Appendix D

Group A Chemical Supply Chains

The purpose of this appendix is to provide an overview of the Group A precursor chemicals’ supply chains and to highlight the unique aspects of the nodes, modes of transportation, and oversight of each. In addition to federally mandated oversight, the commercial handling and movement of precursor chemicals may be subject to state and local laws or ordinances and corresponding regulations depending on the specific jurisdiction, of which there are thousands in the United States. The committee could not review all of their policies on precursor chemicals and has not indicated them on every node in each supply chain, except in the case of fertilizer grade ammonium nitrate (FGAN). Specific data on volumes shipped and imports/exports is excluded in favor of qualitative descriptors, given the fluid nature of commerce from year to year. The general key for reading the diagrams is provided below, along with a glossary defining the different node designations, and is applicable for all diagrams shown.

Aerospace – Users that employ the precursor chemicals as aerospace fuels.

Ag. (Agriculture) – End users who employ the precursor chemicals in agricultural production, e.g., farmers, landscapers, and other horticulturalists.

Ag. Retail. (Agricultural Retailer) – Locations that deal solely with agricultural products, likely in bulk forms, and that may provide application services.

Amt. Prd. (Amateur Production) – Production of a precursor chemical by a private individual.

AN Fact. (Ammonium Nitrate Factory) – A factory whose primary product is ammonium nitrate.

Blaster – A commercial operation that uses explosives, e.g., a mine.

Bunker – A temporary storage location used to hold sensitive chemicals.

Chm. Prc. (Chemical Process) – A manufacturer where the chemical is consumed as part of another chemical manufacturing process, e.g., use of nitric acid for polymer synthesis.

Com. Dist. (Commercial Distributor) – A warehouse, wholesaler, or distributor that temporarily holds bulk precursor chemicals or finished products containing the precursor chemicals; may include distributors that only handle chemicals.

Consumer – A person who purchases a precursor chemical or formulation for personal or professional end use, e.g., a hobbyist purchasing racing fuel or a cosmetician purchasing hair bleach.

Ex. Mfr. (Explosives/Propellants Manufacturer) – A manufacturer that incorporates the precursor chemical into commercial explosive materials.

F. Prd. Mfr. (Finished Product Manufacturer) – A manufacturer that incorporates a precursor chemical into a complete consumer product, e.g., ammonium nitrate cold packs.

Factory – A location where a precursor chemical is manufactured from raw materials, e.g., the synthesis of hydrogen peroxide from methane and oxygen.

Hopper – Temporary storage bins used to transfer materials between transportation modes.

Lab. Supl. (Laboratory Supplier) – A company that retails chemicals to researchers, e.g., Sigma Aldrich.

Other Ind. (Other Industries) – Nonchemical process manufacturers that use the precursors, e.g., in metal casting.

Packager – A location where bulk precursor chemical is divided into smaller containers for retail.

Port – A seaport where goods enter or exit the United States, e.g., the Port of Houston. Most ports will use terminals for temporary storage and transloading (an exception being the Port of New Orleans, where some precursors are directly loaded onto barges).

Remed. (Remediation) – A location where chemicals are used for bulk disinfection, e.g., water treatment.

Retailer – An online or physical location where consumers may purchase products consisting of or containing the precursor chemical, e.g., Amazon, Home Depot, and CVS.

ROW (Rest of World) – Other countries that engage in precursor chemical commerce with the United States not otherwise specified on the chart.

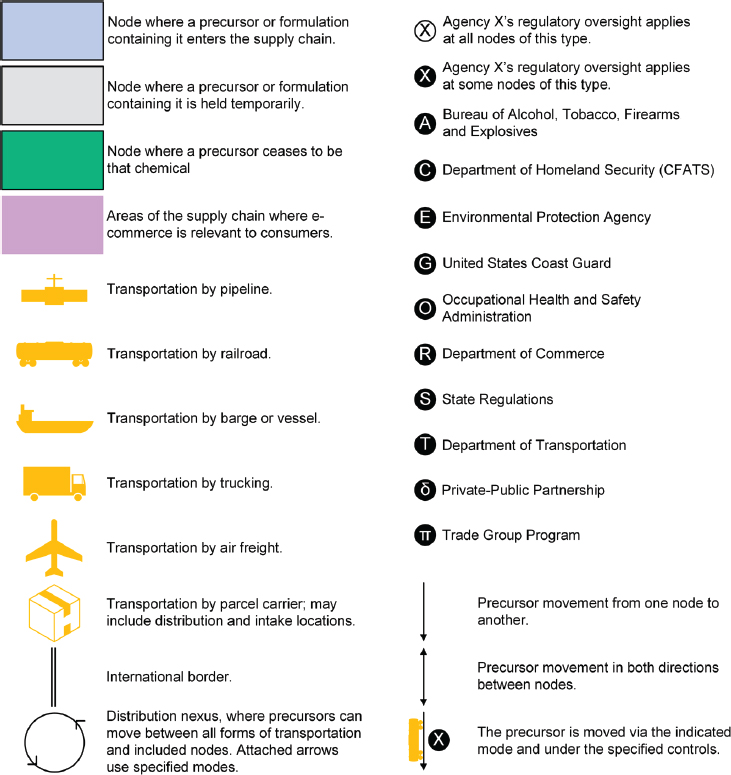

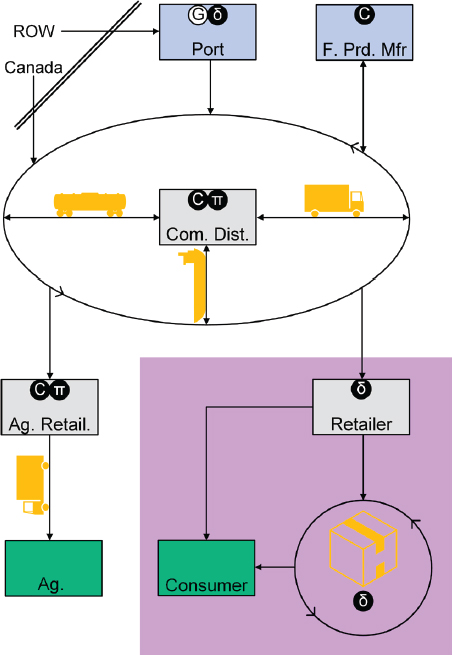

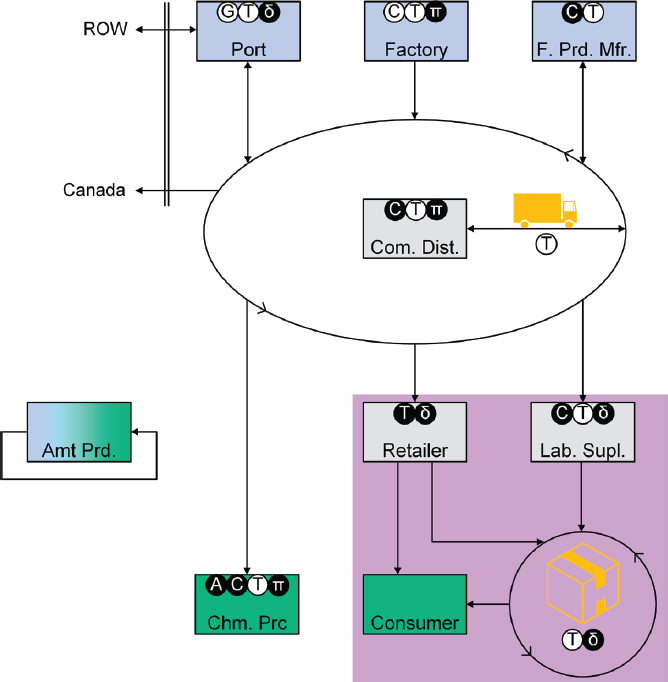

ALUMINUM POWDER, PASTE, AND FLAKE

Aluminum powder is commercially manufactured from bulk ingots using a melting and aspiration process to form an aerosol before aggregation (Figure D-1, Factory 1).56 Paste and flake can subsequently be made from the powder, either in a co-located or other facility (Figure D-1, Factory 2). Paste is made via the addition of solvents to the powder, which is then dried as a thin film to create flake. There is movement of this precursor chemical through ocean ports or across the Canadian border (though it is not made in that country). The majority of aluminum powder, paste, and flake (PPF) is transported via trucks, with railroads being used uncommonly for bulk transport and air freight for sample delivery, noted on Figure D-1 with the letter u. Movement of bulk material through commercial distributors is uncommon, but does occur.

Finished products that include aluminum in an extractable form suitable for IEDs also enter the supply chain and can include paints and coatings, for which precursor-extraction tutorials are available online (these products are not included on the charts once applied to a surface by consumers or other industry).

Another relevant finished product is exploding target kits, which contain separate packages of aluminum powder and ammonium nitrate, though no person or data source could tell the committee who is providing the aluminum powder to that finished product manufacturer (communications to exploding target kit manufacturers were unanswered).

Chemical and other industrial end users (see green boxes in Figure D-1) have been known to return excess product to the supply chain through e-commerce transactions, though the specifics of this practice were not provided to the committee. These excess materials are widely available online in pound-scale packages.249 Private persons are also capable of milling their own powder from bulk aluminum, which could take a week to achieve particles comparable to flake aluminum. The total quantity of aluminum PPF shipped domestically ranges in the tens of millions of pounds per annum.250

EPA only covers aluminum “fume or dust” (CAS number 7429-90-5) under EPCRA § 313.251 This also appears on the TSCA list, but only as “Aluminum,” so it is unclear under what conditions TSCA will apply at the factory nodes given the many possible forms of aluminum metal.252 There is an export restriction on aluminum powder with particle sizes below 200 µm. ATF oversees aluminum PPF at locations where it is mixed to produce ammonal or other commercial explosives and pyrotechnics, as does OSHA. These locations are marked as other industrial end users (Figure D-1, Other Ind.) as those products are beyond the scope of this study.103 DOT regulation of aluminum powder transported by truck, rail, or plane either as a 4.1 (coated, UN1309) or 4.3 (uncoated, UN1396) material depends on specific product testing and may not apply to a given shipment of powder;253 if it does qualify as a 4.3 material, a DOT security plan is always required, whereas 4.1 only requires a security plan if part of a desensitized explosive mixture.113 Private-public partnerships may include C-TPAT at seaports and KSP for aircraft transportation. Trade group programs can apply to both manufacturers and distributors (SOCMA, ACC, and NACD for all but Other Ind., which may include IME).

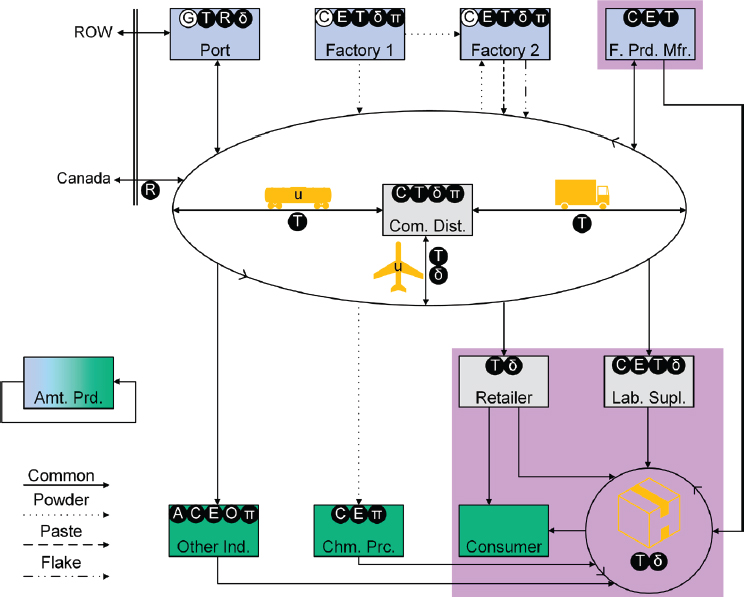

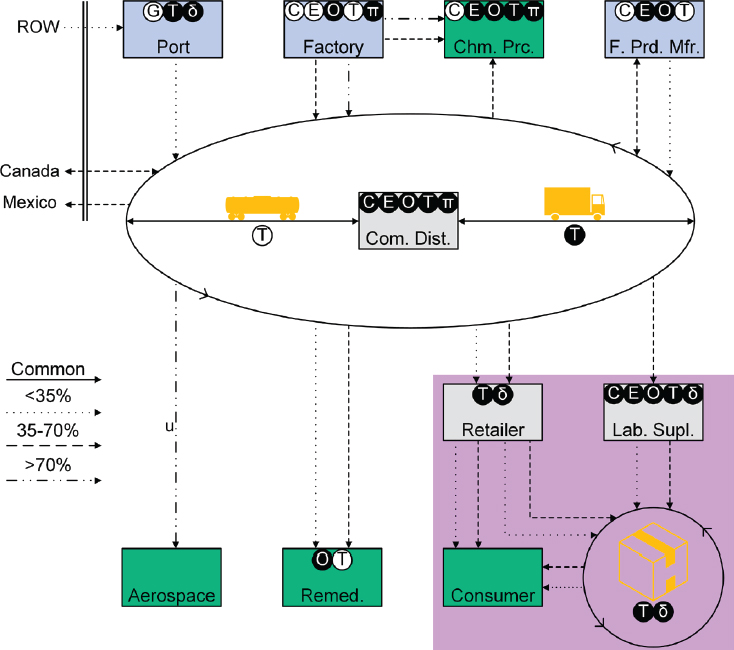

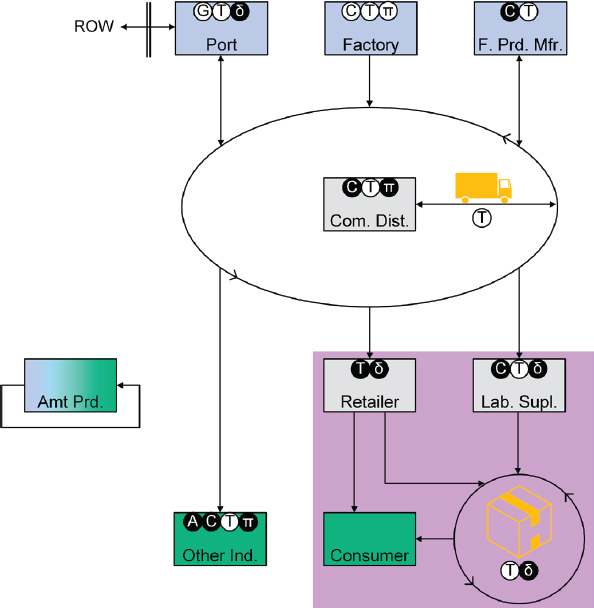

AMMONIUM NITRATE, FERTILIZER GRADE

FGAN is formed as a downstream process of nitrogen fixation, in which nitric acid and ammonia are ultimately neutralized in an aqueous solution and solidified in a prilling tower (Figure D-2, Factory).58,150,254 The majority of FGAN produced in the United States is transported in bulk form, with only a minority being packaged, either onsite or at an external packager or distributor. Finished products of note may include cold packs or exploding targets, though the committee was unable to determine the source or precise grade of the AN in those formulations, and the FGAN manufacturers and trade groups that provided information were clear that they were not sure of the source, as they or their members did not directly sell to those finished product manufacturers.

NOTE: AN can be produced via amateur methods that, although varying in physical makeup, is chemically identical to FGAN/TGAN.

FGAN imports and exports primarily cross the Canadian border in bulk, with the intended destination dependent on the nearest factory or distributor. A smaller amount of material enters and exits through seaports. Bulk shipments typically move via rail, barge, and truck (including transloading), and may be kept at warehouses and distributors en route to end users. The chemical industry is a minority end user, and primarily includes producers of nitrous oxide.255 Agricultural end users, as defined in Chapter 3, make up the bulk of the end-user base. In many instances, local agricultural retailers are the final intermediary before the fertilizer is applied to the fields, which is a service many of them provide, in which case they maintain custody from the retail location to soil. Other agricultural end users, including landscapers and other horticulturalists, may also purchase FGAN from agricultural retailers. Other retailers are unlikely to carry neat FGAN fertilizer, but instead sell packaged blends with other fertilizers; all of these are also available online. Various research-grade AN products are available from laboratory suppliers, though at significantly higher cost than from other types of suppliers.256

There are export restrictions on products containing 15% or more AN. EPA lists AN under TSCA, and under EPCRA § 313 as category code N511, “Nitrate Salts (water dissociable)”; the latter regulation only applies to aqueous solutions and not the solid prills, and is therefore excluded from the majority of the diagram.251 CFATS applies to those nodes containing more than 2,000 lb of material containing ≥ 33% FGAN.88 DOT classifies AN as a 5.1 oxidizer and requires a security plan if more than 3,000 kg is transported.113,253 Some fertilizer blends may be transported as a class 9 miscellaneous HM, provided they meet the requirements of Special Provision 132, which either contains not more than 70% ammonium nitrate, and not more than 0.4% total combustible, organic material calculated as carbon or contains not more than 45% ammonium nitrate and unrestricted combustible material, and therefore would not require a security plan. Trade group programs include programs sponsored by both manufacturers (e.g., ACC) and distributors (e.g., NACD and ResponsibleAg). As defined in Chapter 3, FGAN is further regulated in several states at the agricultural retailer node. KSP may apply to all nodes involved with air shipping, and all seaports include C-TPAT and MTSA.

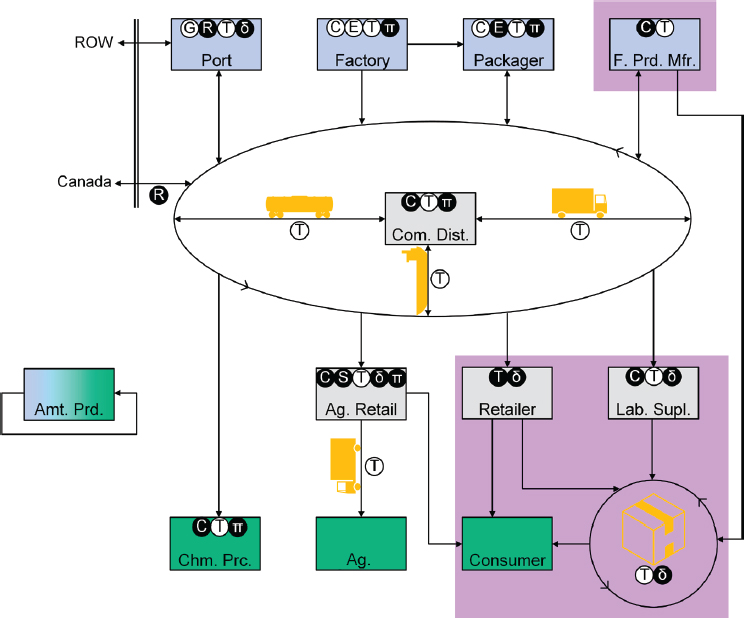

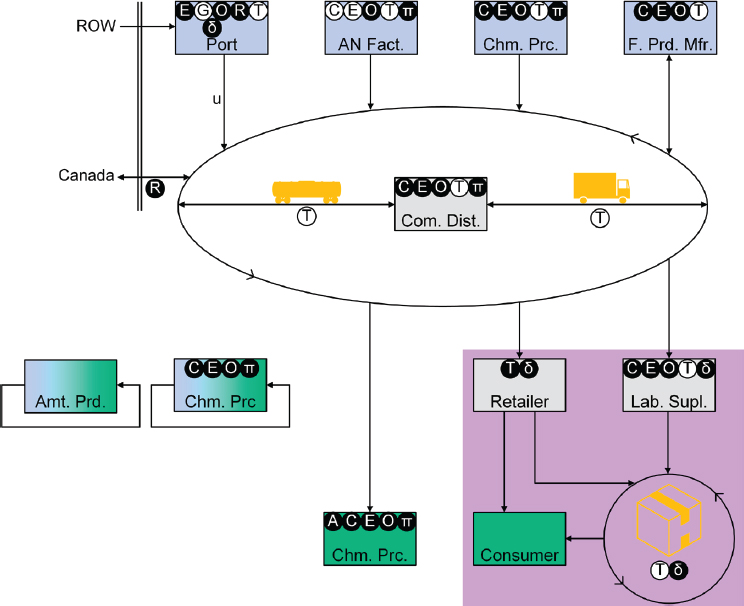

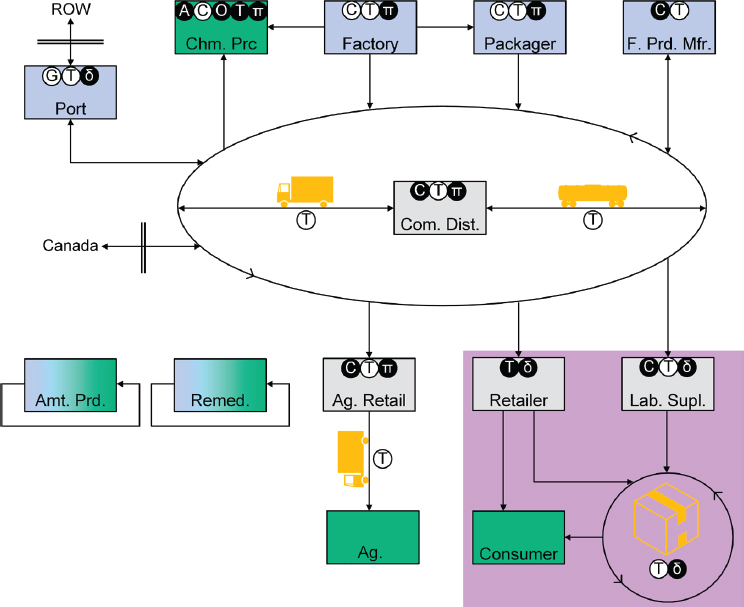

AMMONIUM NITRATE, TECHNICAL GRADE

Technical grade ammonium nitrate (TGAN) is produced using the same general process as FGAN, the only difference being the increased porosity of the TGAN prills (Figure D-3, Factory).57 These grades are separated for the purposes of this report due to the different user bases and the segregated supply chains of the two materials. There are scenarios in which a batch of TGAN is returned to the factory due to physical changes during shipment that made the product unusable (indicated by a double-headed arrow).

Like FGAN, only a limited amount of TGAN is bagged before distribution (1.0–1.5 ton packages) or during distribution (smaller bags). Imports from overseas into the United States are possible, but uncommon, with the majority of imports and exports occurring across the Canadian border, depending on proximity to manufacturers. The same finished product manufacturers buying FGAN (e.g., cold packs or exploding targets) might be buying TGAN, though the primary TGAN manufacturers and trade associations could not provide information on where those finished product manufacturers are obtaining their supplies.

Transport primarily occurs in bulk via rail, truck, and barge, with intermodal transloading between shipping modes and temporary storage occurring in rail-side hoppers. The majority of TGAN is manufactured by or shipped directly to explosives manufacturers or blasters that mix and use it onsite. A small amount is used in chemical processes. TGAN is available at online retailers as finished products (which are frequently bought together with other precursor chemicals),257 or in small packages of neat product.258 Exploding target kits are available at physical locations and online directly from the manufacturer.259,260

NOTE: AN can be produced via amateur methods that, although varying in physical makeup, is chemically identical to FGAN/TGAN.

CFATS and EPA do not distinguish between FGAN and TGAN, so the regulations previously described for FGAN apply. While export restrictions do exist for TGAN, the current lack of exports via ocean shipping precludes its inclusion on the port node. The primary trade group program throughout the TGAN supply chain is that of IME, which sets standards for storage and shipping; other programs may include those of chemical manufacturing and distributing associations. ATF regulations apply at locations where explosives are manufactured from TGAN or at locations that mix components onsite (e.g., a mine or job site); ATF also may oversee storage locations, depending on proximity to DOT class 1 explosives. OSHA will specifically apply controls at these locations as well.103 DOT classifies neat TGAN as a 5.1 oxidizer and requires security plans for shipments in excess of 3,000 kg.113,253 All mixtures with significant combustibles are listed as class 1 explosives and are beyond the scope of this study. KSP may apply to all nodes involved with air shipping, and all seaports include C-TPAT and MTSA.

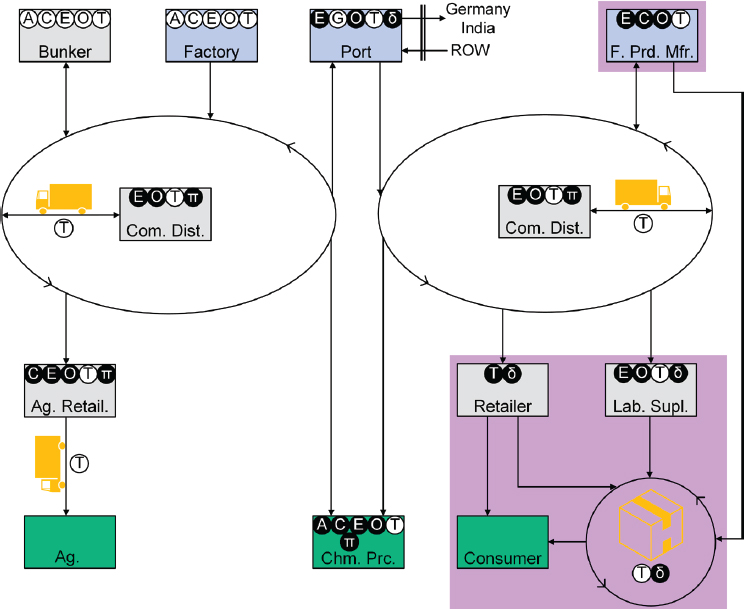

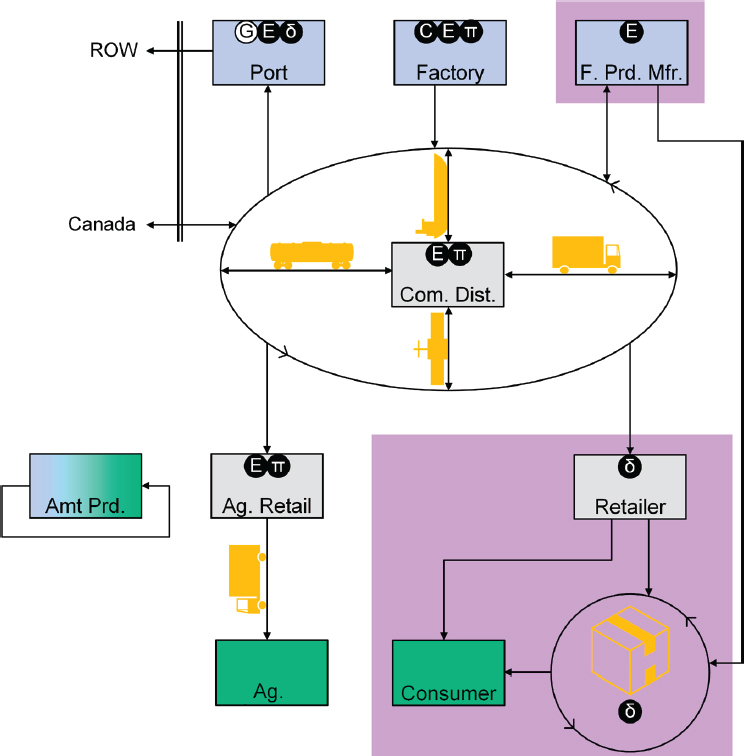

CALCIUM AMMONIUM NITRATE

There are currently no domestic producers of calcium ammonium nitrate (CAN), with all domestic quantities being sourced from other countries (Figure D-4).44 Bulk material typically arrives through seaports (mostly with intermediate terminals existing before entry into the transportation nexus, except for New Orleans, where barges are directly filled from ocean vessels), with some overland transaction from Canada (though they import it first as well). About 5% of the total CAN volume is packaged. Finished products on this diagram include packaged fertilizer blends and cold packs.261 The same transportation modes and other nodes supply a primarily agricultural end-user base. Finished products are available online and at brick-and-mortar retail locations.

CAN would be subject to export restrictions if it were shipped to other countries. The EPA regulations described for FGAN also apply to CAN. Unlike the other formulations, CAN is not regulated by DOT, as the CAN within the supply chain does not meet the AN concentration threshold of >80% given in Special

Provision 150 Part b. ResponsibleAg participation may happen at agricultural retailers, and NACD’s program may apply to distributors. KSP may apply to all nodes involved with air shipping, and all seaports include C-TPAT and MTSA.

HYDROGEN PEROXIDE

Hydrogen peroxide production usually occurs in close proximity to natural gas sources, which provide the hydrogen feedstock used in the anthraquinone process (Figure D-5, Factory).55 Some of this production is co-located with other chemical processes (e.g., pulp and paper bleaching), or the hydrogen peroxide product ships primarily to nodes where those processes occur.148,255 Imports of hydrogen peroxide from overseas are unlikely given the difficulty of transporting highly corrosive, high concentration hydrogen peroxide or the cost of transporting dilute solutions made of mostly water; any imports will probably be finished

products that include hydrogen peroxide within their formulations. There is significant overland transaction across the Canadian and Mexican borders; Canada both imports and exports based on factory proximity to the end user, while Mexico only imports from the United States.

Bulk shipments primarily occur in the 50–70% concentration range, with only a small amount of >70% hydrogen peroxide supplying some military and aerospace end users. Finished products may include health and personal care formulations, which are diluted from concentrated bulk, or further purified hydrogen peroxide for specialty applications (e.g., electronics manufacturing). Some distributors dilute as well. During bulk transportation, containers are typically sealed, barcoded, and cross-referenced with paperwork at the shipper and receiver. Locations where hydrogen peroxide is used for soil remediation and water treatment are labeled Remed. in Figure D-5. Some distributors dilute hydrogen peroxide.

Physical retailers do not typically carry products with ≥35% hydrogen peroxide concentration, with pool and spa suppliers262 using about 27% and personal products being <15% in most cases;263 online retailers carry these products as well. Lab suppliers typically sell around the 30% range, though concentrations as high as at least 60% are available as well.264 On some websites, there are formulations available that claim to be 35% and are marketed as part of pseudoscientific health practices (these may also be available at some physical retail locations, so a direct line from retailer to consumer was included as well).265 Domestic usage of hydrogen peroxide is on the hundreds to thousands of kilotons per annum scale.266,267

CFATS applies to locations meeting the weight (400 lb) and concentration (>35%) thresholds;88 however, remediation nodes are specifically exempted.89 OHSA applies at locations where 7,500 lb or more of ≥52% hydrogen peroxide is present.104 EPA uses the same 52% threshold under EPCRA § 302 and § 304;251 TSCA also applies to relevant production nodes.252 All hydrogen peroxide formulations >8% are considered by DOT to be class 5.1 oxidizers, requiring a security plan if transported in quantities exceeding 3,000 L;113,253 additional requirements are provided for solutions >40% in Special Provision 12, and for mixtures with peroxyacetic acid in Special Provision 145. It was reported to the committee that aerospace nodes may be under controls stipulated by the Department of Defense, but the committee was unable to confirm the applicable regulations and left that node blank on the diagram. Chemical manufacturers and distributors may participate in relevant trade association programs. KSP may apply to all nodes involved with air shipping, and all seaports include C-TPAT and MTSA.

NITRIC ACID

Nitric acid production is typically co-located with another process that uses nitric acid for a separate synthesis. This can either be wholly contained, with no nitric acid entering the external commercial supply chain, or, as is the case for AN producers (Figure D-6, AN Fact.), excess product is sold to other end users.254 If

sold, nitric acid moves in a bulk form to the locations of other chemical processes (e.g., equipment maintenance or polymer manufacturing) or to finished product manufacturers and commercial distributors.255 Bulk shipments to the locations of chemical processes are not commonly routed through distributors, and if that does happen the distributor would not take possession. As with AN and hydrogen peroxide, import and export with Canada occurs, dependent on specific proximi-ties. Imports from overseas, while possible, are uncommon and most likely take the form of finished products. Finished products mainly include cleaning supplies and etchants, which are available at physical and online retail locations.268 Lab suppliers are known to provide fuming nitric acid that is ≥99% concentration.269 Online tutorials allow amateur production of nitric acid.

Nitric acid is export restricted for ≥20% formulations.117 ATF regulatory oversight only occurs at those locations where nitric acid is used to create explosives (Figure D-6, Chm. Prc.). Like other theft or diversion hazards, nitric acid is regulated by CFATS above 400 lb at ≥68% concentration (the water–nitric acid azeotrope, above which it becomes fuming nitric acid).88 EPA lists nitric acid under TSCA and has two entries for nitric acid: (1) under EPCRA

(§§ 302, 304, and 313) and (2) under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) at concentration ≥80%. USCG lists nitric acid as a uniquely hazardous material at concentrations greater than 70%, which dictates chemical-specific handling procedures at facilities under USCG control.95 OSHA oversight is limited to facilities that use ≥94.5% fuming nitric acid at 500 lb or more total quantity.104 All forms of nitric acid are considered by DOT to be class 8 corrosives, with all mixtures ≥20% requiring a security plan if the quantity shipped is >3,000 L.113,253 Chemical manufacturers and distributors may participate in relevant trade association programs, including IME for explosives manufacturers. KSP may apply to all nodes involved with air shipping, and all seaports include C-TPAT and MTSA.

NITROMETHANE

Domestic nitromethane production is limited to one facility (Angus Chemical Company), which nitrates propane to form nitroalkanes (see Figure D-7).59 This facility also produces nitromethane-furfural blends for agricultural customers. Trucks are used exclusively to transport barrels of nitromethane directly from the

factory to large agricultural distributors, locations of chemical processes, or export locations. Some inventory is stored in an offsite bunker while waiting for shipment. The agricultural distributor delivers smaller portions of the blend to an applicator, who maintains custody until it is applied on a farm. All other end users are supplied by imports from overseas, the bulk being reportedly from China. Finished products include other solvent blends, which feed industrial users, and racing fuels and fuel additives used by hobbyists.255 Nitromethane is available as these products online and at physical supply stores and at high purity from laboratory suppliers.270-272

ATF regulates nitromethane once it is included in specified formulations; though Angus does not make these formulations, Angus representatives claim that they are subject to ATF oversight. CFATS covers all facilities with 400 lb of nitromethane regardless of concentration.88 EPA regulates nitromethane under § 313 of EPCRA and TSCA.251,252 Oversight from OSHA only happens once a threshold of 2,500 lb onsite is reached.104 DOT considers nitromethane a class 3 flammable liquid, which requires a security plan if transported quantities exceed 3,000 L.113,253 Chemical manufacturers and distributors may participate in relevant trade association programs, including that of IME for explosives manufacturers and ResponsibleAg for agricultural nodes. KSP may apply to all nodes involved with air shipping, and all seaports include C-TPAT and MTSA.

POTASSIUM CHLORATE

The committee was unable to locate an industrial representative willing to speak on potassium chlorate, so the following diagram (see Figure D-8) and information were sourced from other available documentation.255 Major finished products include matches and specialty agricultural goods. Chemical processes may include making explosives and propellants. Based on DOC data, there appear to be exports to Canada, as well as imports and exports with overseas suppliers. In addition to finished products, neat potassium chlorate is available online both from lab suppliers and retailers.273,274 Online tutorials demonstrate the capacity for amateur production.

ATF provides oversight of potassium chlorate where it is used to make explosives and propellants, as does OSHA. Potassium chlorate is considered a theft and diversion hazard under CFATS with a 400 lb threshold.88 Under DOT, potassium chlorate is a class 5.1 oxidizer, which requires a security plan if transported quantities exceed 3,000 kg.113,253 Chemical manufacturers and distributors may participate in relevant trade association programs. KSP may apply to all nodes involved with air shipping, and all seaports include C-TPAT and MTSA.

POTASSIUM PERCHLORATE

Potassium perchlorate is only manufactured at one domestic location, American Pacific Corporation, which manufactures it as a secondary product of its

ammonium perchlorate process (see Figure D-9).275 It exclusively supplies the automotive industry, which uses it to make airbags (a finished product). All other shipments originate overseas. Other finished products include small amounts of potassium perchlorate for treating thyroid diseases and for oxygen generators.255 Other industries are primarily pyrotechnic manufacturers, which use potassium perchlorate instead of chlorates.276 High-purity potassium perchlorate is available online from various sources in addition to lab suppliers.277,278

Potassium perchlorate is regulated by ATF only at those locations where it is used to make explosives or pyrotechnics, or indirectly at the manufacturing location that also produces ammonium perchlorate. CFATS considers it a theft and diversion hazard with a threshold of 400 lb.88 Under DOT, potassium perchlorate is a class 5.1 oxidizer, which requires a security plan if transported quantities exceed 3,000 kg.113,253 Chemical manufacturers and distributors may participate in relevant trade association programs. KSP may apply to all nodes involved with air shipping, and all seaports include C-TPAT and MTSA.

SODIUM CHLORATE

Like hydrogen peroxide, sodium chlorate is primarily manufactured domestically for use in the pulp and paper bleaching process, which may be co-located (see Figure D-10).55 Some of the sodium chlorate produced is packaged in 1 ton sacks for further distribution. Other chemical processes include metal finishing, refining, making detergents, and explosives manufacturing. There is transaction with Canada dependent on the proximity to the manufacturer, though exports overseas are uncommon. Sodium chlorate can be shipped as either a solid powder or an aqueous solution, though this distinction is not shown on the diagram. Finished products may include herbicides, airbags, and oxygen-generating devices.255 Most water-treatment facilities (Remed.) that use sodium chlorate install their own generators, which produce what they need onsite, and do not connect with the rest of the supply chain. In addition to finished products, neat sodium chlorate is available online from both lab suppliers and retailers.279,280 Online tutorials demonstrate the capacity for amateur production. Canada and the United States account for more than half of global sodium chlorate production, on the megaton per annum scale.281

Sodium chlorate is regulated by ATF and OSHA only at those locations where it is used to make explosives or pyrotechnics. CFATS considers it a theft and diversion hazard with a threshold of 400 lb.88 Under DOT, sodium chlorate is a class 5.1 oxidizer, which requires a security plan if transported quantities exceed 3,000 kg.113,253 USCG lists sodium chlorate as a highly hazardous substance for aqueous solutions of concentration <50% and stipulates additional handling procedures.95 Chemical manufacturers and distributors may participate in relevant trade association programs. KSP may apply to all nodes involved with air shipping, and all seaports include C-TPAT and MTSA.

UREA AMMONIUM NITRATE SOLUTION

Urea ammonium nitrate (UAN) solution production is typically co-located with AN factories (see Figure D-11), where AN and urea are mixed in an aqueous environment to make UAN.254 There is some trade between Canada and the United States depending on the nearest manufacturer; the United States also exports overseas. Distribution can happen though truck, rail, barge, or pipeline as

UAN solution is a liquid product. It moves from the factories through increasingly smaller distributors until it reaches the agricultural retailer, which may provide application services to local farmers and thus maintain custody of the product to the point of end use. There is at least one supplier of UAN-containing fertilizer products online, though it is unknown from where the contents are sourced.282

EPA and USCG both cover UAN under their definitions of aqueous AN.95,251 Chemical manufacturers and distributors may participate in relevant trade association programs, including ResponsibleAg. All seaports include C-TPAT and MTSA.