5

Vehicle Technologies for Reducing Load-Specific Fuel Consumption

The technologies that can be used to reduce fuel consumption in medium- and heavy-duty vehicles vary by vehicle type, duty cycle, and the year the technology becomes available. For instance, a Class 8 tractor trailer operating on the interstate will benefit from technologies that improve aerodynamic performance and reduce rolling resistance, whereas a Class 2b pickup truck will benefit little from these technologies. This chapter first reviews the ways in which energy is lost in the operation of medium- and heavy-duty vehicles. It then reviews technologies and techniques for reducing the fuel consumption of these vehicles, including technologies that improve aerodynamic performance and that reduce rolling resistance, auxiliary loads, and idle. It also covers mass and weight reduction, and intelligent vehicle technologies.

VEHICLE ENERGY BALANCES

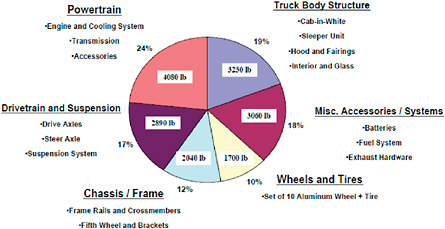

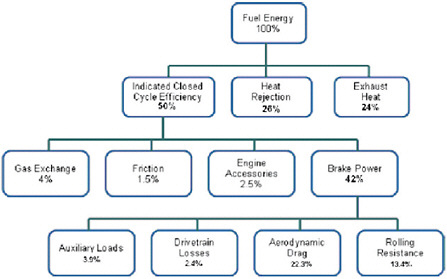

The potential efficiency improvements being considered in this study can be illustrated by reviewing the energy losses for the various vehicle classes. The U.S. Department of Energy (DOE) 21st Century Truck Partnership Technology Roadmap (DOE, 2006) provides the following tables for energy losses. The engine losses were calculated from a typical accounting of fuel energy usage, such as that shown in Figure 5-1. The engine losses are primarily a result of heat transfer to the coolant and heat loss through the exhaust. The remaining energy is used to power the vehicle and auxiliaries under the conditions set forth in the tables below. In Figure 5-1, engine accessories are components essential to engine operation, such as the fuel pump, water

FIGURE 5-1 Energy balance of a fully loaded Class 8 tractor-trailer on a level road at 65 mph, representing the losses shown in Table 5-1. SOURCE: TIAX (2009).

pump, and oil pump, while auxiliary loads are accessories used in a vehicle’s operation, such as the power steering, air compressor, cooling fan, and air-conditioning compressor.

The energy losses for a Class 8 tractor with a 53-ft van trailer, fully loaded to 80,000 lb gross vehicle weight (GVW) and operating on a level road at 65 mph, for one hour, are shown in Table 5-1. The energy losses for a Class 3 to 6 medium duty truck, loaded to 26,000 lb GVW and operating on a level road at 40 mph for 1 hour, are shown in Table 5-2. (Note that this steady-state operating point is not typical of the duty cycle for a Class 3 to 6 medium-duty truck.) The energy losses for a 40-ft transit bus with one-half seated load (32,000 lb) and the air conditioning on, operating over the central business district cycle, for 1 hour, are shown in Table 5-3. Note the high percentage of energy devoted to auxiliary loads.

Vehicle energy balances such as those described in Tables 5-1 through 5-3 identify the energy required to propel a vehicle down the road at a specific speed and with a specific load. The following sections break down these areas of losses as follows: aerodynamics, auxiliary loads, rolling resistance, vehicle mass (weight), and idle reduction.

AERODYNAMICS

Truck Aerodynamics

Anyone comparing the commanding size of a tractor-van trailer combination to a small sedan or even a full-size sport utility vehicle (SUV) understands that the aerodynamic drag1 of these large vehicles exceeds that of any light-duty vehicle. Some quantitative comparisons of those differences will be made later. For now, consider again the energy summary for the tractor-van trailer given in Table 5-1 and Table 5-4. Clearly, for this class of truck, aerodynamic load reduction is a key for successful fuel consumption reduction.

Early Studies

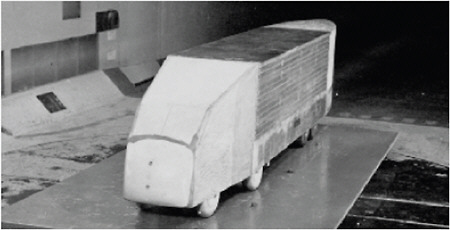

K.R. Cooper of the Canadian National Research Council summarized some of the earliest heavy truck wind tunnel testing performed in 1953 at the University of Maryland (Cooper, 2004). Many of the aerodynamic design solutions now available or being developed for Class 8 tractors and box van trailers were evaluated in that 1953 study. Those devices were shown to reduce aerodynamic drag by about 50 percent as compared to the predominant truck configurations of the 1950s (the cab-over-engine tractor). The “near-practical” streamlined result is shown in Figure 5-2.

Airshield introduced a commercial cab roof-top air deflector in about 1965. This device received some trucking company interest, especially after the 1973 petroleum crisis.

TABLE 5-1 Energy Balance for a Fully Loaded Class 8 Vehicle Operating on a Level Road at 65 mph for One Hour

TABLE 5-2 Energy Balance for a Fully Loaded Class 3 to 6 Medium-Duty Truck (26,000 lb) Operating on a Level Road at 40 mph for One Hour

TABLE 5-3 Energy Balance for a 40-ft Transit Bus Operating over the Central Business District Cycle for One Hour

TABLE 5-4 Operational Losses from Class 8 Tractor with Sleeper Cab-Van Trailer at 65 mph and GVW of 80,000 lb

|

Operating Load |

Power Consumed (hp) |

Power Consumed (%) |

|

Aerodynamic |

114 |

53 |

|

Rolling resistance |

68 |

32 |

|

Auxiliaries |

20 |

9 |

|

Drivetrain |

12 |

6 |

|

Braking |

0 |

0 |

|

Total |

214 |

100 |

|

SOURCE: DOE (2008). |

||

FIGURE 5-2 University of Maryland, streamlined tractor, closed gap, three-quarter trailer skirt, full boat tail. SOURCE: Cooper (2004), p. 15, Fig. 4, Case 8. Reprinted with kind permission of Springer Science and Business Media.

Industry interest was encouraged by the graphic illustrations produced by the National Research Council of Canada, as shown in Figure 5-3.

Recent History

The introduction of the Kenworth T-600 in 1985 marked the industry’s first serious attempt to incorporate aerodynamic improvements in truck tractors (see Figure 5-4). The T-600 included features such as a streamlined hood and fenders, an aerodynamic faired bumper, fuel tank fairings, and air filters mounted under the hood. These changes resulted in a significant reduction in aerodynamic drag compared to contemporary tractor models.

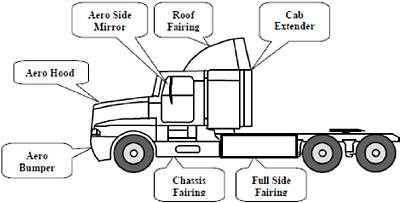

Continuing development led to additional improvements such as cab extenders to reduce the gap between tractor and trailer, more aerodynamic mirrors, and full-length side fairings. By 1990 all major truck/tractor manufacturers had introduced aerodynamic models, although “traditional” models continue to be available. See Figure 5-5 for identification of the common aerodynamic features.

FIGURE 5-3 National Research Council of Canada: Smoke pictures, cab with deflector (right). SOURCE: Cooper (2004), p. 11, Fig. 2. Reprinted with kind permission of Springer Science and Business Media.

FIGURE 5-4 Kenworth 1985 T600 aerodynamic tractor. SOURCE: Photo courtesy of Kenworth Truck Company.

Early Efforts Toward Engineering Measurements

The development of aerodynamic features led to a need for test procedures that could quantify the performance of these features. Most industry standards were developed through a consensus process by the Society of Automotive Engineers (SAE). Some of the widely used standards are as follows:

-

Coast-down tests on a track. By 1976 SAE issued a procedure to quantify and standardize this test, SAE J1263. This standard allows estimation of both the coefficient of aerodynamic drag, Cd, and the rolling resistance coefficient, Crr. SAE J1263 was intended primarily for passenger car applications, and the accuracy and repeatability of this procedure may be inadequate for heavy duty vehicles.

-

Wind tunnel tests. Truck companies began performing wind tunnel evaluations. Since a limited number of wind tunnels are available that can handle full-size trucks, scale models were widely used. By 1981, SAE had developed a recommended practice, SAE J1252,

FIGURE 5-5 Aerodynamic sleeper tractor aerodynamic feature identification.

-

for wind tunnel tests. This procedure is the only accurate method of determining wind-averaged drag, by accounting for the effects of side wind. See Chapter 2 for a description of the SAE J1252 test procedure.

-

Fuel consumption measurement with full-size trucks. In 1986 the SAE and the Truck Maintenance Council (TMC) introduced the joint TMC/SAE Fuel Consumption Test Procedure—Type II, SAE J1321, which provides the in-service fuel consumption of one test vehicle compared to a control truck. This test allows for correction of parameters outside the control of the researchers performing the test, such as ambient conditions and wind.

SmartWay Partnership of the U.S. Environmental Protection Agency

The U.S. Environmental Protection Agency’s (EPA) partnership with the truck industry to reduce emissions (especially greenhouse gases) and fuel consumption alike is described in Chapter 3. The EPA’s SmartWay truck specification has a significant dependence on improved aerodynamic performance. It requires certain fuel consumption reducing aerodynamic design features to be applied on tractor-van trailer combinations (Figure 5-6):

-

The SmartWay tractor must be a high-roof aerodynamic sleeper cab, with aerodynamic bumper, mirrors, side truck fairings, side extender fairings, and roof fairings. All six domestic tractor manufacturers now supply SmartWay compliant tractors.

-

The SmartWay-certified van trailer must be equipped with side skirt fairings plus either a trailer boat tail or a tractor-trailer gap fairing. The combined trailer aerodynamic treatment is estimated to achieve at least a 5 percent fuel consumption reduction compared to a standard trailer. At least eight trailer manufacturers supply SmartWay-compliant trailers (EPA, 2009).

As noted in Chapter 3, California adopted the SmartWay specification and validation processes as integral to its Global Warming Solutions Act in December 2008. That adoption provided for a mandatory introduction schedule of these fuel-saving specifications for both tractors and trailers in the 2011-2013 period (CARB, 2008).

Technology of Aerodynamic Improvements

The standard metric for comparing aerodynamic losses is the drag coefficient, Cd (see in Chapter 2 the section “Truck Tractive Forces and Energy Inventory”). Vehicle designers seek to minimize the drag coefficient in order to reduce fuel consumption at higher vehicle speeds, where aerodynamic drag represents a substantial fraction of the energy needed to keep the vehicle moving.

Drag coefficients for current aerodynamically designed tractors with smooth-sided van trailers (T-T) are about 0.6 to 0.65, which is higher than the values normally found in light-duty vehicles. Most current automobile sedans achieve a Cd of about 0.3 to 0.4, and the Cd of SUVs is typically 0.4 to 0.5. The higher Cd values for tractor trailers is primarily due to the fact that they are essentially large boxes optimized for the movement of freight.

Drag coefficient values are usually measured in wind tunnel tests. The Cd of a vehicle directly facilitates the computation of aerodynamic energy loss. Further, the wind tunnel test can provide a relatively simple and precise method to evaluate the wind yaw2 effects on a vehicle’s Cd (Cooper, 2004). An accurate and repeatable process for establishing Cd values is essential for the successful application of whole-truck computer modeling to evaluate fuel consumption effectiveness of various drag-reducing devices.

Each truck tractor manufacturer has developed in-house processes to validate the technical performance of their aerodynamic solutions. Manufacturers do not publish Cd values, evidently because the procedures used by different manufacturers are not known to be directly comparable. Manufacturers have not agreed to use a common standard such as SAE J-1252.

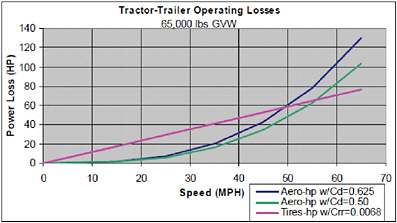

Aerodynamic Energy Loss

As described in the Road Load Power paragraph in Chapter 2, the resisting aerodynamic horsepower is proportional to Cd × A × V3, where A = frontal area and V = forward velocity. This illustrates the important role of vehicle speed on aerodynamic horsepower loss. It is helpful to graphically display aerodynamic power consumption as a function of road speed. Consider Figure 5-7, where the blue (Cd = 0.625) curve is typical of today’s tractor-trailer combination. The green curve represents a 20 percent reduction in the Cd, and therefore in the aerodynamic power loss. A 20 percent reduction in Cd results in a fuel consumption reduction of about 10 percent at 65 mph (TMA, 2007, p. 10).

Figure 5-7 also shows the curve for power consumed by tire rolling resistance. As described in the Chapter 2 paragraph on road load power, the tires’ rolling resistance power loss is proportional to: Crr × W × V, where W = vehicle gross weight and V = forward velocity. The Crr value used in the figure is typical of those on current tractor trailers but not of the lower value required for SmartWay certification.

Heavy-duty tractors not only have higher Cd values than light-duty vehicles, they also have a frontal area that is 3 to 3.7 times larger than cars and SUVs. The large frontal area is driven by the need to package a large payload capacity. As a result, the Cd*A values (drag coefficient times frontal area) of heavy trucks are roughly 4.7 to 7.7 times higher than

FIGURE 5-6 2009 model year Mack Pinnacle (left) and Freightliner Cascadia (right) SmartWay specification trucks. SOURCE: Courtesy of Mack and Freightliner Cascadia.

light-duty vehicles, which results in an aerodynamic power consumption 4.7 to 7.7 times higher. The benefits of aerodynamic features are a strong function of both operating speed and annual vehicle miles traveled (VMT). As Figure 5-7 shows, aerodynamic drag is larger than rolling resistance at speeds above 48 mph for a typical current truck. At 32 mph, however, aerodynamic drag is only half of tire rolling resistance, and aerodynamic drag becomes insignificant at low speeds. The sensitivity to VMT applies to any fuel-saving feature: the more miles a vehicle travels, the larger the potential fuel savings becomes.

In determining whether to apply aerodynamic features to a vehicle, it may be appropriate to consider a duty cycle average road speed hurdle. A method to quantify a weighted aerodynamic-average speed (WAAS) has been established that provides for an average of the mileage-weighted velocity3 (V3). If it is deemed that a speed hurdle is appropriate, a numerical value for the hurdle speed must be established, and the WAAS must be verifiable. For example, will a tractor-container/trailer chassis operate at a low average mph by virtue of its operation over short distances between ports and rail terminals? CARB has taken this issue into account in its greenhouse gas (GHG) regulation, where drayage tractors are exempt if operated within 100 miles of the port. If this approach is applied in the general case, it would likely require use of electronic onboard data recorders to substantiate the short distance and/or below-speed-hurdle reality. The required record keeping and oversight could become very burdensome.

Details of Aerodynamic Solutions

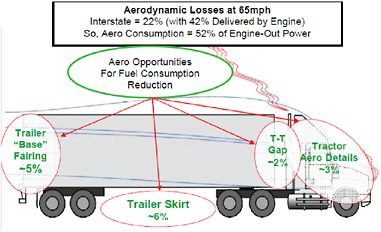

There are four regions of the tractor-van trailer combination truck that are amenable to aerodynamic design improvements. These regions include the various tractor-related details, the tractor-trailer gap, the trailer skirt, and the trailer

FIGURE 5-7 Aerodynamic and tire power losses for tractor-van trailer combination.

FIGURE 5-8 Tractor-trailer combination truck showing aerodynamic losses and areas of energy-saving opportunities. Percent changes refer to fuel consumption. SOURCE: Based on Wood (2006). Courtesy of Richard Wood.

“base” fairing, which are all illustrated in Figure 5-8, along with the approximate fuel consumption reductions that seem to be achievable in the near term.

Aerodynamics of the Truck Tractor

The contemporary image of aerodynamically optimized tractors is that of sleeper cab tractors equipped with many fairings, such as the SmartWay trucks shown in Figure 5-6 and the left-side image shown in Figure 5-9. These tractors are typically used in long-haul applications where the ability to provide “hotel” accommodations is important. However, many long-haul operators use a terminal-to-terminal system that does not require sleeper tractors. These operators use day cab tractors such as that shown on the right in Figure 5-9. Shorter-haul operators tend to avoid aerodynamic fairings because they provide limited fuel savings and are prone to damage in urban operations and during frequent stops at loading docks. Day cab tractors often are equipped with only a roof fairing, and for nonvan applications they may carry no fairings at all. Day cab tractors make up about one-third of all tractor sales, and so they are a significant portion of the market.

Most tractor manufacturers introduced tractor offerings in the 2003 to 2008 period that included purposeful, major improvements in their aerodynamic performance accomplished by attention to many details and utilizing most of the evaluation tools noted earlier. Reports of fuel consumption reductions of up to 6 percent were received during committee site visits.

FIGURE 5-9 Volvo full sleeper cab (left) and day cab (right). SOURCE: Courtesy of Volvo.

TABLE 5-5 Class 8 Tractor Aerodynamics Technologies, Considering the 2012 Time Frame

|

Technology |

Fuel Consumption Reduction (%) |

Cd Improvement (%) |

Cost ($) |

Industry Adoption Rate (%) |

|

Day cab roof deflector |

4-7 |

13 |

1,000-1,300 |

Most |

|

Sleeper roof fairing |

7-10 |

15-20 |

500-1,000 |

Standard |

|

Chassis skirt |

3-4 |

4-7 |

1,500-2,000 |

50-60 |

|

Cab extender |

2-3 |

4-5 |

300-500 |

80-90 |

|

Next-generation package |

3-4 |

6-8 |

2,750 |

2012 Introduction |

|

SOURCE: TIAX (2009), p. 4-35. |

||||

Table 5-5 shows the market shares of various aerodynamic features on aerodynamic-style tractors. Roof shields have a very high market share, while the relatively damage-prone chassis skirts have a lower share. The side-of-cab extender works with the roof shield to minimize the gap between tractors and trailers. This gap has a major role in determining the overall vehicle Cd. The recommended maximum gap3 is typically 30 in. from the rearmost feature on the tractor to the trailer face. Smaller gaps do have drawbacks, however, in that they limit the ability of the vehicle to operate in tight spaces.

The next-generation aerodynamics package shown in Table 5-5 represents the forecast of tractor manufacturers for sleeper cab tractor aerodynamics improvement in the 2012 time frame. These features will be designed and optimized for long-haul applications. It is expected that many of these features may not be compatible with short-haul operations, and thus their application on day cab tractors will be limited. Characteristics of short haul operation include curb encounters, severe road-crossing humps, backing maneuvers, and tight street-side clearances. All of these combine to damage many of the aerodynamic surfaces that could be successful in long-haul duty.

There are two consequences of the fragility of tractor aerodynamic features that must be considered. One is that trucks specified with many aerodynamic features will not be attractive or cost-effective in short-haul operations, because of the fragility of aerodynamic features and because of restricted maneuverability. The other issue is that tractors specified for short-haul operations will be less efficient if they are pressed into long-haul service for any reason. Excessive specialization of tractors can lead to logistics problems for operators, as well as to lower used tractor values in cases where the original operating intent does not match the second buyer’s application. An example of this is sleeper cab tractors with full-height air deflectors pulling flat bed trailers. In this case the aerodynamic feature actually costs fuel rather than saves fuel, because the high roof sleeper increases the frontal area of the truck beyond what the trailer requires. In many cases the application of a high roof sleeper with a flat-bed trailer is just temporary, but in some cases this fuel-wasting combination may be long term.

Another marketplace factor in tractor design that delays full implementation of aerodynamic features is the preference for traditional styling. This preference for a traditional look is prevalent among owner-operators, and many small fleets use traditional styling as a driver retention feature. Notice the differences in traditional styling compared to aerodynamic styling in Figure 5-10. Traditional features known to have high drag-inducing effects include the large, flat bumper, along with features protruding into the airstream such as head lamps, air cleaners, and dual exhaust stacks, as well as “west coast” side mirrors. While manufacturers have made useful aerodynamic improvements to traditional models of years gone by, these traditional features are believed to invoke a fuel consumption increase of at least 5 percent compared to the aerodynamic model. (TIAX, 2009, Table 4-24). Some operators are well aware of the fuel consumption penalty, while others are likely to underestimate it.

Day cab tractors constitute roughly one-third of Class 8 tractors. So far it has not been possible to match the aerodynamic performance of the best sleeper models with day cabs. Fortunately, it appears that many of the day cab and other short-haul tractors accumulate fewer miles and thus consume less fuel than over-the-highway tractors. More specific data gathering is needed to quantify the fuel consumed by various applications of tractor trailers.

A 2-year collaborative study of a variety of design improvements that would reduce aerodynamic drag on tractor trailers was completed in 2007 by four members of the Truck Manufacturers Association (TMA) and DOE. Their research evaluated the effect of post-SmartWay designs on combination tractor-trailer aerodynamics. A number of potential tractor features were evaluated, including alternative rearview mirror designs, treatments of the tractor-trailer gap such as gap fillers and trailer gap flow control devices, and features to manage airflow under the vehicle and between the tractor and trailer. In addition to the tractor features, a number of trailer features also were evaluated.

The 2007 TMA/DOE study started with a computational fluid dynamics (CFD) modeling evaluation of potential aerodynamic feature concepts. The CFD models allowed the researchers to explore the effect of many design parameters on Cd (see in Chapter 2 the section “Computational Fluid Dynamics”). The most promising concepts from the analyti-

FIGURE 5-10 Peterbilt Traditional Model 389 (left) and Aerodynamic Model 387 2 (right) (SmartWay). SOURCE: Courtesy of Peterbuilt Motors Company.

cal study were then tested in either scale model or full-scale wind tunnels to validate the modeling, quantify the Cd improvements and further refine the concepts. Finally, full-scale prototype hardware was created for vehicle testing using the SAE J-1321 protocol (TMA, 2007, p. 5).

The 2007 TMA/DOE study successfully revealed improved aerodynamic design features, but it also served to spotlight the difficulties of achieving major new reductions in tractor and tractor-trailer Cd. This last point also confirms that today’s modern tractor designs already perform well aerodynamically, within constraints such as the need to provide payload capacity and to be compatible with existing infrastructure such as loading docks.

The heat management requirements present another vehicle design factor that influences the aerodynamic characteristics. Larger cooling packages limit the ability of designers to reduce vehicle Cd. The total heat rejection from the vehicle determines the size of the cooling package required. The heat rejection includes engine-related heat rejection from the engine radiator, charge air cooler, and exhaust gas recirculation (EGR) coolers, but there are other sources of heat rejection as well. The transmission and steering systems may have coolers, along with the air-conditioner condenser. The addition of charge air cooling in the early 1990s, and the addition of EGR in 2002, has led to increased cooling system size and heat rejection requirements. Certain engine efficiency design features are mentioned in Chapter 4 that might reduce the size of current truck cooling system components and/or basic engine size itself. For example, “light-hybrid” systems have been mentioned as very useful to reduce light-load engine operation in the tractor-trailer class. Unfortunately, a corresponding reduction of engine size and heat rejection does not seem likely, since peak power demand will still be fulfilled only from the engine under many conditions. Similarly, most “bottoming-cycle” concepts will demand additional underhood space and will greatly increase overall power train heat rejection, as opposed to heat rejected in the exhaust gases, further challenging frontal styling and possibly increasing Cd values.

Aerodynamics of the Truck Trailer (with Focus on Typical 53-Ft-Length Box Vans)

Significant progress has been made with aerodynamic components added to the trailer (see Table 5-6). Unfortunately, there are three major impediments to widespread incorporation of aerodynamic trailer features. One is that in many operations the tractor and trailer owners are not the same. As a result, the trailer owner does not benefit from the fuel consumption reduction achieved by pulling an aerodynamic trailer. The second issue is that there are many more trailers than tractors, since trailers are widely used as temporary storage. As a result, the investment in aerodynamic improvements must be amortized over many fewer miles than is the case for tractors. The third impediment is the reality that there are no aerodynamic-system integrators

TABLE 5-6 Current Van Trailer Aero-Component Performance

|

Trailer Aerodynamic Technology |

Skirts |

Boat Tails |

Nose Cone |

Vortex Stabilizer |

Bogie Cover |

|

Range of fuel economy improvement (% mpg) |

5.6-7.5 |

2.9-5.0 |

2.0->4.0 |

1.0 |

1.0 |

|

Range of costs |

$1,600-$2,400 |

n/a |

$800-$1,260 |

$500 |

n/a |

|

SOURCES: Based on responses to committee questionnaire and information on manufacturers’ websites. |

|||||

in the medium- and heavy-duty trucking industries. Trailer manufacturers are not owned by or related with tractor companies, and trailer aerodynamic-device manufacturers constitute yet a third layer of unaligned companies. For the most part it falls to the carriers themselves to sort through the emerging aerodynamic devices to find the most cost effective solutions.

Table 5-6 gives a partial summary of supplier-reported information obtained from responses to a committee questionnaire4 (see Figures 5-11 to 5-14). Data are typically reported from SAE J1321 full-vehicle tests, in mpg improvement. However, individual testing procedures are not consistent, average test speeds differ, and it is not known whether the statistical requirements of the test procedure are consistently adhered to. Also, the data are not adequate to conclude that benefits achieved by combining aerodynamic devices would be completely additive. In a section below, results from a combination of devices are presented, and these results show that simple addition of individual results does not provide the correct result.

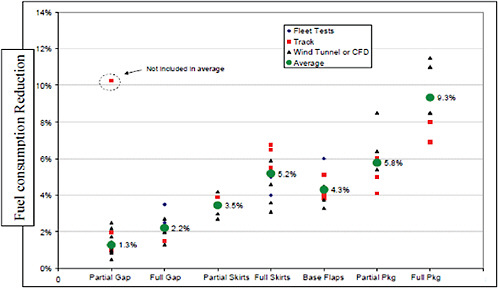

Note that the combined effects of several aerodynamic features (Full Package, in Figure 5-15) provide an average fuel consumption reduction of 9.3 percent. The full package includes the partial gap filler, full or partial trailer skirt, and base flaps (base fairings and boat tails). Further, if it is assumed that individual performances at the 75th percentile would eventually be achieved by 2015-2020, then the combined full package (of partial gap, full skirt, and base flaps) would be 12.1 percent. This result is derived through a method of multiplication of fuel consumptions reductions.5 Although there are more than 10 independent manufacturers of trailer aerodynamic devices, at least eight trailer manufacturers have certified 53-ft van trailers in the EPA’s SmartWay Partnership (EPA, 2009). One trailer manufacturer, Wabash National Corp., announced in July 2009 the production availability of a trailer skirt of its design.

Pneumatic Blowing to Reduce Trailer Drag

One researcher has extensively studied this concept, where low-pressurized air is discharged across curved trailing surfaces used on the trailer’s rear face. Reported results indicate that a fuel consumption reduction of about 8 percent at 65 mph may be achievable with this process. (The 8 percent is net savings, after accounting for the energy to pressurize the required plenum, Englar, 2005, p. 12). Such a system would need to be integrated into the trailer design for effective packaging, including compatibility with loading docks. One trailer aerodynamics manufacturer, AT Dynamics, has recently initiated development for a production-viable active flow control system for trailer rear edges. The cost and complexity of a pneumatic blowing system would be a substantial challenge to production implementation.

Cost-Effectiveness

DOE remarked in a December 4, 2008, research solicitation that “there has not been a strong pull from fleets due to concerns about cost, return on investment, durability and maintenance requirements.” Much of this lack of demand stems from the reality of trailer quantities. Currently, the trailer-to-tractor ratio is about 2.8. Most larger trucking companies report individual ratios ranging from about 1.1 to 4.0. One large private carrier reported a trailer-to-tractor ratio exceeding 8 (Transport Topics, 2009).

This reality adds to the difficulty of adding aerodynamic devices within normal and favorable capital acquisition metrics, such as net present value (NPV). The NPV for trailer skirts is strongly dependent on fuel prices and can easily exceed a 3-year zero-cost hurdle at a 2.8 trailer-to-tractor ratio. The retrofit of trailer aerodynamic devices might be a useful fuel-savings strategy, due to the long lifetime of highway trailers, which is 20 years or more, as a result of their low on-road utilization (compared to tractors).

Another cost-effectiveness issue is the fact that trailer aerodynamic improvements in duty cycles with low average speeds must be judged as a particularly poor value. For example, the fuel consumption benefit decreases by nearly 90 percent if the average speed is 30 mph rather than 60 mph (see Figure 5-7).

Safety Issues for Trailer Aerodynamic Devices

Since damage in normal vehicle operation is a major issue with aerodynamic features, virtually all reporting skirt developers have placed a high priority on ensuring that their designs are significantly road damage tolerant. Many have video clips on their Web sites showing resistance to railroad grade crossing humps, steep loading dock accesses, and snow accumulation or snow piles, as well as low-speed collisions with equipment such as fork-lift trucks. Nevertheless, caution is appropriate, as a proliferation of such low-hanging devices may create a new source of on-road hazards similar to tire tread sections today. One manufacturer, AdamWorks,

|

4 |

Trailer Aerodynamic Component Performance. Private survey, NRC Committee on Medium and Heavy-Duty Vehicles, May to August, 2009. Respondents included AdamWorks, ATDynamics, Air Tab, Freight Wing, Inc., Laydon Composites Ltd., Nose Cone Manufacturing Co., Wabash National Corp., and Windyne, Inc. (remarks only). The committee also obtained material from the websites (accessed August 2009) of manufacturers that did not return the survey questionnaire, including Aerodynamic Trailer Systems (http://fuelsaverbyats.com/ats_company_info.htm), Nose Cone Manufacturing Co.(http://www.nosecone.com/apvan.htm), Transtex Composites (http://www.transtexcomposite.com/); and Windyne Inc. (http://www.windyne.com/). |

|

5 |

The fuel consumption reduction of the combined technology packages is calculated multiplicatively (not additively) according to the following equation: where % FCTech x is the percent reduction of an individual technology, and therefore (1 − % FTech x) is the consumption associated with the reduction (personal communication between TIAX consultant Matt Kromer and C. Salter). |

FIGURE 5-11 ATDynamics trailer tail (left) and FreightWing trailer skirt (right). SOURCE: Courtesy of Freight Wing.

FIGURE 5-12 Nose cone trailer “eyebrow.” SOURCE: Photo provided with permission by FitzGerald Corporation, national marketer for Nose Cone Mfg. Co. Nose Cone is a registered trademark.

FIGURE 5-13 Laydon vortex stabilizer (left) and nose fairing (right). SOURCE: Courtesy of Laydon Composites.

FIGURE 5-14 Trailer bogie cover. SOURCE: TMA (2007).

automatically lowers its trailer skirt as a function of road speed from 16 to 6 in. This strategy permits close proximity of the bottom of the skirt to the road which enhances its high-speed performance while avoiding deployment under more hazardous low-speed conditions.

Aerodynamic features may also provide safety benefits unrelated to their primary purpose of saving fuel. There are numerous testimonials that trailer skirts and boat tails substantially improve trailer tracking stability, especially in crosswinds, and significantly reduce road spray from trailer tires. One trailer skirt manufacturer, Laydon, claims that its devices have been verified to comply with the European heavy truck side under-ride regulation. European Council Directive 89/297/EEC (ECD, 1989) mandates side under-ride

FIGURE 5-15 Summary of trailer aerodynamic device fuel consumption reduction. SOURCE: TIAX (2009).

protection on trucks to prevent pedestrians, bicycle riders, and motorcyclists from falling under the wheels of a vehicle when it turns.

Weight, Length, and Width Issues for Trailer Aerodynamic Devices

Weight

Trailer skirts can add 200 lb or more to a 53-ft trailer’s weight. Boat tails can add up to 200 lb to the trailer. Likewise, nose cones and/or vortex stabilizers can add up to 100 lb weight. Simulations have shown that about 1,000 lb of incremental truck weight incurs about 0.5 percent fuel consumption increase for a tractor trailer in over-the-road duty (NESCCAF/ICCT, 2009, p. 50). For operators running at the legal weight limit, payload is reduced by any empty weight increase, causing a load-specific fuel consumption increase of 2.2 percent per 1,000 lb added to the vehicle’s empty weight. Consideration should be given to allowing carriers to be permitted this increase in weight without penalty.

Length

Boat tails will also impose trailer length increases; again carriers should be permitted such length increase without penalty, even if the boat tail is structural. One boat tail manufacturer has advised receiving a U.S. Department of Transportation (DOT) length exemption under 23 CFR 658.16, Exclusion from Length and Width Determinations, for an additional 4 ft.

Width

Trailer skirts are often installed under the van, not exceeding a 102-in. width limit. Some manufacturers have experimented with side skirts that cover the trailer bogie (and also the tractor bogie). As these are usually non-structural components, it is believed they are permitted within the current width regulation, up to 106 in. width, also according to 23 CFR 658.16. Potential issues include docking in narrow confines and drivers who are unaccustomed to a truck that is potentially 2 in. wider on each side.

Aerodynamics of Tractor-Trailer Interface (Gap)

The gap between the tractor rear face and the trailer front face is filled with large vortices at high road speed. This air motion creates a low-pressure drag on the tractor’s rear face. The conditions worsen with oblique wind direction, which causes more air to get into the gap between the tractor and trailer, increasing trailer drag. The average wind velocity throughout the 48 contiguous states is 7 mph. This results in prevailing effective yaw angles of 7 to 11 degrees on the East and West coasts, and up to 14 degrees in the Midwest. Such conditions combine to increase drag by 30 to 55 percent on tractor trailers (Wood, 2009, pp. 2, 3).

The considerable air turbulence in the gap has been ameliorated by the use of cab extenders. Manufacturers typically recommend that a gap not to exceed 30 inches, as measured from the trailing edge of the extender to the trailer face. Indeed, cab extenders are integral to the SmartWay specification.

Several developers offer a “nose” fairing and vortex stabilizer for installation on the trailer front face, as noted earlier. Several developers have prototyped partial and even complete gap closure devices, with somewhat limited improvement in system performance (1 percent fuel savings for full gap closure on an SAE J1321 test at 65 mph; TMA, 2007, pp. 56, 64).

One developer combined three design elements to manage the gap flows: a smoothed tractor underside (from bumper to back of engine), a vertical airflow blocker on the front face of the trailer, and a significantly increased cab extension. Together, these features achieved a 1.3 percent fuel consumption reduction (J1321 at 65 mph; TMA, 2007, p. 78). However, the effect of these features in the presence of a side wind (which was not reported) may be greater.

Aerodynamics of Trailers, Double Vans, and Trailers with Shorter Than 53-ft Lengths

There are a variety of current and former industry standard van-length trailers: 28-ft trailers (also 27-ft), which are usually used as doubles, plus 45-ft and 48-ft trailers.

It is expected that gap treatments and boat tails will perform on any length single trailer equally as well as with 53-ft trailers. Likewise, 45-ft and 48-ft trailers equipped with skirts should have benefits only slightly smaller than the 53-ft results. While single 28-ft trailers surely can be equipped with skirts, data are not available to quantify that benefit. Further, it is expected that on double trailers some form of gap treatment between the two trailers would be effective, but again no data are available.

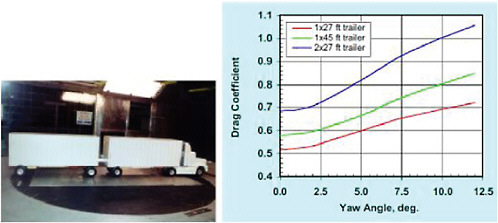

There is some aerodynamic data for multiple trailers. Cooper has reported results for standard trailers without aerodynamic treatments. These results, shown in Figure 5-16, compare a single 27-ft trailer with 27-ft doubles and a 45-ft single. Note that these are Cd data. The 27-ft doubles have a Cd that is 33 percent greater than the single 27-ft trailer, but only 17 percent greater than the single 45-ft. Finally, the 45-ft trailer’s drag is 12 percent greater than the 27-ft trailer’s (these are zero yaw results; Cooper, 2004, p. 17). These data suggest that there is a significant aerodynamic drag penalty for doubles, which is likely to increase under the effect of crosswinds.

Cooper clarifies that, even though the double trailers have 33 percent higher drag than a single trailer, the freight capacity increases by 100 percent (both in terms of weight and cubic volume). So the freight-hauling efficiency provides a net 38 percent drag reduction per unit freight quantity carried and thus a nearly 20 percent fuel consumption reduction per unit freight quantity (Cooper, 2004, p. 17). Cooper’s drag

FIGURE 5-16 Drag coefficient for aerodynamic tractor with single or double trailers. SOURCE: Cooper (2004), p. 17. Reprinted with kind permission of Springer Science and Business Media.

and fuel consumption results bolster arguments that favor the increased use of long combination vehicles (LCVs), as perhaps the most cost-effective vehicle design feature available to reduce fuel consumption in the heavy-duty truck industry.

Laydon Composites Ltd. has recently completed scalemodel wind tunnel tests on double 28-ft trailers equipped with forward-looking skirts, plus a vortex generator on the trailer’s faces. These skirts included trailer and tractor axle skirts. The fuel consumption reduction of the combination shown in Figure 5-17 is 9.9 percent at 60 mph, compared to a standard 28-ft double vehicle configuration. These results are based on yaw averaged and weighted winds, using the National Aeronautics and Space Administration procedure for estimating consumption from the drag results.

Aerodynamics of Trailers Other Than Dry Vans

While the dry van constitutes the largest portion of body styles in the U.S. fleet of trailers, there is a proliferation of

FIGURE 5-17 Laydon double trailer arrangement with trailer skirts and vortex stabilizers on both trailers; SOURCE: Courtesy of Laydon Composites.

other styles. The design of many of these non-dry vans is far less amenable to incorporation of all or even some of the aerodynamic devices found helpful on the dry van. Polk has provided a dataset for all trailers by body style for the state of Florida (Table 5-7). The results are summarized here as a surrogate for the national averages.

Aerodynamics of Van Refrigerated

The trailer-face-mounted refrigeration unit will dictate different gap treatment solutions than those used with the dry van. The refrigeration unit requires an airflow to provide engine combustion air, engine cooling air, and refrigeration condenser cooling air. On the other hand, the refrigeration unit itself may provide an aerodynamically significant reduction in drag, by virtue of providing some vortex control and associated pressure increase on the tractor rear face. Of course, the trailer skirt and trailer base areas are similar to those on a dry van, so similar aerodynamic features can be used. Freight Wing, Inc. has fitted skirts to a refrigerated van (see Figure 5-18), but test results for this trailer type are not yet available.

Aerodynamics of Flatbed Trailers

This trailer body style is among the most problematic of the semitrailer family because the space above the deck carries an endless assortment of products and implements, many with grossly unsymmetrical geometries. The trailer skirt area is judged to be as amenable to aerodynamic treatment as the dry van. One trailer aerodynamics supplier, Freight Wing, has fitted a flatbed with a skirt but has not yet tested the configuration. Note that the trailer model in Figure 5-19 also has a spread axle, which somewhat complicates skirt addition and may limit its potential effectiveness.

TABLE 5-7 Florida Trailer Population by Body Style

|

Body Style |

Population (%) |

|

Auto transporter |

0.4 |

|

Beverage |

1.4 |

|

Container chassis |

4.3 |

|

Dump |

2.3 |

|

Flatbed |

10.6 |

|

Grain |

0.2 |

|

Livestock |

0.3 |

|

Lowbed |

2.0 |

|

Tank |

4.1 |

|

Transfer |

1.4 |

|

Van |

60.9 |

|

Van refrigerated |

11.8 |

|

Other |

0.3 |

|

Total |

100 |

|

SOURCE: Personal communication between L. Hart and C. Salter, committee member, June 2, 2009. |

|

Aerodynamics of Container Chassis

This body style appears substantially similar to a van trailer. A removable container box is attached to a skeleton chassis consisting of a frame, a king pin, and an axle bogie. The difference from an aerodynamic point of view is that this style is equipped with square corners and many external ribs. These ribs provide the requisite strength to the container box to deal with the handling forces when loaded containers are lifted on and off the chassis frame but also can add to the trailer Cd (see Figure 5-20). The trailer skirt area is judged to be amenable to aerodynamic treatments, similar to those of the dry van. One trailer aerodynamics supplier, Freight Wing, has fitted a container chassis with a skirt but has not yet tested the configuration (see Figure 5-21). Unfortunately, typical empty-chassis handling and stowage practices will put trailer skirts at high risk of damage.

Aerodynamics of Tank Trailer

Since tanker trailers are normally operated at the maximum legal weight limit, the design is constrained to achieve minimum tare weight within the structural demands of the unit. While the tank itself is typically cylindrical, often with a hemispherical or somewhat rounded front face, the functional needs often result in an external skeleton of pipes, tubes, and so forth, to facilitate product loading/discharge and personnel protection when accessing certain operational devices. Further, the rear shape of the leading tractor poorly matches the trailer face in aerodynamic terms. Standard high-roof sleepers or day cab air deflectors are too high for tanker-trailer applications. Trailer skirts can be fitted as the dry van. One trailer aerodynamics supplier, Freight Wing, has fitted a tank trailer with a skirt, but has not yet tested the configuration (see Figure 5-22). Because any weight added for aerodynamics will reduce the load that a tanker can carry, these features are not likely to be financially attractive to any operator unless regulatory allowances are made.

Aerodynamics of Auto Transporter Trucks

The population of this body style is relatively small. This design style also has a complex nonaerodynamic array of structural tubes deploying the moving floors. Interestingly, one transport company, Precision Motor Transport Group (PMTG), has created a variety of trailer configurations incorporating curtain sides, rounded noses, and boat tails. This carrier specializes in transport of upscale sedans, and the auto capacity is inferior to the more standard designs. PMGT’s trailer system can hold six to eight sedans, compared to nine to eleven for a typical transporter trailer. The aerodynamic performance must be substantially superior to the traditional design, but no data are available at this time.

PMGT’s solutions raise the question of what could be done to improve other current body styles that have poor

FIGURE 5-18 Refrigerated van trailer with Freight Wing skirts. SOURCE: Courtesy of Freight Wing.

FIGURE 5-19 Freight Wing skirts on flatbed trailer. SOURCE: Courtesy of Freight Wing.

FIGURE 5-20 New 40-ft-long container built by TRS Containers (left) and container chassis (right). SOURCE: Courtesy of TRS Containers, Avenel, New Jersey.

FIGURE 5-21 Container chassis with Freight Wing trailer skirt. SOURCE: Courtesy of Freight Wing.

FIGURE 5-22 Tank trailer with Freight Wing skirts. SOURCE: Courtesy of Freight Wing.

FIGURE 5-23 Sturdy-Lite curtain side design for flatbed trailers. SOURCE: Courtesy of Sturdy-Lite.

aerodynamics. For example, could many of the normal flatbed/lowboy styles accommodate a curtain side/roof frame to achieve a major improvement in aerodynamics with accompanying fuel savings? At least two companies, Edscha Trailer Systems and Sturdy-Lite, market a rolling tarp system that allows any conventional flatbed or lowboy trailer to be converted into a van-style unit and back to a flatbed in minutes. The system works by rolling the fabric tarp on a track that is attached to the side of the trailer. No aerodynamic performance data are available at this time, and a great deal of testing would be required to determine the benefits of this approach compared to normal loading of freight on a flatbed, since so many freight configurations are possible. Notice that the Sturdy-Lite solution incorporates a full-height vertical nose plate, where many flatbed trailers have none, and a rear curtain frame (see Figure 5-23).

Combination of Solutions

In 2005, Walmart initiated a program with a stated goal of doubling the fuel economy of its (then) 7,200-tractor private carrier fleet from 6.5 mpg to 13 mpg by 2015 (see Figure 5-24).

Collaborating with suppliers Peterbilt and Great Dane, evaluated components included an 12-ft 6-in. trailer height (down from industry standard 13-ft 6-in.), 12-in. trailer drop belly (to recover internal volume except over the tractor axles), an aerodynamic tractor with matching lower roof fairing and cab extenders, trailer skirts (as well as the drop box), a rigid 2-ft boat tail, and an auxiliary power unit (for idle management) (italics indicate aerodynamic features).

Walmart reports a 12 percent improvement in fuel economy with this first-generation package of components and design alterations, using the SAE J1321 test procedure. Interestingly, the trailer height reduction of 12 in. reduced the frontal area by 7 percent in this combination; correspondingly, a 3 to 4 percent fuel consumption reduction would be expected from this change alone. Note that some loss of cargo capacity results from Walmart’s changes, and the new trailer height is not compatible with existing loading docks. Components still being evaluated in subsequent generations include a hybridized diesel-electric system and auto-deploying trailer skirts.

FIGURE 5-24 Walmart’s 2008 low fuel consumption tractor trailer. SOURCE: Courtesy of Walmart.

As part of the TMA-DOE collaborative study on tractor-trailer aerodynamics, Mack Trucks studied the separate and combined effects of the three aerodynamic technologies shown in Figure 5-25. The three features were a 24-ft long trailer skirt with 9-in. of road clearance, a pair of boat tail options (2-ft and 4-ft), and a unique flexible gap-closing system. The performance of this combined set of features was evaluated using the SAE J1321 on-road procedure at 65 mph. A fuel consumption reduction of 7.75 percent was measured, which suggests a 15 percent reduction in Cd. While the test parameters met all the precision criteria of the procedure, the prevailing winds and yaw conditions were not reported.

A recent DOE initiative includes a project valued up to $2 million for the development, evaluation, and deployment of advanced aerodynamic trailer technology. The DOE has selected Navistar International Corporation (Fort Wayne, Indiana) for the 30-month project with a goal to design, demonstrate, and bring to market a tractor-trailer combination and tire package that can reduce the fuel consumption of a heavy vehicle by at least 15 percent. Following development, a commercial fleet will evaluate the benefits of the new technology package through real-world use. After the term of the project, the team members will make this fuel-efficient technology package available for sale. Team members on the program include Frito Lay, Kentucky Trailer, Freight Wing, Michelin, and DOE’s Lawrence Livermore National Laboratory.

FIGURE 5-25 Mack truck with aerodynamic device combination. SOURCE: TMA (2007), pp. 57, 58, 60.

Straight Trucks with Aerodynamic Treatment

Trucks with box van bodies are most amenable to the solutions found on van trailers. Nose cones have been widely applied, but little or no SAE J1321 data are available (see Figure 5-26). Many straight trucks operate in urban and suburban settings, where aerodynamic treatments are unlikely to offer a significant fuel savings, but those few straight trucks used routinely in highway operations could see significant benefits.

One trailer aerodynamics manufacturer, Freight Wing, has fitted skirts to a van body straight truck, but no performance data are available (see Figure 5-27).

Aerodynamics of Motor Coach

Because of their frequent high-speed operation, some motor coaches may benefit significantly from aerodynamic drag reduction. However, there is limited information available in the literature, and little additional data were provided during the committee’s site visits that speak directly to motor coach aerodynamics. As such, the estimates of motor coach aerodynamic drag reduction potential in this report are based on extending results of the line-haul analysis to the motor coach segment (see Table 5-8).

The following approaches were considered for optimizing the aerodynamics of the tractor trailer: cab streamlining, boat tailing, underbody treatments, gap treatments, wheel fairings, removal of the mirrors, and active flow control. Of these, gap treatments are clearly not applicable to motor coaches; and given the already-low ride height, skirts and underbody treatments likely do not offer a significant benefit. Active flow control has not yet been demonstrated; moreover, it is most beneficial on streamlined, as distinguished from bluff, bodies (Salari, personal communication, 2009).

Of the remaining options, cab streamlining and boat tails would appear to offer the best prospects for reducing aero-

FIGURE 5-26 Nose Cone fairing on face of straight truck. SOURCE: Photo provided with permission by FitzGerald Corporation, national marketer for Nose Cone Mfg. Co. Nose Cone is a registered trademark.

FIGURE 5-27 Laydon skirt on straight truck. SOURCE: Laydon Composites.

dynamic drag. Boat tails on a tractor trailer are assumed to reduce drag by 6 to 9 percent and to offer fuel consumption benefits of 3 to 5 percent. Additional cab streamlining in the line-haul segment is estimated to reduce drag by 6 to 8 percent and to reduce fuel consumption by 3 to 4 percent. In combination, these approaches would reduce drag by 12 to 18 percent and could offer a 6 to 9 percent reduction in fuel consumption (if average speeds are >60 mph). It is assumed that these benefits come at a similar cost to those assumed for the line-haul segment: $2,750 for streamlining and $1,500 to $2,000 for boat tails. Given the very low manufacturing volumes for motor coaches, the committee expects that actual costs are likely to be higher.

Aerodynamics of Class 2b Pickups and Vans

The potential for aerodynamic drag reduction in the Class 2b segment is estimated based on analysis conducted during the National Highway Traffic Safety Administration (NHTSA) rulemaking for the light-duty Corporate Average Fuel Economy (CAFE) standard published in 2009. Although the NHTSA analysis extends only to Class 2a vehicles (<8,500 lb GVW), it is assumed that similar aerodynamic improvements can be implemented in Class 2b. In general, Class 2b vehicles have form factors similar to that of their smaller counterparts considered in the NHTSA rulemaking, which suggests that this is a reasonable approximation.

TABLE 5-8 Motor Coach—Applicable Aerodynamic Technologies

|

Technology |

Fuel Consumption Reduction (%) |

Cd Improvement (%) |

Cost ($) |

|

Boat tail |

3-5 |

6-9 |

1,500-2,000 |

|

Vehicle streamlining |

3-4 |

6-8 |

2,750 |

The NHTSA rulemaking considered underbody treatments; streamlined hood, windshield, fenders, and grill; reduced ride height (analogous to trailer side skirts); low-drag side mirrors; optimized airflow pathways; and wheels or wheel wells. All together, the NHTSA rulemaking assumes that a 10 percent reduction in Cd is feasible. As in heavy trucks, this level of drag reduction is assumed to result in a 4 to 5 percent reduction in fuel consumption (see Table 5-9). Caution is necessary in the use of these fuel consumption estimates since they apply to a 60 to 65 mph average speed. If these trucks are used principally in a pickup/delivery duty where average speed is about 40 mph, the fuel consumption benefit of the aerodynamic component will shrink by 70 percent. At speeds below 40 mph, the benefit becomes insignificant.

These benefits are estimated to range from $60 to $116 in added cost. These cost estimates were applied independent of vehicle class, so no adjustment was applied to translate these to Class 2b vehicles.

Aerodynamic Summary by Sector

TIAX, in its report for the committee, summarized the aerodynamic fuel consumption potential reduction by time frame and application (see Table 5-10).

The committee believes the potential for aerodynamic improvement for the tractor-trailer application is under-

TABLE 5-9 Class 2b Van and Pickup—Applicable Aerodynamic Technologies

|

Technology |

Fuel Consumption Reduction (%) |

Cd Improvement (%) |

Cost ($) |

|

Vehicle streamlining |

4-5 |

10 |

60-116 |

|

SOURCE: TIAX (2009), p. 4-50. |

|||

TABLE 5-10 Aerodynamic-Related Fuel Consumption Reduction Packages by Sector and by Time Frame

|

Sector |

2013-2015 (%) |

2015-2020 (%) |

|

Tractor trailer |

5.5 |

11.5 |

|

Class 6 box truck |

3 |

6 |

|

Class 6 bucket truck |

0 |

0 |

|

Motor coach |

0 |

8 |

|

Class 2b pickup/van |

3 |

3 |

|

SOURCE: TIAX (2009). |

||

stated by TIAX. In 2013 to 2015 a 9 percent reduction in fuel consumption is achievable versus 5.5 percent based on the “full-package” average in Figure 5-15. In 2015 to 2020 a 15 percent reduction in fuel consumption is achievable versus 11.5 percent at 65 mph. This estimate is based on improved full-package trailer performance (as described in Figure 5-15), plus a next-generation tractor performance of 3 to 4 percent (see Table 5-5). These two performance values are combined and confirmed by the method of multiplication of consumptions.

Also, the committee has recognized the Class 6 Box Truck aerodynamic design features in Table 6-6 that are currently available for implementation and has adopted them in Table 5-10 to report a 3 percent fuel consumption reduction for the 2013 to 2015 period. The 3 percent fuel consumption reduction is achievable provided that such box trucks have an average speed significantly higher than the 30 mph typical for pick-up and delivery duty. At a 30 mph average, the fuel consumption would be about 1 percent.

AUXILIARY LOADS

In addition to driving the wheels, power from the engine cylinders is used for many requisite auxiliary loads. Compressed air is needed for the braking systems; air conditioners are used for driver and passenger comfort; and power-steering systems require power to drive the associated pumps, compressors, and fans; and finally an alternator is used to charge the vehicle’s battery. The power to operate these systems comes from the engine cylinder and represents a use of fuel energy for functions other than putting power to the wheels. (The power required for running the coolant pump, fuel pump, and lubricating pumps is classified under the category of accessories, as shown in Figure 5-1.) The impact that driving these auxiliaries has on an engine’s fuel consumption will be highly dependent on the engine’s speed and the duty cycle on which the vehicle operates. Estimates that approximately 1.7 to 4.5 percent of fuel energy could be saved through the use of dedicated auxiliary power units (APUs) have been reported to the committee.6

Tables 5-1, 5-2, and 5-3 show the power consumption for auxiliaries for different vehicles operating under representative operating conditions. The power consumed by auxiliaries can be significant, approximately 25 percent of the total power in the case of a transit bus with the air conditioner operating. The extent to which these auxiliaries are used is very dependent on the vehicle and its duty cycle, as shown in Tables 5-11 and 5-12.

TABLE 5-11 Examples of Power Requirement for Selected Auxiliary Loads

TABLE 5-12 Auxiliary Use for Line-Haul Duty Cycles

|

Component Name |

Line-haul Duty Cycle (% of time on) |

Local-haul Duty Cycle (% of time on) |

|

A/C compressor |

50 |

50 |

|

Power steering |

10 |

60 |

|

Air brake compressor |

5 |

30 |

|

Engine fan |

5 |

10 |

|

Alternator |

100 |

100 |

|

Oil pump |

100 |

100 |

|

Coolant pump |

100 |

100 |

|

SOURCE: Society of Automotive Engineers (SAE) J1343, “Information Relating to Duty Cycles and Average Power Requirements of Truck and Bus Engine Accessories,” August 2000. |

||

Improvement in these auxiliary systems and the use of electric drives instead of direct mechanical drives from the engine offer potential to reduce fuel consumption. However, the fuel consumption reduction will be very application specific. Hendricks and O’Keefe (2002) suggest that reduction of fuel consumption by optimizing the handling of auxiliary loads is indeed highly dependent on the vehicle and its driving cycle. Also, it is important to realize that reducing the mechanical power requirement from the engine to drive auxiliaries will not necessarily be a one-to-one reduction in fuel consumption. In general, reducing the load on the engine will also result in a decrease in the engine’s thermal efficiency. To gain the maximum benefit from reducing auxiliary power requirements and optimizing their operation, the engine will need to be re-optimized for the new duty cycle. This will need to be done for each vehicle application under consideration. However, it is technically feasible to save a portion of this 2.5 percent of the fuel’s energy.

ROLLING RESISTANCE

Technologies for Reducing Rolling Resistance

Tire rolling resistance accounts for roughly one-third of the power required to propel a line-haul truck at highway speeds on level roads (Bradley and Nelson, 2009; Kenworth, 2008). The force resisting a rolling tire is primarily due to the inelastic cyclic tire deformation when rolling and the shear and compressive forces at the contact patch. The resistive force has been found to be nearly linearly proportional to the load on the tire, and hence it is convenient to define a coefficient of rolling resistance, Crr, as follows:

For a given tire, Crr is mildly dependent on temperature, tread wear, and velocity (LaClair, 2005), which would need to be accounted for in vehicle models and must be considered in on-road comparative testing. Inflation pressure has a pronounced impact on Crr, as does wheel alignment (slip angle). Opportunities for managing these items are discussed below, along with tire technology.

Crr is highly dependent on tire technology, and large reductions in Crr have been seen in the past few decades. Crr is dimensionless, with typical values for modern truck tires of 0.004 to 0.008. For convenience the Crr is often expressed in values of kilograms of force of rolling resistance per metric ton of load (kg/T), which converts the values to 4.0 to 8.0 kg/T.

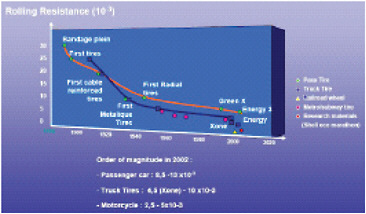

Improved Tires

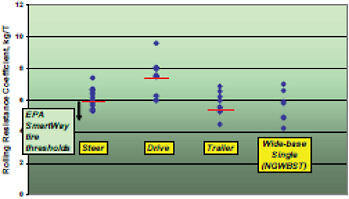

The historical trend in Crr reduction as presented by Melson (2007) is shown in Figure 5-28. A significant recent advancement in tire technology is the New Generation Wide-Base Single (NGWBS) truck tire. With this technology, one NGWBS tire (e.g., 455/55R22.5 and 445/50R22.5 dimensions) replaces two conventional dual tires, as shown in Figure 5-29. In today’s tire usage, conventional dual tires have Crr ranging typically from 5 to 8 kg/T, depending on the design. One of the significant benefits of the current NGWBS tire is its lower rolling resistance coefficient, with a range of 4 to 5 kg/T. As seen in Figure 5-30, dual tires span a range of Crr and can also qualify as low rolling resistance per the SmartWay definition.7

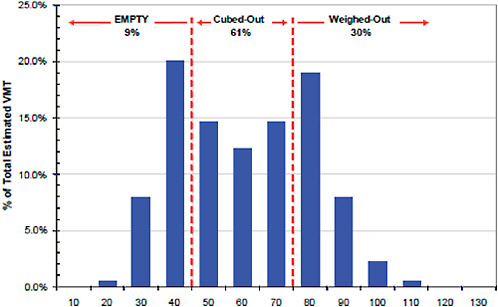

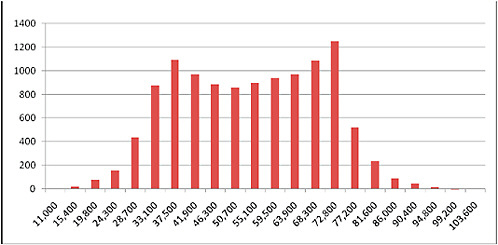

Replacement of typical dual tires with NGWBS tires can give fuel economy improvements approaching 10 percent for combination trucks, based on modeling as well as real-world studies (LaClair, 2005; Capps et al., 2008). Furthermore, U.S. EPA studies (Bachman et al., 2005, 2006) have demonstrated reductions in oxides of nitrogen emissions. The range of fuel economy improvements from tests is 5 to 10 percent, influenced by the vehicle type, driving cycle, and baseline tire (see Figure 5-30). Tire rolling resistance is further impacted noticeably by wear (tread depth), an additional variable in test results (Goodyear, 2003, p. 73). An additional confounding factor to test would be the amount of circumference mismatch in dual tires to minimize scrubbing losses. Typical results from a modeling study of a Class 8 truck show how the impact of tire Crr varies depending on drive cycle and load (see Table 5-13).

Modest further reductions in Crr are projected. Melson (2007) shows the Crr of trailer tires in particular is expected to drop slightly below 0.004. The Aerospace Corporation, in a 1982 study for the DOE, projected that Crr would reach 0.0045 in the following decade, which has proven accurate. Consistent with these sources, Reinhart8 reported to the committee that the NESCAFF/ICCT study team had determined that a Crr of 0.0045 was an appropriate estimate for future technology.

Despite recent advances in tire technology, it should be noted that NGWBS tires, which provide the lowest levels of Crr, are presently not available in tire dimensions used on many Class 3 to 6 vehicles, and tires with the very lowest rolling resistance levels may not be practical for all applications. Tires, like most products, must satisfy a range of performance criteria (e.g., rolling resistance, wear, noise, traction, durability, cost), and several inherent design tradeoffs exist when balancing the tire performance for a particular use. For example, tires designed for optimal mud or

FIGURE 5-28 Rolling resistance technology, 1910-2002. SOURCE: MNA (2007). Courtesy of Michelin North America.

snow traction typically have more void in the tread pattern. This generally provides a tire with a higher Crr than for tires with lower void content, since the reduced rigidity results in increased tread rubber deformation, in both compression and sheer, thereby increasing the hysteretic losses responsible for rolling resistance. Particular needs for individual consumers and tire uses will make it very challenging to have uniformly low rolling resistance for all vehicle applications, and it is likely that some vehicle applications will always use tires with Crr values greater than the lowest levels available on the market. Also, fleet operating practices of running out partially worn tires from steer and drive axles on the trailer will often result in less than fully optimized rolling resistance at different stages of tire life. And even in long-haul vehicles, the practice of retreading steer tires (which legally cannot be operated on the steer axle after retreading) will assure that nearly 10 percent or more of tires in use will always be dual tires. Finally, retreaded tires generally have a somewhat higher level of rolling resistance than new tires. These factors must be taken into consideration when establishing any regulation regarding tire rolling resistance, and it should be well understood that fleet practices will have a very direct impact on the average level of rolling resistance for tires in actual use.

FIGURE 5-29 New-generation wide-base single tire (right) to reduce the rolling resistance of conventional dual tires (left). SOURCE: Presentation to the committee by C. Bradley and S. Nelson, Michelin Tire North America, “Truck Tires and Rolling Resistance,” February 4, 2009. Courtesy of Michelin Tire North America.

Recent proposals have been made to create a tire fuel efficiency rating system for replacement tires and to allow point of sale information to be displayed to inform consumers of the role that tires have on fuel efficiency. The approach is similar to the Energy Star program and EnergyGuide labeling used for household appliances and other products. Pursuant to the Energy Independence and Security Act of 2007, a national tire fuel efficiency consumer information program was developed for passenger car tires by NHTSA (NHTSA, 2009b). The NHTSA proposed rulemaking proposes to require tire manufacturers to rate the fuel efficiency of their tires using the International Organization for Standardization (ISO) 28580 standardized test method for tire rolling resistance measurement. The tire industry has been working recently to develop this test standard, which is applicable to new passenger car, truck, and bus tires. EPA is considering this same standardized test method for future SmartWay definitions.

NGWBS tires also give a weight savings of roughly 340 kg in a typical combination tractor-trailer rig, allowing for an increase in payload capacity, which can further improve freight efficiency. Barriers to the adoption of NGWBS tires have included concerns relative to the following:

-

Perceptions of the difficulty/downtime associated with flats

FIGURE 5-30 Example rolling resistance coefficients for heavy-duty truck tires. SOURCE: Presentation to the committee by C. Bradley and S. Nelson, Michelin Tire North America, “Truck Tires and Rolling Resistance,” February 4, 2009. Courtesy of Michelin Tire North America.

-

Safety/stability in the event of a tire failure

-

Availability of replacement tires

-

Increased road damage

Various studies have been conducted recently to address these above concerns for NGWBS tires, however, and results have demonstrated performance similar to that of dual tires. Furthermore, tire manufacturers have made efforts to minimize or mitigate any inconveniences that could be experienced on the road when using NGWBS tires.

Several of the concerns stated above can be attributed to past experiences and studies of the original 65-series on/off-road and regional single tires (e.g., 385/65R22.5 and 425/65R22.5). These tires are normally operated at elevated service inflation pressures, with consequently reduced tire footprint size and peak tire-road contact stresses that surpass those of traditional tires. Studies of the original “65-series singles” concluded that increased road damage could be attributed to these tires, and this naturally generated concern for state and federal departments of transportation when NGWBS tires were developed and placed into use. Although differences have been observed in various metrics of roadway stresses for dual and NGWBS tires, pavement damage is expected to be similar for these two types of tires for primary roads (Al-Qadi, 2007a,b).

TABLE 5-13 Results of Truck Model Showing Effect of Coefficient of Rolling Resistance, Crr, on Fuel Economy for Several Drive Cycles

|

Heavy Truck (40 ton) 12.01 Diesel Engine |

Fuel Consumption (gal/100 miles) |

Fuel Savings (gal/100 miles) |

Percent |

|

|

Crr = 5.5 kg/t |

Crr = 4.5 kg/t |

|||

|

Suburban use, half loaded |

16.53 |

15.98 |

0.55 |

3.3 |

|

Regional use, half loaded |

15.13 |

14.53 |

0.59 |

3.9 |

|

Long-haul use, half loaded |

12.62 |

11.94 |

0.68 |

5.4 |

|

Suburban use, fully loaded |

21.29 |

20.57 |

0.72 |

3.4 |

|

Regional use, fully loaded |

19.76 |

19.04 |

0.72 |

3.7 |

|

Long-haul use, fully loaded |

14.92 |

14.02 |

0.89 |

6.0 |

|

SOURCE: C. Bradley and S. Nelson, Michelin Tire North America, “Truck Tires and Rolling Resistance,” presentation to the committee, February 4, 2009. Courtesy of Michelin Tire North America. |

||||

For safety concerns, testing has shown that rapid air loss events on NGWBS tires do not compromise the stability and behavior of the vehicle (Bradley and Nelson, 2009). Additionally, rollover performance with NGWBS tires has been shown to be similar to or improved relative to dual-tire rollover performance (Knee et al., 2008).

Regarding flat tires, a vehicle cannot continue driving with a flat NGWBS tire without risking serious damage to the tire and wheel. Although it may be possible to continue to drive a vehicle for tire replacement if one dual tire goes flat, this practice is not recommended and may not be legal. (Federal Motor Carrier Safety Administration Regulation Title 49 Code of Federal Regulations Part 393.75 (a), states, “No motor vehicle shall be operated on any tire that … is flat or has an audible leak.”)

In the United States, the use of NGWBS tires is legal in all 50 states on nonpermit-required vehicles (e.g., for loads up to 80,000 lb). There currently exist some state restrictions on NGWBS tire use where a state oversize or overweight permit is required for vehicle operation. These restrictions are premised on the studies of the original 65-series single tires. Furthermore, the use of NGWBS tires in Canada may require a special permit to operate at the Canadian dual-tire maximum load of 9,000 kg per axle in some provinces. Since

many vehicles operate in both the United States and Canada, an amendment was passed in May 2008 to the Canadian Ministers of Transportation and Highway Safety memorandum of understanding on vehicle weights and dimensions approving the U.S dual-tire load parity of 7,700 kg axle (15,400 kg per tandem axles) for the NGWBS single tires.

Tire Pressure Maintenance and Effects

Rolling resistance is strongly affected by the pressure in a tire, increasing steadily as tire pressure decreases below the recommended inflation pressure. For truck tires, rolling resistance can be expected to increase by about 5 to 8 percent for a 20 percent reduction in pressure. This will typically yield a 2 to 3 percent loss in fuel economy in a Class 8 truck if all tires are underinflated (SmartWay; Goodyear, 2003, p.72). While trucking fleets generally monitor tire pressure more frequently than do personal car owners, substantially underinflated tires are likely responsible for a relatively large level of unnecessary fuel consumption. For passenger cars and light trucks, the NHTSA conducted a study following the passage of the Transportation Recall Enhancement, Accountability, and Documentation Act of 2000 in which tire pressure was measured on 11,530 cars and light trucks. The study found that 27 percent of passenger cars and 33 percent of light trucks have at least one tire significantly underinflated (by 20 percent or more). For truck tires a separate NHTSA study (Woodrooffe et al., 2008) found that tire underinflation is one of the three main causes of truck tire casing removals. The level of underinflation on truck tires across the U.S. fleet is not precisely known; however, the impact on fuel economy can be rather significant.

Given these facts, it is clear that tire pressure monitoring systems (TPMSs) can help improve the fuel consumption and safety of heavy trucks by ensuring that adequate pressure is maintained and, consequently that the rolling resistance is at the design level. There is already a moderate usage of TPMS in fleets, although a detailed quantification of the percentages of trucks equipped with TPMS is not available at this time. Automatic tire inflation (ATI) systems are also commercially available that maintain tire pressure at the desired level.

Use of nitrogen instead of air for tire inflation has been found to reduce pressure loss rate (NHTSA, 2009a). In static laboratory tests the inflation pressure loss for new tires inflated with nitrogen was approximately two-thirds of the loss rate of new tires inflated with air. Similar differences between nitrogen and air permeation rates in new tires were found under dynamic, loaded laboratory testing. This is attributed primarily to the higher diffusion rate of oxygen through rubber compared to nitrogen, which was observed and characterized decades ago. In certain fleet operations the use of nitrogen fill would be effective in place of or in addition to TPMS and would lessen the need for ATI systems. The same NHTSA study reported that inflating tires with nitrogen in place of air had no direct effect on laboratory rolling resistance performance. Walmart reported to the committee that it found a 1.0 to 1.5 percent reduction in fuel use after instituting nitrogen inflation protocols.

Tire/Wheel Alignment

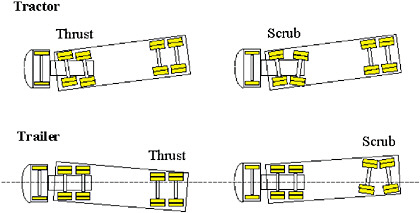

The alignment of each axle has a direct impact on rolling resistance. Misalignment effects that result in a slip angle on a truck’s tires (both toe settings and out-of-perpendicular (thrust) or out-of-parallel (scrub) tandem-axle alignment—see Figure 5-31) can strongly impact rolling resistance, in addition to negatively affecting tire wear and possibly vehicle handling. Camber effects, by comparison, are relatively small on rolling resistance, and the slip angle impact is thus the only alignment effect considered here. For a given slip

FIGURE 5-31 Tractor-trailer tandem-axle misalignment conditions. SOURCE: Kreeb and Brady (2006).

angle, α, on the tire, the added rolling resistance is given by the following relationship (Schuring, 1977):

where Cα is the cornering stiffness of the tire.

An estimation of the impact of misalignment on fuel consumption can be made by assuming that the average misalignment on each wheel of the truck is approximately 0.1°. (This level is consistent with standard practices and recommendations for tandem axle alignment in the industry and typical toe settings.) Based on a cornering stiffness of 3 kilonewtons (kN) per degree, the increase in rolling resistance per tire is about 0.5 N, which for an average rolling resistance coefficient of 7 kg/T with a fully loaded vehicle represents about 0.4 percent of each tire’s rolling resistance. Again assuming that rolling resistance accounts for about one-third of the mechanical energy needed to propel a long-haul truck, the average fuel economy impact is about 0.1 percent. Note that the quadratic dependence of rolling resistance on slip angle means that if the average slip angle is 0.2°, the fuel-savings potential increases by a factor of 4. In any case this analysis indicates that the loss in fuel economy on heavy trucks resulting from wheel alignment is on the order of 0.1 percent. It should be noted once again that these estimates in fuel consumption are intended to provide only order-of-magnitude assessment and that the assumptions used to make this evaluation are generalizations and large variations can exist among different vehicles.

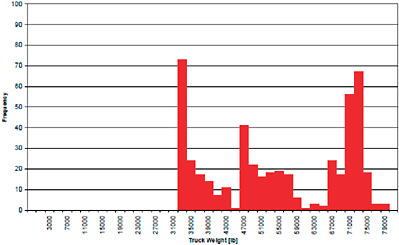

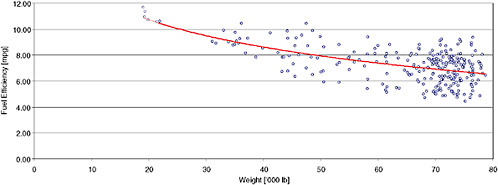

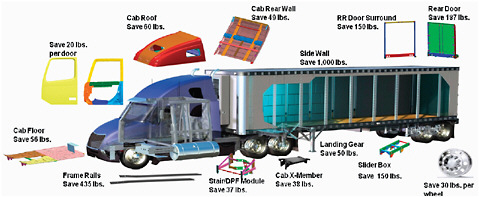

Impact of Reduced Rolling Resistance for Different Truck Classes