C

Reprinted Proceedings of a Workshop—in Brief

Early Sustainment Planning for the United States Air Force: Proceedings of a Workshop—in Brief (National Academies of Sciences, Engineering, and Medicine, The National Academies Press, Washington, DC, 2019), which summarizes the workshop on U.S. Air Force (USAF) sustainment planning early in the development life cycle held in December 2018 in Washington, DC, is reprinted here in its entirety. The original proceedings in brief is available at https://doi.org/10.17226/25393.

September 2019

Early Sustainment Planning for the United States Air Force

Proceedings of a Workshop—in Brief

On December 3-5, 2018, the National Academies of Sciences, Engineering, and Medicine’s Air Force Studies Board (AFSB) convened a workshop in Washington, D.C., on U.S. Air Force (USAF) sustainment planning early in the development life cycle. This workshop was conducted as part of a broader study by the Committee on USAF Sustainment Planning Early in the Development Life Cycle to focus on addressing challenges and identifying opportunities to effectively design and execute sustainment planning across USAF systems and platforms.

Workshop participants heard from a wide range of subject-matter experts from government, industry, and academia to begin examination of how the USAF can enhance and improve its sustainment planning processes. The workshop was one of several meetings convened by the committee in facilitation of a comprehensive study to examine and provide recommendations as follows:

- Identify at what point or phase of the development of a weapons system should sustainment planning be integrated into the program.

- Examine and provide recommendations regarding how sustainment planning should be evaluated throughout the development process.

- Investigate and describe the current challenges with sustainment planning and determine what changes have occurred throughout the USAF acquisition process that may have eroded sustainment planning.

- Identify opportunities for the USAF acquisition offices to gain greater access to sustainment expertise.

The information summarized here reflects the knowledge and opinions of individual workshop participants and should not be viewed as a consensus of the workshop participants, the AFSB, or the National Academies.

RAPID SUSTAINMENT OFFICE

Following welcome remarks, the Honorable Frank Kendall (Committee Chair) introduced and welcomed the representative from the workshop sponsor, Lawrence S. Kingsley (former Deputy Assistant Secretary of the Air Force for Logistics and Product Support). Kingsley opened his comments with an overview of the USAF’s newly established Rapid Sustainment Office (RSO). He explained that the RSO signifies an effort within the USAF to take extraordinarily compelling sustainment

solutions to a very high level in the USAF and fast-track technology in an effort to drive down costs and deliver faster solutions to the field. If the 2-year test program, continued Kingsley, demonstrates a positive return on investment (ROI), the USAF will consider transition to a permanent office. The dialogue then focused on how the study committee might be able to integrate RSO insights into the final study.

AUTONOMIC LOGISTICS INFORMATION SYSTEM

Commander Kevin McGee (Autonomic Logistics Information System [ALIS] Director, via video teleconferencing), Paul W. Behrens (ALIS Next Lead), and John H. Gunselman, Jr. (ALIS Director of Logistics and Sustainment) provided a summary of the current ALIS program and examined the ALIS Next re-architecture effort.

ALIS serves as the F-35 Lighting II Joint Strike Fighter’s (F-35) logistical and sustainment information system. “The F-35 is the first tactical aviation system to have sustainment tools engineered in concert with the aircraft for efficiency and cost effectiveness.”1

The ALIS program has three concurrent lines of effort: (1) Current ALIS Stabilization, (2) ALIS Next Re-architecture, and (3) Agile Software Development Pilot—all with the end goal of a single product incorporating current ALIS functionality on a new architecture with a development team delivering updates using agile development processes.

The sustainment challenges targeted by ALIS Next include addressing impediments to the synchronization of data among the various Standard Operating Units (SOUs),2 the protracted air-vehicle transmission process,3 and a lack of flexibility that denies operators the ability to land at alternate sites and obtain maintenance as needed. Despite the challenges, the panelists believe there are tremendous benefits to having a fully integrated logistics system. They are hopeful that the ALIS

___________________

1 Lockheed Martin, “ALIS: Autonomic Logistics Information System,” https://www.lockheedmartin.com/en-us/products/autonomic-logistics-information-system-alis.html.

2 SOU, or Standard Operating Unit, refers to the portable ALIS server. SOUs provide all ALIS capabilities to support flying, maintenance, and training. They also provide access to applications to operate and sustain the aircraft (U.S. Government Accountability Office, 2016, F-35 Sustainment: DoD Needs a Plan to Address Risks Related to Its Central Logistics System, GAO-16-439, April, https://www.gao.gov/assets/680/676576.pdf.

3 In the current ALIS architecture, the aircraft’s entire historical data need to move with it, even for relatively minor modifications.

Next re-architecture will propel the system to truly modern standards and make sustainment more affordable.

Current ALIS Stabilization

Commander McGee noted that ALIS is the primary and only method used to collate and share logistics and maintenance information for the F-35 fleet of aircraft. The focus of the stabilization effort is to support the current fleet of more than 350 F-35 jets with specific emphases on addressing software problems affecting fleet operations, refreshing obsolete software, and meeting threshold cyber security requirements. Projected benefits include reductions in maintenance administrator times, reduction in aircraft turnaround times, reduction on reliance of Contractor Logistics Support (CLS) to complete maintenance processes, and a reduction in action requests (ARs).

ALIS Next

Commander McGee stated that the current ALIS architecture for software and hardware does not align to the long-term sustainment vision for the F-35. The ALIS improvement imperatives include a re-architecture of the system to today’s technology to allow for improvements in supportability and portability and establish a solid foundation for adding new capabilities to enhance deployed operations. Projected benefits include significant life-cycle cost reduction and a reduced hardware and administrative personnel footprint, as exemplified by the anticipated removal and replacement of all SOUs in the field with smaller components. It also includes improved deployability and automates the installation of software patches, which are currently manually performed.

One participant asked if the ALIS re-architecture would improve the quality of the technical data. The panelists explained that ALIS Next would not specifically address the data products themselves but would instead focus on the information technology (IT) infrastructure architecture. They further noted that Lockheed Martin is currently investing heavily on improving data integrity.

Another participant asked whether re-architecture might allow ALIS to expand to other weapon systems. The panelists replied affirmatively and added that there is a desire for increased modularity in the software to allow for segmented updates instead of the current “big bang” release process. This will allow greater flexibility for other platforms to use the features of ALIS.

Another participant asked if the re-architecture would address wartime operations and consider the necessity to operate with limited or no connectivity to the database. The panelists replied affirmatively and explained that is a fundamental requirement of the ALIS Next effort.

A number of participants asked the panelists to discuss sole-source vendor lock. The panelists explained that there is a current movement to transition supply chain and logistics data manager functions to government control over the next few years so that ALIS-Next infrastructure will be government owned and operated. This shift will lead to “Cloud first” architecture, allowing portability of the ALIS system across “Cloud service” providers and commodity hardware platforms.

Agile Software Development

The goal of agile software development, as noted by several participants, is to fundamentally increase software quality and improve rapid delivery to the fleet by automating test procedures and performing them on a small scale when necessary as opposed to the current large software roles.

CONDITIONED BASED MAINTENANCE PLUS

Brigadier General Steven J. Bleymaier, Director of Logistics, Engineering and Force Protection at Headquarters Air Mobility Command (AMC), joined the meeting along with Major Todd Downs, Branch Chief for Sustainment Innovation at Headquarters AMC, and Colonel Rob Jackson, Chief, Mobility Aircraft Division at Headquarters AMC. The panel, led by Brigadier General Bleymaier, briefed the committee on Conditions Based Maintenance Plus (CBM+).

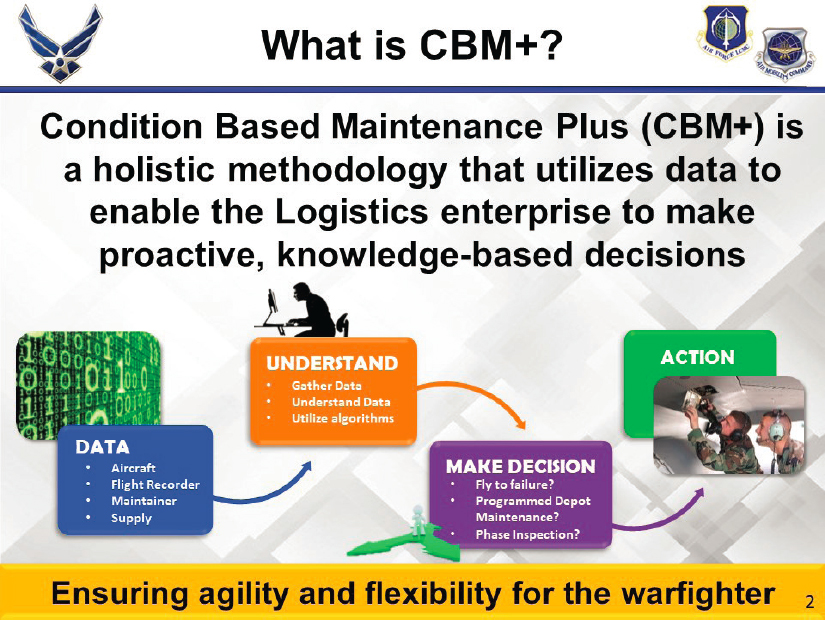

“Conditioned Based Maintenance Plus (CBM+) is a holistic methodology that utilizes data to enable the Logistics enterprise to make proactive, knowledge-based decisions” (see Figure 1). CBM+ leverages big data analytics allowing maintainers to predict problems before they happen. It also generates condition-based analysis allowing for more personalized maintenance packages, as opposed to fixed interval maintenance. The presenter, Bleymaier, noted that currently between 8 to 20 percent of an aircraft’s downtime is due to unscheduled maintenance. This “fly-to-failure” system has maintainers reactively responding to the aircraft. The future vision is to perform maintenance at a time and place of the USAF’s choosing, creating more efficient and effective uses of maintenance and logistics resources that aid overall performance.

Projected benefits of CBM+ include increased productivity, shorter maintenance cycles, lower costs, and increased availability and reliability for the entire USAF enterprise. CBM+ is not a new effort but there is recent vigor at the highest levels of USAF leadership to push for rapid results. The panelists anticipate building on the successes of the C-5M and B-1B CBM+ USAF Pathfinder programs and expect to work with the Major Commands (MAJCOMs) to formalize the CBM+ platform adoption timeline.

CBM+ implementation has four lines of effort: (1) operationalization of CBM+, (2) predictive maintenance alert loop (PMAL), (3) data management infrastructure, and (4) enabling technologies and resources with the goal to build an ecosystem in which CBM+ can thrive.

Operationalization of CBM+

Operationalization, as explained by the panel members, involves providing maintainers and sustainment professionals with tools to better plan and predict impending maintenance needs through a two-pronged effort, both of which are currently in development. Prong 1 comprises 20 percent of the tool, establishing predictive maintenance algorithms to cover induced failures and instances not covered through the Enhanced Reliability Center Maintenance (ERCM). The ERCM comprises 80 percent of the tool, housing the predictive maintenance algorithms and providing alerts utilizing near real-time failure data—current models are static and based on the Failure Mode, Effects and Criticality Analysis (FMECA) and the Failure Mode and Effects Analysis (FMEA) models. This precipitates the conversion of unscheduled to scheduled maintenance and provides the supply chain near real-time forecasting of needs 3, 6, or 9 months down the road and gets the right part at the right place at the right time. It also provides root cause analysis for the engineering community to understand what is driving the failures. It also increases the life span of components and parts. Some participants inquired about data-driven analysis to derive the scope of achievable savings upon the reduction of unscheduled maintenance. Major Todd Downs, who spent 1 year at Delta TechOps, where they have been utilizing predictive maintenance tools, said Delta cut inventory levels by 50 percent for a cost savings of $500 million solely by being able to better predict the probability of failure.

Predictive Maintenance Alert Loop

The Predictive Maintenance Alert Loop (PMAL), the presenters explained, will codify processes and procedures on how the enterprise will act or react to an alert. The panelists discussed some of the lessons learned from the C-5M USAF Pathfinder program that went live in October 2018. The first round of data produced 97 alerts but identification/notification into the field was slow. Component data capture, tracking, and exchange are critical through all phases of the PMAL. PMAL alert sensors point to a component and engineers validate that alert, but the sensor does not currently specify what is particularly wrong within a component, so the maintenance depot has to open up the system and do an overhaul of the component after the aircraft has been grounded for maintenance. The data gathered from inspecting the failed components will be fed back into the predictive maintenance algorithms to improve the accuracy to which failing components are being alerted to the maintenance process.

Data Management Infrastructure

The data management infrastructure, explained the panelists, is the most complex piece of implementation. It refers to a centralized Cloud-based data storage management solution that enables a more efficient and effective process to get data from the aircraft to the network/Cloud and from the flight-line maintainer to the network/Cloud. This line of effort requires a seamless data exchange to replace a system today comprised of analog and digital tools that cause data integrity and data capture issues.

GAO SUSTAINMENT STUDIES

Diana Maurer (Director, Defense Capabilities and Management), John Bumgarner (Assistant Director, Defense Capabilities and Management), and Nate Tranquilli (Assistant Director, Contracting and National Security Acquisition, U.S. Government Accountability Office [GAO]) briefed the committee on the GAO’s ongoing work examining the intersection of USAF sustainment and acquisition.

The panel reviewed the findings of its September 2018 issued Weapon System Sustainment report that examined the ongoing sustainment efforts of select USAF and U.S. Navy Aircraft fixed-wing systems. Specifically for the USAF, the report examined the B-52 Stratofortress, C-17 Globemaster III, E-8C JSTARS, F-16 Fighting Falcon, and F-22 Raptor. The report analyzed condition and availability data, operating and support costs, and sustainment challenges from fiscal year 2011 through March 2017 for each aircraft in a Sustainment Quick Look.4 The GAO are in the process of updating their work to include assessments on all fixed-wing and all rotary-wing aircraft.

The panel referenced several USAF sustainment challenges assessed in its report, such as USAF’s extensive use of older and rapidly aging aircraft. The panel’s analysis indicates that the executed number of flight hours are consistently higher than budgeted flight hours. In addition, the newer systems like the F-22 and the F-35 have some of the more significant sustainment issues. Moreover, the USAF’s supporting infrastructure is also very old—some dating back to World War II or even earlier. Lastly, fiscal pressures and realities will become a defining issue and will have implications for the USAF.

___________________

4 U.S. Government Accountability Office, 2018, Weapon System Sustainment: Selected Air Force and Navy Aircraft Generally Have Not Met Availability Goals, and DOD and Navy Guidance Need to Be Clarified, GAO-18-678, September, https://www.gao.gov/assets/700/694571.pdf.

The GAO concluded that the USAF has documented sustainment strategies with plans to address availability and there are metrics and processes to track system availability. They also concluded that there is leadership commitment and involvement in conversations around those vital issues.

Some areas for concern highlighted by the report include consistently below target availability for the five USAF systems, which is mostly driven by maintenance issues. The report also emphasized systemic challenges across the systems, including unexpected repairs and parts replacements, delays at the depot, and problems with the manufacturing infrastructure. Many systems relied on single-source manufacturing at either the prime or subcontractor level, which created problems, primarily in legacy systems. Additionally, O&S costs remained generally consistent for those systems over the years, but maintenance was becoming a larger and larger piece of the overall O&S expenditure. So overall performance in terms of availability was going down, but the cost of maintenance was going up. The panel utilized F-35 sustainment as a case study for what to do in the early stages to help avoid some of these problematic outcomes at the end. They concluded that decisions about how to manage the sustainment of this very advanced and capable system post-production and post-deployment were either overlooked or neglected.5

Maurer noted that the GAO also found there were significant spare part shortages, and it took on average twice what the metric was supposed to be to repair a spare part. The study also indicated substantial undefined technical data needs—which greatly complicates the ability to sustain such an advanced system. Finally, life-cycle sustainment costs for the F-35 were continuing to grow—at the time of the report, life-cycle sustainment costs were projected to be a total of $1.1 trillion over the life cycle of the system.

Recommendations from the GAO Study

Some of the GAO’s recommendations to the U.S. Department of Defense (DoD) and the F-35 Joint Program Office (JPO), as stated in the report and by the presenters, are to improve the information flow between JPO and the Service, improve sustainment plans, and develop better metrics for contractor accountability. The panelists explained that their recommendations were taken seriously and are being addressed by DoD leaders.

___________________

5 U.S. Government Accountability Office, 2018, Weapon System Sustainment: Selected Air Force and Navy Aircraft Generally Have Not Met Availability Goals, and DOD and Navy Guidance Need to Be Clarified, GAO-18-678, September, https://www.gao.gov/assets/700/694571.pdf.

TAILORING SECTION 804 AUTHORITIES FOR SUSTAINMENT PLANNING

Brigadier General Anthony W. Genatempo (Program Executive Officer for Weapons and Director of the Armament Directorate, Air Force Life Cycle Management Center [LCMC], Air Force Materiel Command [AFMC], Eglin Air Force Base), Michael VandenBoom (Program Manager of Hypersonic Conventional Strike Weapon [HCSW]), and Brian Mikus (Chief of Logistics Air-Launched Rapid Response Weapon [ARRW]) briefed the committee on two current hypersonic weapon prototype development programs. HCSW and ARRW are using rapid prototyping authorized by Section 804 of the Fiscal Year 2016 National Defense Authorization Act.6 With Section 804 authorities, “the rapid prototyping pathway shall provide for the use of innovative technologies to rapidly develop fieldable prototypes to demonstrate new capabilities and meet emerging military needs. The objective of an acquisition program under this pathway shall be to field a prototype that can be demonstrated in an operational environment and provide for a residual operational capability within five years of the development of an approved requirement.”7

Brigadier General Genatempo described the differences between sustainment in the aircraft arena and sustainment in the munitions arena. Aircraft sustainment involves constant upgrades and modifications whereas once produced, a munition’s end goal is its depletion before production of a newer version. In HCSW and ARRW, the end goal is fielding the asset so a great deal of logistics and sustainment planning is happening concurrent with the prototype development phase.

VandenBoom and Mikus concluded that thus far HCSW and ARRW do not differ from normal acquisition programs, and they have not seen a need or a benefit to removing steps using 804 authorities. As the programs progress, they will assess whether there are phases that they can tailor to condense the schedule.

USAF EARLY LIFE CYCLE SUSTAINMENT PLANNING: RAM AND SUPPORTABILITY, THE KEY TO SUCCESSFUL LIFE CYCLE MANAGEMENT

James Colson (Learning Director for Reliability, Availability, Maintainability and Supportability for Defense Acquisition University [DAU]) briefed the committee on his work at DAU. Life-cycle management and the science of supportability and sustainability is not new, he said. In fact, incorporating logistics considerations into the design of weapon systems was official policy dating back to 1964.

___________________

6 U.S. Air Force, 2018, “Air Force Awards Hypersonic Weapon Contract,” August 13, https://www.af.mil/News/Article-Display/Article/1600963/air-force-awards-hypersonic-weapon-contract.

7 Public Law 114-92—November 25, 2015, National Defense Authorization Act for Fiscal Year 2016, https://www.govinfo.gov/content/pkg/PLAW-114publ92/pdf/PLAW-114publ92.pdf.

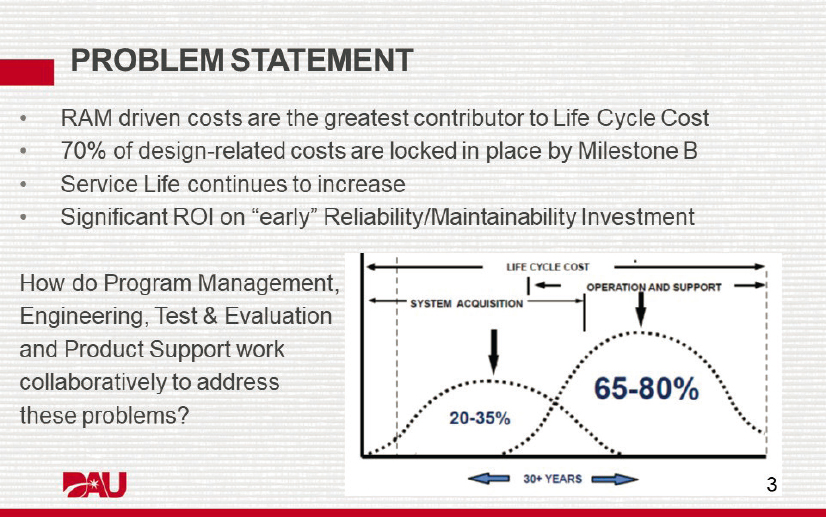

According to Colson, RAM (reliability, availability, and maintainability)-driven costs are the greatest contributor to life-cycle cost (see Figure 2). In fact, 80 percent of the “not suitable” systems failed due to reliability—directly impacting the warfighter’s performance. Data show there is significant ROI on early reliability/maintainability investments and reduced life-cycle costs.

Given that conclusion, Colson stressed the total systems approach of systems engineering whereby supportability is considered early and throughout the system life cycle. He continued that program management, engineering, testing and evaluation, and product support teams should work collaboratively to address these problems. He said we may have veered away from the core science but we have the tools and should utilize them. He stressed the importance of acquiring the product support data necessary to both plan for and support a weapons system throughout its life cycle. This is accomplished by identifying early on what logistics support products (e.g., technical publications like maintenance task analysis, fault rate analysis, and a repair manual) are needed. Colson ended the presentation discussing the range of resources offered by DAU, including courses, online workflow learning, life-cycle logistics tools, and its mission assistance activities.

AIR FORCE LIFE CYCLE MANAGEMENT CENTER, AIR FORCE MATERIEL COMMAND, PRESENTATION

Colonel Theresa B. Humphrey (Deputy Director of Logistics and Logistical Services, Air Force LCMC, AFMC, Wright-Patterson Air-Force Base) briefed the committee on the efforts taking place at the USAF LCMC.

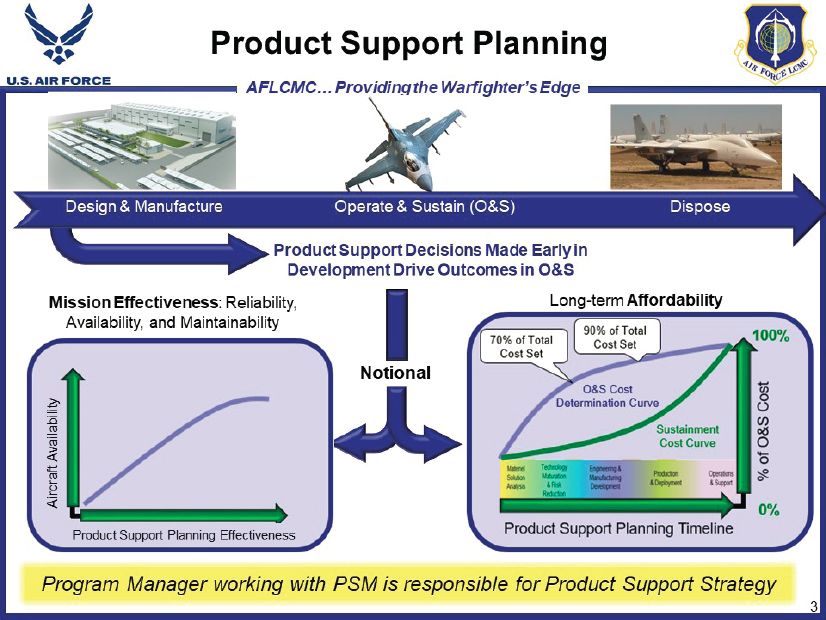

Product Support

Colonel Humphrey described the numerous sustainment-related activities that must take place during the entire system life cycle (see Figure 3). Even prior to approaching Milestone A, there should be some planning for a product support strategy, she said. Because, as the program evolves, requirements get more specific and more defined.

The product support functions include 12 integrated product support (IPS) elements, which are required to deploy and maintain the readiness and operational capability of major weapon systems. They are as follows:

- Product Support Management

- Supply Support

- Packaging, Handling, Storage and Transportation (PHS&T)

- Maintenance Planning and Management

- Design Interface

- Sustaining Engineering

- Technical Data

- Computer Resources

- Facilities & Infrastructure

- Manpower & Personnel

- Support Equipment

- Training and Training Support

Colonel Humphrey described a couple of initiatives aimed at improving the digital integration of these elements. LCMC is the body that represents these 12 product support elements; it functions as a subject matter expert to ensure there is rigor involved with their implementation. However, it does not function as an approval or disapproval body—SAF/AQD8 retains that responsibility.

She also stressed the need for communication and coordination between lead engineers and maintainers and described the division between acquisition and sustainment, which sometimes lead to acquirers not thinking about what was going to happen in sustainment and the sustainment personnel just reacting to decisions made years ago.

MAJCOMs Drive Requirements

Colonel Humphrey noted that LCMC recognized a need to interface more with the MAJCOMs and the USAF staff, particularly the AF/A4 (Logistics, Engineering, and Force Protection) and help them understand why they should be more engaged with the AF/A5/8 (Strategic Plans and Programs) shop during requirements development. Everything starts with the MAJCOMs. They pass on a set of requirements to the program office, which are often heavily focused on capability, and do not always adequately factor in supportability. This does not mean that supportability

___________________

8 Office of the Deputy Assistant Secretary of the Air Force for Logistics and Product Support, which leads sustainment planning efforts within the USAF acquisition structure.

is more important than capability, but overlooking supportability could impede efforts to obtain data rights, for example.

Evolution of Life-Cycle Management

Colonel Humphrey explained that LCMC is relatively new and maturing. In 2012, LCMC Initial Operating Capability and Logistics split from Acquisition as a separate functional office, effectively joining acquisition and sustainment into the life cycle and placing logistics on equal footing with other functional offices.

Colonel Humphrey detailed LCMC’s efforts to invest in its workforce. She described Director Cynthia Abbott’s aggressive approach to leadership training; collaboration with DAU to develop a new product support manager (PSM) course; restructure of the existing competency management tool to better align to the 12 product support elements, ideally to allow identification of gaps in the workforce; and help with moving people around as needed based on skill sets. There are robust efforts on succession planning—deliberately placing people to grow into their roles. There are also ongoing efforts to improve cross-functional integration to help get program managers (PMs) and engineering managers on the same page with the logisticians when it comes to integrating the 12 product support elements. In addition, there is a cross-center integration initiative, where LCMC is trying to acquire people with different experiences into its workforce, and vice versa to get more cross-skills development.

PRESENTATION FROM THE PROGRAM EXECUTIVE OFFICE FOR PRESIDENTIAL AIRLIFT RECAPITALIZATION

Major General Duke Z. Richardson, Program Executive Officer for Presidential Airlift Recapitalization, Air Force LCMC, briefed the workshop and offered insights on early sustainment planning from the program executive officer (PEO) point of view. He began by underscoring three major points. Firstly, PEOs in the USAF are life-cycle PEOs and look beyond mere development. For example, in his current program, NEAT,9 which is very early in its life cycle, a great deal of product support substance is included in the recently released request for information (RFI). Second, in the USAF, values drive requirements and the USAF values performance foremost. Major General Richardson highlighted that the emphasis on performance

___________________

9 U.S. Air Force, 2018, “National Airborne Operations Center (NAOC), Executive Airlift, Airborne Command Post (ABNCP), Take Charge and Move Out (TACAMO),” Solicitation Number NEAT_AoA_RFI, FedBizOpps.gov, https://www.fbo.gov/spg/USAF/AFMC/ASC/NEAT_AoA_RFI/listing.html.

does not suggest that logistical considerations do not appear in the requirements; he simply argues that they do drive the requirements, the need for performance does. Third, he said that there are fundamental differences between commercial aircraft and USAF aircraft. For example, commercial aircraft fly nearly 12 hours per day on predictable routes while the USAF operates in unpredictable circumstances. Furthermore, the commercial aircraft industry primarily values airworthiness while the USAF values effectiveness. Given that variance, their aircraft profiles are vastly different, with the USAF equipment being markedly more complex than standard commercial aircraft and thus sustainability in the commercial aircraft world is vastly different from sustainability in the USAF. While the USAF strives to do better, they should be realistic with expectations.

Major General Richardson continued his briefing by highlighting some of the USAF’s current early sustainment processes. For example, according to Major General Richardson, early stage RFIs cover sustainment-related factors looking at service life, impacts to the military flight profile, and scheduled/unscheduled maintenance, etc. In addition, product support–related requirements are included among requirements documents. He said one could argue whether they are stringent enough, but they are there. Furthermore, once the requirements are established, they go through a rigorous systems engineering process, which includes many design reviews. Perhaps one area to focus on, he suggested, is whether they have all of the right people at the reviews and whether to include supply chain professionals along with the engineers. In addition, PSMs assigned to programs are heavily involved. He suggested that the USAF could do a better job of transcending location because people working on particular programs are oftentimes in different physical locations. Lastly, they create life-cycle sustainment plans, which should start early and mature over time. “I think these steps are happening,” Major General Richardson said. Some of this, he continued, might require figuring out how one can institutionalize this so we get this all of the time and not just when we have the right mix of people.

To conclude, Major General Richardson suggested some areas to improve:

- Exploration into whether only one sustainment key performance parameter (KPP) is sufficient.

- Inclusion of life-cycle costs as part of source selection.

- Increase data expertise among the Program Management Offices.

- Exploration into whether supportability might necessitate its own technical performance measure (TPM).

- Improved integration among the LCMC commander, the sustainment center commander, and the Defense Logistics Agency (DLA) commander.

- More dedicated weapon system sustainment funding; currently the PM gets weapon system sustainment funding (called CAM or Centralized Asset Management) and has to allocate to eight functions, including important areas like depot inductions.

AIR FORCE SUSTAINMENT CENTER (AFSC) PRESENTATION

Kevin Stamey (Executive Director, Air Force Sustainment Center [AFSC], AFMC, Tinker Air Force Base) briefed the committee on the efforts of the AFSC. Stamey said the idea of integrating sustainment planning early into the program is already policy; however, he considered that the USAF might need to evaluate whether the policies should be more tightly enforced. Additionally, Stamey indicated that there is a limited understanding or experience within the acquisition community on sustainment, which exacerbates the fact that the incentives favor near-term priorities.

Role of the Sustainment Center

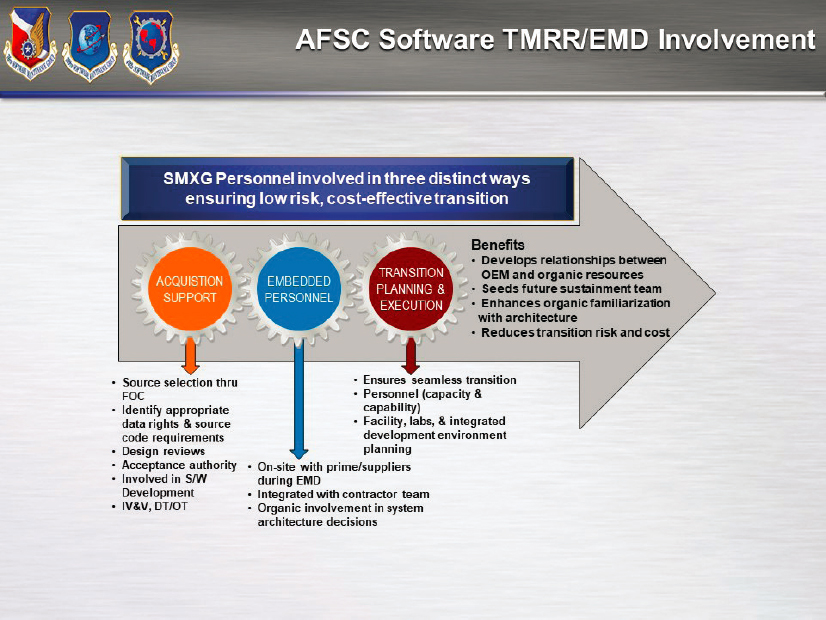

Stamey noted that currently the AFSC’s only formal role is to help coordinate and review life-cycle management plans (see Figure 4). They do not actively have a role in assessing what a given program office will do with that Life Cycle Management Plan; whether it is rolled into an execution document or the contractor’s integrated maintenance facility (IMF). Stamey explained that the sustainment center only has a role when invited so it is in the purview of the program office to seek out its expertise. He advocates for the sustainment center to have a more formal role upfront for sustainers once they know that it is going to be a major weapons system. As such, Stamey recommends that acquirers and sustainers be co-located.

Evaluating Sustainment

Several participants noted that when evaluating sustainment, someone with sustainment expertise must evaluate whether the program’s requirements are consistent with basic sustainment concepts and are sufficient to address them. Stamey recommends assigning a value or a score used by sustainment experts to measure whether a program is meeting sustainment objectives. This would be a way to assess the maturity and viability of sustainment planning so that decision makers understand the life-cycle risk associated with that program.

Technical Data

Stamey cited the lack of data rights as one of the greatest challenges to sustainment. It is a key limiting factor of the success of sustainment. Data rights are not

a new issue. Current initiatives are not enough to address this and it has historically hampered sustainment of the USAF weapon systems. Data rights are often incompatible with the many best practices in sustainment and there is insufficient knowledge of the specific data needed for sustainment. There is even a failure to assert/negotiate data rights when the government is the developer or has leverage.

Stamey explained that the ideal time to leverage data rights is during the request for proposal (RFP). As such, there ought to be sustainment community involvement in the source selection and RFP processes to ensure its reflection and to evaluate any proposals to ensure they adequately provide the data rights necessary to support that weapon system. To facilitate this, Stamey suggests the USAF begin pooling data rights experts to either embed into program offices or assemble into a repository with sufficient bandwidth to support program offices that are aware of their existence.

DISCUSSION WITH THE HONORABLE ROBERT H. MCMAHON, ASSISTANT SECRETARY OF DEFENSE FOR SUSTAINMENT

The Honorable Robert H. McMahon addressed the committee on the final day of the workshop. He offered his insights on the issue of early sustainment planning writ large. He said there is often a dichotomy between the operator and the sustainer and the acquirer and sustainer. To be successful, one needs to think about sustainment during the concept phase of a weapons system; however, they often defer to the operator on requirements because they ultimately have operational responsibility. Similarly, due to the near-term focus of programs, they reward acquirers on cost, schedule, and performance, and they will likely trade that which they are not being rewarded for as opposed to a future high return on an investment item. McMahon continued that he believed there is a misconception that they can always recover and think about sustainment later. The answer, he said, is that they can and do but at a cost. That cost is often in reduced availability, excessive operating costs, and a reactive approach to a solution as opposed to a proactive approach to the solution. Lastly, he emphasized the benefit to fundamentally changing the overall approach to sustainment, despite apprehension among several sectors of the USAF. He closed by thanking the participants for its service and dedication to this important issue.

DISCLAIMER: This Proceedings of a Workshop—in Brief was prepared by Shooshan Kechichian as a factual summary of what occurred at the meeting. She was assisted by Steven Darbes and Catherine Puma. The planning committee’s role was limited to planning the event. The statements made are those of the individual workshop participants and do not necessarily represent the views of all participants, the planning committee, or the National Academies. This Proceedings of a Workshop—in Brief was reviewed in draft form by James Colson, DAU, David Whelan (NAE), Independent Consultant, and Michael Zettler (Lieutenant General, USAF, ret.), Independent Consultant, to ensure that it meets institutional standards for quality and objectivity. The review comments and draft manuscript remain confidential to protect the integrity of the process. All images are courtesy of workshop participants.

PLANNING COMMITTEE: The Honorable Frank Kendall, Chair; VADM (ret.) Mark D. Harnitchek, U.S. Navy, Vice Chair; Lieutenant General (ret.) Andrew E. Busch, USAF; RADM (ret.) Kathleen M. Dussault, U.S. Navy; Wesley L. Harris (NAE); Lieutenant General (ret.) Bruce A. Litchfield, USAF; Ozden Ochoa; Christina L. Truesdale; Angie L. Tymofichuk; VADM (ret.) David J. Venlet, U.S. Navy

RAPPORTEUR: Shooshan Kechichian, Temporary Staff, Air Force Studies Board

AFSB STAFF: Ellen Chou, Director; George Coyle, Senior Program Officer; Ryan Murphy, Program Officer; Adrianna Hargrove, Financial Associate; Marguerite Schneider, Administrative Coordinator; Steven Darbes, Research Associate; Catherine Puma, Research Assistant

SPONSORS: This workshop was supported by the U.S. Air Force.

Suggested citation: National Academies of Sciences, Engineering, and Medicine. 2019. Early Sustainment Planning for the U.S. Air Force: Proceedings of a Workshop—in Brief. Washington, DC: The National Academies Press. https://doi.org/10.17226/25393.