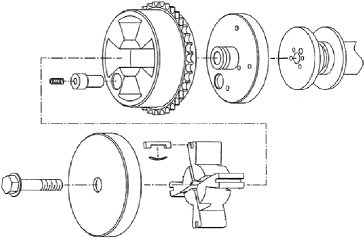

Variable valve timing (VVT) is generally accomplished by phase shifting the camshaft relative to the crankshaft. By phase shifting the camshaft, the valve events are advanced or retarded relative to the crankshaft and the piston position within the cylinder. A cam phaser is used to rotate the camshaft relative to the timing chain sprocket driven by the crankshaft. A typical cam phaser, shown in Figure H.1, consists of the outer housing and sprocket driven by the timing chain driven from the crankshaft and an inner rotor connected to the camshaft. The inner rotor has several lobes, and the space between these lobes and similar lobes on the outer housing is filled with oil. When the oil is trapped, the inner rotor rotates with the outer housing. Adding oil from one side of the lobes and removing oil from the other side moves the inner rotor relative to the outer housing, thereby phase shifting the camshaft relative to the crankshaft.

This oil pressure actuated (OPA) system generally requires a larger oil pump to provide the additional oil flow required, which is a parasitic loss that slightly diminishes the fuel consumption reductions provided by the VVT system alone. Honda recently introduced an electrically-actuated cam phaser (from Denso) in the 1.3L engine of the 2014 MY Fit to provide the desired phase angle for cold starts and a possible reduction in parasitic losses. Electric actuation of the cam phaser replaces oil pressure actuation (OPA) used previously.

FIGURE H.1 Oil-pressure-actuated variable valve timing system.

SOURCE: U.S Patent Office.

BMW uses an alternative cam phaser design in which the end of the camshaft contains helical gear teeth. The chain-driven sprocket contains an axially moveable cap with matching helical gear teeth. By axially moving the cap, the phase of the camshaft relative to the crankshaft driven sprocket can be advanced or retarded. The moveable cap, which is attached to a double acting piston, is moved by applying oil pressure to the appropriate side of the piston.

An alternative to the oil pressure actuated (OPA) system is the cam torque actuated (CTA) system developed by BorgWarner. Rather than using oil pressure applied to the cam phaser, the CTA system relies on the reaction of the valve spring forces during valve opening or closing. During valve opening, a retarding torque is developed by the valve spring force which is used to retard the timing of the camshaft relative to the crankshaft. Conversely, during valve closing, an advancing torque is developed by the valve spring force which is used to advance the timing of the camshaft relative to the crankshaft. A solenoid-controlled spool valve directs the oil flow into the desired side of the cam phaser for advance or retard and out of the other side of the cam phaser. The advantages of the CTA system are fast response and elimination of the need for a larger oil pump. The CTA system was first introduced in the Ford 3.0L Duratec V6 engine in the 2009 MY, with later introductions in the 3.5L and 3.7L V6 and 5.0L V8 engines (Austin 2010). Ford indicated that their twin independent variable cam timing (Ti-VCT) system provides up to 4.5 percent improvement in fuel economy, with a 7 percent improvement in rated power and a 5 percent improvement in low speed torque (Ford 2010). Cost of the CTA system is estimated at 1.3 times the cost of the OPA system.

REFERENCES

Austin, M. 2010. Cam-Torque Actuated Variable Valve Timing System. Car and Driver, August. http://www.caranddriver.com/features/cam-torque-actuated-variable-valve-timing-system-feature.

Ford. 2010. Twin Independent Variable Camshaft Timing (Ti-VCT) Helps Make 2011 Ford Mustang a True Thoroughbred. Ford Motor Company, February 8. https://media.ford.com/content/fordmedia/fna/us/en/news/2010/03/24/twin-independent-variable-camshaft-timing--tivct--helps-make-20.html.

Weaver, S.G. 2012. The Ins and Outs of Variable Valve Timing (VVT) Systems and Their Role in Vehicle Emissions. Underhood Service, June 14. http://www.underhoodservice.com/the-ins-and-outs-of-variable-valvet-iming-vvt-systems-and-their-role-in-vehicle-emissions/.