3

Equipment Reliability and Maintenance

SUBSTANTIAL CAPITAL investments, in the form of facilities and equipment, are required for manufacturing almost all goods of economic significance. The productivity of these investments is a fundamental element of competition among companies and nations. Events that slow or interrupt the manufacturing process or degrade the product impair the competitiveness of a manufacturing enterprise.

The term equipment reliability and maintenance (ERM) encompasses not only equipment, such as machines, tools, and fixtures, but also the technical, operational, and management activities, ranging from equipment specifications to daily operation and maintenance, required to sustain the performance of manufacturing equipment throughout its useful life. This chapter addresses all causes of diminished or degraded output. The panel considers ERM to be a significant factor in the competitiveness of manufacturing firms, an assessment supported by the case studies in the section on present practice (pp. 57-63).

Historically, the evolution of ERM can be traced from breakdown maintenance and repair to preventive maintenance to predictive maintenance. Breakdown maintenance and repair is the after-the-fact restoration of failed equipment. Preventive maintenance is the systematic servicing of equipment to reduce the possibility of failure. Predictive maintenance, in use in U.S. industry for only four or five years, is usually understood to involve the use of computer software to detect conditions that might eventually lead

to equipment failure. Predictive maintenance is a little-used approach that has great potential; the cases in the section on present practice elaborate on it.

A few basic definitions are used in this chapter. The theoretical capacity of a manufacturing process or machine is the output per unit of time of continuous operation at the maximum safe operating speed. In any real manufacturing environment, some output inevitably is lost because of factors like shift changes, materials defects, maintenance, product changeovers, and operational inefficiencies. Most process engineers employ a deterministic safety factor approach that reflects a reasonable level of unavoidable loss of output. They design processes for a theoretical or running capacity, which is calculated on the basis of a system's estimated efficiency.

In actual, day-to-day production, manufacturing engineers generally monitor two basic measures of equipment or process performance, scheduled and actual. Scheduled output is the output expected from an operation for a given allocation of time, material, and labor; it is usually based on a published output rate. Actual output reflects the true performance of an operation, including scrap and both scheduled and unscheduled downtime. These figures are often given on a yield basis (e.g., output per unit of time or material input).

These definitions are important when comparing data for different firms in an industry. A conservative specification of rated capacity, however, can yield misleading data for equipment performance.

IMPORTANCE

ERM affects drastically the three key elements of competitiveness —quality, cost, and product lead time. Well-maintained machines hold tolerances better, help to reduce scrap and rework, and raise part consistency and quality. By increasing uptime and yields of good parts, ERM can reduce capital requirements, thereby cutting total production costs. It also can shorten lead times by reducing downtime and the need for retooling.

The replacement and displacement of conventional electro-mechanical factory equipment by mechatronic equipment have given rise to a very different set of reliability and maintenance requirements. The recent rush to embrace computer-integrated manufacturing (CIM) has further increased the use of relatively unknown and untested technology. The factory is becoming a web of interdependent subsystems, interconnected by computer controllers that communicate horizontally across peer processes

and vertically to supervisory controllers above or slaves below. Much of the controller software was written with the assumption that all equipment works properly when, in fact, complicated and unpredictable failure modes, unanticipated by the system and equipment designers, are becoming increasingly apparent. It is seldom possible to predict how a system will fail when something somewhere in the plant breaks down. Because causal relationships are frequently hidden, repair is often time-consuming, expensive, and tedious. A better job of debugging these systems via simulation, analysis, and rapid development needs to be done.

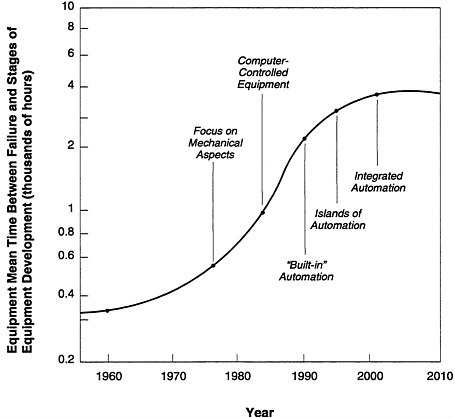

Software and sensors have the potential to enhance ERM and so mitigate the added complexity associated with these technologies (see Figure 3-1). The trend toward integrating mechatronic equipment into factorywide systems provides a framework for extensively exploring and exploiting this approach. The potential

FIGURE 3-1 Improvements in equipment reliability with increasing computerization. Source: VLSI Research Inc.

impact of these integrated systems on capital investment alone is significant (forgetting impact on quality, cost, and lead time). If U.S. machine tool utilization, for example, were to go from 50 percent to 100 percent, investment could be cut in half.

PRESENT PRACTICE

In U.S. manufacturing, equipment availability is generally ensured by the existence of standby equipment, i.e., buying two machines when one will produce the desired throughput. Preventive maintenance, therefore, loses its urgency and breakdown maintenance becomes the order of the day. More importantly, the important maintenance issues do not surface.

The rapidly increasing complexity of factory equipment has led many U.S. manufacturers to look to suppliers for smarter equipment that will ease the need for a technically strong supporting infrastructure. This trend is producing a generation of catalog engineers who are adept at ordering equipment from a catalog but who lack the knowledge to evaluate equipment designs. Suppliers are responding by applying microcomputer technology to more phases of manufacturing operations and processing. The term artificial intelligence is appearing in sales literature that increasingly is offering catalog solutions as alternatives to technical proficiency.

This approach to maintenance is in marked contrast to that taken in other countries. In Japan, for instance, many firms are engaged in a 10-year program to upgrade predictive maintenance to the point where ERM becomes the responsibility entirely of operators. Attainment of set performance levels by equipment is celebrated with the sipping of sake. In firms whose management understands facility issues, including the implications of ERM efforts, just-in-time (JIT)1 is less a measure of inventory than an indication that all processes are under control. Managers with this understanding can take a plant beyond the benefits of JIT to realize the potential benefits of ERM. The Japanese are succeeding at this because they have an integrated view of manufacturing as a system. Many U.S. manufacturing managers do not.

Japanese companies that have excelled in this area characteristically have the ability to develop and produce their own equipment. This is true even of smaller companies. Veteran engineers in one Japanese company with fewer than 50 employees, for example, developed all of the firm's equipment, tools, and dies. While this does not mean that U.S. end-users should do all equipment design in-house, it does suggest the need for drastic improvement of in-

house knowledge bases. (See Chapter 6, Manufacturing Skills Improvement for more on this topic.)

U.S. industry is not without examples of emphasis on ERM. U.S. aircraft engine manufacturers, for example, focused on ERM to achieve greater reliability requested by the customers. Standards are published for maintenance and operation and for comparing performance of aircraft engines. Results of these performance comparisons are published in the trade press.

The ERM programs of several U.S. and Japanese manufacturers are outlined in the following paragraphs.

U.S./Japanese Automobile Part Stamping

Wholly owned and joint-venture manufacturing facilities established in North America by Japanese firms during the 1980s provide a basis for comparing U.S. and Japanese ERM practices in a variety of areas. One example is the stamping of automobile hoods, fenders, doors, and other major steel components.

The key technology in stamping is the transfer press, which incorporates a mechanism for moving parts between five or six dies. High acquisition and operating costs (stamping dies and presses constitute a substantial part of the capital investment in automobile manufacture) lead automakers to run multiple sets of dies on a given line. Die change time, which necessarily represents scheduled machine downtime, is a critical element of overall operating performance, and rapid, efficient die changing is a key basis of competition in stamping operations.

The U.S. facilities of Japanese automakers, using U.S. workers to operate three to five presses, often achieve at least twice the productivity of comparable U.S. facilities on a per-line or perpress basis. ERM practices contribute significantly to this achievement.

The ERM techniques of Japanese firms are basic practices that are carried out religiously. The Japanese stamping lines, for example, are specified to run at a lower, more reliable rate than equivalent U.S. lines. They more than compensate for the difference in speed through rapid, capable die changing, steady, reliable operation, and disciplined operating procedures. Dies are cleaned and lubricated routinely, and repairs are completed to original specifications before problems become major. Moreover, Japanese plants are characterized by a highly disciplined approach to basic housekeeping—floors and manufacturing equipment are kept spotlessly clean. The cumulative effect of these practices is reflected in the product—mass-produced automobile body parts that are

comparable, if not superior, to those produced by manufacturers of low volume, luxury cars.

Near Deject-Free Pump Production

Between 1979 and 1982, the Japanese Nishio pump factory of Aishin Seiki reduced equipment breakdowns from 700 per month to effectively zero, while achieving an extraordinary level of quality— 11 defects per 1 million pumps produced. Aishin Seiki's success reflects neither high technology nor large investments in new facilities. Rather, it is the result of a strategy for achieving zero defects and zero breakdowns through common-sense engineering, attention to basics, and hard work and team effort guided by a top-management vision. The strategy, which focuses on achieving economical life cycle cost for equipment and other physical assets, began in Japan in the early 1970s. It is a logical outgrowth of previous ERM philosophies stemming from the practice of preventive maintenance.

Aishin Seiki's ERM practices aim to maximize equipment effectiveness in terms of both quality and productivity by:

-

establishing a total system of productive maintenance covering the entire life of equipment;

-

involving all departments, including equipment planning, equipment usage, and maintenance;

-

requiring universal participation by top management as well as shop floor personnel; and

-

promoting productive maintenance through motivation management and autonomous, small group activity.

The goal of the strategy is to eliminate the six main downtime losses:

-

losses caused by unexpected breakdowns;

-

losses from setup time associated with periodic changes and adjustments of tools and dies;

-

losses that result from idling, minor stoppages induced by sensors, and blockages of work in chutes;

-

losses attributable to differences between actual and design speeds of equipment;

-

process-related losses associated with defects and reworking; and

-

yield losses that occur between start-up and steady production.

The strategy was implemented in four stages.

-

In the preparatory stage, management (1) decides to employ the strategy, (2) mounts an educational campaign to reduce or eliminate resistance to it, (3) creates a hospitable organization and establishes basic policies and goals, and (4) formulates a master plan.

-

In the introduction stage, the ERM program is kicked off.

-

The implementation stage calls for (1) ensuring early successes and hands-on experience by focusing initial efforts on equipment that offers the most potential for improvement, (2) establishing an autonomous maintenance program for operators, (3) creating a system of planned maintenance that anticipates an increase in work load, (4) improving operating and maintenance skills through training, and (5) developing a prototype equipment management program.

-

The final, or establishment, stage calls for (1) making the new ERM strategy the norm for conducting business and (2) providing a process for continuous improvement.

The Nishio factory is not an isolated showcase. Similar results are being achieved in old as well as new factories throughout Japan. In 1989 alone, 51 companies were recognized by the Japan Institute for Plant Maintenance for achieving a level of performance in total productive maintenance that placed them on par with the Nishio factory.

Diagnostic Monitoring of Steam Turbine Generators

With an aging complement of steam turbine generators and few new plants in the planning cycle, the U.S utilities industry is responding to increasing demand for electricity by adopting new practices for maintaining and improving the availability of existing equipment. Preventive maintenance practices in this industry evolved by trial and error. While they are generally effective, these practices have been considerably enhanced by state-of-the-art maintenance planning, management, and implementation technologies that incorporate information on equipment design, application, and operation.

One utility moved from manual plotting of stator performance data to a computer-based, continuous monitoring system on its 10-year-old turbines that were installed in the mid-1980s. The on-line system included hardware, software, and diagnostic engineering services. Initial emphasis was on detecting problems before they became serious enough to force outages. The system was later expanded to incorporate preoutage maintenance plan-

ning, the cost of generator outages, prevention of in-service failure, and the increasing percentage of older units in service.

Software problems during system installation and checkout and numerous false diagnoses attending a later upgrade incurred extensive debugging that involved both vendor and user. Still, the system has served the utility well. Problems have been diagnosed in time for corrective action, greatly minimizing damage to turbines. In one instance, the expert system embedded in the diagnostic system recommended that a generator in which it had detected a fault be kept in service until the scheduled outage. This correct diagnosis avoided both an unscheduled outage for repair and a probable forced outage later had the problem gone undetected during the scheduled outage.

ERM in the U.S. Semiconductor Industry

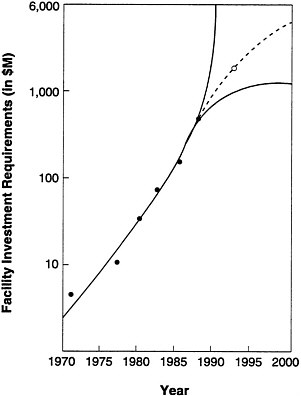

The cost of a typical state-of-the-art manufacturing facility for semiconductor memory chips has risen eightfold since 1980, from $25 million to $200 million. Over the next several product generations, the cost of such facilities is expected to reach between $500 million and $750 million (Figure 3-2 ). U.S. semiconductor industry capital investment of about $3.5 billion in 1988 strained the resources of even the largest companies.2 Such investments warrant serious attention to ERM in this industry.

Since 1987, Intel Corporation has used ERM techniques to increase uptime and speed throughput for both the currently installed and the next generation of equipment. The company developed a two-part strategy that focused on reducing the operations and support costs of installed equipment while simultaneously influencing the design of a new generation of equipment using life cycle cost data from the factory floor. Partnerships with key equipment suppliers were critical to the success of both parts of the program. U.S. semiconductor manufacturers traditionally have not communicated with their original equipment suppliers, nor have they taken advantage of engineering and managing upgrades, modifications, maintenance, and spare parts issued internally. Japanese suppliers, in contrast, benefit from close customer technology exchange programs with leading Japanese semiconductor manufacturers. Intel and several of its key equipment suppliers have begun to turn the domestic situation around. Their technology exchange programs today include concurrent engineering of next-generation equipment for new product and process requirements and replacement of Intel factory equipment engineering and maintenance staff with supplier personnel.

FIGURE 3-2 Expected trend in cost of state-of-the-art semiconductor manufacturing facilities. Source: VLSI Research Inc.

Key elements of the design/development phase include training and development to enable suppliers to perform highly specialized equipment analyses, such as failure modes and effects criticality analysis (FMECA), fault tree analysis, design for testability, design for fault tolerance/isolation/tracking, and design for remote diagnosis. Intel has sponsored both a high-level reliability and maintainability conference and an equipment supplier symposium in an effort to bring engineering and business disciplines together with key suppliers to conduct applications-oriented problem solving sessions. An equipment life-cycle training course was developed to train new suppliers, manufacturing engineers, and procurement teams. Procurement specifications have been upgraded to require that all key process equipment suppliers have a basic level of ERM expertise.

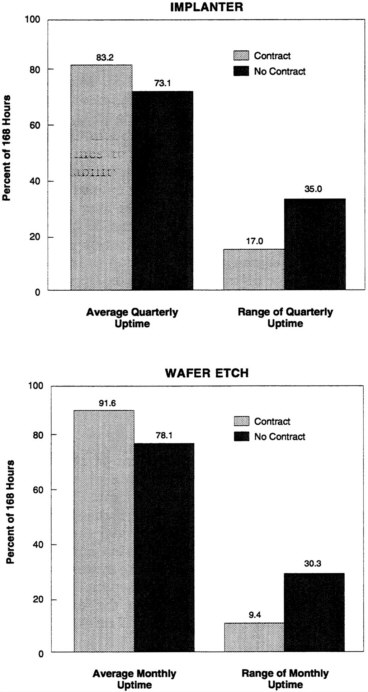

Results in trial fabrication plants for both wafer etch and implanter equipment show a substantial increase in average monthly uptime and increased predictability by reducing the range of monthly

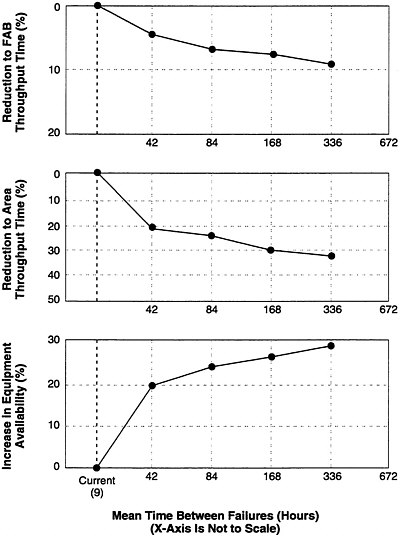

uptime (Figure 3-3 and Figure 3-4). In photolithography, attempts to increase mean time between failures have yielded a 30-percent increase in availability and an approximately 30-percent decrease in area throughput time while achieving a 10-percent reduction in total fabrication throughput time (Figure 3-5). Mean time between failures for a wide variety of assembly equipment has increased in the range of 200 to 2300 percent, resulting in equipment uptime averages in excess of 90 percent of available hours (in a 168-hour week).

Benefits of Intel's ERM program have included reduced cost per unit at each process step, as factory operations and support costs associated with downtime or slower area throughput time have been reduced. Additional capacity can be made available in many cases by increasing equipment utilization rates rather than by adding units of equipment. This adds up to important savings because the base cost of many types of equipment exceeds $1 million per unit.

Indirect benefits often outweigh direct savings. For example, meeting process parameters more reliably via FMECA increases factory yields and reduces work-in-process inventory. Such continuous improvements will be required to keep direct cost per unit and factory overhead competitive in the global marketplace.

VISION

The ideal manufacturing environment of the future has no maintenance organization and every piece of equipment is expected to be available 100 percent of the time. The entire manufacturing organization, including executive management, recognizes the value of high equipment availability and the role of ERM in achieving it. Sensors monitor the condition and performance of equipment throughout the manufacturing system and feed back relevant data to system controllers that interact with technically sophisticated human operators who use the data to maximize throughput, effect timely maintenance, and recover promptly from equipment failure.

Equipment design employs new approaches that use broader data bases. Simultaneous design, or concurrent engineering, i.e., designing the production line or process at the same time as the product it is to produce, is the watchword. Designers have access to comprehensive data from the equipment itself, as well as a wealth of information about the needs and performance of the installed base of industrial users. Across each industry is a reli-

FIGURES 3-3 and 3-4 Results in trial fabrication plants for both implanter equipment (1987-8) and wafer etch equipment (1988), with and without service contract, show a substantial increase in average monthly uptime and increased predictability by reducing the range of monthly uptime. Source: Intel Corporation, 1989.

FIGURE 3-5 For photolithography, attempts to increase mean time between failures have yielded a 30% increase in availability and an approximately 30% decrease in area throughout, while achieving a 10% reduction in total fabrication throughput time. Source: Intel Corporation, 1989.

able body of knowledge, much like that available for engines in the aircraft industry today. Testability is a fundamental criterion for design, and an arsenal of reliable testing methods has given rise to equipment that facilitates experimentation.

U.S. manufacturing will want to jump to this futuristic plane from its present plateau. It cannot. This vision for ERM is rooted in the evolution of product and process design and intelligent

manufacturing control. Present problems need to be resolved at a practical level, while high-technology approaches to ERM are developed in the next generation of equipment.

BARRIERS TO PROGRESS

Barriers to this vision of ERM are manifold. Perhaps the greatest is a general lack of awareness in the manufacturing organization, especially at the top, of the nature of ERM and its capacity for improving quality and productivity. The very terminology of ERM can impede its adoption and practice.

Even with greater awareness and understanding of ERM and sufficient good data to convince top management of its value, a serious deficit in the technical skills infrastructure required to implement an effective ERM program would still have to be overcome.

Lack of Awareness

In 1980, U.S. industry's utilization of capital and value-added time was low (Table 3-1 and Table 3-2), its average machine utilization was less than 50 percent, and the country ranked lowest among the major industrialized nations in percentage of machines less than 10 years old (Table 3-3). Although more recent data are not available, the consensus is that the situation has changed little in the past decade.

Finance-driven managers who do not understand manufactur-

TABLE 3-1 Low Utilization of Capital

|

Equipment Category |

Availability |

|

Transfer Lines |

50%-55% |

|

NC Machine Tools |

30%-70% |

|

Conventional Machine Tools |

30%-60% |

TABLE 3-2 Low Value-Added Time

|

Work State |

Fractional Time |

|

Cutting |

5%-6% |

|

Auxiliary |

4%-12% |

|

Waiting |

82%-91% |

TABLE 3-3 Age of Machine Tools

|

Country |

% Under 10 years |

% Over 20 years |

|

United States |

31 |

34 |

|

Canada |

41 |

37 |

|

West Germany |

36 |

27 |

|

France |

34 |

31 |

|

Italy |

41 |

29 |

|

Japan |

59 |

– |

|

United Kingdom |

38 |

24 |

|

SOURCE: Lawrence Livermore Laboratory. 1980. Technology of MachineTools, Machine Tool Systems Management and Utilization. Berkeley,CA: University of California at Berkeley, October 1980. |

||

ing operations and competitiveness can be misled by engineering and production managers who specify low rated capacities and scheduled yields. Capital authorization processes3 provide only an appearance of effectively managing some of the crucial bases of competition, including ERM (on which production capacity is clearly dependent). Arguments that blame insufficient capacity on old machines that cannot be replaced because of high cost are suspect because the most cost-effective increase in U.S. manufacturing capacity may well be achievable through improved maintenance practices for existing equipment.

Manufacturing management has labored against prevailing views of manufacturing as an appendage to business, a necessary evil, bureaucratic and hence slow to respond, driven by internal pressures and short-term thinking, and not part of the strategic business plan. In general, manufacturing has been slow to recognize the value of the scientific base; it has placed inordinate value on activity (go fast to go slow) and subscribed to a trial and error approach to problem solving that fails to attack root causes. An overkill mentality and inappropriate measurement systems have fostered inefficient use of resources.

Many U.S. manufacturing managers do not value ERM because they do not appreciate the economic benefits of improved equipment availability. Making a case for increased spending on ERM to a management that perceives itself to be at a strong competitive disadvantage relies on demonstrating a benefit-to-cost relationship. But it is not yet known how to prove ERM's value using generally accepted accounting principles and short-term measurement systems that yield little information on life-cycle costs and benefits of equipment.4

Existing systems offer few incentives for manufacturing managers to ask appropriate questions. In fact, to the extent that they lead management to treat maintenance as an indirect cost that increases factory overhead, these systems may be putting the U.S. asset base at risk. Cost models associated with short-term measures, which rapidly drive future costs to zero in a present value analysis using a relatively high rate of return, lead managers to emphasize initial purchase price in equipment acquisition. In short, plant managers are given short-term cost-reduction targets that only can be achieved by deemphasizing maintenance staffs and equipment repair, the true costs of which will appear only over the long term.

Lack of Data

The hard data needed to make a convincing argument to management are hard to find. No available method of measuring system reliability (e.g., equipment effectiveness = availability × speed ratio × yield) has yet been widely accepted by U.S. manufacturers, and manually collected production downtime data are questionable, inasmuch as waiting time for repairs is seldom reported. As a result, it is difficult to make comparisons, share results and good practices among cooperating operations, and measure ERM performance trends in any one factory in a universally credible way.

Lacking standard measures of ERM and using reward systems that typically do not encourage operators or supervisors to record or try to maximize equipment performance, industry can give suppliers very little information about its equipment beyond installation. The suppliers, largely isolated, are in most cases not likely to commit resources to providing a capability that many U.S. manufacturers, because they have not yet understood its value, have not demanded.

Given customer preoccupation with initial cost and technical features, equipment is frequently designed to perform specific tasks within the constraints of an acquisition budget, with little regard for optimizing economic performance over its lifetime. Reliability—which may be the driver for a few key components or safety features, but is generally a secondary consideration for entire systems— is usually built in after the fact on the basis of experience and limited information. Suppliers are reluctant to project ERM performance, claiming lack of control over user application, adherence to recommended preventive maintenance schedules, and adequacy of repair. Firms that do value ERM, typically driven by powerful cus-

tomer demands or regulatory influences, are forced overseas in their search for suppliers who are willing to quantify machine reliability and to work to meet ERM goals.

Lack of Skills

Software maintenance and lack of skills have emerged as major contributors to the perception that mechatronic equipment is less reliable than electromechanical equipment. Although companies technically unprepared to deal with these problems stand to suffer increased costs and reduced capacity, extreme pressure to minimize current-period costs continues to lead operations managers to sacrifice the hiring and training of maintenance personnel.

In contrast to design engineers who, because they are charged in most cases directly to a product, are viewed as contributors, manufacturing engineers and skilled workers are considered manufacturing overhead and, hence, as opportunities for cost reduction. In many companies, career paths for these employees are deemphasized, and responsibility for their training and development is specifically assigned to no one.

Lacking strength in manufacturing systems engineering, many plants rely on system integrators distinct from the equipment builders to configure their manufacturing systems. These outside suppliers of engineering services hesitate to experiment at the expense of their customers and so are unlikely to foster significant improvements.

This situation is reflected in the radically different perceptions of the performance of newly installed equipment in the United States and Japan. The U.S. view is that “the equipment is now performing at its best and over time performance will degrade.” The Japanese view is that “the equipment is now performing at its worst and work needs to be done to improve its performance dramatically.”

Emphasis on short-term profitability at the expense of preventive maintenance programs, personnel, and spare parts actually decreases long-term profitability by increasing the frequency of catastrophic events (i.e., breakdowns that demand emergency repair). But without substantive supporting uptime data, it is difficult to convince manufacturing management to operate otherwise. If the results of manufacturing technology research are to be effectively coupled to practice, a systematic, interdisciplinary attack—involving engineering, business, psychology, sociology, and finance, to name a few—must be mounted in order to change the status quo. To

effectively promote ERM, a clear and strong initiative is needed to identify what needs to be changed, what the objective should be, and how to make the change, in order to have an immediate and significant impact with lasting effects.

RESEARCH NEEDS

In a highly competitive world market, a manufacturer that needs two machines to produce what another manufacturer, by assuring the reliability of its equipment, can produce with one, will not be cost competitive. The use of first-class equipment, operating at full capacity, is vital to competitiveness in the world market, a fact U.S. manufacturing managers must be made to believe and given the tools to act upon.

The panel has ranked research needs in ERM within two broad categories. One relates to people, the other to equipment (Table 3-4). Technology alone will not yield significant improvements in ERM —it is only an enabler. The problem needs to be viewed in its totality, with a balanced emphasis on human and technological issues and barriers.

Making progress with people-related issues will be much harder than solving technological problems. The task will require a major departure from the traditional lines of demarcation between the trades necessitating, in essence, a cultural change—probably the most difficult problem U.S. industry faces. While total abandonment of tradition, or complete cultural change, is neither possible nor desirable, U.S. manufacturers may need to import, adapt, and fine-tune techniques from other countries such as Japan.

U.S. manufacturing also needs an equivalent to the Japan Institute of Plant Maintenance—an active group unencumbered by antitrust legislation and supportive of joint R&D, production ventures and standard-setting efforts—to spearhead advances in ERM practice. Japanese efforts in this area have dramatically improved quality, lowered cost, and reduced plant breakdowns from 10 percent to as little as 1 percent of previous levels within three years. The charter of a U.S. plant maintenance institute might include: competitive assessment of ERM (United States versus other countries), research to improve ERM competitiveness and spread best practice, assistance to companies attempting to improve ERM, ERM training assistance, a forum for technology transfer, and recognition of companies that meet predefined ERM thresholds. Some specific needs in these areas are addressed below.

TABLE 3-4 ERM Research Needs

|

People-Related Needs

Before anything can be done about equipment, U.S. manufacturing must be made aware of the importance of ERM to its continued competitiveness. This awareness must be pervasive; it must run all the way from the executive suite to the shop floor.

Effective management of ERM requires realistic awareness of the benefits of and necessary decisions related to ERM, the technical knowledge that will permit managers to make appropriate

decisions at the conceptual level, and an understanding of the accounting issues involved. Management leadership is essential to solving manufacturing 's problems because only management is positioned to have the overview essential for effective decision making and leading.

ERM issues will not be addressed unless management chooses to address them. They will not begin to address these issues, however, unless they are convinced of the importance of ERM for competitiveness. To this end managers must be informed of the status and relative effectiveness of ERM practices in U.S. and foreign industries. This would be helped greatly by a competitiveness assessment that reflects ERM differentials. Workshops sponsored by the National Research Council could serve to acquaint manufacturing executives with present practice in the United States and Japan. Because management needs both knowledge and data to know what to do and how to do it, a concurrent effort must be mounted to identify and supply the hard data without which even an enlightened management will be unable to identify the areas that need improvement.

If the vision set forth in this report is ever to be realized, the skills and capabilities that will be needed by managers at each level of the organization, and the agencies and institutions—universities, industries, companies, community colleges, etc.—best positioned to cultivate these skills, must be identified.

Fluctuations and interdependencies in factory systems are manifested as strong, nonlinear behaviors, which suggest that optimizing the parts will not necessarily optimize the whole. Too often, engineers work hard to improve one element of a system, only to discover that in doing so they have degraded the total system. An understanding of enterprise optimization is needed to guide the application of technical work in the plant.

Technology management is becoming an accepted discipline in a growing number of U.S. academic institutions. A complementary focus is needed on using technology. Quantifiable reasons must be found for employing technologists in the manufacturing sector of an enterprise. Well-understood methods of directing the work of these technologists are needed, as are mechanisms for implementing the results they achieve. Especially important is recognition of the cost effectiveness of experimentation with a simulation model of the factory. Managers and engineers should be aware of the benefits of using simulation methodology during process design. By allowing the ERM process to be modeled dur-

ing system design, simulation fosters a total systems approach to design.

The gap between engineers and managers needs to be narrowed. Product and process engineers should be involved in manufacturing decision making, with financial analysts supplying guidance. Current emphasis should shift from graduating applied scientists and specialists to producing engineers and interdisciplinarians. Needed are more career or professional engineers from interdisciplinary programs that cut across engineering disciplines to also embrace elements of business, psychology, and sociology. These bridges outside the engineering school will help recast the industrial engineer of yesterday as the systems engineer of today.

In addition to a broader professional Master of Science degree, greater emphasis is needed on the production of master technicians. The unavailability of internship programs is a serious deficit in U.S. manufacturing.

Who is, and is not, walking the floors of today's plants is also of concern. Few U.S. manufacturers have programs that provide white collar staff with exposure and experience in the actual manufacturing process. Many of the managers who cannot improve their plants arrived in manufacturing with finance/MBA training and had never set foot in a factory. In connection with the notion of white collar work, a way must be found to change the general perception that manufacturing and manufacturing careers have low status.

Schools have followed business's lead in the past; when business deemphasized manufacturing in the 1960s, schools closed their manufacturing laboratories. There is no reason to expect that they will not respond similarly to a reemphasis on manufacturing. Some two-year colleges are already cooperating with manufacturers to teach technical skills to shop floor personnel. Manufacturing engineering and software training programs are badly needed. Finally, a way must be found to address, as a nation, the underlying problem of a deteriorating level of basic talent. Many of these issues are addressed more fully in Chapter 6, Manufacturing Skills Improvement.

Equipment-Related Needs

Equipment-related needs can be grouped under the categories of performance measurement (identifying what we need to know and how to measure it), tools and techniques (what we can do for

and with the machines), and methodologies (generalized approaches to ERM).

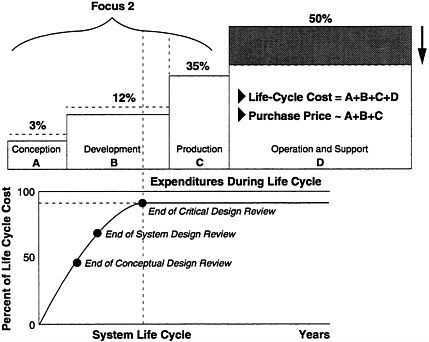

Performance measurement

A standard methodology for measuring the performance of ERM is needed, as is a way to quantify the benefits of ERM for top management. Though generally accepted accounting principles are inadequate for manufacturing decision making, no substitutes have gained wide acceptance. Without a measurement system that can quantify relationships between engineering work and profit/asset benefits, assess the costs of equipment waiting (e.g., load, unload, operator, material) and downtime, and allocate maintenance costs to reflect reality, results will be anecdotal and perception of the basis for changing the incentive structure will remain shaky. A more enlightened approach to reducing equipment life-cycle costs would be to increase capital investment at the concept and design stages in order to improve equipment reliability, maintainability, and predictability and thereby reduce operations and support costs that inflate factory overhead (Figure 3-6).

To evaluate the cost of machine downtime, one must first know a machine 's value per unit of time, which can be obtained through a variety of methods related to capacity utilization (see definition of theoretical capacity on p. 55). Needed is a production monitoring system capable of providing information about all machine shutdowns, classifying discrete events, and aggregating these events within categories. Given the opportunity cost of shutdown, such a system could calculate the benefit of reducing or eliminating each category of downtime. Further, a logical model of machine failure that can relate different kinds of failures, mean times between them, and their causes, is needed. Industrywide collections of such information will facilitate sharing of technical data—both ERM statistics and qualitative information about the relative effectiveness of different techniques—and help pinpoint areas where improvement is essential to global competitiveness.

Tools and techniques

Needed in equipment design is a design-for-reliability approach that takes into account all life-cycle costs (acquisition, installation, operation, maintenance, repair, and salvage). This approach should delineate basic principles that are demonstrably effective and universally applicable. ERM does not begin on the manufacturing

FIGURE 3-6 An enlightened approach to reducing equipment life cycle costs: Increase capital investment at the concept and design stages. Source: Intel Corporation, 1989.

floor; it begins in the office with the design of product, process, and equipment.

While judgment is required to ensure that manufacturing equipment is efficiently utilized, sensor technologies and self-diagnostics may be sufficient to ensure that it is reliably maintained. Research needs in this area are amplified in Chapter 2, Intelligent Manufacturing Control.

A clear link must be established between equipment requirements and reliability. Critical specifications must be defined and formulated to ensure reliability and identify pitfalls, stumbling blocks, and best practice. Systematic methodologies that will enable manufacturers to communicate equipment requirements in clear, operational terms need to be developed.

In the area of human–machine interface, research is needed to delineate the guidelines and practices needed for establishing this important junction.

Development of standards for design and test, for measuring and evaluating ERM, and for operator–equipment interfaces, would be a great facilitator in each of the areas discussed above.

Methodologies

Concurrent engineering warrants study as a means of building ERM considerations into equipment from the beginning. To this end, the training of finance and accounting people to guide and support the concurrent engineering process is critical.

Operational changes that will enhance ERM must be identified. One need is a checklist of procurement practices that will ensure that reliability, or lack of it, is recognized in specific equipment. In addition, practices that will promote effective implementation and continuous improvement of ERM must be developed.

A strawman model that would support analysis of the impacts of various methodologies on the manufacturing environment would be useful. Such a model should address matching of capabilities, design issues and rules, maintenance, installed base, culture, and organization. Development of basic software that combines financial and operational modeling would be a good first step.

Summary

Manufacturing is easily the most challenging and complex system in any organization. ERM must be recognized as an integral part of manufacturing that has a major impact on quality and productivity. Viewed as a discrete activity performed at different points in the manufacturing process, ERM will not achieve its full potential. It must be viewed as a system within the larger manufacturing system, a system that can be modeled in successful operation.

The research agenda should reflect the present perspective on ERM. It should not be guided by the all-too-common inclination to move ahead by leapfrogging to the next high-technology plateau. Rather, research should follow the model that takes the long-term view while working hard on short-term activities. The Japanese have done it by adhering to the basic principles of motivation, commitment and understanding, and training and discipline. Inquiries into ERM in the next generation of equipment should be based on practical investigations into improving it in the present generation.

To this end, research in the area of ERM should be directed at finding ways to:

-

inculcate the attitude that equipment should improve through use;use;

-

identify and analyze operational changes that might enhance ERM and inform equipment suppliers of these changes;

-

communicate ERM requirements in clear, operational terms;

-

support industrywide collection and analysis of standardized ERM data;

-

foster an understanding of enterprise optimization; and

-

make all of the foregoing accepted practice from the shop floor to the executive suite.

NOTES

1. Just-in-time (JIT) is a method of manufacturing by which parts and assemblies are made or delivered as needed, thereby greatly reducing inventory.

2. National Advisory Committee on Semiconductors. 1989. A Strategic Industry at Risk. Washington, D.C. November 1989.

3. In many companies, the capital approval process specifies different levels of authorization depending on the size of the request. Small investments (under $100,000, say) may need only the approval of the plant manager; expenditures in excess of several million dollars may require the board of directors' approval. This apparently sensible procedure, however, creates an incentive for managers to propose small projects that fall just below the cut-off point where higher level approval would be needed. Over time, a host of little investments, each of which delivers savings in labor, material, or overhead cost, can add up to a less-thanoptimal pattern of material flow and to obsolete process technology. (excerpt from: Kaplan, R. S. 1986. Must CIM be justified by faith alone? Harvard Business Review 64(2): 87-95.)

4. Kaplan, R. S. 1989. Management accounting for advanced technological environments. Science 245 (August 25): 819-823.