerhouse has grown, it has become possible for the institute to enter into joint R&D projects with first-tier foreign companies and research organizations. 26 Technology obtained via such collaborations remains a vital aspect of ITRI’s operations.

________________

24Private sector income is derived through activities such as sale of intellectual property to industry, provision of knowledge-based services to industry, other forms of technology transfer, and royalty payments. ITRI’s budget has not grown for many years despite pleas from industry to MOEA to increase ITRI’s funding. Interview with John Chen, Director, ITRI Display Technology Center, Hsinchu, Taiwan, February 14, 2012. Interview with Taiwanese semiconductor executive, Hsinchu, Taiwan, February 15, 2012. ITRI’s budget is subject to periodic public pressure based on the perception that it is channeling public resources to companies and industries that are already mature and do not need public assistance. In 1994, ITRI’s budget was cut in half by the Legislative Yuan based on such criticism. Douglas B. Fuller, Globalization for Nation Building: Industrial Policy for High Technology Products in Taiwan (MIT Working Paper MIT-IPC-02-002, January 2002), p. 12.

25Interview with Taiwanese semiconductor executive Hsinchu, Taiwan, February 15, 2012. ITRI recruits employees by offering them a good work environment, a large working team, and excellent career development prospects. Taiwan’s system of compulsory military service has served as a major source of educated personnel for ITRI. The Ministry of National Defense assigns 400 soldiers to ITRI annually, of which 70 percent are graduates of the leading universities in Taiwan. Only 10 percent of Taiwan’s soldiers are qualified for assignment to ITRI. They serve at ITRI for at least four years as an alternative to active military duty. Terence Tsai and Borshivan Cheng, The Silicon Dragon: High-Tech Industry in Taiwan (Edward Elger, 2006) p. 32. Taiwan has had a system of compulsory military service since 1949. Alternatives to active duty military service include “national defense service,” which is available to draftees with advanced degrees, particularly in engineering and the sciences. Qualified individuals who choose this option receive three months of officer training and a commission in the reserves, followed by four years of work in a government or academic research institution such as ITRI or Academia Sinica. Annual turnover is extremely high, averaging about 10 percent but in some divisions rising to 15-20 percent, posing a continual challenge to management. Interview with Mao-Jian Wang, National Tsing Hua University, Hsinchu, Taiwan, February 16, 2012.

26A number if ITRI’s foreign collaborations involve establishment of a research center on ITRI’s premises by the foreign partner. “Festo Inaugurates Automation Parts Engineering Center at ITRI,” Taiwan Economic News (February 9, 2004); Corning operates a research center within ITRI on glass technology including bendable glass. “Corning Inaugurates Research Center in Taiwan,” Asia Pulse (March 13, 2006). In a recent and significant example of technology acquisition from abroad, ITRI’s entry into the field of flexible electronics (bendable electronic devices and displays) was made possible by friendly technology transfer from Eastman Kodak Company to ITRI. Dr. John Chen,

TABLE APP-A3-1 ITRI Foreign Technology Partnerships

| Foreign Partner | Year Initiated | Themes |

| Intel Corporation | 2011 | Memory chips |

| Lawrence Berkeley National | 2011 | Renewable energy |

| Laboratory | ||

| Corning | 2006 | Optical glass, materials |

| Microsoft | 2005 | Forward versatile disc (FVD) |

| Alvarion Ltd. | 2010 | WiMAX, wireless |

| Spirit Aerosystems | 2009 | Carbon fiber |

| Hewlett Packard | 2004 | Radio frequency identification (RFID) |

| IBM | 2009 | Cloud computing |

| Novartis | 2008 | Pharmaceuticals |

| Applied Materials, SUSS | 2009 | Semiconductor manufacturing |

| Microtec | equipment, 3D ICs | |

| SOURCES: “ITRI, Intel Announce Research Project,” Taipei Times Online (December 7, 2011); “ITRI Signs MoU with LBNL on Renewable Energy Technology Development,” Taiwan Economic News (August 11, 2011); “Corning Inaugurates Research Center in Taiwan,” Asia Pulse (March 13, 2006); “Microsoft Launches Windows Engineering Center in Taiwan,” China Post (September 10, 2005); “ITRI, Israeli Firm to Build WiMAX Testing Lab,” Central News Agency (February 9, 2010); “Taiwan Institute to Cooperate with U.S. Firm in Carbon Fiber Research,” Central News Agency (July 17, 2009); “HP Sets Up First RFID Center on the Island,” China Post (April 14, 2004); “ITRI to Spearhead Green Energy and Biotech Research,” Taiwan Economic News (September 7, 2009); “Novartis Signs Five Year Cooperation MoU with MOEA,” Taiwan Economic News (January 11, 2008); “ITRI and Applied Materials Team Up on 3DIC Technology,” ITRI Today (4th quarter 2009). | ||

Technology Development

ITRI’s six core laboratories do not perform basic research, but are tasked with undertaking “exploratory and pioneering” research with respect to technologies with potential commercial applications.27 Projects can run five

________________

currently the Director of ITRI’s Display Technology Center, held numerous R&D managerial positions at Kodak between 1982 and 2006. Kodak, which had developed technology for large area roll-to-roll (R2R) fabrication of flexible displays, gave up on commercialization and sought to sell the technology “to someone who was competent,” eventually selecting ITRI. Chen led an ITRI team to Kodak’s labs in Rochester where a Kodak delegation worked with them to facilitate the technology transfer, which included transfer of equipment. ITRI’s subsequent development of R2R manufacturing processes for flexible displays was “all based on Kodak technology” but now exceeds the highest technological levels reached by Kodak. “This was the beginning of flexible displays [in Taiwan].” Interview with Dr. John Chen, Director, ITRI Display Technology Center, Hsinchu, Taiwan, February 14, 2012.

27ITRI President Johnsee Lee, “ITRI Pushes Technology Sector to New Frontiers of Innovation,” Taiwan Journal (October 19, 2007).

years or more.28 Their competencies are concentrated in hardware-related fields, although ITRI is working to refocus on software, systems and services.29 The core laboratories develop and test prototype products, production equipment and materials, and experiment with new applications.

- Electronics and Optoelectronics Research Laboratories: ITRI’s Electronics and optoelectronics research laboratories focus on manufacturing technology in the fields of nano-electronics, micro-optical-mechanical electronics, optoelectronic 3D integrated circuit packaging, 3D image processing, flexible electronics, and advanced display technology. This laboratory is currently heavily involved in research involving flexible electronics.

- Information and Communications Research Laboratory: ITRI’s Information and Communications Technologies Laboratory conducts research on core technologies for the development of IT-enabled services (ITES). This laboratory coordinates with other national projects involving system-on-chip, e-learning and telecommunications.

- Green Energy and Environmental Research Laboratory: ITRI’s Green Energy and Environmental Research Laboratory conducts research in the areas of energy efficiency, clean environment, renewable and alternative energy, natural resources, and energy management and policy.30

- Material, Chemical and Nanotechnology Research Laboratory: ITRI’s Material, Chemical and Nanotechnology Laboratory collaborates with Taiwanese companies to develop materials and components for application in the fields of electronics, green energy, optoelectronics, and panel display. In addition, it develops high-tech

________________

28Interview with John Chen, op. cit.

29“An Interview With ITRI President Shyu Jyuo-min,” Taiwan Today (December 17, 2010).

30In 2011, a research team from the laboratory won an Angel Business Communications; (ABC) Solar Industry Award, the first Asian laboratory to achieve this honor, for development of a “green energy antenna.” This device “integrates antenna transmission and solar panel power storage technology, simultaneously improving the conversion efficiency of solar energy optoelectronics and the efficiency of antenna reception and emission.” ITRI has reportedly secured international patent rights for the technology and is seeking “international cooperation partners for technology transfer.” According to estimates, application of the new technology at a 3-G base station with power consumption of 500W could product about 30 percent supplementary power mitigating peak hour power consumption and relieving the load on the power grid. Lillian Lin, “ITRI’s Green Energy Atenna Technology Wins Solar Industry Award” Central News Agency (September 7, 2011). This lab has developed carbon capture and storage (CCS) technology jointly with Taiwan Cement Corp. which reportedly cuts the cost of carbon capture from the current international level of over $45 per metric ton to under $26 per metric ton. “Taiwan Unveils Microalgal Biofuel Technology,” Central News Agency (October 2, 2010). It has also developed processes to transform microalgae into biodiesel fuel. “ITRI Wins Prominent Display Technology Award from Industry Group,” Central News Agency (May 19, 2011).

-

fibers and specialty chemicals intended to transform the textile and chemicals industries into high value-added sectors.31

- Mechanical and Systems Laboratory: ITRI’s Mechanical and Systems Technologies Laboratory develops technologies to assist Taiwanese companies in the areas of precision manufacturing, green energy and intelligent automation.

- Medical Device and Biomedical Technologies Laboratories: ITRI’s Medical Device and Biomedical Technologies laboratories are performing research to create and expand a biomedical industry in Taiwan that will develop products according to the “biomedical 3Ps (preventive, predictive, personalized).

ITRI research projects are aimed at the development of technologies that can be commercialized, and involve the creation of specific product prototypes. ITRI’s main site in Hsinchu, Taiwan displays scores of recent product prototypes that have emerged from its laboratories, including a number that have won international R&D awards. In most cases, the commercial potential of these prototypes is readily apparent.

Technology Integration

ITRI operates a number of technology integration centers. ITRI “hopes the centers will become spin-off companies.”32 The centers are more mission-oriented and dynamic than the core laboratories—new ones are frequently

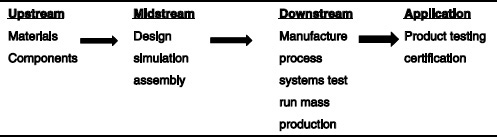

FIGURE APP-A3-3 Coordinating and integrating industrial technologies at ITRI.

SOURCE:: ITRI.

________________

31In 2011, this lab won the silver award of Display Component of the Year by the world’s leading display industry group, the Society for Information Display. The award was given for development of the first and only technology permitting mass production of flexible and transparent displays of all sizes. The ITRI team dedicated ten years to developing this technology. Oscar Wu and Mai Huang, “ITR Wins Prominent Display Technology Award from Industry Group,” Central News Agency (May 19, 2011).

32Interview with Dr. Yi-Jen Chan, Director, ITRI Electronics & Optoelectronics Research Laboratories, Hsinchu, Taiwan, February 14, 2012.

formed while others spin off to become start-up ventures. Currently, ITRI technology centers are addressing topics in displays, nanotechnology, cloud computing, and measurement standards. The centers seek to establish capabilities for the integrated production of advanced technologies by fostering the creation of an entire industry supply chain.

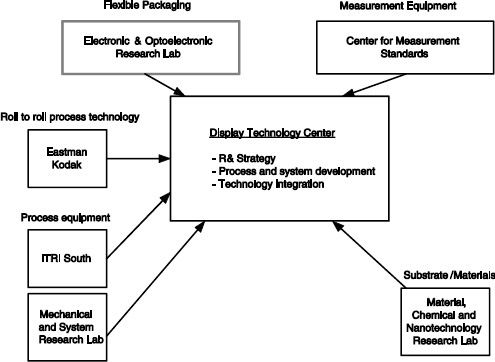

The technology centers coordinate and integrate research and technology obtained from various ITRI core laboratories, foreign partners, and Taiwanese industry. They have discretionary funds with which they can commission R&D in the core laboratories. At present, ITRI’s Display Technology Center (DTC) is performing work on flexible displays which integrates the research efforts of five separate ITRI labs as well as technology licensed from foreign companies. DTC Director John Chen observes that “we are the program office or integrator … we have the fab here so we can concentrate on process integration strategy. We don’t work on materials, we rely on our colleagues [in ITRI’s Material, Chemical and Nanotechnology Research Lab] to develop the materials we need.”33 DTC’s main facility is a 3,124 sq.m second generation laboratory pilot line (glass substrate size 370x470mm2) which has been used to produce flexible 20-inch thin film transistor liquid crystal displays (TFT-LCDs).

FIGURE APP-A3-4 Flexible display program integration.

________________

33Interview with Dr. John Chen, Director, DTC, Hsinchu, Taiwan, February 14, 2012.

TABLE APP-A3-2 Developing ITRI Industrial Chain for Flexible Electronics

| Topic | Companies |

| Materials | Chang-Chun |

| Equipment | Shuz-Tung |

| Gallant Precision Machining | |

| Panels | AUO |

| CMO | |

| Chi Mei Optoelectronics | |

| System | Elan Microelectronics Corp. |

DTC commonly engages in contract services, joint R&D, technology transfer, cross-licensing, and evaluation and verification of customers’ flexible displays materials, equipment and systems. It is currently partnering with local Taiwanese companies to establish the foundation for a complete industrial chain for the manufacture of flexible electronics products.34

DTC Director Chen observes that the multidisciplinary approach to R&D practiced in ITRI’s technology centers is the key to the launch of new industries:

The biggest strength of ITRI is the multidisciplinary cooperation. We create a complete manufacturing supply chain in its early stages. That is the secret. Then you can scale it up, then you have a complete supply chain for the industry. So DTC does not just work with display companies, but also materials suppliers and equipment makers.35

Decades of application of this holistic approach has transformed Taiwan into a major manufacturing center for electronic information products. Barry Lam, former head of Kinpo Electronics and founder of Quanta Computer, commented about the Taiwanese IT industry chain in a 2011 oral history interview:

The supply chain is very complete in Taiwan. We have semiconductor foundries here in Taiwan. We have good design houses. We have many good assembly houses. We also have many components, such as CD-ROM drive. We gave up on the hard drive business at the time, so we didn’t catch the momentum when the industry was blooming. Assembly was done mostly in Thailand or Southeast Asia. We pretty much know how to make most components in mass production. So from components … that’s why even when we make resistors and capacitors, our price is still very cheap. For components, from PCB boards to chips, we can make it

________________

34ITRI Display Technology Center presentation (February 14, 2012).

35Interview with DTC Director John Chen, Hsinchu, Taiwan, February 14, 2012.

all in Taiwan. So, we can even complete the design in Taipei. And, why? Because all the vendors are concentrated in Taipei. Taipei is not big, so it’s easy to deal with everything in Taipei and everything can be done here. This is good, isn’t it?36

Technology Diffusion

ITRI’s technology is transferred to Taiwanese industry through numerous channels. ITRI research organizations participate in a large number of topical R&D alliances designed to ensure that the participating companies follow, monitor, and in some cases participate in ITRI research projects in a manner which enhances the prospect they can successfully absorb and apply new technologies. 37 ITRI licenses technology to domestic companies, frequently on more favorable terms than could be obtained from foreign sources.38 It performs contract R&D for companies.39 Since 2005 it has auctioned off blocks of intellectual property on an exclusive basis.40 ITRI’s OpenLab is an incubator for new companies which provides facilities, utilities, business services and research support to start-up companies—in 2005 OpenLab was honored as the “best incubator in Asia” by the Asian Association of Business Incubation.41 Among other services ITRI offers pilot production opportunities to companies prior to the commercialization of products, which enables companies to use ITRI’s pilot lines for process verification, product development and semi-commercial production. The newly-formed ITRI College provides customized training programs for Taiwanese companies, as well as government officials and researchers from developing countries in

________________

36Interview with Barry Lam, “Taiwanese IT Pioneers: Barry (Pak-Lee) Lam,” recorded March 2, 2011 (Computer History Museum, 2011) p. 29.

37An important aspect of ITRI’s industry-coalition building is organizing member companies to specialize in specific developmental areas so they do not duplicate effort. In 2003, for example, ITRI formed a “SIP alliance” with twelve of Taiwan’s leading information technology firms pursuant to which they would share their silicon intellectual property, an initiative that arose out of the recognition that many local IC design houses were doing the same work. “From the government’s point of view, this is a waste of resources,” an MOEA spokesperson commented. “12 Top IT Firms Form SIP Alliance,” China Post (April 9, 2003).

38In 2006, ITRI’s Electronics and Optoelectronics Research Laboratories licensed indium tin oxide transparent electrode technology to nine Taiwanese producers of light-emitting diodes (LEDs) on terms that “would help the island’s LED makers pare their spending on intellectual property licenses from foreign sources.” “ITRI Lab Licenses Advanced Electrodes to LED Makers,” Taiwan Economic News (July 7, 2006).

39ITRI performs contract research for both domestic and foreign companies to develop new products, improve manufacturing processes and to comply with environmental and safety requirements. In addition, it offers professional measurement, inspection and certification services to help companies address technical obstacles in world markets.

40“ITRI Puts Up 111 Patents for Sale,” Taiwan Economic News (May 18, 2006).

41“ITRI OpenLab to be Honored as Best Incubator in Asia,” Taiwan Ajourd’hui (June 10, 2005).

innovation competencies and six technological areas.42 Finally, former ITRI employees taking positions in Taiwanese high tech companies bring extensive know-how and in some cases, technology which they are expected by their former employer to commercialize.

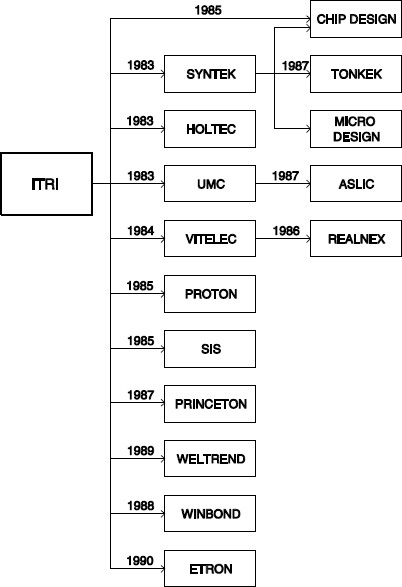

Spin-offs

ITRI’s most dramatic method for technology diffusion is the spin-off of parts of itself to form new companies or to join existing companies (the latter being referred to as “spin-in”).43 ITRI spinoffs entail transfer of employees, technology and in some cases equipment to a new company, coupled with the provision of a wide range of incubation services (legal and business counseling, provision of office space and utilities at modest cost, and introductions to sources of financing and to potential customers). Since ITRI’s founding in 1973 it has formally spun off a total of 162 companies, and informally contributed to the launch of several hundred others. 44 As of early 2012, roughly two dozen spin-offs were under consideration with five in the incubation phase.

Picking Winners

ITRI’s venture capital subsidiary, the Industrial Technology Investment Corporation (ITIC) plays a key role in facilitating ITRI spin-offs.45 When ITRI laboratories seek to spin off a promising technology ITIC screens the proposal, assessing whether the technology has commercial potential, and sizing up the business prospects for the new venture and the competition it is likely to encounter. ITIC works closely with ITRI’s Commercialization and Industry Service Center (CIS) in assessing whether a given proposal has commercial

________________

42ITRI College does not issue degrees because its training is for the purpose of hands-on application by companies in an industrial context. Technological training is offered in IT and telecommunications, optoelectronics, electronics, biomedicine, device research, energy, the environment, materials and chemical engineering and mechanical and systems R&D.

43A recent example of a spin-in arrangement is the 2008 formation of Hi-Tech Energy Co to produce lithium batteries. Hi-Tech Energy is a joint venture between ITRI and Taiwan’s Welldone Co., a producer of batteries. The joint venture was “led by a team of ITRI specialists.” R&D at the joint venture was to be led by Yang Mo-hua, “an ITRI battery export.” “Taiwan Spearheads Lithium-Battery Module Effort,” Taipei Times (May 15, 2008).

44“ITRI Encourages Formation of Spin-in Technology Venture Firms,” Taiwan Economic News (January 31, 2012).

45ITIC was established in 1979 as a wholly-owned subsidiary of ITRI to facilitate the development of high technology industries and the upgrading of traditional industries. ITIC was established because at the time Taiwan lacked a venture capital industry. ITIC provided capital to a number of Taiwanese companies that were spun off by ITRI, including United Microelectronics Corporation (UMC), Acer Display Technologies (Now AU Optronics), and Taiwan Mask Corporation. ITIC currently provides funds to over 50 companies and operates an incubation center with 30 start-ups representing various high tech sectors. As of early 2012, ITIC had four funds supplying venture capital to start-ups. ITIC has a staff of 23 professionals, half of whom have ITRI backgrounds and half previously held positions in industry. Twelve individuals comprise ITIC’s venture capital team. Interview with Ching-Jiunn Chang, Vice President, ITIC, February 13, 2012.

TABLE APP-A3-3 Examples of ITRI Spin-off and Spin-in Ventures

| Year | Company | Products |

| 1999 | Taiflex Scientific | Electronic materials |

| 1997 | Prolific Technology | ASIC designs |

| 2005 | Neo Precision Technology Co. | High-speed spindles for machine tools |

| 2006 | Amos Technologies Inc. | Radio-frequency identification (RFID) |

| 2003 | Phalanx Biotech Group | Gene chips |

| 2008 | Hi Tech Energy Co. | Lithium battery modules |

| 2001 | Phison Electronics Corp. | Flash memory |

| 2004 | DelPoint | Solar cells |

| SOURCE: “Taiwan to Roll Out High-Speed Spindles for High End Machines Tools,” Taiwan Economic News (November 21, 2005); “Mosel Vitelec, ITRI Set Up Venture Firm to Tap into RFID Market,” Taipei Times (November 8, 2006); “Gene Chip Venture Phalanx Inaugurated,” China Post (January 24, 2003). | ||

prospects. If the answer is affirmative, ITRI will provide funding and incubation services, and in some cases will recruit one or more outside experts with business experience to join the new venture.46

ITIC provides early stage financing to some ITRI spin-offs, usually in amounts under $US 1 million. ITIC takes an equity stake in new ventures which it normally expects to sell at some point in the future. ITIC’s decision on whether to provide financial/support to a given start-up is taken independently of ITRI and ITIC is not obligated to invest in any ITRI spin-off. As of early 2012, ITRI had 24 spin-offs under consideration, of which ITIC would typically approve funding for one third of the group and turn the others down. The success rate for ITRI spin-offs funded by ITIC is currently about 3 out of 10.

Incubation

The ITRI OpenLab Incubation Center, near Hsinchu Science Park, provides temporary support for ITRI spin-off and startup companies. The Incubation Center features nearly 140,000 square feet of leasable space which can be used for offices, research space, or product assembly. Companies in the incubator receive management advice, technical consulting services, legal help, and access to ITRI’s research facilities and pilot production lines.

________________

46Interview with Ching-Jiunn Chong, Vice President, ITIC, Taipei, Taiwan, February 13, 2012.

K.S. Pua, an ITRI alumnus who with four other ITRI staffers co-founded the successful start-up Phison Electronics Corp., a maker of flash memory systems, recalled the importance of ITRI’s support in the early days of his company between 2000 and 2003.47 The new company was allotted space at ITRI’s Incubation Center, which “not only provided office space, but also facility management,” so that “we didn’t have to worry about the trash, water, power, or other sundry things.” The rent was “comparatively cheap.” ITRI loaned Phison laboratory equipment that the start-up could not have otherwise afforded. Its legal adviser assisted Phison in defending a lawsuit. The new company assembled its products “right in the office,” achieving a turnover of $36.7 million in 2002. The Incubation Center Director, C.J. Chang, advised Phison to apply for a grant from MOEA’s Small Business Innovation Research (SBIR) program and assisted the company in drawing up the application. ITRI helped Phison to recruit qualified employees, connected it with investors, and vouched for it in its pitches for funding. Phison had 12 employees when it entered the Incubation Center in August 2000 and 60 when it left in January 2003.48

A key milestone in Phison’s history was the formation of a close relationship with Toshiba, which invested in Phison, provided a source of demand for its USB flash drives and assisted the company in securing patents and fending off legal challenges.49 Initially Toshiba had no idea who or what Phison consisted of, so ITRI made a presentation to Toshiba introducing the company. On the basis of the presentation and ITRI’s established high technology bona fides, Toshiba decided to invest in the company, becoming its largest shareholder.50

THE HSINCHU TECHNOLOGY CLUSTER

ITRI’s contribution to Taiwan’s industrial development has been substantially enhanced by its physical presence in a technology cluster in the Hsinchu area. Innovation or technology clusters are concentrations of knowledge-based companies pursuing research, development and production of advanced technology products in proximity to each other. The most successful clusters draw upon nearby universities for talent and research, and benefit from

________________

47In 1998, Pua’s team at ITRI designed a controlled which was sold to Kodak. Interview with K.S. Pua, Hsinchu, Taiwan, February 14, 2012.

48K.S. Pua, Driven to Success: Tech Star Phison’s US $1 Billion Journey (Taipei: Common Wealth Magazine, 2012) pp. 46-49.

49Characterizing Toshiba as an “umbrella” and a “shield,” Pua states that “Toshiba was the ‘door deity’ that protected us from the outside world,” Pua (2012), Driven to Success, (2012) op. cit. p. 40. Toshiba has been investing in Taiwan since the 1950s, when it acquired a five percent equity stake in Tatung Co., which was then Taiwan’s only integrated electronics company. Toshiba licensed technology to Tantung, enabling the company to develop competencies in high-end compressors, CRT picture tubes, and LCDs. Today, Tantung is a diversified multinational corporation producing consumer electronics products.

50Interview with K.S. Pua, Phison Electronics Corp., Hsinchu, Taiwan, February 14, 2012.

an array of supportive government policies, particularly the provision of research infrastructure. The most well-known innovation clusters in the United States are Silicon Valley, Research Triangle in North Carolina and Boston’s Route 128. Technology clusters are particularly important in “bringing the upstream, midstream and downstream aspects into one complete series of connections, which possess high speed communication exchange, technical support and other competitive advantages,” and in sectors with comparatively long industrial chains, such as semiconductors and photovoltaics, the cluster effect is particularly powerful.51

Taiwan’s Hsinchu technology cluster has evolved into one of the most productive in the world. According to a recent estimate firms located inside HSP are 66 percent more productive than firms located outside.52 In 2010, 139,416 people were employed in HSP itself.53 At the end of 2010, HSP contained operations of 449 companies which generated over $40 billion in that year. The semiconductor industry was dominant in terms of percent of total revenue.54

In addition, many small technology companies are located just outside the HSP itself and contribute to the cluster effect. At present HSP receives around 1,000 visiting missions per year seeking to understand how such a technological-industrial complex can be established and managed.55

The Hsinchu technology cluster has been extensively studied by academics and by other countries and regions seeking to replicate its success. John A. Mathews, an Australian professor of competitive dynamics, has written

TABLE APP-A3-4 Hinschu Park Revenues by Sector

| Sector | Percent of HSP Revenue |

| Semiconductors | 68.44 |

| Optoelectronics | 19.08 |

| Computers | 5.99 |

| Telecommunications | 3.28 |

| Precision machinery | 2.22 |

| Biotechnology | 0.42 |

________________

51Hwa Meei Liou, “Overview of the Photovoltaic Technology Status and Perspective in Taiwan,” Renewable and Sustainable Technology Reviews (2010).

52John A. Mathews, “The Hsinchu Model: Collective Efficiency, Increasing Returns and Higher- Order Capabilities in the Hsinchu Science-Based Industry Park, Taiwan,” Keynote Address, Chinese Society for Management of Technology 20th Anniversary Conference, Hsinchu, Taiwan, December 10, 2010.

53Interview with Mao-Jiun Wang, National Tsing Hua University, Hsinchu, Taiwan, February 16, 2012).

54Presentation by HSP administration, Hsinchu, Taiwan, February 15, 2012.

55Japan International Cooperation Agency, Report on Taiwan Mission (GRIPS Development Forum, April 7, 2011).

extensively about the Hsinchu phenomenon, concluding that “firms generate mutual advantages by clustering together,” and collectively form “powerful engines of wealth generation.” In Hsinchu, these advantages have been enhanced by the presence of ITRI and the two science-oriented universities— “companies attracted to the Hsinchu park have been able to count on the universities for supplies of skilled professional staff, while they have been stimulated by exposure to the technological innovations emanating from ITRI.”56

The basic elements of a successful cluster are sometimes referred to today as “Marshall’s trinity,” based on the pioneering nineteenth century work of the British economist Alfred Marshall in his study of the Sheffield industrial district of Britain.57 According to Marshall the trinity consists of three basic elements:

- Supplier linkages: Cluster-based firms foster economies with respect to transportation, communications, supply chain, infrastructure and logistics.

- Labor: Specialized activities within the cluster foster growth of a pool of skilled labor, permitting increased specialization by enterprises located in the cluster.

- Knowledge spillovers: As Marshall expressed it, in an industrial district the “secrets of trade are in the air,” and presence in the cluster enables firms to access market intelligence, new designs and new applications.58

All of these factors are present in abundance in the Hsinchu technology cluster and are critical elements in its success.

Supplier Linkages

Hsinchu Science Park has greatly facilitated the development of Marshall’s “supplier linkages” by encouraging technology-intensive firms to locate in proximity with each other. Such arrangements reduce transportation costs with respect to materials and parts. 59

________________

56Mathews, Hsinchu Model (2010) op. cit. p. 10.

57Paul Krugman, a U.S. economist and winner of the Sveriges Riksbank Prize in Economic Sciences (e.g. the Nobel Prize in Economics) reiterated the importance of Marshall’s trinity in Geography and Trade (Cambridge, MA: MIT Press, 1991).

58The synopsis of Marshall’s work is drawn from Mathews, Hsinchu Model (2010) op. cit. p. 13

59Agglomeration of firms from a given sector’s supply chain in a cluster enables them to specialize, achieving increased economies of scale, higher capacity utilization with respect to the specialized machinery they employ, and improved skill sets. “If the minimum efficient scale of production varies across a range of products through different stages of the production process, manufacturers can choose an optimal combination of operations by working closely with many specialized suppliers.” Eric Y. Cho and Hideki Yamawaki, Clusters, Productivity and Exports in Taiwanese Manufacturing Industries (Presented at Gerald R. Ford School of Public Policy, University of

Although companies in the supply chain cooperate, they also compete—any company that falls short of expectations can quickly be replaced by another. Competition continually drives down costs and forces companies to improve yields. Reflecting these dynamics, the HSP Administration has assembled data which reportedly demonstrates that firms within the park generate an average value-added (revenues minus costs as a percent of total revenues) of 50 percent, versus 30 percent for Taiwanese manufacturing enterprises located outside of the park—or a productivity edge of 60 percent.60

HSP contains complete or nearly complete industry supply chains in a number of sectors, most notably semiconductors. The presence of materials, design, equipment, fabrication, and testing companies in the park is cited as a major locational and competitive advantage by semiconductor industry executives.61

Skilled Labor

The second element of Marshall’s trinity, pool of skilled labor, is available to companies operating in HSP thanks in substantial part to the presence of two research universities adjacent to the park.62 National Chiao

TABLE APP-A3-5 Hinschu Park Industry Supply Chain for Semiconductors

| Sector | Number of Companies in HSP |

| Wafer fabrication | 17 |

| Fabless design | 129 |

| Equipment | 17 |

| Lead frame | 3 |

| Wafers | 6 |

| Test | 3 |

| Mask | 5 |

| EDA design tools | 5 |

________________

Michigan, October 16-17, 2009) pp. 6-7. Ding-Yuan Yang, founder of Winbond, explained the dynamic as follows, “Taiwanese companies may not coordinate well enough, but each company clearly defines its own focus. And [they] break down the PC industry into parts. Each company does what it does best. Some do the keyboards, some do the monitors, some do the motherboards and some do the casing. This is what I call the ability to innovate.” Interview with Ding-Yuan Yang, “Taiwanese IT Pioneers: D.Y. (Ding-Yuan) Yang, recorded February 23, 2011 (Computer History Museum, 2011).

60Mathews, Hsinchu Model (2010) op. cit., p. 16.

61Presentation by HSP administration, Hsinchu, Taiwan, February 15, 2012.

62In 2010, 130,000 people were employed in HSP. Of these, 65 percent had junior college or higher degrees (compared with 18 percent in Taiwan’s manufacturing sector as a whole). 17,000 HSP employees held master’s degrees and 1,200 had doctorate degrees. “Hsinchu Science Park, a Bastion for Growth, Innovation and Cluster-Based Industries,” China Post (December 15, 2010).

Tung University (NCTU) was established in Hsinchu in 1958 and adjoins Hsinchu Science Park. NCTU supplied much of ITRI’s original R&D staff as well as much of the engineering talent for HSP when the park was created.63 NCTU was the first university in Taiwan to operate a semiconductor research laboratory, and one of its professors, Simon Sze, is the author of The Physics of Semiconductor Devices, otherwise known globally as “the semiconductor Bible.”64 At present 65 percent of the CEOs, Presidents and General Managers of companies located in HSP are NCTU graduates.65 It compares its relationship with HSP to that of Stanford with Silicon Valley.66 The University has colleges of engineering, biological science, computer science, photonics, and electrical and computer engineering, and research centers specializing in nanotechnology, photonics, bioinformatics, biomedical electronics, intelligent information/communication, brain research and interdisciplinary science.67 Its students commonly work as interns in HSP and join companies in the park upon graduation. Many top ITRI managers also serve as NCTU faculty members.

National Tsing Hua University (NTHU), adjacent to NCTU, has produced two Nobel laureates in physics and one in chemistry. NTHU is regarded by some as the premier research university in Taiwan, holding the highest citation rate for papers published by faculty in either Taiwan or China. Nearly 50 percent of the university’s research budget is attributable to grants won by NTHU faculty.68 NTHU includes colleges of life sciences, electrical engineering and computer science, technology management, engineering, and nuclear science. Researchers at NTHU have reported recent breakthroughs in nanotechnology and semiconductors.69

________________

63John A. Mathews and Mei-Chin Hu, “Enhancing the Role of Universities in Building National Innovative Capacity in Asia: The Case of Taiwan,” World Development (Vol. 35 No. 6, 2007), p. 1012.

64Pao-Long Chang, Chintay Shih and Chiung-Wen Hsu, “The Formation Process of Taiwan’s IC Industry—Method of Technology Transfer,” Technovation 14(3) (1994) p. 163.

65NCTU alumni who have played a prominent role in Taiwan’s high technology industrial development include Dr. Stan Shih, founder of Acer Group; Dr. Robert Tsao, founder and former chairman of United Microelectronics Corporation; Dr. Ken Kao, founder of WiFi leader D-Line Corporation; and Dr. F.C. Tseng, Vice Chairman of Taiwan Semiconductor Manufacturing Corporation. Source: NCTU presentation, February 16, 2012, Hsinchu, Taiwan.

66Interview with Ming-Jan Yao, Professor and Associate Dean, School of Management, National Chiao Tung University, Hsinchu, Taiwan, February 16, 2012.

67NCTU is the site of a number of national laboratories, including the National Chip Implementation Center, The National Nano Device Laboratories, the National Measurement Laboratory, the National Space Organization, the National Center for High Performance Computing, and the National Synchrotron Radiation Research Center.

68Mathews and Hu, “Enhancing the Role of Universities” (2007) op. cit. p. 1013.

69“Taiwanese Researchers Make Nanotechnology Breakthrough,” Central News Agency (August 18, 2011). The Hsinchu technology cluster is also supported by Taipei-based National Taiwan University (NTU), Taiwan’s leading university for teaching and research, which is about one hour’s drive from Hsinchu. In 2011, NTU established a research center jointly with Intel on machine-to-machine (M2M) communication, a cutting-edge field which aims to integrate billions of machines to exchange information and make correct decisions independently. The Intel-NTU Connected Catext Computing Center, the project vehicle, will study smart sensing, “green sensing” and context

ITRI itself is a magnet drawing experienced and talented overseas Taiwanese back to the Hsinchu technology cluster. 70

Alumni networks from the two science universities and NTU have played a central role in the development of the semiconductor and PC industries in the Hsinchu technology cluster. 71

The work discipline, efficiency, adaptability and élan of Taiwan’s high technology workforce are frequently cited by the founders’ generation of the country’s information technologies industries as a key element in the country’s success.72

Knowledge Spillovers

The third element in Marshall’s trinity, “knowledge spillovers,” occur in HSP in part due simply to the proximity of research institutions and companies to each other, but the presence of ITRI and the universities amplifies

________________

analysis. NTU researchers are collaborating with ITRI in a number of key technology areas, including biomedicine, systems-on-a-chip, and wireless communications. Interview with Dr. Si-Chen Lee, President, NTU; Dr. Ching-Hua Lo, Vice President for Administrative Affairs, NTU; and Dr. Ji-Wang Chern, Dean for Research and Development, Taipei, Taiwan, February 17, 2012.

70Ding-Yuan Yang, who served as head of planning and marketing for ITRI, observed in a 2011 oral history interview that “In the past 10 to 20 years, many friends or classmates from abroad came back to Taiwan because of fast development in Taiwan. We suggested that some come back to ITRI first for a few years and then to go into industry. The projects that ITRI supported provided a beacon, or a rallying cry; it was if they raised a flag for people to rally to. So many people kept coming back to Taiwan. For they had a specific target to go for, when they come back from overseas, lot of people who studies abroad come back to Taiwan for the same reason.” Interview with Ding-Yuan Yang, “Taiwanese IT Pioneers: D.Y. (Ding-Yum) Yang,” recorded February 23, 2011 (Computer History Museum, 2011) p. 28.

71A TSMC executive has observed that “engineers in the Hsinchu Science Park not only work very hard, but they share the same backgrounds. Most of them graduated from the same university, took the same classes, were taught by the same professors, and had similar work experience at ITRI.” Anna Lee Saxenian, “Taiwan’s Hsinchu Region: Imitator and Partner for Silicon Valley” (Stanford Institute for Economic Policy Research Discussion Paper No. 00-44, June 16, 2001) p. 27. Saxenian, Dean of the University of California at Berkeley’s School of Information, who has extensively studied HSP, observes that “it would not be unusual for a Taiwanese engineer to call a former classmate in the middle of the night to get help solving a technical problem, and many started companies with their classmates. Acer managers are far more likely to contact former teachers, classmates or colleagues when they encounter a business problem … than turn to a private consulting firm or institution.” Ibid.

72Barry Lam, informally known as the “laptop king, served as president of Kinpo Electronics, which he built into the world’s largest contract calculator maker, and later founded Quanta Computer, a maker of notebooks. Lam later recalled that National Taiwan University’s electrical engineering program provided a stream of “good engineers from my school [Lam was an NTU alumni] who were eager to learn new skills. We had low employee turnover and we had a lot of talented engineers, who were focused and honest. So the team spirit was very high. This was the fundamental competitive edge of Taiwan, the foundation was strong. How should I put it? Employees are extremely loyal to companies they work for, due to the profound Confucian influence on Taiwanese people. We had tremendous motivation. We could accomplish anything we set our hearts on.” Interview with Barry Lam, “Taiwanese IT Pioneers: Barry (Pak-Lee) Lam,” recorded March 2, 2011 (Computer History Museum). p. 9.

spillover effects. ITRI scans the entire world for promising new technologies and devotes substantial resources and effort to spreading information about them to local companies and educational institutions. Its numerous R&D alliances are structured to draw upon knowledge gleaned from international markets and research efforts and to deliver that knowledge to domestic firms. Knowledge spillovers from ITRI also occur as its employees take positions in Taiwanese companies—between its founding in 1973 and 2008, an estimated 13,000 ITRI staff moved into industry, many of them remaining with the Hsinchu cluster.73 Research spillovers from the universities were given a powerful boost by the enactment in 1999 of legislation patterned on the U.S. Bayh-Dole Act of 1980, which allows universities to own intellectual property developed out of government-funded R&D. 74

Fostering New Clusters

Demand for sites in HSP long ago exceeded the Park’s capacity, and Taiwan has opened Southern Taiwan Science Park (1996) and Central Taiwan Science Park (2003). HSP has opened science parks in five satellite locations.75

Taiwan’s Statute for Industrial Innovation, enacted in 2010, emphasizes the formation and upgrading of knowledge-based industrial parks “to facilitate

TABLE APP-A3-6 New Clusters and Their Focus Areas

| Park | Industries | |

| Jhunan Science Park Tongluo Science Park | Biotechnology, optoelectronics IC design, SiP, digital life, avionics, biomedical |

|

| Longlan Science Park | Optoelectronics | |

| Hsinchu Biomedical Science Park | Biomedical | |

| Yilan Science Park | Knowledge-based series | |

________________

73Mark Dodgson, John Mathews, Tim Kastelle and Mei-Chih Hu, “The Evoloving Nature of Taiwan’s National Innovation System: The Case of Biotechnology Networks,” Research Policy 37 (2008) p. 435. Anna Lee Saxenian observed in her 2001 study of Hsinchu and Silicon Valley that “In the Hsinchu region, as in Silicon Valley, engineers move frequently between firms and between sectors; and there is a community of senior engineers who move not only between firms, but also between the public and private sector, between universities and the private sector, between the manufacturing sector and the venture capital industry, and between Taiwan and Silicon Valley. They meet regularly at alumni gatherings and class reunions, professional association meetings, industry conferences and trade shows, and a variety of related special events … The intense communications within this community fosters imitation, joint problem solving and transfer of information and know-how about management, technology, the job markets, and new firms and products.” Saxenian, “Taiwan’s Hsinchu Region” (2001) op. cit., pp. 26-27.

74The Science and Technology Basic Law and ancillary implementing regulations provide that IPR developed whole or in part with government funds belongs to the research organization. The new rules have made it possible for academic researchers to reap substantial rewards through commercialization of research results. Mathews and Hu, “Enhancing the Role of Universities” (2007) op. cit. pp. 1008-12

75Hsinchu Science Park Annual Report (2010) pp. 12-13

clustering and innovation.” The government is encouraging the formation of parks dedicated entirely to specific themes, such as biomedicine, logistics, and media. The new law authorizes local governments to establish industrial parks without central government approval. The minister of Economic Affairs indicates that such policies are being implemented to foster “an overall economic environment that is conducive to innovation, the creation of value, and the free flow and application of knowledge.”76

CHALLENGES

Taiwan appears to the outside world as an extraordinarily successful high technology powerhouse. However, its leaders recognize that vulnerabilities exist which could substantially erode the gains which the country has made since the 1970s. The overwhelming majority of Taiwan’s businesses are small enterprises which lack the resources and scale for global competition. The country is arguably not well prepared for an era of global patent warfare, in which infringement litigation can suppress or destroy technology-based start-up companies. A longstanding talent shortage has been exacerbated by an exodus of skilled workers to mainland China. And the American connection, long an important aspect of Taiwan’s high tech development, may fade as the number of Taiwanese students pursuing advanced degrees in the U.S. progressively declines.

ITRI Funding

ITRI’s budget has not grown for a decade. Its leadership has put a good face on the situation by stating that lean budgets force the institute to rely on other research organizations, which is a key element of its mission. But ITRI is not growing apace with Taiwanese industries that it is tasked with supporting, and the detrimental effects of its limited budgets are evident in a number of areas.

Some observers believe that ITRI is trying to focus on too many technologies with two small a budget, diluting the impact of its efforts. Its low compensation levels for staff have contributed to a manpower shortage (see below). ITRI reportedly would like to attract more foreign expertise to Taiwan but the available funding is inadequate to create attractive compensation packages. Underfunding may explain what observers characterize as the “underpatenting” of ITRI’s technologies, which exposes licensees to litigation.

________________

76“Statute for Industrial Innovation Changes Thinking on Upgrading Industries,” Council for Economic Planning and Development website,

<http://www.cepd.gov.tow/encontent/m1.aspx?No+0014260>.

The Talent Shortage

Notwithstanding the fact that Taiwan enjoys an excellent science and engineering educational infrastructure, the country has long faced the prospect that it will not have enough skilled people to staff its laboratories, research centers, and high tech manufacturing businesses. Additional talent is available in Southeast Asia and mainland China, but Taiwanese investment in these regions has resulted in a major outflow of engineers and skilled managers from Taiwan itself to other parts of Asia, particularly China, where a substantial part of Taiwan’s high tech production based is now located.77 Although nearby Korea and Japan have large pools of skilled labor, attracting talent from these countries has proven difficult.

An executive at AU Optronics, a major producer of flat panel displays, said in a 2005 interview that his industry needed about 5,500 additional skilled workers per year, but that available talent equaled only about 70 percent of that total. Top universities like National Taiwan University, National Tsing Hua University and National Chiao Tung University between them were turning out 3-4,000 graduates per year and “cannot meet market demand.”78 A 2005 ITRI study found that the country’s semiconductor industry would need 37,500 new skilled workers over the next three years but that the island’s educational system could supply only 21,800 during that time frame.79

ITRI itself has been affected by the talent drain. Companies based in China and Singapore reportedly are prepared to pay five times ITRI levels to lure its researchers, one factor underlying ITRI’s annual average manpower turnover of 10 percent.80 In April 2011, ITRI Chairman Tsai Ching-yen warned that ITRI had been hurt by a “talent drain” crisis. He said that 38 ITRI-type organizations had been established in China in recent years and that “all these mainland institutions have set their sights on luring our researchers and engineers away.” He noted that a 68-year old retired ITRI department chief

________________

77“Taiwan’s Wafer Fabs Need More Manpower,” Central News Agency (March 26, 2011); “Industries Facing Shortage of Skilled Workers, Poll Finds,” Taipei Times (April 8, 2005); “Taiwan Legislator Warns of High-Tech Exodus,” South China Morning Post (July 5, 2000); “Taipei’s Talent Exodus,” Time Asia (May 21, 2000); “High-Tech Talent Flows to China,” Taipei Times (March 25, 2002). In the fall of 2010 Taiwan’s President Ma Ying-jeou reportedly ordered a study by the country’s National Security Council (NSC) of the talent shortage. The study found that roughly 700,000 Taiwanese citizens resided in the Shanghai area of China alone. National Taiwan University Professor Chen Tain-jy, who participated in the NSC study, commented that “Taiwan is gradually losing its trained professionals … Singapore is using high pay to recruit Taiwan’s medical and health care personnel, Hong Kong is luring away Taiwan’s medical and health care personnel, and South Korea is targeting Taiwan’s technical talent … How to keep talented and experienced people at home has become a serious issue that Taiwan cannot afford to ignore.” “Taiwan Faces Serious Brain Drain Crisis,” Central New Agency (April 18, 2011).

78“Industry Facing Shortage of Skilled Workers,” Taipei Times (April 8, 2005).

79“Talent Shortage Escalates in Taiwan’s High-Tech Industries.” Taiwan Economic News (April 11, 2005).

80“Talk of the Day—Anti-Fat Cat Clause Hinders Manpower Recruitment,” Central News Agency (September 12, 2011).

“was recently hired by China with a lucrative compensation package that included the promise of a villa in two years. The new Chinese employer “mainly hopes the former ITRI official can use his connections in Taiwan’s high tech industry to help recruit more Taiwanese talent to work in China.”81

Enterprise Scale

Taiwan’s economy is dominated by small businesses, which account for over 97 percent of the country’s enterprises and employ over 77 percent of the work force.82 These companies typically have a small capital base and only a few employees, and have proven particularly vulnerable to the global economic downturn which began in 2008.83 While many small and medium enterprises are innovative, they frequently lack the resources and skills needed to bring new products to the global market, to build brand recognition, and to respond to legal and regulatory challenges outside of Taiwan. One of the most important considerations underlying the creation of ITRI was the recognition by the government that Taiwan’s small companies could not afford the equipment, training and other costs associated with advanced R&D.84 While ITRI has partially offset this intrinsic disadvantage, turning ITRI research “into a successful product by SMEs has been a struggle.”85 Even small Taiwanese startups that have achieved technological breakthroughs have proven vulnerable to competitive challenges from large multinationals because they “lack critical mass.”86

The government of Taiwan commonly seeks to offset the fact that most companies are too small to undertake expensive research by forming them into

________________

81“Taiwan Faces Serious Brain Drain,” Central News Agency (April 18, 2011). ITRI faced a manpower crisis beginning in March 2011 when Taiwan’s Executive Yuan released an “anti-fat cat” decree to the effect that the monthly salary of high-caliber researchers at ITRI should not exceed the level earned by deputy-ministerial level officials, or about $5,500. The new rule was hampering recruiting efforts. ITRI researchers reportedly earn about half what they would be paid for comparable work in the United States. ITRI Chairman Tsai Ching-yen commented that “such rigid restrictions will only become more difficult for us to retain our researchers in some cutting edge fields.” “Talk of the Day—Anti-Fat Cat Clause Hinders Manpower Recruitment,” Central News Agency (September 12, 2011).

82“SME Competitiveness Seen Growing With High Management Efficiency,” Central News Agency (October 3, 2008).

83“Taiwan’s Suffering SMEs Cry for Help,” Taiwan Economic News (December 3, 2008).

84Tommy Shih, “Scrutinizing on Economic Development Model—The Taiwanese Semiconductor Industry Revisited,” Industrial Marketing and Purchasing Group (IMP Group) (2009), p. 10.

85Interview with Taiwanese semiconductor executive, Hsinchu, Taiwan, February 14, 2012.

86Interview with Taiwanese semiconductor executive, Hsinchu, Taiwan, February 14, 2012. In 1984, Dr. Bo-bo Wang, established Microtek, a Taiwanese enterprise which developed the first computer-affiliated scanner in the world. Roughly 20 similar Taiwanese companies entered the field, and for a time Taiwan was the world’s leading producer of scanners. However, when major image-processing firms entered the field (Cannon, HP), Taiwanese scanner firms were driven from the market. T-J. Chen, “The Emergence of Hsinchu Science Park as an IT Cluster,” in S. Yusuf, K. Nabeshihua and S. Yamashita (eds.), Growing Industrial Clusters in Asia: Serendipity and Science (Washington, D.C., The World Bank, 2008) p. 70

technology alliances. ITRI bases the alliances on its laboratories, which it uses to teach small firms to catch up with leading edge technologies sufficiently to enable them to perform contract work for the industrial chains of larger Taiwanese and foreign high tech enterprises. As a result, larger Taiwanese firms like Tantung, Acer and Mitac can “rely on hundreds of loosely affiliated domestic suppliers to which they can pass on an endless variety of low-margin, yet quite demanding manufacturing and design tasks.”87 ITRI commonly encourages SMEs in such alliances to divide up research tasks, to specialize and to avoid duplication of effort.88 Organizing successful technology alliances is challenging and a number of them have failed due to divisions among the participating companies.89

The government has also established a panoply of programs to support SMEs. Beginning in 1996, MOEA’s Small and Medium Enterprise Administration has utilized an SME Development Fund to promote the establishment of small business incubators in Taiwan.90 An SME Credit Guarantee Fund guarantees 70-90 percent of commercial bank loans to SME’s for purchase of machinery, plant construction, and modernization of equipment.91 In 2011, Taiwan’s Financial Supervisory Regulatory Commission set a target for domestic banks to offer domestic SMEs a total of $7.33 billion in

________________

87Dieter Ernst, “What Permits David to Defeat Goliath? The Taiwanese Model in the Computer Industry,” (Alborg University, International Business Economics Research Paper Series, 1997) p. 9.