Variable Compression Ratio Engines

Harry Ricardo built the first known variable compression ratio engine as a test engine in the 1920s to study knock in aircraft engines. Variable compression ratio was achieved by raising or lowering the cylinder and cylinder head of the engine relative to the crankshaft. This work led to the development of the octane rating system that is still in use today. Variable compression ratio engines have subsequently been investigated for decades, but none have been commercially produced due to mechanical complexity, difficulty of control, and cost. Some of the variable compression ratio engines that have been investigated are shown in Figure 2.14 and include the following:

- Adjustable piston. An early concept for variable compression ratio was the use of an adjustable piston in the cylinder head. Adjusting the piston changes the clearance volume at top dead center, thereby altering the compression ratio. Ford and Volvo have evaluated this concept in the past.

- Hydraulic piston. Teledyne Continental Motors developed variable compression ratio pistons for both 1790 cu. in. and 1360 cu. in. tank engines to achieve very high output while limiting peak cylinder pressure by reducing compression ratio. The variable compression ratio piston consisted of a moveable top that used engine oil pressure to extend the piston top for the highest compression ratio. To limit peak cylinder pressure, a pressure relief valve in the piston allowed the piston top to move downward, thereby reducing compression ratio (Grundy et al. 1976). Ford patented a similar concept in the 1980s (Caswell 1984). Mercedes has also experimented with a similar concept (Joshi 2012).

- Articulated cylinder head. Saab introduced its system at the 2000 Geneva Motor Show. In the Saab system, one side of the cylinder head with integrated cylinders is attached to the crankcase with a hinge, and a lifting mechanism is placed on the other side of the crankcase. The cylinder head can pivot up by four degrees to increase the volume of the combustion chambers, thereby lowering the compression ratio. Saab claimed that the technology could change the compression ratio from 8:1 to 14:1 while the engine was running (Evans 2009).

- Rocker arm. Peugeot introduced its system at the 2009 Geneva Motor Show. In the Peugeot system, each piston is attached to a rocker arm and the center of the rocker arm is connected to the crankshaft. An intermediary gear is added to the other end of the rocker arm. Hydraulic jacks in the engine block next to the cylinders manipulate a gear rack to raise or lower the rocker arm gear in order to change the length of the piston stroke, thereby changing the volume of the combustion chamber and, consequently, the compression ratio (Evans 2009).

- Eccentric big end rod bearing. Waulis Motors Ltd’s patented concept uses an eccentric wheel on the connecting rod big end bearing. The eccentric wheel includes a gear that meshes with a ring gear. Rotating the ring gear will adjust the position of the eccentric wheel, thereby adjusting the clearance volume at top dead center.

- Eccentric crankshaft bearing. Gomecsys has developed a fourth-generation variable compression ratio engine. This system houses the crankshaft bearings within eccentric wheels contained within the cylinder block. Rotating the eccentric wheels changes the clearance volume at top dead center. FEV has developed a similar variable compression ratio engine shown in Figure O.1 (Green Car Congress 2007), which is discussed later in this section.

- Eccentric piston pin. An eccentric piston pin has also been proposed as a means of varying the clearance volume at top dead center.

- Multi-link rod-crank. Nissan has developed a variable compression ratio engine in which an extra linkage is mounted to the crankshaft in place of the connecting rod. The connecting rod is connected to this linkage. The linkage is also connected to an actuator shaft so that the compression ratio can be changed (Joshi 2012). A similar concept was investigated by PSA.

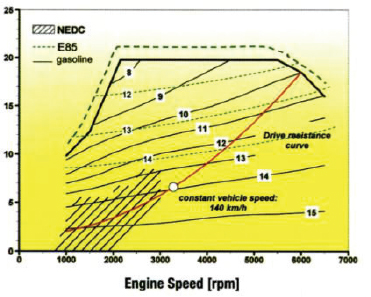

An example of the compression ratios that might be used over an engine’s speed/load map is shown in Figure O.1. At light loads, compression ratios as high as 15:1 are used, whereas at maximum loads, the compression ratio is reduced to 8:1. An interesting application of variable compression ratio to an FFV engine is also illustrated in Figure 2.14 (McAulay 2009). Since E85 has a significantly higher octane rating than gasoline, higher compression ratios would be used during operation on E85. As shown, at moderate loads, compression ratios about 2 ratios higher are used. At maximum loads, a compression ratio of approximately 12:1 is used.

FIGURE O.1 Variable compression ratios used for gasoline and E85 for an FFV.

SOURCE: J.L. McAulay, Copyright: Massachusetts Institute of Technology, 2009. Used with permission.

REFERENCES

Evans, S. 2009. MCE-5 to Debut 220-HP .5L Engine with Variable Compression Ratio at Geneva. Motor Trend, February 25. http://wot.motortrend.com/mce5-to-debut-220hp-15l-engine-with-variable-compression-ratio-at-geneva-3891.html#ixzz2YVpc7J4G.

Green Car Congress. 2007. FEV Displays Turbocharged, Direct-Injected, E85 Variable Compression Ratio Engine. Green Car Congress, April. http://www.greencarcongress.com/2007/04/fev_displays_tu.html.

Joshi, M., and A. Kulkarni. 2012. Variable Compression Ratio (VCR) engine – A review of future powerplant for automobile. International Journal of Mechanical Engineering Research and Development 2(1), January-September.

McAulay, J.L. 2009. Assessing Deployment Strategies for Ethanol and Flex Fuel Vehicles in the U.S. Light-Duty Vehicle Fleet. MS Thesis, MIT, June.